Quick Answer: Effective pickleball demand forecasting and inventory planning combine advanced data analytics, industry trend analysis, and flexible production strategies to ensure optimal stock levels while minimizing excess inventory and supply disruptions.

In today’s dynamic sporting goods landscape, accurate demand forecasting and inventory planning are critical for distributors and retail chains specializing in pickleball equipment. The increasing popularity of pickleball has fueled demand fluctuations, making it essential for supply chain managers to adopt innovative strategies. This article outlines the challenges you may face, explains the underlying causes, and offers actionable solutions designed to align production capabilities with real-time market demands.

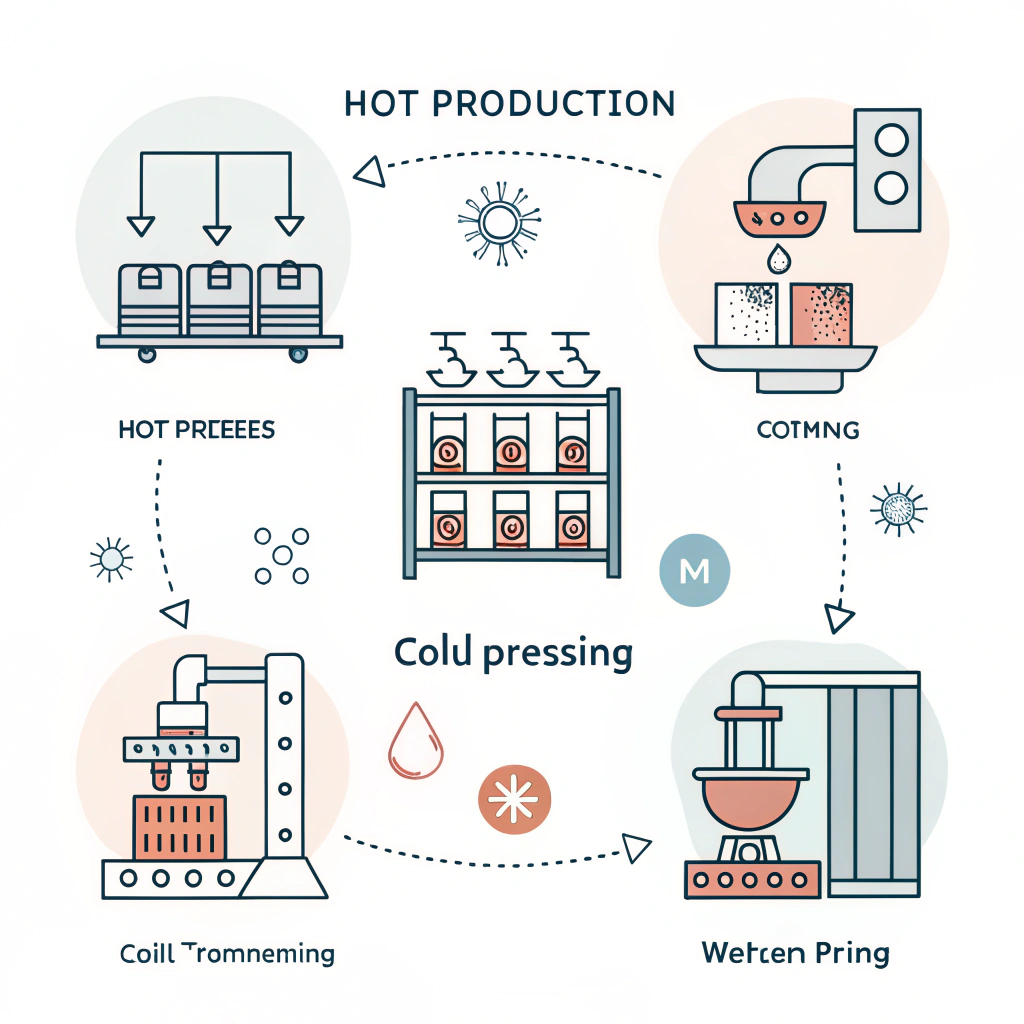

Pickleball, once a niche sport, is rapidly becoming mainstream due to its accessibility and fast-paced gameplay. However, this growth comes with forecasting challenges. Distributors often struggle with predicting seasonal spikes, managing promotional impacts, and balancing inventory of high-performance paddles made from carbon fiber1, fiberglass, and composite materials. Additionally, diverse production techniques such as hot pressing, cold pressing, and thermoforming add complexity to the forecasting process due to varying lead times and cost structures.

