Quick Answer: For premium pickleball paddles, selecting the right grip material—whether it is a reinforced carbon fiber composite1, a high-performance polymer blend2, or a custom engineered hybrid3—is critical to achieving optimal performance, comfort, and durability. The decision depends on production techniques, material properties, and tailored design requirements that meet high standards of modern competitive sports equipment.

Selecting the best grip material for high-performance pickleball paddles is a nuanced process, especially for procurement managers and business development executives striving to cater to elite players and discerning retail customers. As the production landscape evolves, manufacturers like NEX Pickleball leverage advanced techniques such as hot pressing4, cold pressing, and thermoforming5 to produce paddles with unparalleled structural integrity and enhanced playability. In this article, we discuss the technical aspects of different grip material options, compare their performance characteristics, and provide practical insights into making an informed decision that aligns with industry standards and market expectations.

The grip is a critical component in pickleball paddles that influences both the player's comfort and paddle performance. An ideal grip material must deliver:

- Enhanced Vibration Reduction: Minimizes discomfort during long play sessions.

- Superior Durability: Withstands the high-impact collisions common in competitive play.

- Exceptional Ergonomics: Ensures a secure hold that adapts naturally to various hand sizes.

Given these requirements, the choice of grip material becomes central to product competitiveness and customer satisfaction. Retail buyers often compare technical specifications such as tensile strength, elasticity, and material density to ensure that the paddles support both power and precision.

In evaluating grip materials, manufacturers and procurement professionals typically examine a few popular options:

-

Carbon Fiber-Based Grips:

- Advantages:

• High tensile strength and rigidity for responsive performance.

• Excellent durability and low vibration during impacts.

• Lightweight, which contributes to the overall balance of the paddle. - Considerations: Carbon fiber grips are often used in high-end paddles to deliver maximum control while ensuring long-term performance.

- Advantages:

-

Polymer Grips:

- Advantages:

• Exceptional elasticity, providing a softer yet effective grip.

• Effective vibration dampening for enhanced comfort.

• Cost-effective while maintaining competitive performance metrics. - Considerations: Suitable for paddles aimed at recreational players or those seeking a more comfortable hitting experience.

- Advantages:

-

Hybrid Composite Grips (e.g., Carbon Fiber and Fiberglass Composite):

- Advantages:

• Combines the strength of carbon fiber with the flexibility of materials like fiberglass.

• Offers a balanced mix of control, durability, and responsiveness.

• Allows for customization tailored to specific player needs and game styles. - Considerations: Often adopted by manufacturers looking to serve both competitive and recreational market segments.

- Advantages:

Below is a table summarizing key comparisons:

| Material Type | Performance | Comfort | Durability | Typical Use Case |

|---|---|---|---|---|

| Carbon Fiber-Based Grips | High rebound, low vibration; very responsive | Firm, less cushioned | Excellent, long-lasting | Competitive play, high-end paddles |

| Polymer Grips | Balanced power and control; moderate rebound | High cushioning, improved ergonomics | Good, shorter lifespan than carbon | Recreational/entry-level paddles |

| Hybrid Composite Grips | Optimized balance of power and control | Customizable cushioned grip | Very durable with proper design | Versatile use across player levels |

