Quick Answer: Advanced manufacturing techniques1 optimize paddle surface textures to enhance spin performance by carefully controlling material properties, weight distribution, and texture finishes. By selecting high-quality composite materials and utilizing processes like hot pressing, cold pressing2 and thermoforming3, manufacturers can create a paddle that maximizes grip, minimizes vibration, and generates superior spin.

In today’s competitive pickleball market, enhancing the paddle’s spinning capability is a key performance factor. This article examines the technical details behind surface textures, material selections, and advanced manufacturing techniques that contribute both to paddle durability and spin performance. We aim to provide product managers, R&D engineers, and procurement specialists with the insights they need to make informed decisions regarding paddle design and production. Our focus is on the engineering trade-offs and technical subtleties that can mark the difference between a mediocre paddle and one that offers unmatched spin control.

Pickleball paddles are more than simple tools for hitting a ball. They are a combination of advanced materials and sophisticated production methods. One critical factor that determines a paddle's effectiveness is its surface texture. The texture directly impacts the amount of spin generated on the ball. However, achieving the ideal surface involves overcoming several challenges:

• Maintaining a balance between a gritty surface that enhances spin and a smooth finish that maximizes control.

• Ensuring uniform weight distribution so that the torque generated during contact is centralized and effective in spinning the ball.

• Preserving the integrity of delicate composite materials during processing through methods such as hot pressing, cold pressing, or thermoforming.

