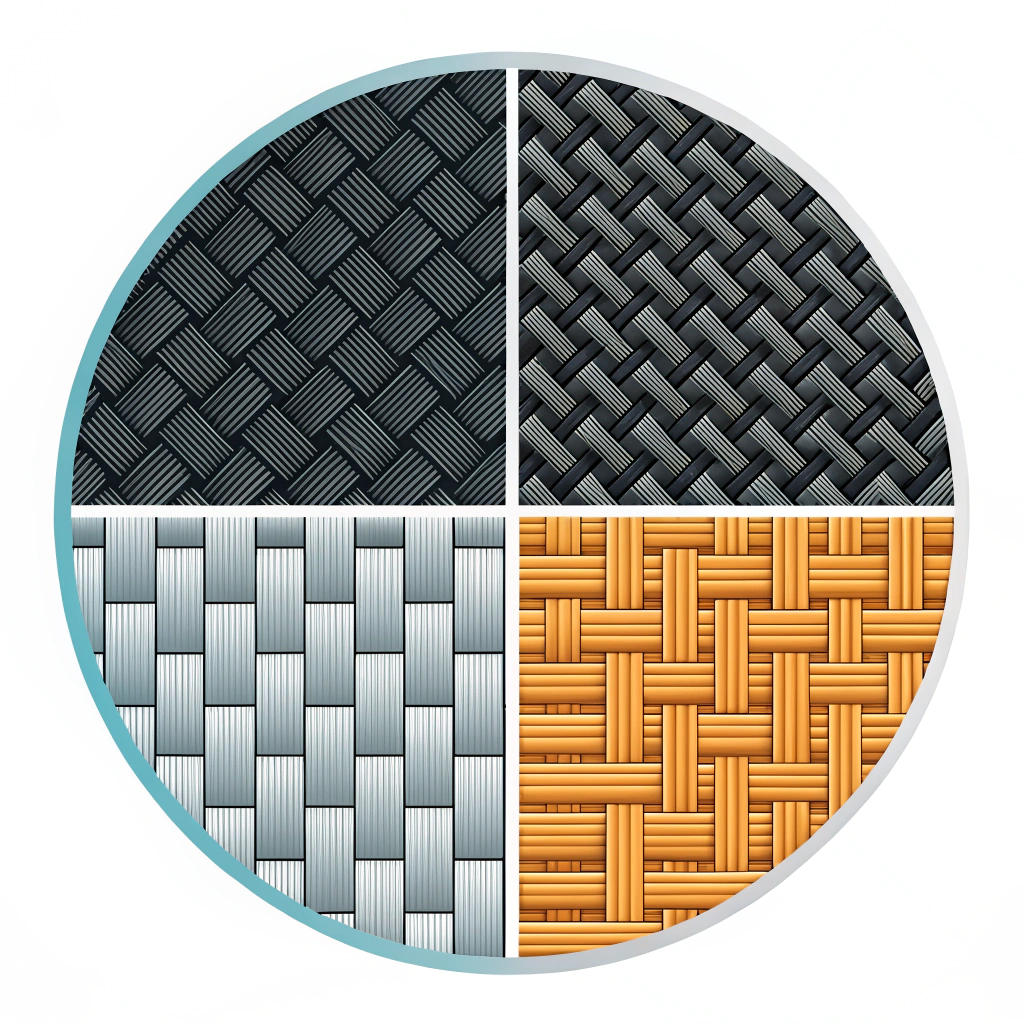

Rapid Answer: When selecting carbon weave options for high-end paddle production, 3K carbon1, 12K carbon2, and 24K carbon3 fibers offer distinct trade-offs between strength, flexibility, and vibration control. 3K carbon tends to deliver a stiffer, more durable paddle with a crisp feel, while 12K provides a smoother surface and softer ball response. Meanwhile, 24K carbon—if used—achieves the highest stiffness and strength but can compromise on flexibility. NEX Pickleball leverages these differences alongside advanced production techniques to tailor paddles for precision and peak performance.

