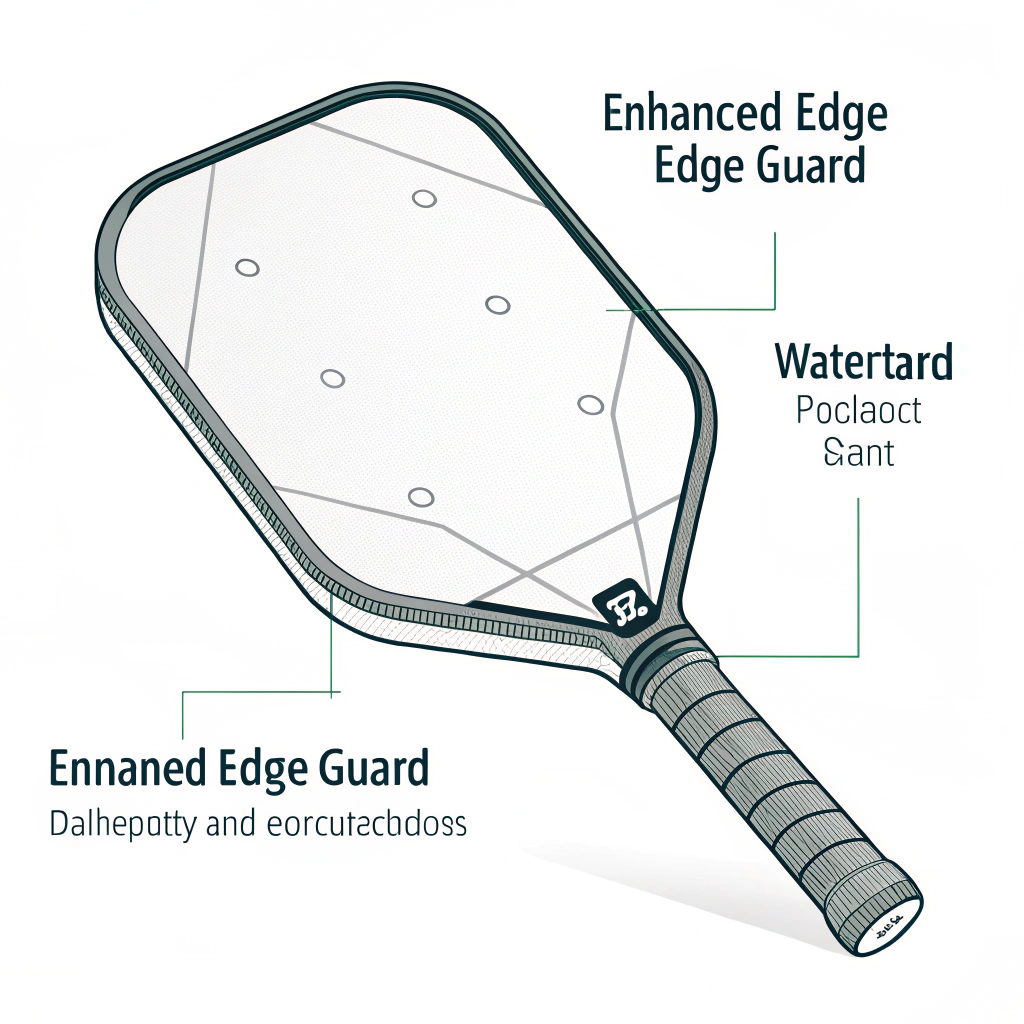

In this article, we quickly answer that the durability of pickleball paddle edge guards is heavily influenced by both material selection and the manufacturing process; understanding root causes and implementing targeted corrections can significantly enhance performance and longevity.

Pickleball paddle edge guards are crucial for preventing damage such as nicks, scrapes, and abrasions. However, many manufacturers face recurring issues with edge guard failures that compromise paddle durability. These failures not only affect playability but also increase production costs and reduce customer satisfaction. In our analysis, we explore engineering factors that lead to failures, including the interplay between material properties and process conditions during production.

