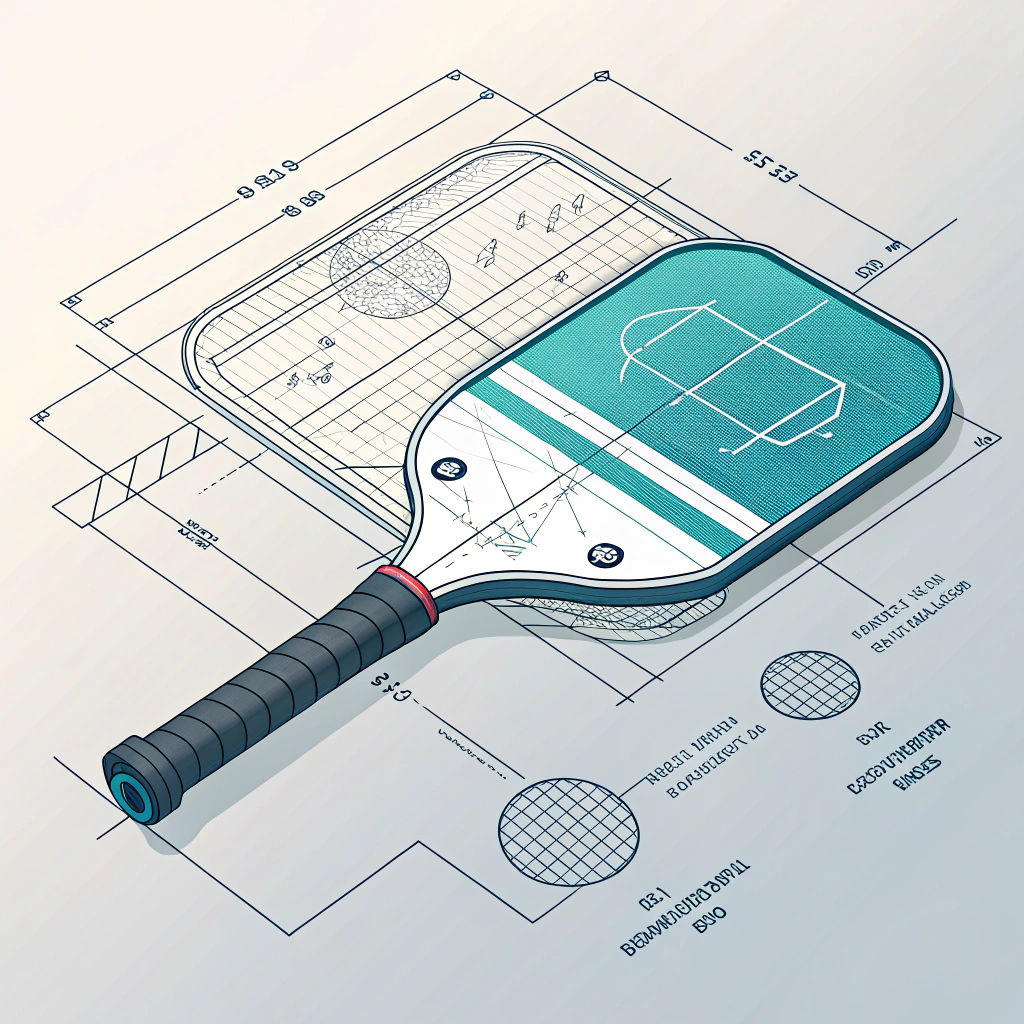

Quick Answer: By integrating advanced CAD design1 with precise production techniques—hot pressing2, cold pressing3, and thermoforming4—R&D managers can systematically transform innovative concepts into high-performance pickleball paddles that excel in real-world court performance.

As R&D managers and product developers in the sports equipment industry, you know that transforming a design from CAD into a paddle that performs on court involves a multitude of intricate steps. The key lies in understanding how design, material selection, and advanced production processes coalesce to produce paddles that offer superior power, control, and durability.

In this article, we break down the R&D pipeline for pickleball paddle manufacturing, explore common production methods, and compare techniques such as hot pressing2, cold pressing3, and thermoforming4. We also analyze how the transition from computer-aided design to physical production has a profound impact on performance in competitive play.

