Quick Answer: Advanced pickleball paddle innovations leverage state‐of‐the‐art materials and production techniques—such as hot pressing1, cold pressing2, and thermoforming3—to deliver unmatched performance and durability. By integrating materials like various types of carbon fiber4, fiberglass5, and composite cores, manufacturers can optimize paddle weight, balance, and control, making them ideal for both recreational and competitive play.

In today’s competitive sports equipment market, companies in the B2B sector are continually seeking innovative ways to design and manufacture high-performance pickleball paddles. With technology adoption on the rise and market trends evolving rapidly, understanding the latest production methods and material advancements is key to gaining a competitive edge. This article delves into the challenges and innovative solutions behind modern pickleball paddle manufacturing while offering data-supported insights and actionable recommendations for technology adoption and strategic partnerships.

Modern pickleball paddles must meet rigorous standards in terms of durability, performance, and comfort. However, meeting these requirements has never been straightforward. Some of the core challenges include:

• Ensuring consistent quality despite high production volumes

• Balancing lightweight design with sufficient strength

• Innovating material compositions to enhance ball control and reduce vibration

• Adapting production processes for both mass manufacturing and custom orders

These challenges necessitate a deep dive into advanced manufacturing techniques that not only address quality control and performance but also allow for scalability and customization. Manufacturers like NEX Pickleball are setting industry standards by adopting a blend of traditional craftsmanship and novel technology.

To overcome manufacturing challenges and meet the high-performance needs of today’s players, manufacturers are increasingly relying on innovative materials.

