In this article, we provide a quick answer: a robust quality inspection checklist for high-performance pickleball paddles should cover production processes, material integrity, design precision, and compliance with industry standards. This checklist not only helps in verifying the manufacturing quality but also minimizes procurement risks by ensuring each paddle meets strict performance and safety criteria.

Ensuring the quality control of pickleball paddles is crucial for any business engaged in the procurement of sports equipment. A detailed inspection checklist helps quality assurance managers and procurement specialists verify that every paddle produced meets the stringent standards expected in competitive sports. In this article, we dive deep into the critical components that influence the paddle performance, the manufacturing processes involved, and propose a comprehensive checklist that serves as a guideline for supplier evaluation.

When evaluating pickleball paddles, you must focus on several key aspects that influence performance and durability:

-

Material Quality: High-performance paddles are crafted from premium materials like various types of carbon fiber1 (3K, 12K, T300), fiberglass, and advanced composite materials2. Each material has unique benefits:

- Carbon Fiber: Provides strength and responsiveness.

- Fiberglass: Offers flexibility and improved control.

- Composite Materials: Deliver a balanced performance with enhanced durability.

-

Core Construction: The core material determines the paddle's hardness, shock absorption, and overall feel. From Nomex Honeycomb Core3 to Polymer Honeycomb Core, each has distinct characteristics that should align with player needs and usage scenarios.