Key forecasting challenges include:

• Unpredictable market trends due to evolving player preferences

• Inaccurate demand estimation leading to stock-outs or excess inventory

• Coordination complexities between production planning and inventory control

• Variability arising from different production processes and material properties

These issues are compounded by macroeconomic factors and local market trends affecting sports equipment. Distributors must continuously refine their strategies while ensuring seamless communication with manufacturing partners like NEX Pickleball.

Understanding the reasons behind forecasting inaccuracies is crucial for designing robust solutions:

-

Market Volatility:

The sudden surge in pickleball popularity leads to unpredictable buying patterns. Seasonal events, tournaments, and partner promotions can rapidly shift demand metrics. -

Production Variability:

Different manufacturing processes — whether hot pressing for high-strength paddles or cold pressing for enhanced control — result in varying production cycles. Each process has its own advantages and limitations, affecting the overall inventory planning. -

Complex Supply Chains:

The journey from raw materials to finished products involves multiple steps and stakeholders. Any delay or misalignment at one step can cause discrepancies in final product availability. -

Data Limitations:

Many distributors rely on historical sales data that may not capture the latest market dynamics or incorporate emerging trends in the sports equipment industry. -

Material Diversity:

With products made from 3K Carbon Fiber, 12K Carbon Fiber, T300 Carbon Fiber, and various composites, differing material characteristics result in varying production costs, durability, and performance attributes. Forecasting algorithms must account for these nuances.

Understanding these root causes paves the way for targeted strategies that enhance predictive accuracy and streamline inventory management.

A robust solution for inventory planning and demand forecasting in the pickleball sector involves a multi-pronged approach. Below is a table summarizing some key solutions and their benefits:

| Solution Element | Description | Benefits |

|---|---|---|

| Data Analytics & Predictive Modeling | Leveraging historical data, market trends, and machine learning algorithms to predict demand | Better accuracy in forecasting, identification of trends |

| Collaborative Planning | Aligning production schedules with retailer and supplier insights | Smoother supply chain operations, reduced uncertainty |

| Flexible Production Processes | Utilizing different production methods (hot pressing, cold pressing, thermoforming) based on demand | Adjust production speeds to meet fluctuating market needs |

| Safety Stock & Buffer Management | Increasing safety stock levels for high-demand or unpredictable products | Prevents stock-outs during demand surges |

| Real-Time Inventory Monitoring | Implementing IT systems that provide real-time data on inventory levels | Quick decision-making, reduced excess stock |

| Scenario Analysis & Forecast Adjustments | Regular review and adjustment of forecasts based on current data and market trends | Improved responsiveness to market changes |

By applying these strategies, supply chain managers can ensure the right products are available at the right time. For example, if predictive analytics signals an upcoming surge in demand for carbon fiber paddles ahead of a major tournament, the production team can increase output or adjust ordering schedules accordingly.

The first step is integrating advanced data analytics tools that can process historical sales data, market trends, and seasonality factors. This allows for the creation of predictive models2 that forecast demand with greater precision. Techniques such as time series analysis, regression models, and even machine learning algorithms can be employed.

In practical terms, these models generate forecasts segmented by:

• Product type (e.g., paddles with 3K, 12K, or T300 carbon fiber)

• Production method (hot pressing vs. cold pressing vs. thermoforming)

• Region or sales channel

By continuously updating these models with real-time data, companies can improve forecasting accuracy and reduce reliance on outdated statistics.

Demand forecasting improves with closer collaboration between manufacturers, distributors, and retailers. Sharing actionable insights through integrated IT systems enables joint planning sessions. For instance, the manufacturing team at NEX Pickleball works along with distributors to forecast demand based on upcoming marketing promotions, seasonal events, or unique market conditions.

Collaboration tools and shared dashboards can help track key performance indicators like inventory turnover, order fill rates, and production lead times. This transparency ensures that any forecast deviations are quickly addressed, mitigating risks associated with sudden demand spikes.

A significant advantage for partners working with NEX Pickleball is the flexibility provided by different production processes. Whether it's using hot pressing for products that warrant higher impact resistance or cold pressing for products requiring precise control, aligning the production method with the current forecast is essential.

Flexible production offers the following advantages:

• Quick customization for bulk orders or special promotions

• Optimization of production schedules to balance between demand surges and regular operations

• Enhanced product availability by aligning manufacturing techniques with inventory requirements

In addition, adopting a mixed manufacture approach—for instance, combining carbon fiber and fiberglass in a composite solution—can help meet varying customer needs and reduce production bottlenecks.

