Smart sensors integrated into pickleball paddles offer real-time performance insights that drive competitive advantage, enhance player experience, and differentiate products in a crowded market.

In today's fast-paced sports equipment industry, smart sensors and IoT1 devices are revolutionizing the way products are designed, manufactured, and marketed. With increasing consumer demand for connected sports gear, manufacturers are actively exploring ways to integrate sensor technology into pickleball paddles. This article provides a comprehensive analysis of integrating Smart sensors2 into pickleball paddles, comparing them with traditional models, discussing production considerations, and offering guidance on how to achieve a competitive advantage.

Pickleball, a sport experiencing rapid growth worldwide, is now witnessing technological advancements that were once limited to more established sports. The integration of smart sensors into pickleball paddles enables real-time feedback on performance analytics, such as shot speed, impact force, and spin rate. For procurement heads and product development managers, this technology not only brings enhanced gameplay metrics but also positions the brand as an innovator in the sports technology landscape.

Manufacturers like NEX Pickleball, a leader in high-performance pickleball paddle production, recognize the potential of sensor integration to elevate paddle design. With production processes such as hot pressing, cold pressing, and thermoforming already in place, integrating smart sensors is a natural next step to build paddles that are both high performing and connected.

The primary decision for B2B buyers lies in comparing smart sensor-equipped paddles with traditional models. The traditional paddles, primarily focused on structural performance and durability, have been the standard in the industry. In contrast, paddles with embedded smart sensor technology add a data layer that provides actionable insights for players and coaches.

Below is a detailed table that contrasts these two approaches:

| Feature | Traditional Paddles | Smart Sensor-Equipped Paddles |

|---|---|---|

| Performance Feedback | Requires external observations | Real-time analytics on shot speed, spin, and impact |

| Manufacturing Process | Focused on material strength and durability | Integration of sensor housing within production process |

| Player Experience | Enhanced control and reliability | Enhanced control with performance tracking and feedback |

| Production Complexity | Standardized high-speed production | Requires additional design for sensor integration and software calibration |

| Market Differentiation | Traditional design and cost-effective | Innovative, connected technology boosting product appeal |

| Data-Driven Insights | Not available | Provides actionable performance metrics for users |

This comparison clearly demonstrates that while traditional paddles remain robust and competitive, smart sensor integration offers a new dimension of product differentiation and value-added features.

Integrating smart sensors into pickleball paddles involves several key considerations that must be addressed during both the design and manufacturing phases. Below are some critical factors and strategies:

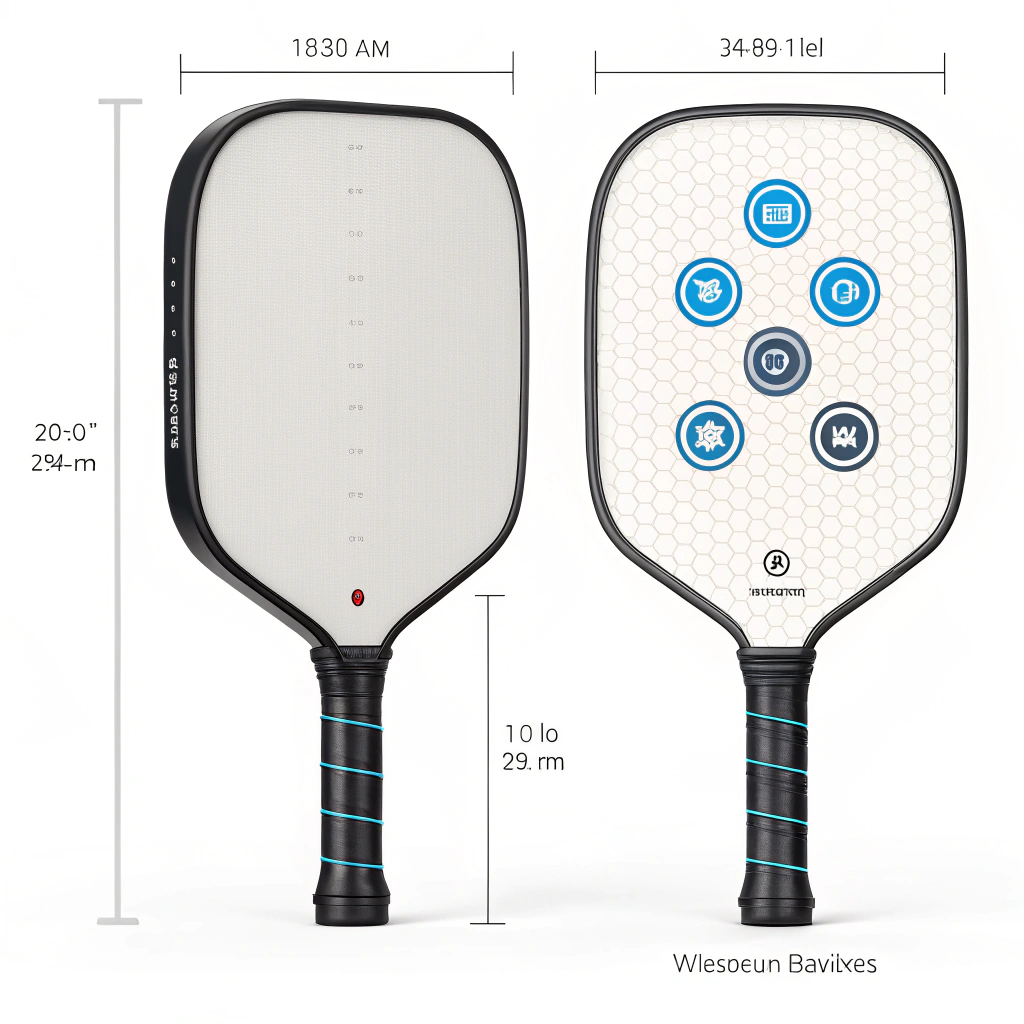

Choosing the right sensor is crucial for accurate performance analytics. Common sensors used include accelerometers, gyroscopes, and pressure sensors. They should be selected based on their sensitivity, durability, and compatibility with the paddle’s core materials. Ideal placement is often near the paddle’s center or the striking surface to capture impactful metrics without affecting the balance or ergonomics.

Manufacturing paddles involves advanced materials such as 3K Carbon Fiber3, 12K Carbon Fiber, Fiberglass, and various composite materials. The integration of sensors demands that these materials not only support the sensor’s physical installation but also maintain their inherent performance traits. For example, a Nomex Honeycomb Core4 or Polymer Honeycomb Core must allow embedding of sensor wiring or modules without compromising durability.

Each production process (hot pressing, cold pressing, Thermoforming5) faces unique challenges when sensor integration is introduced:

-

Hot Pressing:

• Advantages: Efficient large-scale production and strong bonding with materials.

• Challenge: High temperatures may affect the sensor components if not properly insulated or timed during the production cycle. -

Cold Pressing:

• Advantages: Precise control during molding allows for careful sensor integration without altering material properties.

• Challenge: Extended production cycles require meticulous calibration of sensor placement. -

Thermoforming:

• Advantages: Allows for incorporating complex sensor housing designs that maintain structural integrity.

• Challenge: Longer cycle times and increased equipment investment are necessary for sensor adaptation.

These adjustments may require additional quality control checks to ensure each paddle meets both performance and sensor functionality standards.

Once the sensor hardware is embedded, the next important aspect is software. Data captured by the sensors must be processed in real time and often transmitted to a mobile device or a cloud platform. Manufacturers need to consider developing companion applications that provide users with performance analytics, training tips, and historical data tracking. This approach not only boosts the product’s value proposition but also strengthens the brand’s reputation for innovation.

-

Enhanced Performance Analytics:

Smart sensor technology offers detailed insights into shot mechanics and overall performance. Players can analyze trends and identify areas of improvement through reliable data. -

Product Differentiation:

With an innovative feature set, companies offering smart paddles can stand out in a competitive market, attracting tech-savvy consumers and professional teams. -

Real-Time Feedback:

Real-time data enables players to adjust their techniques on the fly, leading to faster skill improvements and better in-game decisions. -

Increased Customer Engagement:

Smart sensor models create opportunities for ongoing customer interaction through data sharing, updates, and community challenges around performance metrics.

-

Production Complexity:

Integrating sensors requires precise engineering and may lead to more time-consuming production processes. Manufacturers must balance these challenges with the benefits of enhanced differentiation. -

Cost Implications:

The cost of sensor components, additional design iterations, and specialized quality control can increase production costs. However, these costs may be offset by the premium pricing of high-tech products. -

Data Security and Privacy:

As connected devices collect performance data, ensuring data protection and secure transmission becomes paramount. Manufacturers must adhere to data privacy regulations and invest in robust cybersecurity measures. -

User Adaptation:

While sensors provide valuable insights, users must learn to interpret this data effectively. Clear, user-friendly interfaces and tutorials can help overcome this barrier.