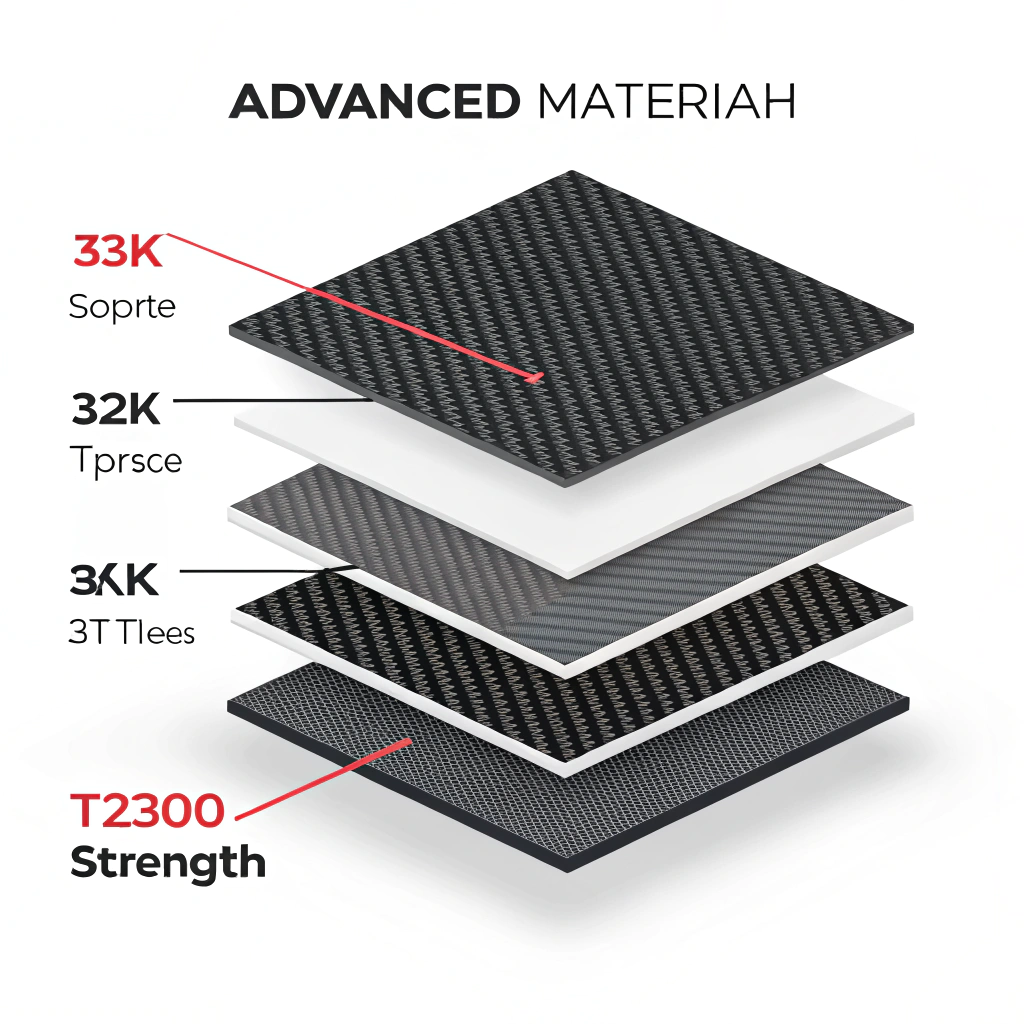

Carbon fiber4 is one of the most crucial materials in paddle design, offering a strong and lightweight solution. At NEX Pickleball, several carbon fiber types are used based on performance needs:

- 3K Carbon Fiber: Renowned for its strength and flexibility, this material provides high rebound force while reducing vibration. It is ideal for paddles where durability and power are paramount.

- 12K Carbon Fiber: With a higher thread density, this variant delivers a smooth surface and enhanced hardness. It ensures superior impact resistance, making it suited for competitive play that demands extra strength.

- T300 Carbon Fiber: Offering a balanced mix of tensile strength and weight reduction, T300 is perfect for paddles that need rapid response and agility without compromising on sturdiness.

Fiberglass5 is another key component, offering an excellent balance between power and ball control. For instance, E-Glass Fiberglass exhibits high elasticity and tensile strength, contributing to a wide sweet spot and unique ball feel.

Beyond single-material solutions, composite materials combine the benefits of various elements. Combinations such as carbon fiber paired with fiberglass result in paddles that are not only strong and lightweight but also offer exceptional control. Additionally, innovative core materials like bamboo core and honeycomb core (including Nomex, Aluminum, and Polymer Honeycomb cores) play a decisive role in shaping paddle performance by enhancing shock absorption and minimizing vibrations.