Modern inventory management systems facilitate access to real-time data regarding stock levels across warehouses and retail points. This integration is critical for swift decision making. When systems instantly flag a low stock level, distributors can trigger replenishment processes or adjust forecasts accordingly.

Real-time monitoring also supports:

• Automated reordering systems that reduce manual intervention

• Dynamic adjustment of safety stocks based on current sales velocity

• Enhanced visibility of inventory turnover rates for each product variant

Implementing such systems not only minimizes the risk of over-stocking but also allows businesses to keep pace with rapidly changing consumer behavior.

5. scenario analysis5 & Forecast Adjustments

Effective forecasting is not static. Regular scenario analysis helps in understanding potential future states and preparing contingency plans. For instance, a sudden change in consumer behavior, such as an unexpected spike in demand due to viral marketing, may necessitate a swift revision of inventory levels or even a change in production strategy.

Scenario analysis involves:

• Evaluating best-case, worst-case, and most-likely scenarios

• Incorporating external factors such as economic indicators and competitor actions

• Adjusting safety stock levels to account for uncertainties

Regular reviews of these forecasts help in smoothing out the impact of unexpected variations, thereby ensuring sustained market availability and customer satisfaction.

While these forecasting and inventory planning strategies can significantly improve supply chain performance, there are some limitations to consider:

• Data quality and availability can restrict the accuracy of predictive models.

• Over-reliance on historical data may not capture emerging market trends, thus requiring continuous model recalibration.

• Implementation of advanced IT systems comes with high initial costs and training requirements.

• Collaborative planning demands a strong trust relationship and data sharing mechanisms among all partners.

Despite these challenges, the benefits of embracing an integrated, data-driven approach typically outweigh the potential downsides, especially for businesses operating in the competitive sports equipment sector.

In summary, effective pickleball demand forecasting and inventory planning are essential for maintaining a competitive edge in the sporting goods market. By integrating advanced data analytics, embracing flexible production techniques, and leveraging real-time inventory monitoring, businesses can optimize their supply chain management and mitigate risks.

Key takeaways for supply chain managers include:

• Invest in data analytics and predictive modeling to anticipate market trends.

• Cultivate collaborative relationships across the supply chain to ensure synchronized planning.

• Utilize a mix of production processes to provide flexibility in meeting fluctuating demand.

• Implement real-time inventory monitoring systems to enhance responsiveness.

• Regularly conduct scenario analyses and adjust forecasts based on evolving market dynamics.

By following these recommendations, your organization can achieve better inventory turnover, reduce excess stock, and ensure that products, such as high-performance pickleball paddles, are always available when your customers need them. Ultimately, these strategies support informed decision-making and sustainable growth in a rapidly expanding market.

Taking action today can lead to long-term benefits. If you need further advice or a demonstration of these strategies in action, consider scheduling a consultation to explore custom solutions tailored to your unique supply chain challenges.

People Also Ask

Q1: What are the key factors in forecasting demand for pickleball products?

A1: Key factors include analyzing historical sales data, understanding market trends and seasonality, recognizing the impact of production methods on lead times, and incorporating real-time inventory data to fine-tune forecasts.

Q2: How do production techniques affect inventory planning in the sports equipment industry?

A2: Production techniques such as hot pressing, cold pressing, and thermoforming influence the manufacturing cycle and product characteristics, which directly impact lead times, batch sizes, and overall inventory levels needed to meet demand.

Q3: What role does real-time inventory monitoring play in managing supply chain risks?

A3: Real-time inventory monitoring ensures that supply chain managers have up-to-date information on stock levels, enabling quick decision-making, automated reordering processes, and effective adjustments to safety stock, thereby reducing risks associated with stock-outs or overstocking.

-

carbon fiber: Click to learn more about the properties, manufacturing processes, and advantages of using carbon fiber in high-performance sporting equipment. ↩ ↩

-

predictive models: Click to explore how predictive models use historical data and machine learning techniques to forecast demand with enhanced accuracy. ↩ ↩

-

collaborative planning: Click to understand the benefits of fostering closer collaboration between manufacturers, distributors, and retailers in optimizing supply chain performance. ↩ ↩

-

real-time inventory monitoring: Click to read about implementing IT systems that track inventory levels in real time for improved decision-making and risk mitigation. ↩ ↩

-

scenario analysis: Click to discover how scenario analysis can prepare your business for various demand situations by evaluating best-case, worst-case, and most-likely scenarios. ↩ ↩