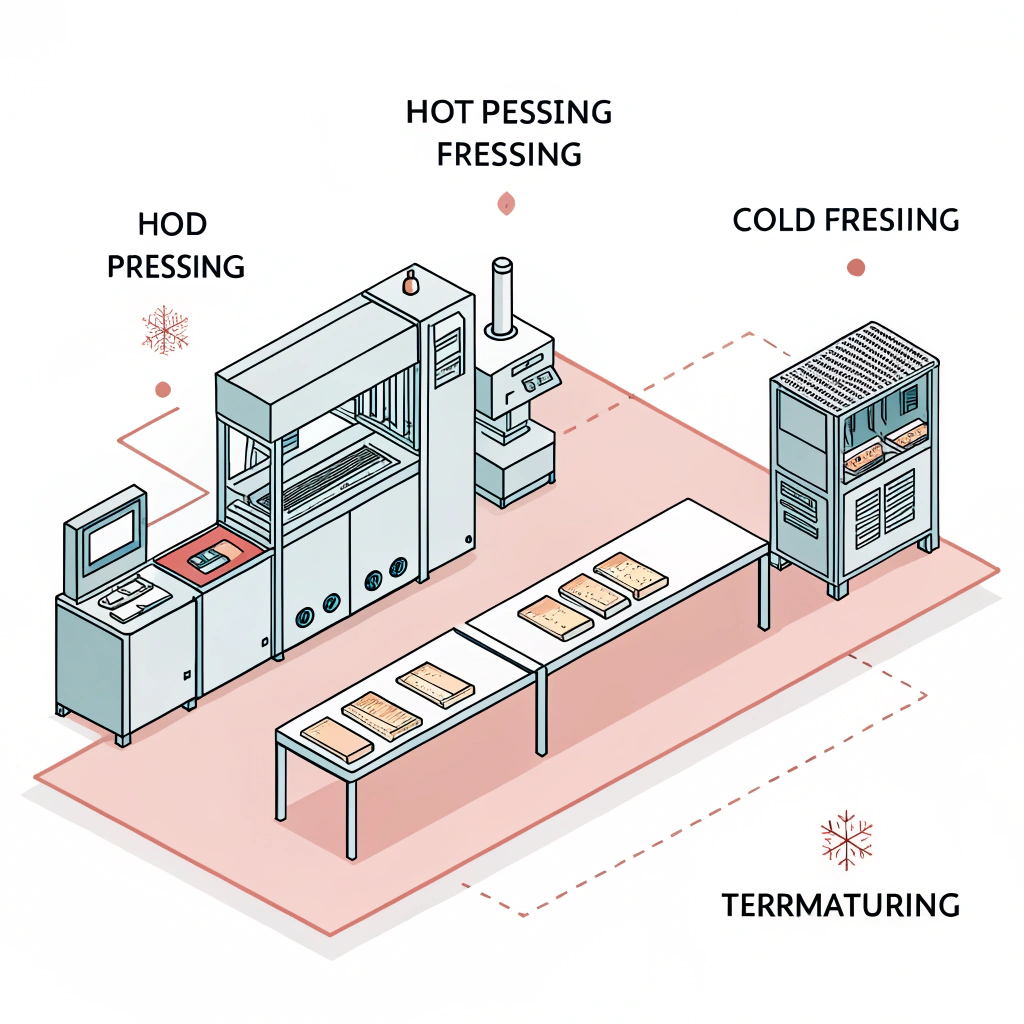

Edge guard failure is most often due to a combination of manufacturing defects1 and process inconsistencies. Variations in adhesive application, differences between production methods like hot pressing, cold pressing, and thermoforming, and the inherent properties of materials such as carbon fiber2, fiberglass, and composite materials all contribute to the risk of edge guard deterioration over time.

The selection of materials plays a vital role in the performance of edge guards. Poor adhesion, insufficient impact resistance, and mismatches between the edge guard and paddle core can lead to early failure. The primary factors include:

- Inadequate Carbon Fiber Variants: For instance, 3K carbon fiber provides flexibility but might lack the robustness of 12K or T300 carbon fibers in certain angles of impact.

- Fiberglass Limitations: Although fiberglass materials like E-Glass offer flexibility, they might not provide sufficient rigidity in high-stress areas, leading to material fatigue over time.

