A quick answer: Integrating Kevlar reinforcement1 into pickleball paddle construction can significantly improve durability and impact resistance, offering an innovative edge over traditional composite materials when balanced with advanced manufacturing processes such as hot pressing2, cold pressing3, and thermoforming4.

In today’s competitive sports equipment market, manufacturers continuously seek ways to push the boundaries of performance and durability. For pickleball paddles, material innovation is critical, especially when evaluating the benefits of adding Kevlar reinforcement against conventional materials like carbon fiber and fiberglass. This article explains the technical pros and cons of Kevlar integration, its compatibility with existing production methods, and provides a clear comparison to support your technical and procurement decision-making process.

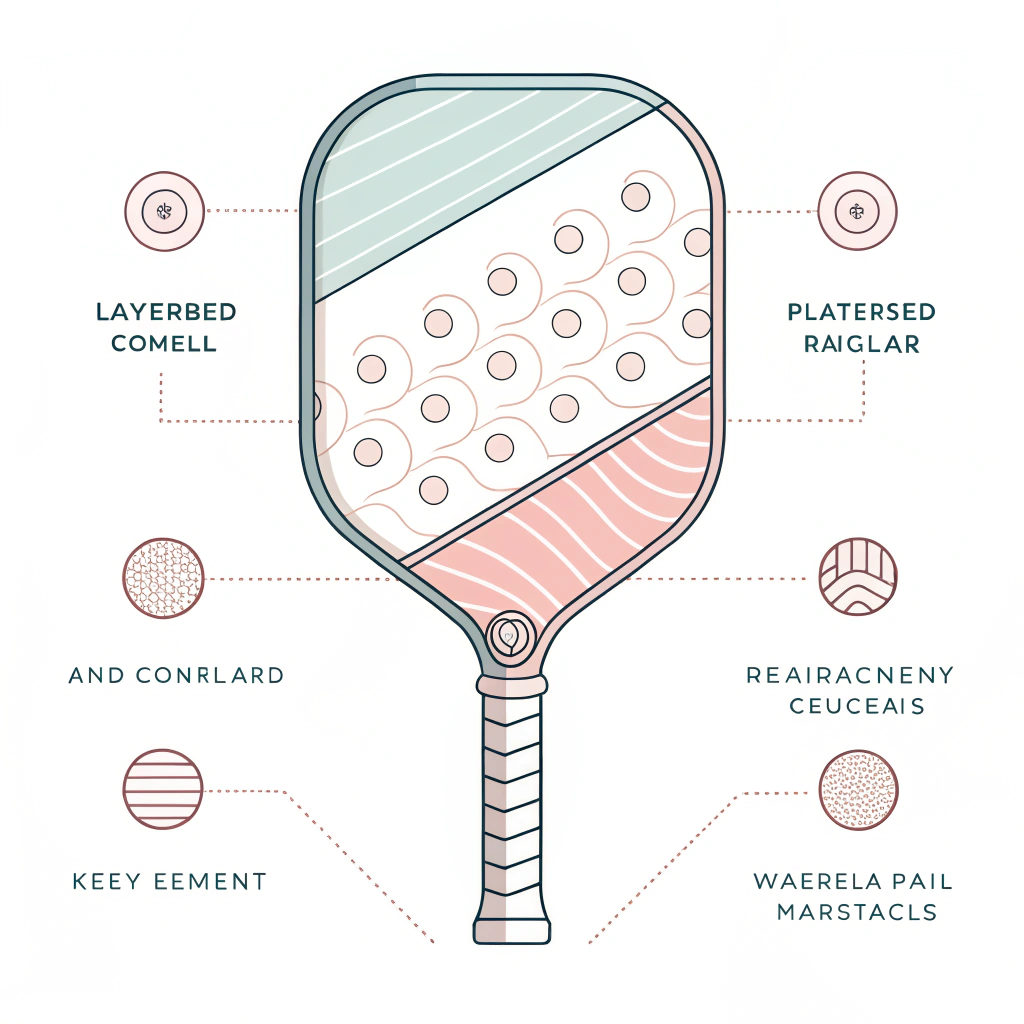

Pickleball paddle performance hinges on several key components, including the face material and core composition. With evolving player demands and increasing competition, manufacturers and technical product managers are looking for ways to enhance paddle performance through improved material durability and impact resistance. The integration of Kevlar reinforcement is being considered as an additional layer within composite structures to boost these characteristics. However, the challenge lies in balancing improvements in durability and impact performance without compromising on weight or control.