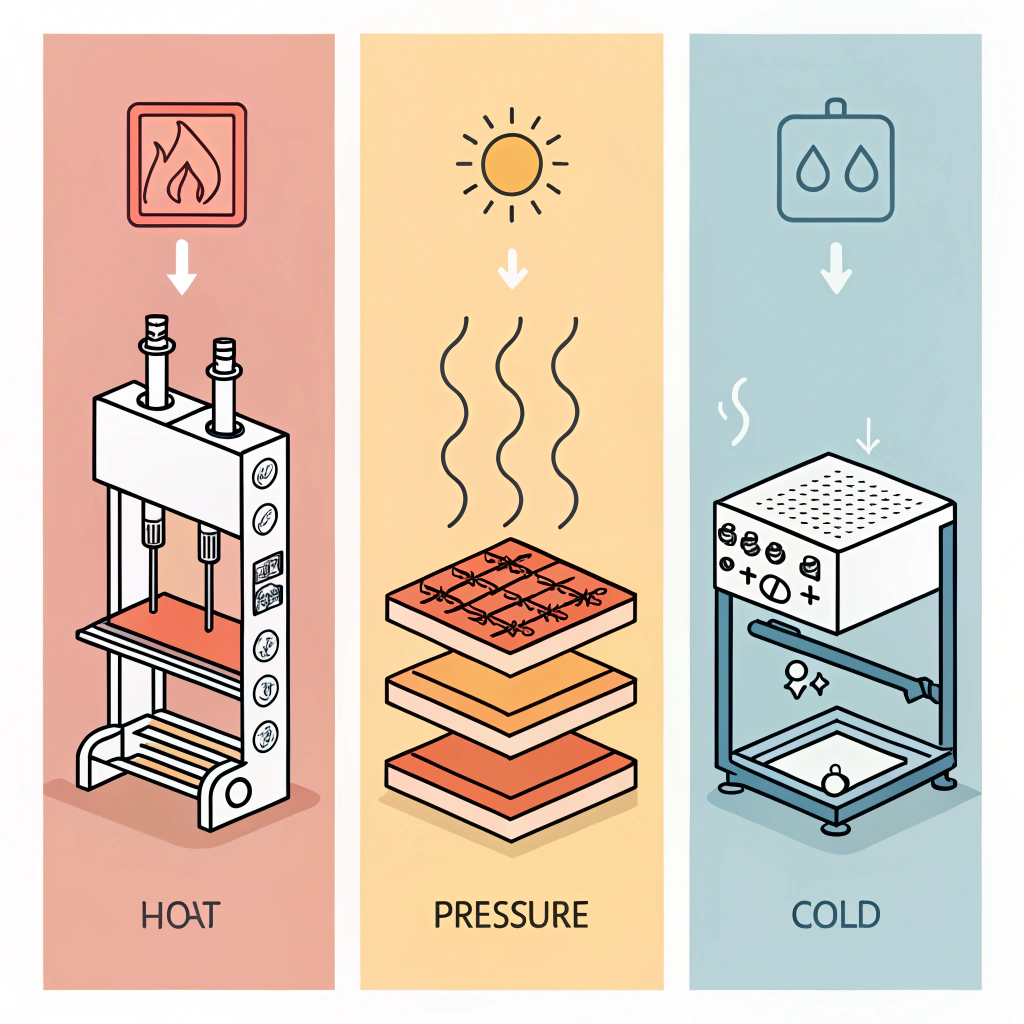

The production process can significantly impact the final performance of the paddle grip. NEX Pickleball uses three primary methods that each contribute uniquely to the paddle’s properties:

- Produces a high-strength structure through combined heat and pressure.

- Ensures that the grip material is securely bonded to the paddle, enhancing durability and performance.

- However, the exposure to high temperatures may alter some microstructures, potentially affecting the feel for players who value subtle tactile differences.

- Involves applying mechanical pressure at room temperature to shape the grip material without altering its inherent properties.

- Provides more precise control over the texture and thickness, critical for achieving optimum grip performance and comfort.

- The downside is a longer production cycle and the need for stringent equipment calibration.

- Involves heating materials to a softening point before molding them into the desired shape.

- Ideal for creating intricate designs and ensuring a uniform distribution of grip materials.

- Although it is more time-consuming and requires higher equipment investment, thermoforming can facilitate premium paddle customization for niche markets.

Table 2 below presents a quick production process overview:

| Process | Key Advantage | Limitation | Best Suited For |

|---|---|---|---|

| Hot Pressing | High production efficiency; strong bonds | Potential alteration of feel | Bulk manufacturing of high-strength paddles |

| Cold Pressing | Precise material control and feel | Longer production cycles | High-end paddles demanding superior tactile quality |

| Thermoforming | Complex and intricate designs | Higher costs and longer lead time | Custom-made premium products |

When evaluating which grip material best fits your production needs, consider the following factors:

- Rebound Force and Responsiveness: Manufacturers need materials that can efficiently transfer energy upon ball impact. Carbon fiber, particularly the 3K and 12K variants used in paddle bodies, successfully complements superior grip materials in delivering rapid ball rebound.

- Vibration Damping: A grip's ability to absorb shock—a key factor in reducing fatigue—is essential. Polymer-based and hybrid grips emerge as notable choices because of their inherent cushioning qualities.

- Impact Resistance: The material should withstand continuous impacts and prolonged play without significant wear.

