Automated quality control in pickleball paddle manufacturing offers a decisive leap forward by reducing human error, increasing inspection precision, and ultimately enhancing production efficiency. This article explains the challenges of traditional manual inspection, compares it with automated systems, and provides actionable insights for production managers and engineers considering integration.

Manual Versus Automated Quality Control: An Overview

In today's competitive manufacturing landscape, ensuring the consistency and quality of products is critical. Traditional manual inspection methods have been the backbone of quality control for years. However, these methods often involve human fatigue, inconsistent results, and time-consuming processes that can lead to production delays. In contrast, automated inspection systems1 utilize advanced imaging, robotics, and AI-driven analytics2 to scrutinize every detail in paddle construction, thereby offering enhanced precision and repeatability.

For a production manager in the pickleball paddle manufacturing industry, such as those at NEX Pickleball, adopting automation can specifically address challenges related to product consistency, especially in high-performance products. With multiple production processes like hot pressing, cold pressing, and thermoforming, ensuring that every paddle meets rigorous quality standards is paramount. The integration of automated quality control not only minimizes defect rates but also drives overall operational efficiency.

Understanding the Challenges of Manual Quality Control

Manual quality control methods have their merits, such as a human's ability to notice subtle defects and variability that might escape sensors. However, there are inherent drawbacks that can impact production efficiency and consistency:

• Inconsistent Evaluations: Human inspectors may differ in judgment due to fatigue, experience, or environmental factors.

• Limited Throughput: Humans can only inspect parts at a limited speed, which becomes a bottleneck in large-scale manufacturing.

• Higher Costs: Labor-intensive inspection processes involve higher recurring costs as well as training expenses.

• Lack of Real-Time Data: Manual methods often fail to provide immediate feedback, making it challenging to adjust production parameters on the fly.

At NEX Pickleball, where high-performance paddles are produced with precision techniques, even slight inconsistencies in paddle quality can impact player performance and brand reputation. Therefore, transitioning to automated quality control presents a compelling opportunity to optimize inspection processes.