-

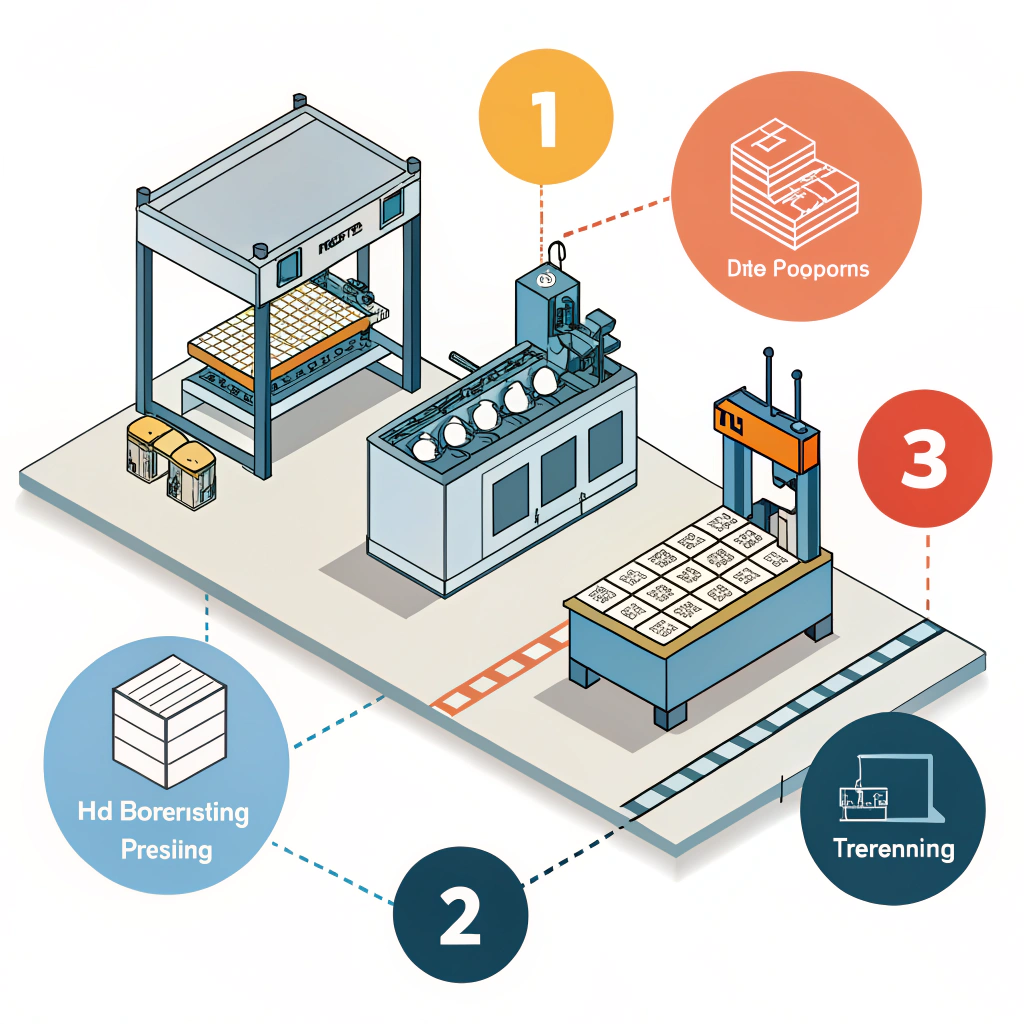

Production Process Consistency: Paddles are manufactured using processes such as hot pressing4, cold pressing, and thermoforming5. Each method affects the final product’s performance:

- Hot Pressing: Ensures structural integrity but may affect the material feel.

- Cold Pressing: Provides accurate control over material distribution.

- Thermoforming: Allows for intricate designs while maintaining performance consistency.

-

Design and Ergonomics: The shape of the paddle, grip size, and handle length should provide optimal balance, weight distribution, and comfort. A well-designed paddle also ensures better vibration control and ball response.

These factors form the backbone of a quality assurance checklist, making it easier to benchmark supplier processes and reduce risks in your procurement strategy.

Understanding the production methods is vital for a quality inspection checklist because each process has advantages and disadvantages impacting overall paddle quality. The table below summarizes the production methods and their key attributes:

| Production Process | Advantages | Disadvantages | Quality Check Focus |

|---|---|---|---|

| Hot Pressing | High production efficiency; strong and durable paddles; excellent impact resistance | Alters some material properties; requires high equipment investment | Ensure consistency in heat application and uniform pressure distribution |

| Cold Pressing | Precise control over paddle thickness; material properties remain intact; excellent ball feel | Slower production cycles; demands high-quality pressure control equipment | Verify even pressure application and dimensional accuracy |

| Thermoforming | Intricate design possibilities; precise material distribution; maintains paddle stability | Longer production times; higher equipment costs | Inspect mold precision and temperature control accuracy |

It is essential to carry out sample testing of each batch during production to make sure that every process produces paddles that meet performance benchmarks.

The following checklist should be used during the inspection process to validate the quality and performance of pickleball paddles before finalizing procurement:

-

Face Material:

- Check for the presence of high-grade carbon fiber1 or fiberglass.

- Verify the even distribution of material layers and lack of visible defects.

- Confirm that the material orientation matches the specified design.

-

Core Materials:

- Ensure that the core (e.g., Nomex Honeycomb Core3, Aluminum Honeycomb, Polymer Honeycomb) is intact and uniformly distributed.

- Inspect any bonding failures or delamination, which might affect durability.

- Measure the core thickness and compare it with the design specifications.

-

Hot Pressing Process:

- Check for residual heat marks or any sign of warped material due to uneven heat application.

- Confirm that the paddle’s structure has maintained integrity despite the high-pressure environment.

- Verify the paddle’s impact resistance through sample drop tests.

-

Cold Pressing Process:

- Assess how well the paddle retains its intrinsic material properties.

- Ensure that the mechanical pressure has not created micro-fractures or distortions.

- Verify dimensional consistency across multiple samples.

-

Thermoforming Process:

- Inspect the finish of the paddle surface; it should be smooth with uniform texture.

- Check molded areas for any imperfections like bubbles or inconsistent thickness.

- Validate that the paddle design meets the intricate shape specifications without compromising performance.

-

Shape and Balance:

- Verify that the paddle's shape meets design standards for optimal weight distribution.

- Check the symmetry and balance by measuring static weight, swing weight, and twist weight.

- Compare the dimensions with standard guidelines (e.g., maximum length does not exceed industry regulations).

-

Grip and Handle:

- Inspect the grip material to ensure it provides the required comfort and anti-slip properties.

- Measure the handle length and diameter to ensure they correspond to the ergonomic requirements.

- Ensure that the paddle’s handle allows for a secure and comfortable hold, reducing the risk of slippage during play.

-

Impact and Vibration Testing:

- Conduct tests to measure the paddle's shock absorption during high-impact interactions.

