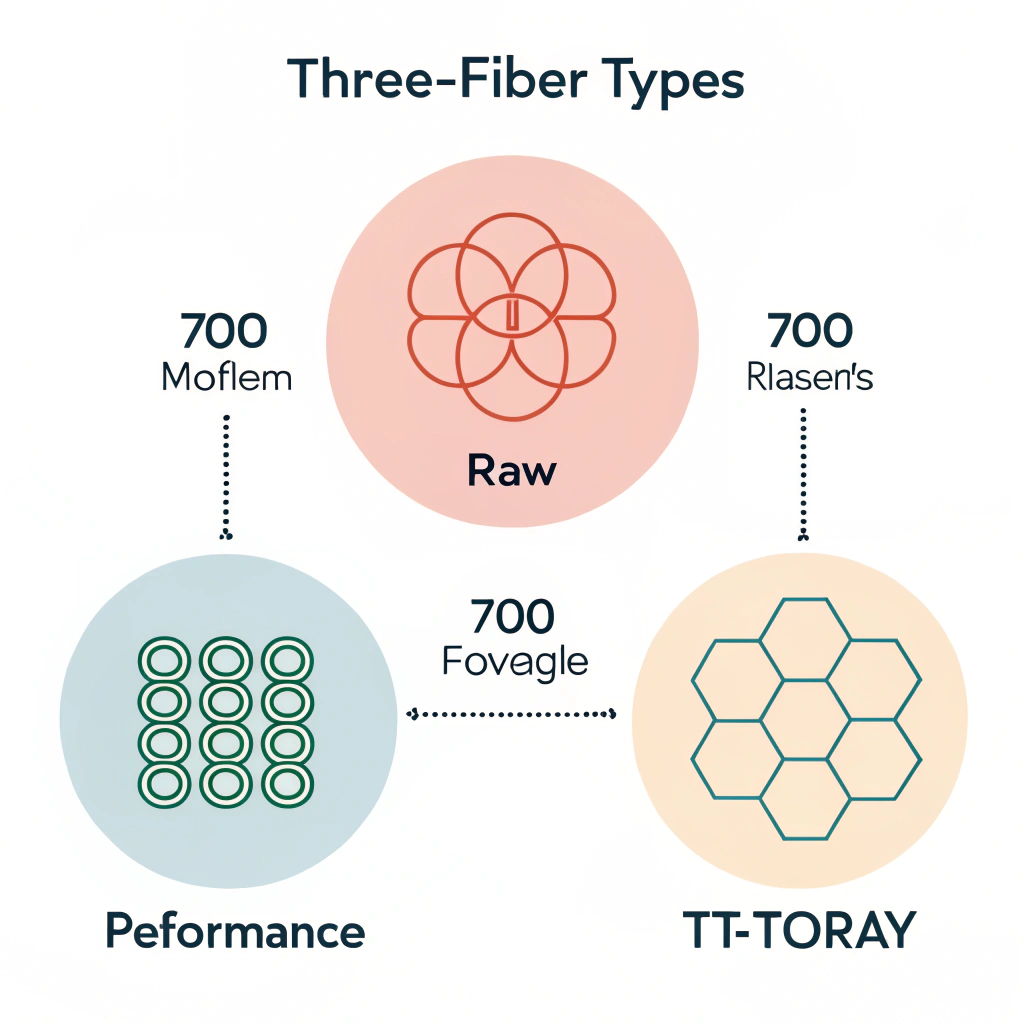

In today’s high-performance pickleball market, the best material for paddle faces depends on your specific performance and production needs. In brief, Raw fiber1 provides reliable baseline performance, T700 carbon fiber2 offers enhanced durability, power, and control, and Toray carbon fiber3 pushes the limits on strength and lightweight performance. Choosing the right fiber means balancing material properties with your manufacturing process preferences.

The selection dilemma for paddle face materials starts with understanding the different properties of each fiber type. As procurement managers and technical buyers, your decision will be influenced by factors such as tensile strength, impact resistance, production costs, and compatibility with advanced manufacturing processes. Below, we conduct a comprehensive comparison of Raw, T700, and Toray fibers.