When stunning designs are validated only in the digital realm, many manufacturers encounter a common problem: the inability to faithfully translate CAD brilliance into a real-world product. This disconnect can lead to paddles that, despite looking impressive in simulations, do not meet the rigorous demands of on-court performance.

The main challenges include:

- Material inconsistencies: The properties of materials like carbon fiber and fiberglass can vary depending on processing techniques.

- Production variability: Even advanced processes such as thermoforming or hot pressing may alter the paddle’s tactile feel or stress distribution.

- Design limitations: While CAD provides precision, the physical reality during impact, vibration absorption, and ergonomics requires iterative testing and refinement.

To narrow the gap between digital designs and tangible performance, it is critical to comprehend the variables that affect production:

-

Material Behavior:

Each material, whether it’s 3K Carbon Fiber, 12K Carbon Fiber, or Fiberglass, exhibits unique responses to stress and pressure. Their reaction during the production process can affect the final product’s properties. -

Production Process Influences:

The methods used—hot pressing, cold pressing, or thermoforming—play a direct role in the paddle’s structural integrity and ball response. For instance, while hot pressing may maximize impact resistance, it might also compromise the natural flexibility of the materials. -

CAD to Physical Transition:

Differences in CAD simulation versus physical prototyping can result in a variation of design outcomes. Factors like mold precision, pressure control, and thermal gradients during processing require close monitoring. -

Quality Control and Testing:

Rigorous prototype testing and iterative refinements are essential to bridge the gap between design and performance. Every batch must undergo shock absorption tests, vibration analysis, and ergonomic evaluations.

To address the design-to-performance gap, manufacturers deploy several advanced techniques. Here’s a detailed look at our three primary production methods:

