Quick Answer: To reduce scrap rates in laminate production for pickleball paddles, manufacturers must optimize process parameters, fine-tune production methods like hot pressing, cold pressing, and thermoforming1, and implement rigorous quality control measures. These steps not only improve material yield but also ensure that the paddles maintain superior performance and durability.

In the competitive field of pickleball paddle manufacturing, high scrap rates in the laminate production process can significantly drive up costs while compromising efficiency. Scrap not only represents wasted material but also lost production time, affecting overall profitability. Production managers and quality control experts at manufacturing facilities are continually seeking ways to reduce wastage without sacrificing the mechanical qualities of composite materials, such as carbon fiber2 and fiberglass laminations3.

Scrap in laminate production often originates from processing inefficiencies and minor deviations that lead to substandard products. Given that processes like hot pressing, cold pressing, and thermoforming each have unique characteristics, optimizing these methods becomes vital. Successful scrap reduction strategies must, therefore, address the specific challenges associated with these processes, ensuring that every paddle produced meets strict performance standards.

Understanding the factors that contribute to high scrap rates is the first step in addressing the issue. Some common causes include:

-

Material Variability: Composite materials, whether carbon fiber types (3K, 12K, T300) or fiberglass, can exhibit slight inconsistencies in quality and texture. These variations might affect the adhesion or curing process during lamination.

-

Processing Parameters: Temperature, pressure, and time are critical factors in each production method. Even minor fluctuations can lead to incomplete curing or weak laminations.

- In hot pressing, uneven heat distribution can alter the material properties.

- In cold pressing, insufficient or excessive pressure may damage the fibrous structure.

- In thermoforming, inaccuracies in reaching the softening point can lead to improper molding.

-

Equipment Calibration: Outdated or improperly calibrated machinery can contribute to an inconsistent output. Poor maintenance further exacerbates this issue, making it difficult to achieve a consistent laminate layer.

-

Operator Expertise: Human error is a critical factor in any manufacturing process. Variations in techniques or lack of proper training can result in inconsistent pressing, incomplete curing, or even damage to the laminates during handling.

-

Environmental Conditions: Ambient temperature, humidity, and ventilation within the production facility can impact the curing process. Fluctuations in these conditions may cause variation in laminate thickness and uniformity, leading to more scrap.

-

Material Handling and Storage: Improper storage conditions or handling procedures can degrade composite materials before they enter the production line. Moisture absorption or exposure to extreme temperatures may compromise material integrity.

To address the above challenges, several strategies can be implemented:

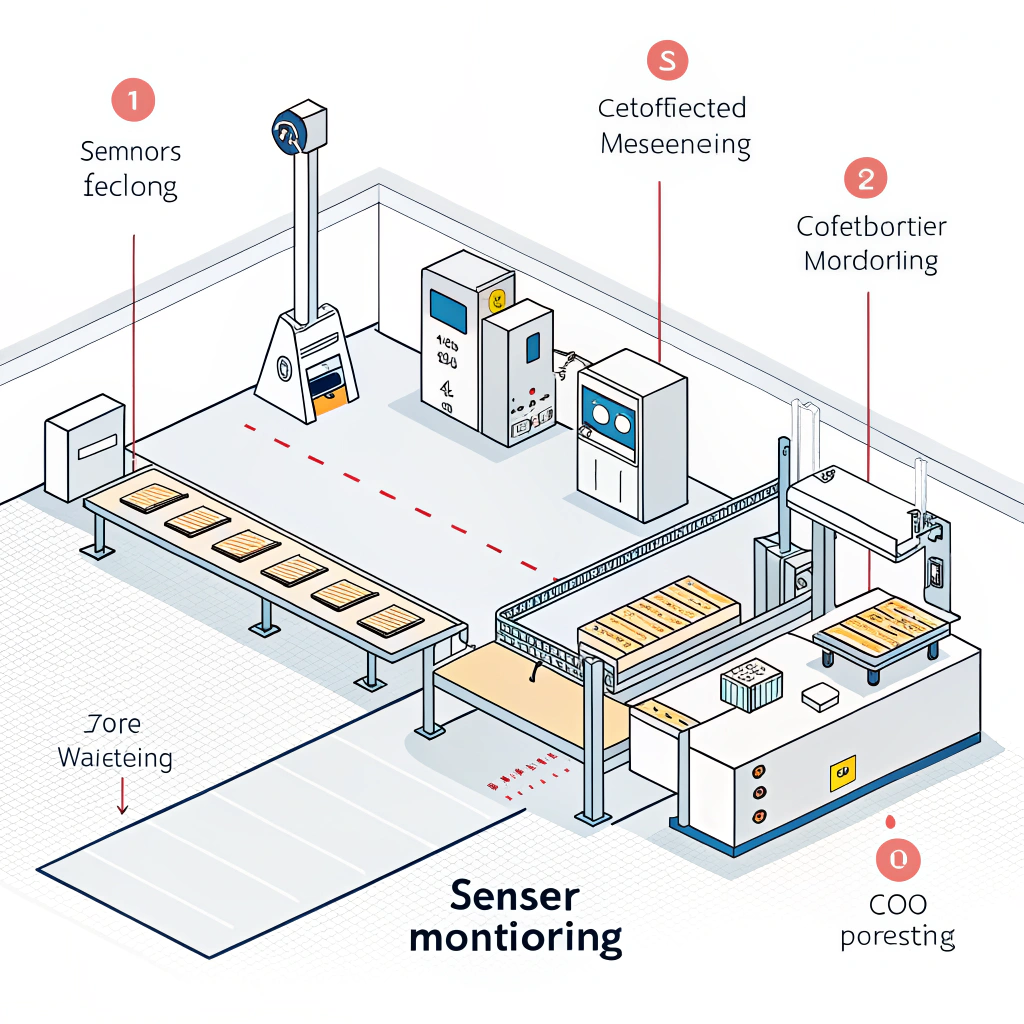

Ensuring that each process consistently operates within its optimal range is critical. This involves:

- Regular calibration of machinery.

- Continuous monitoring of temperature, pressure, and timing during the production cycle.

- Strict adherence to standard operating procedures (SOPs) for all production shifts.

- Schedule routine maintenance checks and quick repairs.

- Invest in modern equipment that offers more precise control over pressing and forming parameters.

- Implement automated monitoring systems to track performance trends and detect deviations early.

- Implement incoming quality control inspections for raw materials.

- Collaborate closely with suppliers to ensure a consistent supply of high-quality composites.

- Use statistical process control (SPC) techniques like SPC techniques4 to monitor material performance and reduce variability.

- Develop detailed training programs for operators, focusing on handling composite materials and operating equipment.

- Establish clear, visual guidelines and checklists at each process station.

- Encourage a culture of continuous improvement, where feedback and process modifications are welcomed.

Deploy advanced data analytics to monitor scrap rates and identify areas for improvement:

- Integrate real-time sensors and IoT devices5 to capture process parameters.

- Use historical production data to identify patterns correlated with increased scrap rates.

- Adjust production parameters dynamically based on data-driven insights.

Below is a table summarizing the process-specific strategies to optimize production and minimize scrap:

| Process | Key Focus Areas | Suggested Improvements | Expected Benefits |

|---|---|---|---|

| Hot Pressing | Temperature uniformity and pressure control | Regular equipment calibration; use thermal imaging to monitor heat distribution | Enhanced curing; reduced material distortion and scrap |

| Cold Pressing | Precise mechanical pressure management | Implement advanced pressure sensors; train operators for precision | Reduced mechanical errors; consistent laminate thickness |

| Thermoforming | Material softening control and mold accuracy | Use specialized molds; adopt real-time temperature monitoring | Accurate shapes; minimized excess material and waste |

| Material Quality Control | Raw material consistency and condition | In-house testing and supplier audits; use SPC techniques | Higher product consistency; less variability leads to lower scrap |

| Operator Training | Consistent practices and error reduction | Develop detailed SOPs; conduct regular training sessions | Improved operator performance; process standardization |

While implementing these solutions, several considerations and limitations must be taken into account:

- Initial Investment: Upgrading equipment or integrating data analytics systems may require a significant upfront cost. However, the long-term savings from reduced scrap rates often justify these expenses.

- Process Inertia: Changing established manufacturing processes can meet resistance from staff accustomed to traditional methods. Implementing incremental changes with measurable benefits can help overcome this barrier.