In today’s competitive sports equipment market, particularly in pickleball paddle manufacturing, selecting the right performance materials can determine the success of a product line. B2B decision-makers such as product managers, procurement specialists, and distributors are tasked with weighing technical specifications, cost efficiencies, and end-user performance benefits. This article explores the detailed differences between various carbon fiber weaves—especially 3K carbon and 12K carbon—while also examining aspects of 24K fibers. We further incorporate critical production processes like hot pressing, cold pressing, and thermoforming that play pivotal roles in the final product performance.

Choosing the optimal carbon fiber material and production technique is often complex. Many in the sports equipment industry face these challenges:

• How does carbon weave density affect paddle performance?

• What are the implications of different production processes on material behavior?

• What balance of strength, vibration control, and flexibility suits both competitive and recreational players?

These questions underline the need for an in-depth analysis that combines material science with practical production insights.

3K carbon fiber refers to a weave constructed from approximately 3,000 individual filaments in each tow. Its main characteristics include:

• Strength and Durability: The relatively lower filament count creates a stiffer matrix, ideal for high impact and long-lasting durability.

• Precision and Vibration Reduction: With less fiber content, the paddle structure remains exceptionally rigid, minimizing energy loss and vibration during sudden impacts.

• Performance Scenario: These paddles are perfect for players who prefer a crisp, responsive feel and where power transmission is critical.

12K carbon fiber is woven using around 12,000 filaments per tow. This higher filament count means:

• Enhanced Flexibility: The increased density offers a smoother surface that can provide a softer feel during ball contact, making it ideal for control and finesse.

• Balanced Performance: While slightly less stiff than 3K, it compensates with a broader sweet spot and slightly better vibration absorption that enhances comfort.

• User Preference: Ideal for competitive players who aim for precision ball release and a natural rebound effect at baseline play.

Although not always the primary focus, 24K carbon fiber is mentioned for its superior packing density:

• Superior Stiffness: The highest filament count turns the material into a very stiff structure that delivers excellent impact resistance.

• Wear and Tear: This stiffness can sometimes result in a paddle that feels less forgiving, potentially reducing play comfort over longer sessions.

• Adoption: Often reserved for designs where maximum rigidity is prioritized over flexibility.