Manufacturers must assess:

• Whether Kevlar reinforcement can be efficiently integrated into existing composite layering processes5.

• How production techniques like hot pressing, cold pressing, and thermoforming influence the performance of Kevlar-enhanced paddles.

• The trade-offs between using Kevlar and traditional materials such as carbon fiber or fiberglass, which are already proven in delivering control and a preferred hitting feel.

Understanding the reasons for considering Kevlar begins with an evaluation of existing paddle performance issues such as:

- Material Degradation: Traditional paddle materials can experience wear and tear over time, especially when exposed to high-impact collisions. Over multiple uses, the paddle surface may show compromises in integrity.

- Impact Resistance: While carbon fiber and fiberglass offer excellent control and rebound, they sometimes do not provide sufficient shock absorption, which can affect both performance and the paddle's lifespan.

- Manufacturing Constraints: Each production process has its own set of advantages and limitations. For instance, hot pressing increases production efficiency but may alter material characteristics, while cold pressing retains material properties but is time-consuming.

- Weight and Balance: Adding extra layers for reinforcement can increase weight. The goal is to maintain a balance between improved durability and optimal weight distribution for a comfortable playing experience.

Introducing Kevlar reinforcement aims to address these challenges by providing high tensile strength and durability without significantly increasing paddle weight. Its integration, however, needs careful calibration during production to avoid compromising the performance attributes that players demand.

Below, we provide a comprehensive comparison table highlighting key attributes of Kevlar reinforcement versus traditional materials used in pickleball paddles.

| Feature | Kevlar Reinforcement | Traditional Materials (Carbon Fiber / Fiberglass) |

|---|---|---|

| Durability | Superior abrasion and impact resistance due to high tensile strength. | Well-tested durability; performance may degrade with repeated impact. |

| Impact Resistance | Excellent shock absorption with reduced vibration. | Good impact absorption; may require additional design tweaks to minimize vibrations. |

| Weight Considerations | Lightweight but integration must avoid excessive weight buildup. | Lightweight and reliable when used in optimized composite structures. |

| Production Compatibility | Requires precise layering during advanced processes such as thermoforming. | Compatible with hot pressing, cold pressing, and thermoforming without major adjustments. |

| Manufacturing Complexity | Incorporating Kevlar may demand additional calibration in composite layering. | Established production processes with extensive historical data. |

| Cost Implications | Potentially higher cost due to material price and processing techniques. | Cost-effective and widely available, offering predictable production expenses. |

The table above shows that while Kevlar offers impressive improvements in durability and impact resistance, there are practical challenges concerning production compatibility and cost. This is critical for technical product managers and procurement specialists to consider when making recommendations for product innovation.