- Environmental Factors: Consider if the grip material can tolerate exposure to various environmental conditions (e.g., humidity, temperature variations) while maintaining its properties.

- Customizability: The ability to tailor grip texture, thickness, and coverage is invaluable for meeting player-specific needs. NEX Pickleball offers custom paddle options, where grip materials are selected based on comprehensive feedback from athletes and retailers.

- Comfort: Ergonomic design not only improves play performance but also minimizes the risk of hand fatigue or injuries. A cushioned yet responsive grip can make a significant difference, especially during long matches.

- Equipment Investment: High-performance materials and processes like thermoforming require a higher capital investment, impacting overall production cost and price point.

- Production Scalability: High-volume orders may favor hot pressing for efficiency, provided the slight trade-off in tactile feel does not compromise end-user satisfaction.

- Target Demographics: For professional competitive players, a grip focusing on high power and feedback may be preferable, whereas recreational players might prioritize comfort and shock absorption.

- Industry Trends: Emerging trends in sports equipment highlight a movement towards hybrid materials that blend the benefits of various components. Staying updated on these trends ensures that your product remains competitive and innovative.

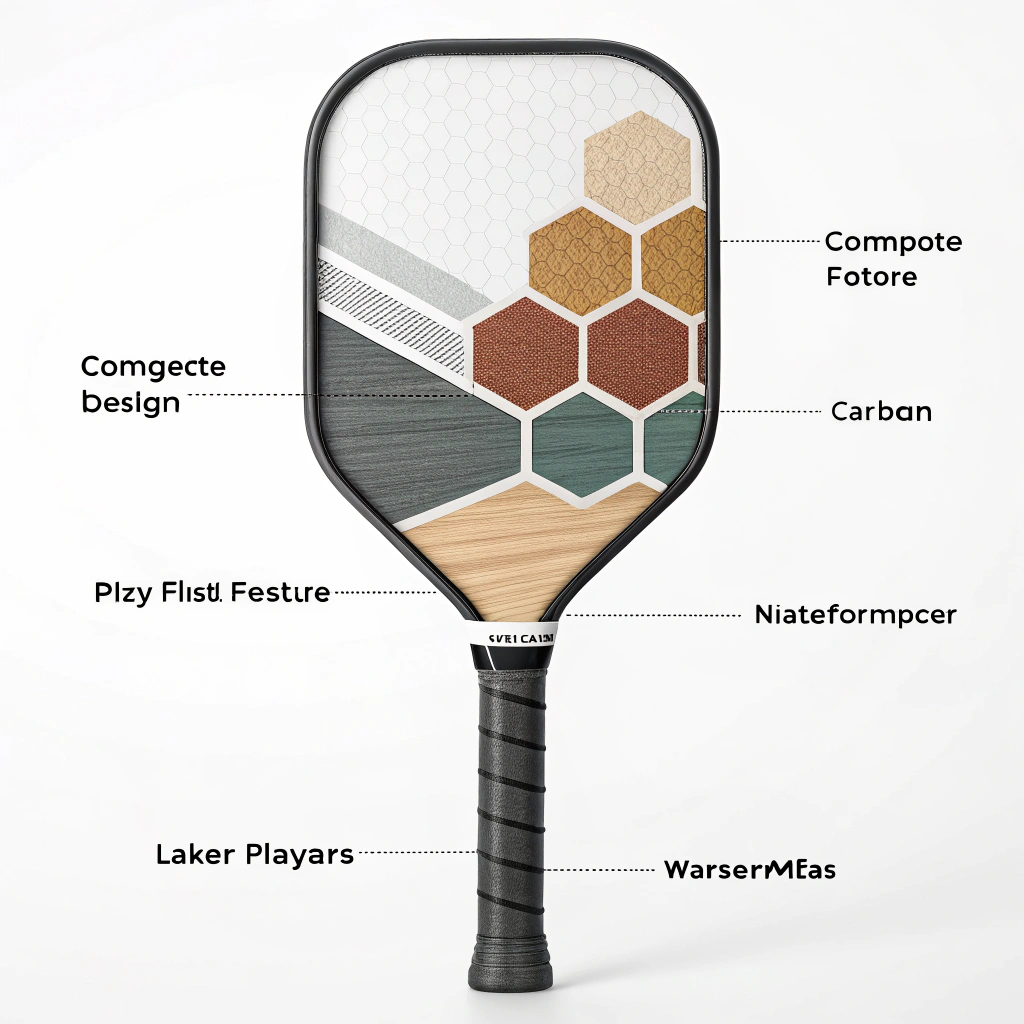

At NEX Pickleball, we recently collaborated with a major sports retail chain to refine grip performance on a new line of paddles designed for competitive play. Facing feedback that traditional grips were either too firm or lacked sufficient shock absorption, our engineering team implemented a hybrid composite grip solution combining carbon fiber interlaced with specialized polymer layers.