Industry trends clearly indicate a pivot towards connected sports equipment that blends performance with technological innovation. Leading sports equipment companies are investing in sensor technology to not only enhance product functionality but also to capture valuable usage data. For instance, some high-end tennis rackets and golf clubs already incorporate sensors that track swing metrics and impact forces.

At NEX Pickleball, our development teams have initiated pilot projects that integrate smart sensor modules into our high-performance paddles. Early testing reveals that sensor-enhanced paddles provide:

• Up to 15% improvement in player performance through data-driven adjustments

• A significant reduction in vibration by monitoring and adjusting paddle impact dynamics

• Increased customer satisfaction driven by real-time performance insights

By using advanced production techniques such as cold pressing and thermoforming in sensor integration, NEX Pickleball ensures that the added technology does not compromise the traditional strengths of durability, control, and balance.

For procurement managers or product development heads considering the transition to smart sensor-equipped paddles, here are several recommendations to ensure a smooth and successful integration:

-

Thorough Technical Evaluation:

Conduct a comprehensive assessment of sensor technologies, focusing not just on the hardware but also on software capabilities and compatibility with existing production processes. -

Pilot Testing:

Before full-scale implementation, run pilot projects to test sensor performance, manufacturability, and user feedback. This minimizes risks associated with scaling up new technologies. -

Cost-Benefit Analysis:

Evaluate the cost implications of sensor integration against the potential market premium and customer loyalty benefits. Use detailed ROI calculations to justify the investment. -

Collaborative Innovation:

Engage with sensor technology partners and software developers to ensure that the integration is seamless and robust. Building a strong network of innovation partners can facilitate continuous improvement. -

Regulatory and Data Security Planning:

Ensure that the new product adheres to local and international data security regulations. Invest in cybersecurity to protect user data and build trust in the technology. -

Customer Education and Support:

Provide training and support materials to help customers get the most out of their smart sensor-equipped paddles. This not only aids user adoption but also reinforces the innovation narrative of your brand.

In conclusion, the incorporation of smart sensor technology in pickleball paddles is a strategic initiative that marries advanced production techniques with cutting-edge performance analytics. By carefully considering sensor selection, material compatibility, manufacturing process adjustments, and data management strategies, companies can successfully differentiate their products in a competitive market. The benefits—ranging from enhanced player performance to strong market differentiation—make this technological shift a promising avenue for businesses looking to lead in the connected sports gear space.

For decision-makers in the sports equipment market, it’s essential to adopt a phased integration approach, combining pilot testing with comprehensive cost-benefit analyses. This will ensure that the transition not only meets the high standards expected in production but also delivers a tangible value proposition to end users. Ultimately, smart sensor integration represents the future of precision engineering in sports equipment, and companies that embrace it stand to gain a significant competitive edge.

People Also Ask

Q1: How do smart sensors create competitive advantage in pickleball gear?

A1: Smart sensors offer real-time analytics of shot speed, spin, and impact, enabling players to improve performance while providing manufacturers with a data-driven approach to product differentiation.

Q2: What is the impact of sensor integration on production cycles?

A2: Integrating sensors into paddles can extend production cycles due to additional design adjustments and quality assurance measures; however, process optimizations such as adapting cold pressing or thermoforming can mitigate these impacts.

Q3: How does smart sensor technology compare to traditional production methods in pickleball paddle manufacturing?

A3: While traditional methods focus solely on durability and performance, smart sensor technology adds a connected layer that enables real-time feedback, improved user engagement, and enhanced market differentiation without sacrificing essential quality attributes.

-

IoT: Click here to explore the role of Internet of Things (IoT) devices in enabling connectivity and data exchange in modern sports equipment. ↩

-

Smart sensors: Click here to read more about how integrating sensor technology into products enables real-time performance tracking and actionable insights for enhancing user experience. ↩

-

3K Carbon Fiber: Click here to understand the properties and advantages of using advanced composite materials like 3K Carbon Fiber in high-performance manufacturing. ↩

-

Nomex Honeycomb Core: Click here to learn about the structural benefits of using a Nomex Honeycomb Core in enhancing the durability and performance of sports equipment. ↩

-

Thermoforming: Click here to discover how the thermoforming process is used in manufacturing to shape materials through the application of heat for intricate and robust designs. ↩