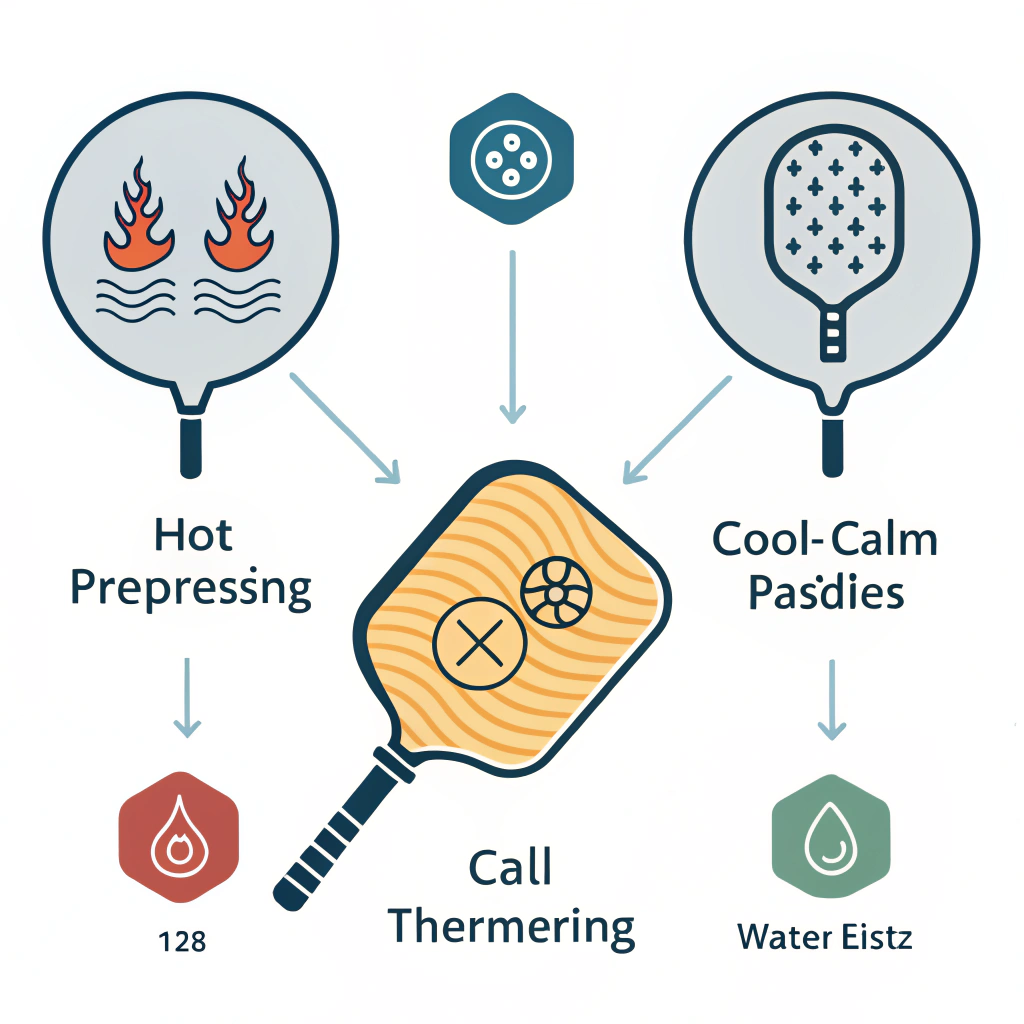

Hot pressing involves applying both heat and physical pressure to bond and shape materials.

-

Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Strengthens the bond between layers, resulting in robust paddles that can withstand high impact forces.

- Enhances impact resistance and structural integrity.

-

Disadvantages:

- The intense heat may modify certain material properties, potentially affecting paddle feel.

- Requires significant capital investment in specialized equipment.

Cold pressing is performed at room temperature under significant mechanical pressure.

-

Advantages:

- Offers precise control over the paddle thickness and material layering.

- Preserves the inherent properties of the materials, ensuring superior control and flexibility.

- Ideal for designs where maintaining the original material science attributes is crucial.

-

Disadvantages:

- Longer production cycles, which may not be ideal for high-volume production.

- Requires precision equipment to manage consistent pressure and avoid material deformation.

Thermoforming uses heat to soften the material followed by molding into complex shapes.

-

Advantages:

- Allows for intricate design details with precise material distribution.

- Maintains paddle stability by ensuring an even application of the material across the entire structure.

- Suitable for premium or custom paddle production where design nuances are paramount.

-

Disadvantages:

- Production time is generally longer with higher equipment costs.

- Better suited for high-end products rather than mass-produced lines.

To compare these processes at a glance:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High impact resistance, efficient for mass production | Potential for material alteration, high equipment cost |

| Cold Pressing | Precise control, maintains material properties | Longer cycles, requires delicate pressure management |

| Thermoforming | Intricate design capabilities, uniform material distribution | Longer production time, premium cost, ideal for custom orders |

Given the specifics of each production method, it becomes essential to align them with the intended performance outcomes. Some key considerations for R&D teams include:

-

Material-Process Compatibility:

When designing paddles using 12K Carbon Fiber, its higher density and hardness mean that cold pressing could be preferable to preserve the material’s surface smoothness and maximize impact resistance. In contrast, if a design focuses on vibration reduction, a Nomex Honeycomb Core5 processed via hot pressing might be more suitable. -

CAD Design Detailing:

The level of detail and precision achievable through CAD can be fully realized only when selected production methods do not compromise these design features. This requires tight collaboration between design engineers and production teams to ensure that aspects like ergonomic grip design and weight distribution remain intact post-production. -