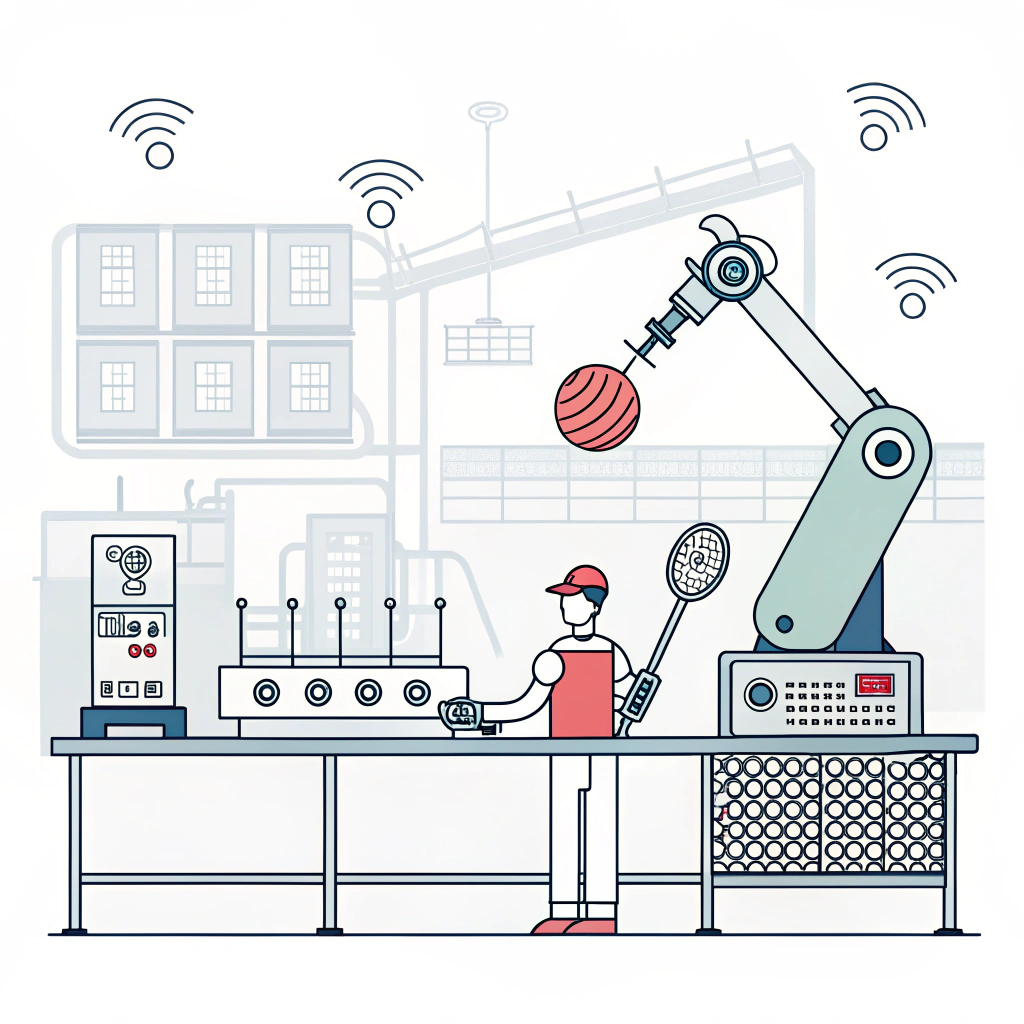

Automated Quality Control Systems: How They Work

Automated quality control systems employ an array of sensors, cameras, and digital analysis software to examine paddle dimensions, surface finish, and material integrity. These systems are designed to replicate and exceed the capabilities of human inspectors by offering:

- Consistency: Automated systems provide uniform evaluations, ensuring that every paddle is measured against the same parameters.

- Speed: High-speed cameras and advanced image processing can rapidly inspect multiple aspects of the paddle simultaneously.

- Data Integration: These systems offer real-time data collection and analytics, enabling immediate process adjustments and better traceability.

- Reduced Waste: Faster detection of defects leads to quicker adjustments, minimizing material waste and production downtime.

In essence, automated systems become an integrated part of the manufacturing process. They not only serve as the gatekeepers for product quality but also as diagnostic tools that help identify underlying issues in the production line. When applied to advanced processes like thermoforming3 or cold pressing4, automatic inspections can discern subtle variances in material properties, ensuring that the paddle's performance characteristics meet the stringent requirements of competitive textile.

Comparative Analysis: Manual vs. Automated Quality Control

Evaluating the differences between manual and automated quality control in a structured manner can help decision-makers choose the appropriate method for their production lines. The following table summarizes key aspects of both approaches:

| Aspect | Manual Quality Control | Automated Quality Control |

|---|---|---|

| Speed | Slower due to human limitations | Fast, high-throughput inspection |

| Consistency | Variable due to human factors | Uniform and repeatable across production cycles |

| Cost | High labor and training expenses | High initial investment but lower operational cost |

| Data Collection | Limited, manual recording | Real-time digital data analytics and reporting |

| Adaptability | Flexible, but error-prone | Programmed parameters, less flexible with unplanned defects |

| Defect Detection | Relies on inspector expertise | High-resolution sensors identify minute defects |

This comparison underscores that while manual inspections offer flexibility and human judgment, the efficiency, consistency, and data-driven advantages of automated inspections are hard to ignore for high-scale, high-performance manufacturing.

Implementing Automation in Quality Control: A Step-by-Step Guide

For production managers looking to integrate automation into their quality control processes, the following steps offer a practical roadmap:

-

Evaluate Current Production Processes

Assess how products are manufactured—consider all key processes like hot pressing, cold pressing, and thermoforming—and identify areas where defects most commonly occur. This evaluation should include an analysis of the existing manpower used for manual inspections and the associated costs. -

Research Available Technologies

Identify automated systems that match your production needs. Options can range from high-speed cameras and AI-based defect detection to robotic arms for physical inspection. Consider solutions that offer scalability and integration with your existing manufacturing systems. -

Define Quality Parameters

Establish clear quality metrics for paddle dimensions, material integrity, surface finish, and core properties. These parameters serve as benchmarks for configuring your automated system to detect deviations accurately. -

Pilot Testing

Before full-scale integration, conduct pilot tests on a limited production line. Evaluate how well the system identifies defects, its impact on throughput, and overall compatibility with your production processes. -

Training and Integration

Train staff on operating automated systems and interpreting the data they provide. While the system automates many repetitive tasks, human oversight remains essential for interpreting complex issues. -

Monitor and Refine

Once implemented, continuously monitor the system’s performance. Utilize real-time data to make process adjustments and further refine inspection criteria, ensuring that the system evolves alongside production needs. -

Budget and ROI Analysis

Conduct a thorough analysis of the initial investment versus projected long-term gains in efficiency and defect reduction. Automated systems often require high upfront costs, but the savings from reduced errors, waste, and increased production throughput can justify the expense over time.