- Composite Mismatches: When using composite materials (such as a blend of carbon fiber and fiberglass), the difference in material behavior during impacts can cause delamination or edge wear.

The manufacturing process significantly impacts the final quality of the edge guard. Here are some process-related root causes:

- Adhesive Application: Inconsistent application of glue during assembly can result in weak bonding between the edge guard and the paddle. The choice of adhesive, such as CA glue3 (cyanoacrylate) in its gel or thick gel form, requires precise handling to avoid accidental bonding of unintended areas.

- Pressure Consistency During Fabrication: Processes like hot pressing and cold pressing must maintain optimal pressure. Variations in pressure can lead to irregular material distribution, resulting in weak points around the edges.

- **Temperature Control in Thermoforming4: Temperature fluctuations during thermoforming affect the material's ability to properly mold, potentially leaving areas that are less protected against impacts.

To better understand the root causes and potential solutions, it is useful to compare the three primary manufacturing processes:

| Process | Advantages | Disadvantages | Application Considerations |

|---|---|---|---|

| Hot Pressing | - High production efficiency - Strong, impact-resistant paddles - Ensures structural integrity | - May alter material properties - High equipment investment | Best for large-scale production where strength is prioritized |

| Cold Pressing | - Precise control over thickness - Maintains material properties - Excellent vibration reduction | - Longer production cycles - Requires high-quality, precision equipment | Suitable for high-performance, precision-demanding designs |

| Thermoforming | - Allows intricate designs - Precise material distribution - Enhances paddle stability | - Longer production time - Higher equipment costs | Ideal for premium products or custom paddle designs |

By examining these processes, it becomes clear that each has distinct advantages and tradeoffs. The choice depends on the specific goals of the manufacturing operation, such as whether the emphasis is on speed, precision, or visual design.

Given the identified root causes, here are clear solutions to mitigate edge guard failures:

- Evaluate Carbon Fiber Options: Use the optimal blend of 3K, 12K, and T300 carbon fibers based on the desired flexibility and strength. For competitive play, T300 carbon fiber could enhance performance, while 3K might suffice for recreational paddles.

- Enhanced Composite Materials: For paddles that demand both power and control, consider combining carbon fiber with fiberglass. This composite approach balances the benefits of both materials, offering better shock absorption and improved durability.

- Select Quality Core Materials: A robust core, such as a Nomex Honeycomb Core5 or Aluminum Honeycomb Core, improves the overall structural integrity, ensuring that edge guards remain intact under high-impact situations.

- Adhesive Application Control: Implement strict quality control measures during adhesive application. Using CA glue (gel type or thick) with disposable gloves and precision applicators can reduce mishaps. Training assembly line staff on optimal techniques is essential.

- Maintaining Uniform Pressure: For both hot pressing and cold pressing, invest in advanced sensors to monitor and regulate pressure throughout the process. This guarantees a consistent material distribution, especially around the edges.

- Precise Thermoforming Conditions: Establish rigorous temperature control throughout the thermoforming process. Automated systems with real-time feedback can help maintain the ideal heating profile, ensuring that coatings and edge tapes adhere effectively.

- Rigorous Testing Regimen: Each paddle should undergo vibration, impact, and adhesion testing before release. This can include both field tests and laboratory simulations to predict and mitigate potential failures.

- Regular Process Audits: Conduct frequent audits of the production line to ensure that all parameters—temperature, pressure, and adhesive consistency—remain within preset limits.

- Feedback Loop Implementation: Develop a responsive system to incorporate real-world feedback quickly. Use data from returned products to fine-tune processes and materials continuously.

A recent case study conducted by a leading paddle manufacturer showed that by switching from a standard CA glue to a gel-based formulation and enforcing a controlled cold pressing process, edge guard failures dropped by over 30%. The study highlighted three main findings:

- Controlled Adhesive Application: Manual training and automated glue dispensers led to a more consistent bond, reducing premature detachment.

- Enhanced Pressure Monitoring: The introduction of high-precision pressure sensors resulted in a more uniform edge guard application.

- Temperature Regulation Improvements: Fine-tuning thermoforming parameters ensured a better material distribution, particularly at the edges, decreasing wear and tear during repeated impacts.