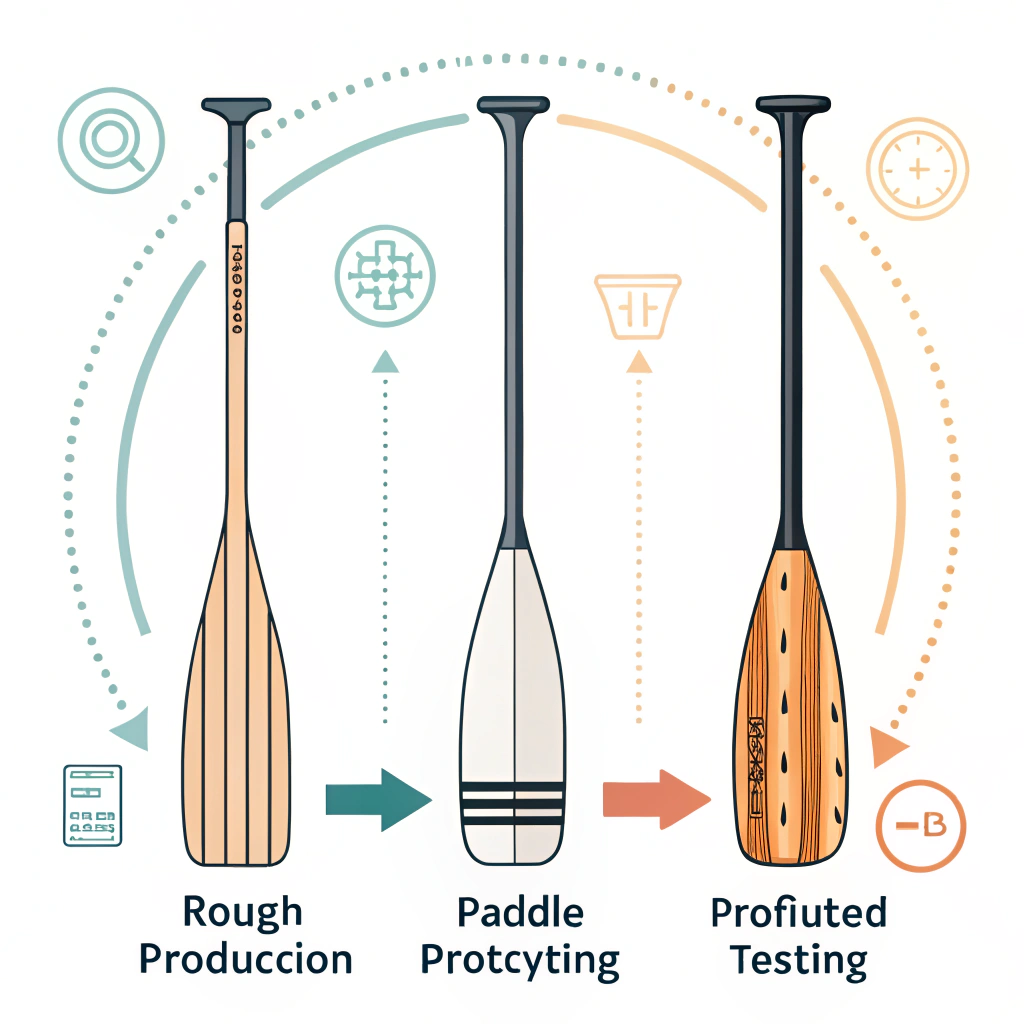

Prototyping and Testing:

Iterative testing is indispensable. Utilizing different production methods to create prototypes allows R&D managers to gather valuable performance data. Detailed comparison tests on court performance—such as measuring rebound force, vibration characteristics, and ball control—can dictate the choice of production process. -

Customization Requirements:

Many of today’s competitive paddles require custom modifications, whether for brand identity or specific player needs. Flexible production systems that support on-demand printing services can deliver bespoke solutions. At NEX Pickleball, we work closely with clients to modify design parameters such as grip size, weight distribution, and material composition to match specific performance requirements.

Consider a scenario where a product development team used CAD design1 to create a paddle optimized for both power and control. The initial concept involved a unique combination of T300 Carbon Fiber face and a Bamboo Core Composite for lightness and durability.

The team developed several prototypes using different production methods:

-

Hot Pressed Prototype:

- Resulted in a stiff paddle with high rebound force.

- Enhanced durability but reported slight reduction in comfort during long play sessions.

-

Cold Pressed Prototype:

- Maintained the intended flexible feel and superior ball touch.

- Production time was longer, but players reported a more balanced performance in terms of control.

-

Thermoformed Prototype:

- Allowed for a highly tailored shape which improved material distribution across the paddle.

- Offered excellent on-court stability, yet the production cost was notably higher.

The rigorous testing phase revealed that the cold pressing method provided the ideal balance between retaining the original design intent from CAD and delivering high performance on the court. This insight led the team to streamline their production process by integrating advanced pressure control systems and refining material handling procedures.