Key Benefits of Automating Quality Control in Paddle Manufacturing

For high-performance pickleball products, the adoption of automated quality control offers several tangible benefits:

• Enhanced Product Consistency: By ensuring that every paddle meets the set quality parameters, manufacturers can maintain uniform performance, which is critical for both recreational and competitive play.

• Improved Production Efficiency: Automation speeds up the inspection process, enabling faster production cycles and lower lead times—vital for meeting market demand and on-time delivery.

• Reduced Operational Costs: Although the investment in automation may be significant, the reduction in labor costs and fewer defect-related losses lead to a favorable cost-benefit ratio in the long run.

• Real-Time Process Monitoring: Automated systems provide immediate feedback, allowing for rapid troubleshooting and minimizing downtime due to quality issues.

• Data-Driven Decision Making: With precise data collection, manufacturers gain insights into recurring defects, enabling proactive measures to improve overall process efficiency and product quality.

Case Study: Enhanced Paddle Quality at NEX Pickleball

Consider the example of NEX Pickleball, a pioneer in high-performance pickleball paddle manufacturing. By integrating an automated quality control system into their manufacturing process, they achieved several improvements:

• Defect Reduction: Automated inspections enabled the early detection of material inconsistencies, particularly in paddles using 12K Carbon Fiber5 and composite materials.

• Improved Consistency: The integration of digital quality assurance resulted in every paddle meeting exacting standards, which is crucial given the competitive nature of the sport.

• Process Optimization: Data from automated systems led to adjustments in production parameters, resulting in a more efficient manufacturing timeline and reduced waste—all while maintaining the integrity of the paddle's performance characteristics.

This case study illustrates how automation, when tailored to the specific needs of pickleball paddle production, can elevate both product quality and operational efficiency.

Actionable Recommendations for Production Managers

For production managers and quality control engineers contemplating automation, it's essential to focus on the following recommendations:

- Conduct a thorough evaluation of your current quality control process to identify inefficiencies.

- Consider the long-term benefits of automation in reducing human error and improving consistency.

- Pilot an automated system on a smaller scale before complete implementation.

- Invest in training and data analytics to fully leverage the capabilities of your automated system.

- Regularly review system performance data to continually optimize production parameters.

By following these steps, managers can make informed decisions that enhance production output and ensure that every paddle not only meets but exceeds quality expectations.

People Also Ask

Q: How to get more control in pickleball?

A: Achieving more control in pickleball can be linked to both equipment design and player technique. For equipment, ensuring the paddle has the right balance of weight, ergonomic grip design, and surface texture can significantly improve control. Players can also enhance their control by maintaining a relaxed grip and using more finger action for touch shots.

Q: What pickleball paddles are manufactured in the USA?

A: Several renowned brands manufacture pickleball paddles in the USA, including Avoura from Encinitas, California; Engage from Oxford, Florida; Paddletek from Niles, Michigan; Players Pickleball from Ferndale, Washington; Revolin from Holland, Michigan; and select models from Selkirk in Coeur d'Alene, Idaho.

Q: What is power and control in pickleball?

A: In pickleball, power and control refer to the paddle's performance characteristics. A power paddle is designed to deliver aggressive, hard shots, while a control paddle focuses on touch, finesse, and accuracy. The design, balance, and materials used in the paddle play key roles in determining its power and control capabilities.

-

automated inspection systems: Click to read an article detailing how integrated sensor technologies and robotics enhance precision in manufacturing quality control. ↩ ↩

-

AI-driven analytics: Click to understand how AI-driven analytics can optimize quality control by providing data-driven insights in manufacturing environments. ↩ ↩

-

thermoforming: Click to learn about thermoforming processes, including material shaping techniques used in high-performance manufacturing. ↩ ↩

-

cold pressing: Click to explore cold pressing methods and their applications in assembling composite materials. ↩ ↩

-

12K Carbon Fiber: Click to gain insights into the properties and benefits of 12K Carbon Fiber in enhancing product strength and performance. ↩ ↩