The following table summarizes the improvements observed across different production batches:

| Key Process Parameter | Before Improvement Effectiveness (%) | After Improvement Effectiveness (%) |

|---|---|---|

| Adhesive Bond Consistency | 75 | 92 |

| Pressure Uniformity | 68 | 88 |

| Thermoforming Accuracy | 70 | 90 |

| Overall Edge Guard Durability | 65 | 85 |

This data reinforces that targeted modifications in manufacturing processes and material choices can dramatically improve paddle durability.

For production supervisors and quality control managers, the following best practices can further optimize edge guard performance:

- Set Clear Material Specifications: Ensure technical data sheets for materials like 12K Carbon Fiber and E-Glass Fiberglass are available and rigorously adhered to during procurement.

- Implement a Continuous Improvement Program: Use lean manufacturing principles to create a continuous feedback loop that adjusts the adhesive application process, pressure controls, and temperature settings based on performance data.

- Regular Maintenance and Calibration of Equipment: Schedule periodic maintenance for pressing and thermoforming machinery to prevent inconsistencies that might lead to defects.

- Document Process Variations: Maintain detailed logs for each production run, including temperature profiles, pressure readings, and adhesive batch numbers. This documentation aids in root cause analysis if issues arise.

- Employee Training and Safety Protocols: Ensure that all staff involved in the production process are well-trained in the intricacies of each technique. Using disposable gloves and following safe handling practices can prevent errors during adhesive handling.

- Collaborate With Material Experts: Consult with material scientists to continuously evaluate and test new materials that might offer enhanced performance characteristics.

In summary, solving pickleball paddle edge guard failures requires a multifaceted approach that integrates optimal material selection, precise manufacturing control, and proactive quality assurance measures. By addressing material-level weaknesses and process-level variations, manufacturers can extend the paddle's lifespan, elevate performance levels, and ultimately achieve greater customer satisfaction.

Adopting a systematic root cause analysis not only pinpoints specific factors affecting durability but also guides the selection of the best manufacturing technique—whether that is hot pressing, cold pressing, or thermoforming. With strategic process enhancements, including better adhesive management, strict pressure control, and precise temperature regulation, manufacturers can see significant improvements in edge guard resilience.

For OEM and B2B partners, investing in these improved practices translates directly into better product performance and fewer returns or warranty claims. As production supervisors and quality control managers, focusing on these technical details and best practices will enable you to deliver a product that truly meets the high standards demanded by competitive play.

More than ever, leveraging advanced manufacturing technologies and materials will set your product apart in the booming pickleball market. With a commitment to continuous improvement and data-backed strategies, you can confidently optimize your production processes, ensuring that every paddle stands up to the demands of both casual and professional games.

-

What is the best edge guard for pickleball paddles?

After extensive testing, both the Paddlesshop Premium Paddle Edge and No-Brand Edge Tape A (Pre-Cut Designs) have proven effective at extending paddle lifespan while enhancing gameplay performance. -

What is the best glue for pickleball paddle edge guard?

Many adhesives work well, but CA glue in gel or thick gel form has shown superior performance. It requires careful handling and disposable gloves to avoid accidental bonding during application. -

How to protect the edge of a pickleball paddle?

The most common method is to apply high-quality edge tape, which protects against nicks, scrapes, and abrasion, thereby extending the paddle's useful life.

-

manufacturing defects: Reading this article will help you understand the common faults in production processes, which can lead to product failures and increased costs. Back to "manufacturing defects" ↩

-

carbon fiber: Explore detailed insights into carbon fiber properties, manufacturing variations, and its impact on structural integrity. Back to "carbon fiber" ↩

-

CA glue: Learn more about cyanoacrylate adhesives, including application techniques and safety practices for industrial use. Back to "CA glue" ↩

-

Thermoforming: Discover the thermoforming process, its advantages, limitations, and the critical controls needed for optimal molding. Back to "Thermoforming" ↩

-

Nomex Honeycomb Core: Gain insights into the benefits of Nomex Honeycomb Core in enhancing product durability and performance in high-impact applications. Back to "Nomex Honeycomb Core" ↩