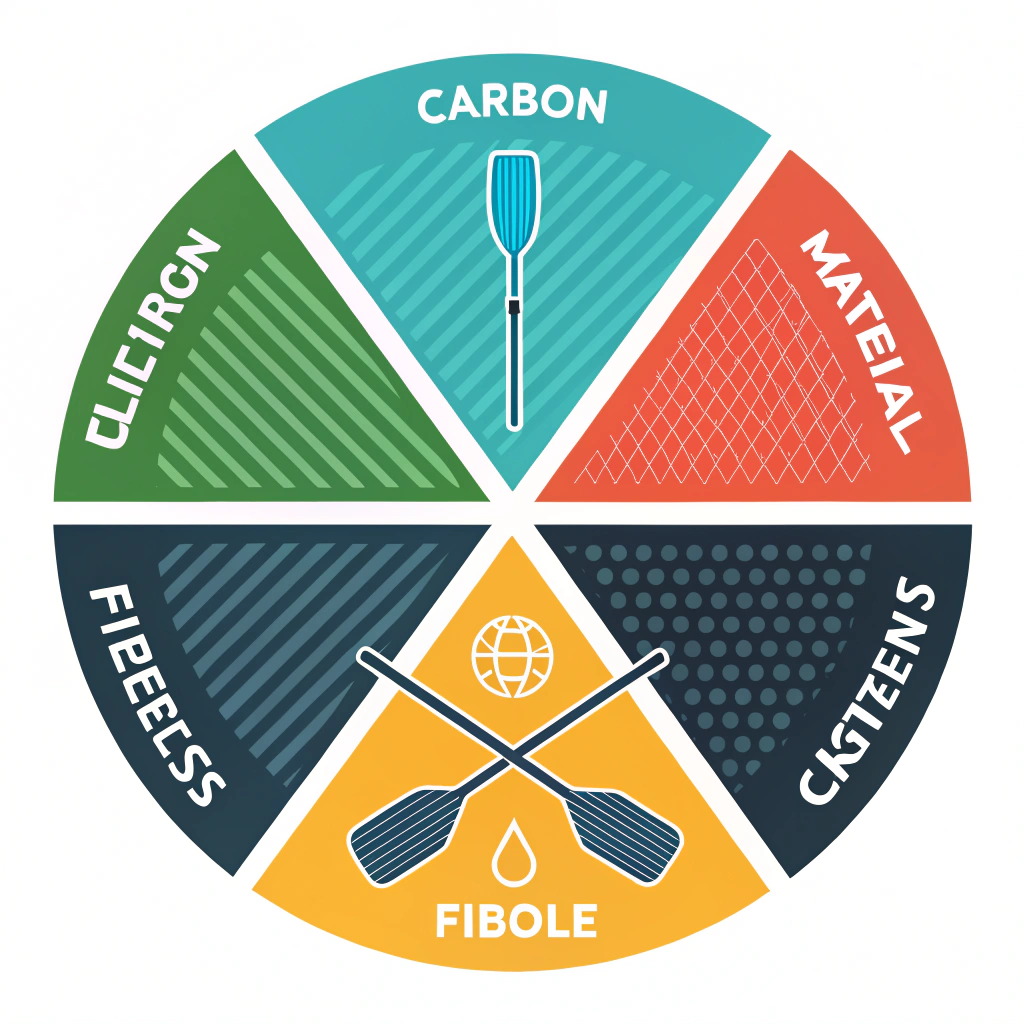

Moreover, material selection plays a crucial role. Manufacturers must decide between options like various types of Carbon Fiber4, Fiberglass, and Composite Materials5. Each material interacts differently with surface texturing methods, influencing paddle properties such as rebound, vibration reduction, and durability.

Understanding why surface texture creation is so critical requires some insights into material science and production techniques:

-

Material Science and Composite Engineering:

Composite materials, such as a mix of Carbon Fiber4 and Fiberglass, offer a gritty yet resilient surface ideal for spin generation. The material’s microscopic texture can be fine-tuned during the pressing process to produce fine ridges that interact with the ball surface. -

Manufacturing Process Influence:

Advanced production techniques determine the final product characteristics. For instance, hot pressing ensures strong structural integrity, while cold pressing preserves material properties that yield a superior tactile feel. Thermoforming, with its detailed mold designs, enables the creation of complex surface textures that can enhance spin. -

Engineering Trade-offs:

Achieving an optimal balance often means making trade-offs between production efficiency and quality. Processes that deliver high-quality, spin-enhancing textures might require longer production times or higher initial investment, which must be factored into procurement decisions.

These reasons underscore the importance of aligning manufacturing processes with performance requirements, particularly for high-performance paddles intended for competitive play.

Below is a solution framework that outlines the key steps to enhance pickleball paddle spin through strategic surface texturing.

The first challenge is to choose materials that naturally lend themselves to improved spin. Consider the following material options:

• 3K Carbon Fiber: Offers flexibility and high rebound force, making it suited for paddles that require great power and spin.

• 12K Carbon Fiber: With its higher thread density, this material provides a smoother, yet robust, surface that excels in spin efficiency and durability.

• T300 Carbon Fiber: Balances tensile strength with light weight, ideal for paddles where a centralized weight distribution promotes enhanced spin.

• E-Glass Fiberglass: Provides an inherently gritty feel while maintaining elasticity, granting excellent ball control and texture for spin.

• Composite Mixes: Combining Carbon Fiber with Fiberglass can generate an optimal surface finish that provides both power and a distinctive grip.

These choices are critical because the texture depth and composition directly affect how the paddle interacts with the ball.