These data-driven decisions underscore the importance of matching production techniques to design objectives, ensuring consistency between digital intent and physical performance.

When assessing the production process for your pickleball paddles, keep in mind these targeted suggestions:

-

Balance Efficiency and Precision:

Evaluate whether the need for large-scale manufacturing outweighs the benefits of fine-tuned control, especially for high-end, custom products. In some cases, investing in advanced cold pressing or thermoforming setups may result in long-term gains in product quality and market differentiation. -

Leverage Data from Prototyping:

Use detailed performance metrics from prototype testing to further refine your CAD designs. Establishing a robust feedback loop between design, testing, and production is critical for continuous improvement. -

Invest in Collaborative Tools:

Integrate digital tools that assist in translating CAD designs into production parameters. Modern simulation software can predict material behavior under different production conditions, minimizing trial-and-error phases. -

Understand Material Nuances:

Not all high-performance materials react similarly under pressure or heat. Working closely with material scientists can help choose the optimal composite for your desired paddle performance. For instance, understanding the difference between 3K Carbon Fiber and 12K Carbon Fiber can directly influence decisions regarding production techniques. -

Prepare for Customization:

The modern market often demands customization—whether for team branding or enhanced personal performance. A flexible production process that supports on-demand modifications can be a key differentiator in competitive markets. -

Document and Standardize Processes:

Ensure each production run is carefully documented in terms of process parameters and product performance. Standard operating procedures (SOPs) can help maintain consistency across manufacturing batches, especially as production scales.

The journey from CAD design to a competitive, high-performance pickleball paddle is complex yet achievable through meticulous planning and the right mix of production techniques. By understanding the strengths and limitations of hot pressing2, cold pressing3, and thermoforming4, R&D managers can make informed decisions that directly enhance product durability, performance, and overall market competitiveness.

Integrating thorough prototyping and performance testing into the R&D workflow is key to translating digital designs into paddles that meet both design intent and on-court demands. For companies looking to push the boundaries of sports equipment innovation, this systematic approach ensures that every paddle performs at its peak, regardless of the stage from conceptual design to the final product delivered to players.

We invite you to explore these methodologies further and consider how strategic adjustments in your production processes can result in tangible competitive advantages on the court.

Q1: How does CAD design influence pickleball paddle performance?

A1: CAD design plays a crucial role by enabling precise modeling of paddle dimensions, weight distribution, and grip ergonomics. This precision helps in identifying potential areas of improvement during prototyping, ultimately translating into enhanced on-court performance.

Q2: What are the advantages and disadvantages of hot pressing, cold pressing, and thermoforming in paddle manufacturing?

A2: Hot pressing offers efficient production and strong impact resistance but may alter material properties. Cold pressing provides enhanced control and preserves material characteristics but has longer production cycles. Thermoforming allows for intricate designs and uniform material distribution, though it requires a longer production time and higher equipment investments.

Q3: How does material selection impact the durability and performance of pickleball paddles?

A3: Material selection is central to paddle performance; for example, carbon fiber variants and fiberglass each provide distinct benefits in terms of strength, flexibility, and vibration reduction. The choice of core material—such as Nomex, aluminum, or polymer—further determines shock absorption levels and overall paddle responsiveness.

-

CAD design: Reading this article will provide insights into how computer-aided design revolutionizes product development by enabling detailed modeling, simulation, and rapid prototyping for enhanced manufacturing precision. ↩ ↩ ↩2

-

Hot pressing: This article dives into hot pressing techniques used in manufacturing, explaining how heat and high pressure improve product durability and impact resistance. ↩ ↩ ↩2 ↩3

-

Cold pressing: Learn about cold pressing methods that allow for precise material layering and retention of material properties, ideal for applications where flexibility and control are key. ↩ ↩ ↩2 ↩3

-

Thermoforming: Discover how thermoforming leverages heat to mold materials into complex shapes, ensuring design intricacy and uniform material distribution during production. ↩ ↩ ↩2 ↩3

-

Nomex Honeycomb Core: Explore the benefits of using Nomex Honeycomb Core in composite manufacturing, including its excellent vibration damping and lightweight structural advantages for high-performance products. ↩ ↩