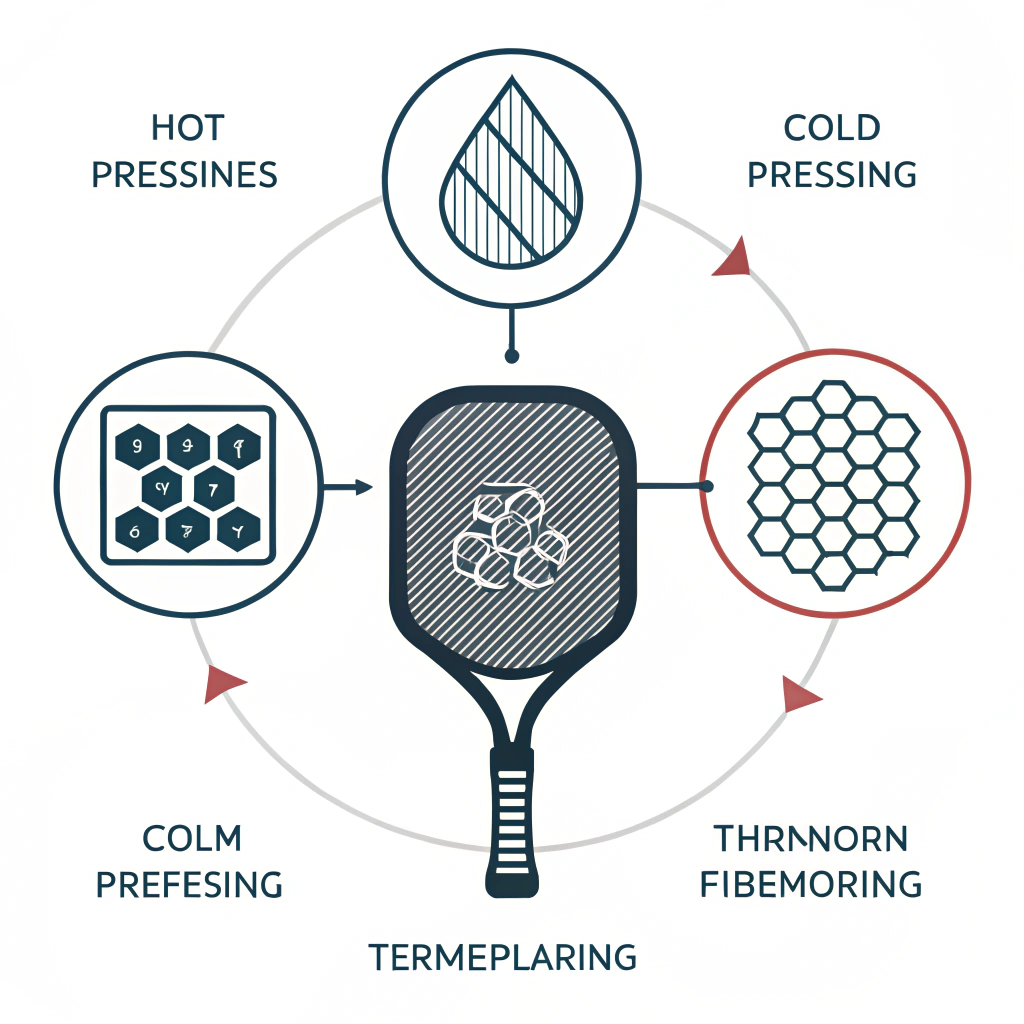

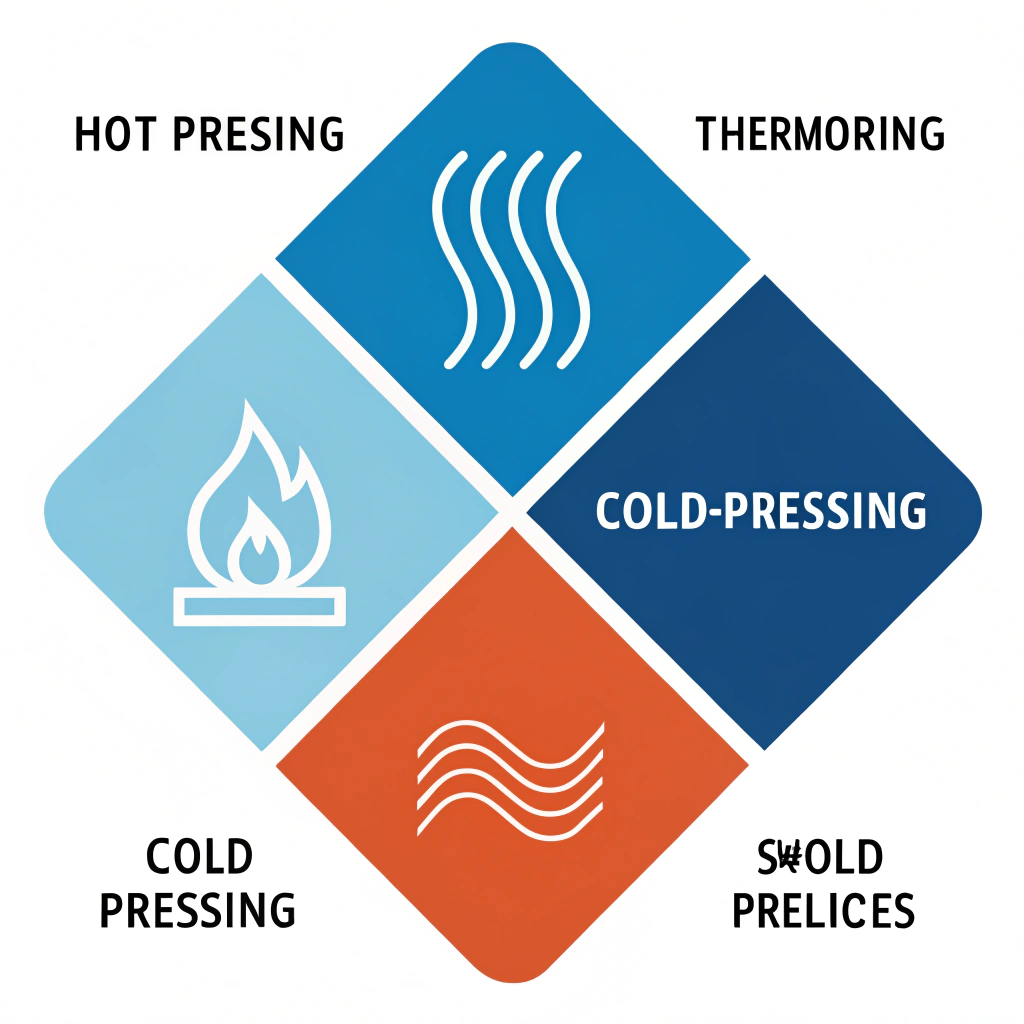

Achieving the desired performance characteristics requires more than just using premium materials—it also demands precision manufacturing processes that maintain the material integrity and ensure a perfect balance of weight and strength. The three primary production techniques are:

Hot pressing involves applying high temperature and pressure to the materials, resulting in a strong bond and consistent shape. Its main advantages include:

- High production efficiency suitable for large-scale manufacturing

- Enhanced impact resistance due to the strong bond formed

- Excellent structural integrity, making paddles ideal for high-performance use

However, the process may alter some material properties, impacting the tactile feel of the paddle, and it requires significant upfront investment in specialized equipment.

In contrast, cold pressing shapes the paddle material at room temperature using mechanical force. This method is essential when precise control over thickness and material structure is needed. Its benefits include:

- Exceptional precision in controlling paddle thickness and material density

- Preservation of the inherent properties of the materials for optimal control

- Superior ball feel and improved responsiveness during play

The drawback here is that cold pressing generally leads to longer production cycles, which might affect efficiency.

Thermoforming is a versatile process where the material is heated to a soft state before being molded into a desired shape. This approach enables the creation of paddles with intricate designs and uniform material distribution. Key advantages include:

- Ability to produce complex and ergonomic paddle designs

- Maintenance of stability and balanced material performance

- Application to a diverse range of high-performance materials