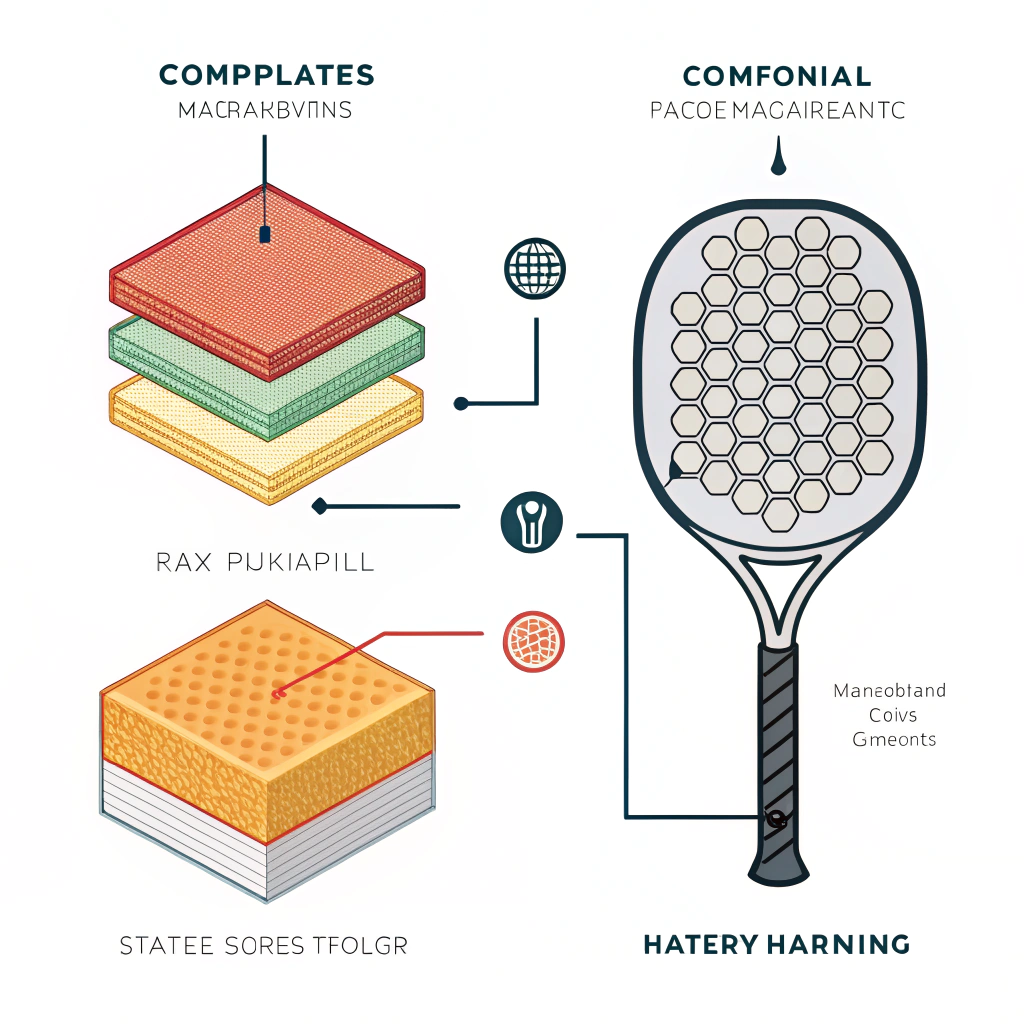

Using the appropriate production processes is equally important. Let’s compare three prevalent processes and their relevance to surface texture optimization:

| Manufacturing Process | Advantages | Limitations |

|---|---|---|

| Hot Pressing | • High production efficiency • Produces strong, durable paddles • Achieves excellent impact resistance | • May alter some intrinsic material properties • Requires a high initial investment |

| Cold Pressing | • Precise control over paddle thickness • Maintains material properties for better control • Delivers a superior ball feel | • Longer production cycles • Demands precise pressure control and quality equipment |

| Thermoforming | • Capable of intricate designs and surface textures • Ensures stable distribution of materials • Ideal for custom or premium paddles | • Longer production time • Higher equipment costs |

Using a process like thermoforming can intentionally sculpt the paddle face to create micro-textures microscopically engineered to enhance granted spin. However, if production speed is essential, cold pressing might be the optimum solution, as it balances material integrity with detailed surface control.

Once the materials and processes are chosen, the next step involves engineering the surface texture for maximum spin. There are several key elements to consider:

• Grit-Enhanced Composite Hitting Surface: Adding fine grit or textured elements to the paddle’s composite surface increases friction, which in turn enhances spin when the ball is struck.

• Balanced Weight Distribution: Ensuring the material and design provide a centralized weight balance is critical. This balance directly influences the paddle’s ability to generate torque and spin. Manufacturers need to refine the design so that the weight distribution is even across the paddle to avoid any off-center pivot that could diminish spin.

• Precision Surface Finishing: Post-processing techniques like surface roughening or micro-etching can refine the sensory feedback of the paddle. This minimizes vibration and improves spin generation during high-speed play.

It is essential for engineers to carry out iterative testing, comparing prototypes under controlled conditions. Performance metrics such as rebound speed, spin generation, and vibration feedback are analyzed using specialized equipment and on-court testing.