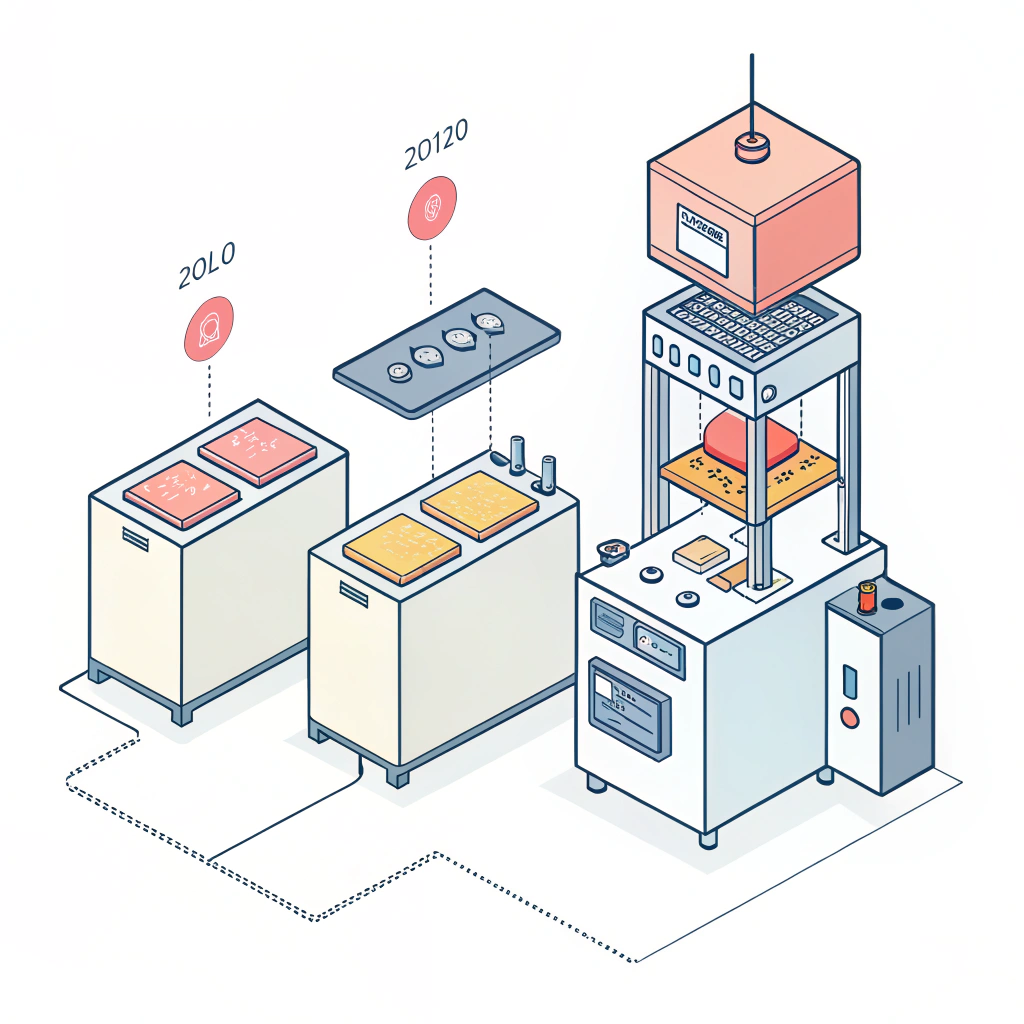

In modern paddle manufacturing, three production processes are predominantly used: hot pressing, cold pressing, and thermoforming. Each process interacts differently with composite materials and has specific implications when incorporating a new component such as Kevlar.

Hot pressing involves heating materials and applying pressure to form the paddle. This method:

• Offers high production efficiency.

• Produces paddles with excellent structural integrity.

• May, however, alter material properties due to the elevated temperature, which could affect the Kevlar layer’s performance if not carefully managed.

Cold pressing shapes materials at ambient temperatures using mechanical pressure. Its precision helps in retaining the material’s inherent characteristics:

• Enables precise control over thickness and structure.

• Is ideal for designs that require a delicate balance among multiple composite materials.

• May face challenges when integrating Kevlar if the process parameters are not impeccably adjusted to handle the different thermal and pressure profiles of Kevlar.

Thermoforming entails heating the material until it becomes malleable and then shaping it in a mold:

• It allows for the creation of intricate designs with an even material distribution.

• Preserves the material stability and enhances paddle performance.

• Requires strict control of production conditions, making it a suitable candidate for custom-designed paddles with Kevlar, where complex layering can be optimized.

These processes need to be reviewed carefully when considering Kevlar as an added reinforcement. For instance, while Kevlar’s excellent properties promise enhanced impact resistance, the manufacturing team must ensure that the heat or pressure applied during production does not compromise its structural integrity.

When incorporating Kevlar reinforcement, engineers and production managers must review several technical parameters:

-

Layering Structure:

The placement of the Kevlar layer within the composite is crucial. Typically, it is added between layers of carbon fiber or fiberglass to maximize its benefits without affecting paddle weight adversely. The arrangement often requires:- Precise measurement of layer thickness.

- Specialized adhesives or bonding techniques to ensure the integrity of composite layers.

- Testing for optimal balance between rigidity and flexibility.

-

Heat and Pressure Sensitivity:

Kevlar’s performance could be altered if exposed to excessive heat or pressure. Therefore, adjusting the production parameters of hot pressing and thermoforming is essential. Manufacturers must run trials to find the optimal temperature and pressure ranges that do not degrade the Kevlar layer. -

Cost-Benefit Analysis:

Although Kevlar might bring higher material costs, its long-term benefits such as prolonged lifespan and reduced frequency of replacements can justify the higher initial expenditure. The practical decision should weigh the enhanced performance with the increased cost per unit. -

Testing and Quality Control:

Pilot production runs with Kevlar reinforcement should include extensive testing for:- Shock absorption capability.

- Vibration reduction under high-intensity impacts.