- Material-Specific Challenges: Not all materials behave identically; what works for carbon fiber laminates may not be as effective for fiberglass. Customized approaches for each material are necessary.

- Environmental Adjustments: Some process optimizations might be sensitive to environmental conditions. Factories located in regions with variable climates might need additional controls such as humidity regulators or dedicated climate-controlled areas.

Drawing on examples from the industry, several manufacturers have demonstrated considerable improvements in scrap rate reduction after adopting integrated production optimization measures.

One manufacturer integrated thermal imaging cameras in their hot pressing process, allowing for a more uniform heat distribution analysis. Within three months, scrap rates dropped by 15%, and the overall tensile strength of the laminates improved noticeably. These improvements were attributed to the tighter control over temperature and press duration.

Another facility focused on upgrading their pressure sensors and training operators extensively on precision techniques. By standardizing the force applied at each pressing stage, they reported a 20% reduction in defective laminates and a higher consistency in paddle performance.

A leading production facility adopted IoT sensors to gather real-time data on environmental conditions and machine performance. Over a six-month period, data analytics helped them fine-tune their pressing cycles, resulting in a 25% reduction in scrap—the highest among the reviewed methods. The data also enabled predictive maintenance, reducing unplanned downtime and further contributing to overall cost savings.

A summary table of these case studies is provided below:

| Case Study | Process Optimized | Improvement Measured | Key Outcome |

|---|---|---|---|

| Thermal Imaging in Hot Pressing | Hot Pressing | 15% reduction in scrap | More uniform heat distribution and improved laminate strength |

| Enhanced Pressure Control in Cold Pressing | Cold Pressing | 20% reduction in defective laminates | Increased pressure precision, leading to consistent production quality |

| IoT-Driven Production Adjustments | Integrated Data Analytics | 25% scrap reduction | Real-time process adjustments and predictive maintenance reduced downtime |

In the highly competitive realm of pickleball paddle manufacturing, reducing scrap in laminate production is essential for operational efficiency and profitability. By addressing key factors such as material variability, process parameters, equipment calibration, and operator training, manufacturers can achieve significant gains in efficiency and product quality.

Key action recommendations include:

- Prioritize the calibration and standardization of production processes.

- Invest in modern, high-precision equipment and integrate real-time monitoring systems.

- Strengthen material quality control and collaborate closely with suppliers.

- Implement regular operator training programs and encourage a culture of continuous improvement.

- Utilize data analytics to detect inefficiencies and adjust production processes dynamically.

A strategic approach to scrap reduction can lead to cost savings, improved product quality, and enhanced competitiveness in the marketplace. Adopting these strategies will not only reduce scrap rates but also streamline manufacturing processes, ensuring that every paddle produced upholds the highest standards expected by professional athletes and recreational players alike.

-

Do paddle erasers work?

Paddle erasers, often used to modify or adjust the paddle’s surface, primarily serve as a temporary solution to correct minor balance issues; however, they do not address the underlying production quality or reduce scrap during manufacturing. -

How to reduce pickleball paddle vibration?

Reducing paddle vibration can be achieved by optimizing the composite material composition and core structure, ensuring that lamination processes such as hot pressing, cold pressing, or thermoforming are precisely controlled, which enhances shock absorption and minimizes unwanted vibrations. -

Why put lead tape on pickleball paddle?

Lead tape is applied to pickleball paddles to fine-tune their balance and weight distribution, which can improve paddle stability and control during play; however, it is a post-production adjustment rather than a method to reduce scrap rates in manufacturing.

-

thermoforming: Click to learn about the process of heating and molding thermoplastic materials into specific shapes—an essential technique for achieving precise, uniform designs in manufacturing. ↩

-

carbon fiber: Click to explore how carbon fiber is produced and utilized in high-performance composite materials, enhancing product strength without adding excessive weight. ↩

-

fiberglass laminations: Click to understand the role of fiberglass laminations in reinforcing composite structures, offering a cost-effective balance between durability and flexibility. ↩

-

SPC techniques: Click to delve into Statistical Process Control (SPC) methods that help monitor, control, and improve the quality and consistency of manufacturing processes. ↩

-

IoT devices: Click to discover how Internet of Things (IoT) devices are integrated into manufacturing systems to provide real-time monitoring and data analytics for process optimization. ↩