This method, however, tends to be slower and requires higher equipment costs, making it more suitable for premium and custom-made paddle production.

The following table summarizes the main points of the three production processes to assist decision-makers in understanding their relative strengths and limitations:

| Process | Advantages | Disadvantages | Best Use Case |

|---|---|---|---|

| Hot Pressing | High efficiency; strong structural integrity; ideal for mass production | Possible alteration of material feel; high investment costs | High-performance paddles; large volume orders |

| Cold Pressing | Precise thickness control; preserves material properties; excellent ball feel | Longer production cycles; requires precision equipment | Custom designs; paddles needing fine control |

| Thermoforming | Intricate design capability; uniform material distribution; maintains stability | Slower production; higher equipment cost | Premium products; specialized paddle designs |

At the heart of advanced paddle manufacturing is rigorous quality control. Each paddle undergoes multiple phases of testing—from initial material stress tests to final product evaluations—to ensure it meets strict performance standards. Companies like NEX Pickleball use cutting-edge technology to automate these inspections, ensuring consistency across every batch.

Customization is another significant factor in today’s competitive market. Recreational players and professional athletes alike often seek paddles tailored to their unique needs—whether that involves specific grip sizes, weight distribution, or surface treatments designed to boost ball spin control. With on-demand print services available, NEX Pickleball can offer personalized paddles that meet both branding and performance criteria. This ability to customize not only enhances player satisfaction but also opens new opportunities for team branding and exclusive retail distribution.