Below is a summary table that highlights the key attributes:

| Feature | Raw Fiber Technology | T700 Carbon Fiber | Toray Carbon Fiber |

|---|---|---|---|

| Tensile Strength | Standard baseline strength | High tensile strength offering enhanced durability | Even higher tensile strength with optimized lightweight design |

| Durability | Reliable for basic performance | Superior durability, ideal for competitive play | Exceptional durability under high stress and repeated impacts |

| Power and Control | Standard performance | Excellent balance between power, spin control, and feedback | Enhanced control with quicker return response |

| Process Compatibility | Versatile with all production processes | Performs well with hot pressing, cold pressing, and thermoforming4 | Best with precision processes such as thermoforming for premium paddles |

| Cost and Investment | Lower initial cost | Moderate cost given its balanced performance | Higher cost due to proprietary manufacturing and performance edges |

| Market Adoption | Common in entry-level paddles | Preferred by serious and competitive players | Gaining traction for elite competitive play |

Raw fiber technology is often considered the foundation for paddle production. It offers a reliable performance that caters to a wide range of recreational paddles and early competitive models. For buyers looking for cost-effective solutions without sacrificing too much on performance, Raw fiber represents a dependable choice.

- Baseline Performance: Raw fiber provides sufficient strength and resilience for everyday play. Its standard properties make it easy to integrate into most production lines.

- Manufacturing Flexibility: Raw fibers are highly compatible with a variety of processes, including hot pressing and cold pressing. This flexibility allows manufacturers to optimize production speed without a steep learning curve.

- Cost Efficiency: Given its established presence in the market, Raw fiber is often more affordable. It offers a lower barrier to entry for manufacturers looking to produce quality paddles economically.

However, while Raw fiber is cost-effective and versatile, it may not deliver the advanced performance metrics required for top-tier competitive paddles.

T700 carbon fiber represents a significant upgrade from Raw fiber with clear improvements in durability and performance. It is known in the industry for delivering a gritty surface that enhances spin and precision.

- Superior Strength: T700 offers higher tensile strength, which translates to enhanced impact resistance. This means players can expect a paddle that withstands repeated high-energy impacts without degradation.

- Enhanced Control and Spin: The texture of T700’s surface provides a better grip on the ball, boosting spin and precision during gameplay. These attributes are crucial for competitive play where every stroke matters.

- Process Compatibility: T700 works well with advanced production methods. Whether you employ hot pressing for high production efficiency or cold pressing for precision work, T700 maintains its structural integrity. It performs reliably in thermoforming4 as well, allowing for intricate design details and material distribution.

For procurement managers, while T700 comes at a slightly higher cost than Raw fiber, the investment is justified by its performance benefits. The material’s strength and control factors mean that paddles made with T700 can maintain a competitive edge during play.

Toray carbon fiber is an industry leader in ultra-high-performance materials. It is engineered to offer not just better strength but also lighter weight, which is critical for rapid response and agile maneuvers on the court.

- Advanced Material Engineering: Toray fibers are produced with state-of-the-art methods that deliver higher density thread structures. This results in a paddle face that is even more resilient and returns energy during the ball impact almost instantaneously.

- Performance Enhancement: With improved tensile and compressive strength properties, Toray offers a performance upgrade over even T700. It is especially beneficial for elite players who demand quick turnaround and precise ball control.

- Cost Considerations: While Toray fiber has a higher unit cost due to its superior manufacturing process, the performance benefits such as enhanced control, lower weight, and durability justify its use in competitive and premium paddle markets.

- Manufacturing Impact: Toray fibers require careful handling during production to fully exploit their benefits. They are best incorporated in processes that can maintain precise environmental and mechanical controls, such as thermoforming. This ensures that the paddle design retains optimum material distribution and performance qualities.

For companies aiming to position their products at the top end of the market, Toray carbon fiber is an appealing option despite the higher investment. It is a material that caters to customers who are willing to pay a premium for enhanced performance and longevity.

The performance of these fibers isn’t only about the materials themselves—it’s also shaped by the production processes used. At NEX Pickleball, three primary production techniques play a crucial role:

-

- This process involves heating the composite materials under pressure, resulting in a robust and durable product. While it offers high production efficiency, there is a trade-off as the heat may alter some intrinsic material properties.

- Best For: Raw fiber and T700 fiber, where strength and production speed are balanced.

-

Cold Pressing:

- Cold pressing uses mechanical pressure at room temperature, preserving the natural properties of the fibers. This method is ideal for ensuring precise control over the paddle’s structural components, resulting in enhanced ball feel and responsiveness.

- Best For: Applications where fine control is essential, especially with T700 fibers to maintain performance consistency.

-

Thermoforming:

- By heating the material to a softening point before molding, thermoforming allows for intricate designs and consistent material distribution. This method is critical for extracting the full potential of advanced fibers such as Toray.

- Best For: High-performance paddles that require complex, optimized structures that enhance both durability and responsiveness.