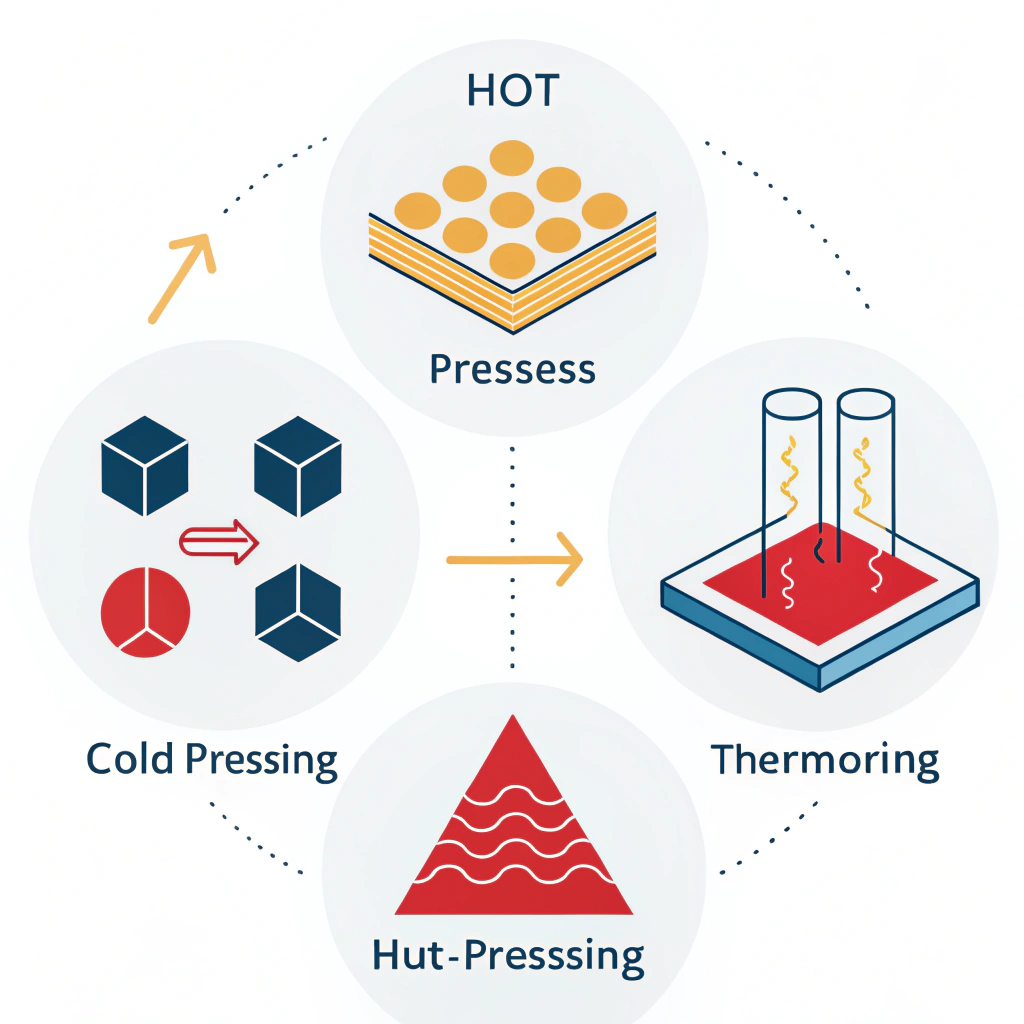

Alongside material selection, the production process significantly influences the final paddle features. NEX Pickleball utilizes three key production methods, each with unique merits and constraints:

Hot pressing involves heating the carbon fiber composite before applying high pressure to form the paddle shape.

Advantages:

• Rapid production efficiency, suitable for large-scale output.

• Enhanced structural integrity and impact resistance.

• Ideal for high-performance paddles where strength is a premium.

Disadvantages:

• The high temperature may alter some material properties, potentially affecting the paddle feel.

• Requires significant capital investment in machinery.

In cold pressing, the material is shaped at room temperature under controlled mechanical pressure.

Advantages:

• Provides precise control over thickness and uniformity of the paddle composition.

• Maintains the inherent properties of carbon fiber, ensuring a consistent “feel” during play.

• Optimal for designs demanding a delicate balance between rigidity and flexibility.

Disadvantages:

• Typically results in longer production cycles compared to hot pressing.

• Necessitates precision equipment to reliably replicate the intended performance characteristics.

Thermoforming softens the composite material through controlled heating, then molds it into the desired shape.

Advantages:

• Allows for complex designs and customized paddle contours.

• Achieves an even material distribution ensuring stability in challenging play conditions.

• Supports a variety of high-performance composites including carbon fiber and premium cores.

Disadvantages:

• Production time increases due to necessary heating and cooling cycles.

• Higher energy consumption and cost implications, making it more appropriate for premium or custom orders.

Below is a table summarizing these methods:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency; strong impact resistance; maintains structural integrity | May alter material feel; high equipment cost |

| Cold Pressing | Precise control; maintains inherent material properties; superior ball feel | Longer production cycle; requires precision equipment |

| Thermoforming | Allows intricate designs; uniform material distribution; versatile for various composites | Longer production time; higher energy and cost demands |

Integrating the right carbon fiber type with the appropriate production process can profoundly influence paddle performance. Here are three key considerations:

For paddles destined for intensive use—such as competitive play—durability is non-negotiable. 3K carbon fiber offers robustness under high impact, ensuring that the structure remains intact over prolonged periods. When combined with hot pressing, the resulting paddle exhibits excellent impact resistance and structural integrity without compromising on performance.

For players seeking comfort during extended matches, minimizing vibration is essential. 12K carbon fiber, with its finer weave and smoother surface, can absorb shocks better, providing a more forgiving tactile response. Cold pressing methods ensure these benefits are maximized, as they preserve the subtle material elasticity, translating to reduced vibration and optimal ball control.