Consider a case study where a manufacturer applied a composite mix of 12K carbon fiber with E-Glass fiberglass using thermoforming:

• Problem: The initial paddles lacked sufficient spin, despite having an excellent power profile.

• Approach: Engineers introduced a textured surface finish during the thermoforming process. They also refined the weight distribution by incorporating lightweight polymer honeycomb cores that did not compromise the paddle’s structural integrity.

• Results: Subsequent testing showed that the new design improved spin generation by up to 20%, while concurrently reducing vibration. This iterative process was documented through detailed trial assessments over multiple production cycles, validating the importance of controlled texturing and balanced design.

This case study illustrates the measurable benefits of integrating advanced manufacturing processes with meticulous surface design. It is a clear testament to how engineering innovation can bridge the gap between raw material properties and in-game performance.

Before implementing these solutions, consider the following tips:

• Quality Control: Implement rigorous testing protocols to assess surface texture uniformity and weight distribution. This can include quality assurance measures such as computerized vibration analysis and high-speed imaging during impact tests.

• Cost-Benefit Analysis: While advanced manufacturing techniques improve performance, they might come with higher costs compared to conventional methods. It is important to conduct a detailed cost-benefit analysis, ensuring that the performance gains justify the production expense.

• Customizability and Client Requirements: Different players and market segments might have varying needs. Offering adjustable surface textures or customizable paddle designs can be a competitive advantage. This approach allows for tailored production runs based on specific client demands, from recreational play to high-stakes competition.

• Sustainability Practices: Emphasize sustainable production practices by selecting environmentally friendly materials where possible and optimizing energy consumption during manufacturing. This not only appeals to a growing segment of eco-conscious buyers but can also yield long-term cost benefits.

In summary, optimizing paddle surface textures for improved spin performance involves:

- A strategic selection of high-quality materials, especially composites that naturally lend themselves to textured surfaces.

- Utilization of advanced manufacturing processes—hot pressing, cold pressing, and thermoforming—to engineer and control the nuances of the paddle’s surface.

- A detailed focus on creating micro-textures that improve friction and balance weight distribution to drive effective spin.

- Iterative testing and case study validations that provide tangible data supporting design decisions.

- Considerations regarding quality control, cost-benefit evaluation, and client-specific customization to ensure the final product meets performance expectations.

For companies involved in the production or procurement of pickleball paddles, integrating these advanced manufacturing processes and surface engineering techniques can be a significant competitive advantage. By adopting these strategies, you can enhance the performance of your paddles, ultimately leading to a better playing experience. Industry professionals are encouraged to invest in R&D efforts that further explore material innovations and process optimizations to stay ahead in a rapidly evolving market.

Actionable steps for procurement specialists include conducting vendor audits on manufacturing capabilities, requesting detailed testing data, and seeking opportunities for pilot projects that test new surface textures in real-world environments. By aligning procurement decisions with production processes that prioritize precision and performance, your organization can ensure product quality, customer satisfaction, and sustained competitive advantage.

People Also Ask

Q: What is the best surface for pickleball spin?

A: The best surfaces for pickleball spin are typically those with a composite hitting surface enhanced with grit or textured graphite. Such surfaces provide the right amount of friction to generate superior spin during play.

Q: What makes a pickleball paddle have more spin?

A: A pickleball paddle with more spin often features an evenly distributed weight, ensuring a centralized movement during contact. This balance, combined with engineered micro-textures on the paddle face, increases friction and allows for greater spin generation.

-

Advanced manufacturing techniques: Read this article to understand innovative production methods that optimize product performance and ensure competitive advantages in manufacturing. ↩

-

Cold pressing: Learn about cold pressing techniques that maintain material integrity while delivering precise control over product thickness and texture. ↩

-

Thermoforming: Discover how thermoforming is used to create intricate designs and surface textures, offering high customization and performance in manufacturing processes. ↩

-

Carbon Fiber: Explore the benefits of carbon fiber in enhancing structural strength, reducing weight, and improving product durability in advanced composite applications. ↩ ↩2

-

Composite Materials: Gain insights into composite materials and how combining different components can yield optimized properties for enhanced performance and durability. ↩