Understanding the interaction between material selection and production method is key. For instance, while T700 and Toray fibers are both excellent, the choice between them might also depend on whether your production line can support the precise controls needed by thermoforming processes to fully leverage Toray’s advantages.

When deciding between Raw, T700, and Toray fibers for pickleball paddle faces, consider the following factors:

-

Performance Requirements:

For paddles intended for high-level competitive play, performance attributes such as superior impact resistance, ball control, and lightweight design will be essential. In this case, T700 or Toray fibers are the top choices. -

Budget and Volume:

If you operate on tight margins or aim for mass-market appeal, Raw fiber provides a cost-effective solution without significant compromises on playability. T700 offers a middle ground, delivering high performance with a moderate cost increase. -

Production Capabilities:

The capabilities of your production line matter. If your manufacturing process can handle the detailed requirements of thermoforming, adopting Toray fiber may bring the most advanced performance metrics. Conversely, simpler production techniques might favor the use of T700 or Raw fibers.

Below is a simplified decision table to guide your material selection:

| Requirement | Recommended Material | Key Considerations |

|---|---|---|

| High Performance & Precision | Toray Carbon Fiber | Requires advanced production process; higher cost |

| Balance of Performance & Cost | T700 Carbon Fiber | Superior durability and control, versatile processing |

| Cost Efficiency & Versatility | Raw Fiber Technology | Lower cost, reliable performance, widely applicable |

At NEX Pickleball, our extensive experience with high-performance materials means we can help tailor paddle specifications to meet your precise needs. Whether you require custom paddle options with specific material combinations (like a blend of carbon fiber and fiberglass composite) or a fully optimized design using advanced thermoforming processes, our expertise ensures that you receive products engineered to deliver on both performance and durability.

Our recommendations are based on the following guidelines:

- For products aimed at elite-level athletes and competitive environments, prioritize Toray carbon fiber to ensure superior control, lightweight performance, and resilience.

- For a balanced product mix that targets both serious players and intermediate users, T700 carbon fiber offers a great compromise with enhanced durability and control, while remaining amenable to a variety of production processes.

- For entry-level to mass-market recreational paddles, Raw fiber technology provides a cost-effective solution without significant performance trade-offs.

Manufacturers must align these material choices with their production capabilities. For instance, if you invest in thermoforming technology, you’ll be better positioned to maximize the benefits of Toray fibers. On the other hand, if your production process is geared toward high-volume hot pressing, adopting T700 fibers might be more optimal.

In summary, selecting the appropriate pickleball paddle face material—be it Raw, T700, or Toray fiber—requires a careful analysis of performance attributes, production methods, and budget constraints. Raw fiber offers baseline performance with cost efficiency, T700 carbon fiber delivers an excellent balance of durability and control, and Toray carbon fiber stands out for elite performance with its superior strength-to-weight ratio.

We recommend that procurement managers:

• Evaluate your production capabilities and process maturity.

• Consider your target market’s performance expectations.

• Choose the material that best aligns with your manufacturing strategy and customer needs.

At NEX Pickleball, our team of experts is ready to help you integrate these advanced material solutions into your product line. Reach out to discuss how our tailored paddle designs can help you gain a competitive edge in the market.

People Also Ask

• What does T700 mean in pickleball paddles?

T700 carbon fiber is renowned for its exceptional durability, power, and control. It provides a textured surface that enhances ball spin and precision, making it a preferred choice for competitive play due to its superior strength and lasting performance.

• What is the difference between Toray 700 and 800?

Toray fibers, particularly in comparison between the 700 and 800 series, differ in terms of tensile and compressive strength. The 800 series is engineered to be approximately 11% stronger than the 700 series, offering a lighter weight and a swifter response, which translates into improved performance under intense play conditions.

-

Raw fiber: Click to read more about the fundamental characteristics and cost-efficient benefits of Raw fiber technology, including its adaptability to various production methods. ↩ ↩

-

T700 carbon fiber: Click to explore detailed insights on T700 carbon fiber’s superior tensile strength, enhanced durability, and how it strikes a balance between performance and production efficiency. ↩ ↩

-

Toray carbon fiber: Click to understand Toray carbon fiber’s advanced material engineering, its ultra-lightweight strength, and why it is favored for elite, high-performance applications in competitive environments. ↩ ↩

-

Thermoforming: Click to learn about thermoforming processes, including how controlled heating and molding can optimize the material properties for superior paddle design. ↩ ↩ ↩2

-

Hot pressing: Click to discover the hot pressing method, its impact on material durability, production efficiency, and key considerations for integrating this process in high-volume manufacturing. ↩ ↩