- Consistent weight distribution and paddle balance.

- Long-term durability under repetitive play conditions.

A structured approach using a detailed checklist and iterative testing protocols will help ensure that the introduction of Kevlar meets the enhanced performance metrics.

Table 2: Key Technical Parameters for Kevlar Integration

| Parameter | Target Range/Consideration | Testing Method |

|---|---|---|

| Layer Thickness | 0.5-1.0 mm (depending on composite design) | Microscopic measurement and material analysis |

| Optimal Temperature Range | 110°C – 140°C (for thermoforming processes) | Thermal profiling and endurance tests |

| Pressure Settings | 15-25 MPa for cold pressing; variable for hot pressing | Pressure sensor calibration during pilot runs |

| Adhesive Compatibility | Use high-performance, heat-resistant adhesives | Bond strength tests and long-term durability checks |

| Vibration Reduction Efficiency | Target improvement of 20-30% over non-Kevlar paddles | Vibration measurement equipment and impact tests |

These technical checkpoints provide a roadmap for integrating Kevlar in pickleball paddle manufacturing while ensuring that the paddle retains its superior playability and durability.

Consider a scenario where a leading sports equipment manufacturer conducted a pilot study incorporating Kevlar reinforcement into their paddles. The study aimed to enhance durability without compromising the paddle's balance and playability.

Key outcomes:

• Performance Testing:

The Kevlar-enhanced paddles showed a 25% reduction in surface wear compared to traditional composite paddles during simulated high-impact conditions.

• User Feedback:

Players reported improved stability and reduced vibration during gameplay, which positively impacted their control and overall playing experience.

• Production Adjustments:

Fine-tuning the thermoforming process allowed the integration to maintain quality control, ensuring that the additional Kevlar layer did not disrupt the manufacturing timeline while still resulting in a high-quality product.

This case study underscores the importance of aligning advanced materials with appropriate production techniques to achieve both improved performance and operational efficiency.

In conclusion, integrating Kevlar reinforcement into pickleball paddle construction offers significant benefits, particularly in the domains of enhanced durability and improved impact resistance. However, successful integration requires a balanced approach that considers material properties, production challenges, and overall cost implications.

Key action recommendations include:

• Conducting rigorous cost-benefit analyses to balance material performance enhancements with manufacturing expenditures.

• Adjusting production parameters for hot pressing, cold pressing, or thermoforming to ensure that the Kevlar layers are not compromised during manufacturing.

• Implementing detailed testing protocols, particularly focusing on vibration reduction, shock absorption, and long-term durability.

• Collaborating with experienced material specialists to fine-tune the composite layering process and ensure a seamless integration of Kevlar into the overall paddle design.

For technical product development managers or procurement specialists, these insights provide a Foundation from which you can make an informed decision. Exploring the advanced benefits of Kevlar reinforcement may ultimately lead to a significant competitive advantage in the rapidly evolving sports equipment market.

People Also Ask

Q: What is the best material for pickleball faces?

A: Graphite-faced paddles are popular due to their lightweight properties and soft touch, which offer excellent control and feel during play. This material is commonly used by top manufacturers as it provides both precision and a comfortable playing experience.

Q: Can you use an eraser on a Kevlar pickleball paddle?

A: Yes, for paddles with carbon fiber or Kevlar surfaces, erasers are generally safe to use. It is advisable to use a non-abrasive eraser, particularly designed for pickleball paddles, and test on a small area first to ensure the surface remains undamaged.

Q: How do you add texture to a pickleball paddle?

A: A common method is to lightly sand the paddle surface using fine-grit sandpaper (typically 220–400 grit) in a circular motion. This process creates a consistent texture across the paddle face while preserving its integrity when done carefully and followed by thorough cleaning.

-

Kevlar reinforcement: Click to explore detailed insights on the properties, benefits, and application techniques of Kevlar reinforcement in composite manufacturing. ↩

-

Hot pressing: Click to read about the hot pressing process, its operational advantages, and the impact of temperature and pressure on material properties. ↩

-

Cold pressing: Click to understand the cold pressing method, how it preserves material characteristics, and its role in precision manufacturing. ↩

-

Thermoforming: Click to learn about thermoforming, the process of heating materials for molding, and its significance in advanced composite production. ↩

-

Composite layering processes: Click to explore the technical aspects of composite layering, including design considerations and integration techniques for advanced reinforcement materials. ↩