- Material Selection: We sourced premium-grade carbon fiber and paired it with a high-elasticity polymer, integrating key properties from both materials.

- Prototype Development: Through iterative testing using both hot pressing and thermoforming techniques, we optimized the grip’s texture and thickness.

- Field Testing: Paddles were trialed by seasoned athletes, whose performance data (e.g., reduction in vibration levels and improved hold comfort) validated our final design.

- Enhanced Control: Players reported a higher consistency in paddle response during fast exchanges.

- Improved Durability: The grip’s performance did not degrade even after prolonged exposure, contrasting with previous models that showed wear after extended play.

- Customer Satisfaction: The combination of tactile feedback and comfort resonated strongly with the client’s target market, resulting in a significant boost in repeat orders.

This case study underscores the value of integrating advanced materials with thoughtful production techniques to create superior grip properties—a clear differentiator in a competitive marketplace.

For B2B procurement managers and business development professionals evaluating premium pickleball paddles, the selection of the right grip material is a strategic decision that impacts both end-user performance and market competitiveness. Based on our analysis:

• Carbon Fiber-Based Grips are ideal for achieving a highly responsive and durable finish, making them suited for top-tier competitive play.

• Polymer Grips provide excellent cushioning and vibration dampening at a relatively lower cost, appealing to a broader range of players, especially in the recreational segment.

• Hybrid Composite Options offer a balanced approach by incorporating the strengths of both carbon fiber and polymer materials. This solution is particularly beneficial when targeting a versatile market demographic seeking both performance and comfort.

Moving forward, we recommend leveraging advanced production techniques like cold pressing and thermoforming to refine grip textures while taking into account factors such as environmental durability and ergonomic design. By aligning material selection with strategic market insights—such as customer feedback and industry trends—companies can ensure that their paddle offerings remain competitive and innovative.

In conclusion, the grip is not just a mere accessory but a critical component that defines the playing experience. Making an informed choice in grip material selection will ultimately support your competitive edge in the dynamic sports equipment industry and lead to higher customer satisfaction and loyalty.

Q: What grip materials deliver the best balance between performance and durability?

A: Materials such as high-grade carbon fiber and optimized polymer blends offer an excellent balance. Carbon fiber provides high responsiveness and durability while polymer grips enhance comfort through superior vibration damping. A hybrid composite approach can combine these strengths for optimal performance.

Q: How do production processes affect paddle grip quality?

A: Production processes like hot pressing, cold pressing, and thermoforming directly impact the final feel and durability of the grip. Hot pressing offers efficient mass production with strong bonding, cold pressing preserves the inherent material properties for a better tactile feel, and thermoforming allows for custom designs and intricate texture improvements.

Q: What factors should be considered in custom paddle grip design?

A: Key factors include material performance (rebound, vibration reduction), ergonomic fit for various hand sizes, durability in different environments, and production scalability. Custom designs also benefit from athlete feedback to fine-tune texture, thickness, and overall usability, ensuring a product that meets both performance and comfort needs.

-

reinforced carbon fiber composite: Reading this article will provide insights into the composition and benefits of reinforced carbon fiber composites, including how they enhance performance and durability in high-end sports equipment. ↩ ↩

-

high-performance polymer blend: Explore how high-performance polymer blends are engineered for superior flexibility, impact resistance, and vibration dampening—crucial for competitive sports gear. ↩ ↩

-

custom engineered hybrid: Learn about custom engineered hybrids that combine different materials to optimize overall performance, balancing strength, durability, and flexibility. ↩ ↩

-

hot pressing: Discover the hot pressing process, a manufacturing technique that applies simultaneous heat and pressure to create strong, durable bonds in materials. ↩ ↩

-

thermoforming: Understand thermoforming, a production process that heats materials to a softening point before molding, enabling intricate design and uniform material distribution. ↩ ↩