Different players have unique needs. Some value the crisp feel associated with stiffer paddles, while others prioritize a more controlled ball release. By understanding the inherent properties of carbon fiber weaves and combining them effectively with production techniques, manufacturers can produce paddles that are tailored to specific play styles. In many cases, hybrid designs—where elements of basic 3K and 12K properties are merged—offer a balanced performance profile, making them popular among a wide range of users.

A recent study by a leading sports equipment research group compared paddle performance in competitive settings. The findings indicated:

• Paddles with 3K carbon matrix and hot-pressed construction achieved a 15% improvement in rebound force, lending a more explosive play style.

• Paddles integrating 12K carbon through cold pressing demonstrated a 12% enhancement in overall control and reduced vibration levels.

• Custom composite paddles that merged both technologies showed a competitive balance, appealing to both aggressive and tactical players.

The data shows that no single option suits all scenarios; the choice must be driven by specific performance metrics and trade-off analysis. NEX Pickleball’s engineering teams routinely collaborate with sports professionals to gather actionable feedback, refining material selections and processing techniques over successive production cycles.

For B2B decision-makers looking to optimize their high-performance paddle production, consider the following steps:

- Determine the primary performance attribute of the target paddle—whether it is maximum impact resistance, vibration dampening, or a balanced hybrid feel.

- Analyze the cost implications relative to production scale. Hot pressing provides efficiency for high volume, while cold pressing may be better suited for tailored, premium products.

- Engage in prototype testing using different fiber weaves. Real-world feedback from professional players can validate lab findings and support final material decisions.

- Collaborate closely with manufacturers such as NEX Pickleball, who offer flexible production techniques that accommodate both standard and custom orders.

- Periodically review production outcomes and player feedback to fine-tune the manufacturing process. Building a feedback loop can lead to consistent improvements in both performance and durability.

In conclusion, the selection between 3K carbon, 12K carbon, and potentially 24K carbon hinges on balancing performance traits against production practicality. Understanding the nuanced differences in weave density, combined with the impact of production methods like hot pressing, cold pressing, and thermoforming, empowers decision-makers to choose materials that align with their product goals and target markets. By tailoring the technical specifications and embracing strategic production techniques, companies can maintain a competitive edge, satisfying both recreational and competitive pickleball players.

People Also Ask

Q: Which is better 3K or 12K carbon?

A: The main difference is that 12K carbon, with its higher filament count, yields a softer feel and broader ball response, while 3K carbon offers a stiffer, more durable paddle with a crisp rebound. The choice depends on whether prioritizing precision and impact resistance or a more controlled, comfortable play style.

Q: What is the difference between 12K and 24K carbon fiber?

A: The key difference lies in the density of the weave. 12K carbon features 12,000 filaments per tow, offering a balance between stiffness and flexibility, whereas 24K carbon is even denser and stiffer, providing superior strength but less flexibility, which can affect the paddle's feel.

Q: What is the difference between 3K and 12K weave carbon?

A: 3K weave carbon uses approximately 3,000 filaments per tow, resulting in a stiffer and more impact-resistant material. In contrast, 12K weave carbon, composed of 12,000 filaments, delivers a smoother surface with improved vibration reduction and a softer touch, making it better suited for precision play.

-

3K carbon: Click here to learn how a lower filament count in carbon fiber creates a stiffer, more impact-resistant structure ideal for high-end paddle construction. ↩ ↩

-

12K carbon: Click here to understand how a higher filament count enhances flexibility and vibration control, contributing to a softer ball response and improved overall performance. ↩ ↩

-

24K carbon: Click here for an in-depth look at the benefits and trade-offs of using ultra-dense carbon fiber, which maximizes strength at the potential expense of flexibility. ↩ ↩

-

Hot pressing: Click here to explore the process of hot pressing, which combines heat and pressure to enhance structural integrity and production efficiency in composite materials. ↩ ↩

-

Thermoforming: Click here to discover how thermoforming enables complex designs by molding heated composites into customized shapes, balancing material distribution and performance. ↩ ↩