The integration of advanced production processes with a comprehensive quality control framework allows manufacturers to deliver paddles that are both durable and finely tuned for peak performance. This balance between standardization for mass production and individual customization is essential for companies looking to thrive in the evolving B2B sports equipment landscape.

The world of sports equipment manufacturing is rapidly evolving. As demand for high-performance and customizable paddle designs grows, companies must navigate the following market trends:

- The convergence of advanced materials with modern production technologies increases product reliability and user satisfaction.

- There is a growing emphasis on sustainability and efficient production processes that reduce waste and energy usage, a factor that is beginning to shape production methods and material selection.

- B2B partnerships are critical for innovation; manufacturers are increasingly partnering with industry leaders to share technological advancements and streamline the supply chain.

For senior product managers and business development executives evaluating emerging technologies, here are some actionable recommendations:

• Evaluate production scalability: Ensure that the chosen manufacturing processes (hot pressing, cold pressing, or thermoforming) align with projected volume requirements and quality standards.

• Prioritize material innovation: Investigate the latest developments in carbon fiber and composite materials to stay ahead of competitors in terms of performance and durability.

• Invest in quality control automation: High-precision testing and consistent evaluation protocols can significantly improve product reliability, thus enhancing overall customer trust and brand reputation.

• Explore customization options: On-demand customization not only improves player performance but also provides opportunities for market differentiation through branding and personalized services.

By paying close attention to these trends and strategic factors, decision-makers can better position their companies to capitalize on the expanding market for high-performance pickleball paddles.

Advanced manufacturing techniques and innovative material applications are revolutionizing the design and production of pickleball paddles. As market demands evolve, the emphasis on precision production—whether through hot pressing, cold pressing, or thermoforming—will only grow. Data-driven decision-making, coupled with ongoing investments in quality control and customization, will be key to maintaining a competitive edge.

For businesses in the sports equipment sector, there is a clear opportunity to leverage these insights for strategic partnerships and technology adoption. Embracing these advancements not only improves product performance and durability but also opens up new revenue streams through premium, customized offerings.

We encourage industry leaders to continually monitor market trends and invest in R&D to explore further innovations in material science and production processes. By staying ahead of the curve, companies can ensure they offer the highest quality products, ultimately leading to greater market share and customer satisfaction.

People Also Ask

Q1: What are the advantages of hot pressing in paddle manufacturing?

A1: Hot pressing offers high production efficiency and excellent structural integrity, ensuring that paddles are durable and impact-resistant. It is particularly beneficial for mass production where consistency is key, though it may slightly alter the material feel.

Q2: How does cold pressing improve paddle performance?

A2: Cold pressing allows for precise control over the paddle’s thickness and material properties, preserving the intrinsic qualities of the materials. This results in better ball control, responsiveness, and a more refined tactile feel, ideal for custom designs.

Q3: What role does thermoforming play in designing high-performance paddles?

A3: Thermoforming enables manufacturers to mold paddles into intricate and ergonomic shapes while ensuring uniform material distribution. This method is particularly suited for premium and custom-made paddles, offering enhanced stability and performance features.

-

hot pressing: Click to learn how this process uses heat and pressure to form strong, durable bonds in manufacturing high-performance sports equipment. Back to hot pressing ↩ ↩2

-

cold pressing: Click to explore how cold pressing maintains material integrity and precision, crucial for achieving optimal control in paddle production. Back to cold pressing ↩ ↩2

-

thermoforming: Click to understand how thermoforming molds heated materials into complex shapes, offering advanced design flexibility for specialized products. Back to thermoforming ↩ ↩2

-

carbon fiber: Click to discover the properties of carbon fiber, including its strength-to-weight ratio and its applications in enhancing sports equipment performance. Back to carbon fiber ↩ ↩2

-

fiberglass: Click to read about how fiberglass contributes to balancing power and control in paddle manufacturing by offering high elasticity and durability. Back to fiberglass ↩ ↩2