- Check for vibration damping performance using standardized test protocols.

- Record and analyze test data against predetermined performance benchmarks.

-

Visual and Dimensional Inspections:

- Perform a detailed visual inspection for any surface imperfections, such as bubbles, scratches, or inconsistent material layering.

- Use calipers or other precision instruments to measure critical dimensions and verify they meet the required tolerances.

- Confirm that color, finish, and overall surface quality align with product specifications.

-

Compliance with Regulations:

- Validate that the paddle dimensions meet official regulations (e.g., overall length and height limits).

- Check for any markings or labelling that confirm compliance with sports equipment safety standards.

- Ensure that the product documentation accompanies the paddle, detailing materials and manufacturing processes.

-

Batch and Production Data:

- Require suppliers to provide detailed production reports, including process details and quality assurance test results.

- Maintain traceability records for each batch to assist in identifying any issues that arise post-procurement.

- Use serial numbers or batch codes to link the physical product with production data.

-

Supplier Certification:

- Ensure that the supplier holds certifications relevant to manufacturing standards and quality control.

- Request periodic audits and quality assurance certificates to verify ongoing compliance.

- Confirm that the supplier adheres to industry advancements in production techniques.

Below is a summarized quality inspection checklist for quick reference:

| Checklist Category | Inspection Items | Verification Method |

|---|---|---|

| Material Verification | Face material quality, core uniformity, adhesive bonding | Visual inspection, material tests |

| Production Process | Heat marks, pressure consistency, mold precision, thickness | Sample testing, measuring instruments |

| Design & Ergonomics | Balance, grip quality, handle dimensions | Dimensional measuring tools, ergonomic tests |

| Performance Testing | Impact resistance, vibration damping, surface integrity | Standardized test protocols, calibration equipment |

| Compliance & Documentation | Adherence to regulations, batch traceability, supplier certification | Audit reports, certification documents |

Even with a comprehensive checklist, there are potential pitfalls that quality assurance managers and procurement specialists must remain aware of:

-

Inconsistent Material Distribution

A common issue is the uneven distribution of materials (e.g., in the case of composite paddles). This inconsistency can lead to reduced impact resistance and a compromised feel. Regular sample testing and material analysis are recommended to mitigate this risk. -

Process Control Variability

The reliability of the production process, whether it is hot pressing4, cold pressing, or thermoforming5, is critical. Variability in process control — such as fluctuations in temperature or inconsistent pressure — can introduce defects. Establishing standard operating procedures (SOPs) and investing in high-precision equipment can help maintain consistency. -

Ergonomic Misalignments

Even if a paddle is built with high-quality materials, ergonomic misalignments (such as an oversized grip or unbalanced weight distribution) can drastically affect performance. Detailed ergonomic testing, coupled with feedback from player trials, is essential to ensure the paddle meets the practical needs of its end users. -

Documentation Lapses

Missing or insufficient production documentation can obscure traceability. Keep thorough records to ensure you can quickly trace any issues back to their source. This documentation is also essential for compliance audits and future quality improvements.

Implementing the quality inspection checklist effectively requires a proactive approach:

-

Standardize Testing: Develop a set of standardized tests for every production batch. This includes both visual inspections and mechanical testing to ensure every paddle meets the same performance benchmarks.

-

Train Inspection Teams: Ensure that the teams involved in the inspection process understand the technical specifications and quality criteria. Frequent training sessions on new production techniques and quality standards can improve the overall reliability of inspections.

-

Collaborate with Suppliers: Engage regularly with your suppliers to discuss quality issues and process improvements. Transparency and regular audits can help build trust and a shared commitment to quality.

-

Use Technology for Traceability: Invest in digital tools to track production data, inspection results, and identify trends or recurring issues. This can facilitate more informed decision-making in supplier evaluation and future procurement decisions.

A thorough quality inspection checklist is vital in ensuring that pickleball paddles consistently meet high-performance standards. By focusing on material quality, production processes, design ergonomics, and strict compliance measures, quality assurance managers can effectively evaluate supplier reliability and reduce procurement risks. The proposed checklist not only streamlines the evaluation process but also enhances accountability, ensuring that every paddle delivered is primed for high-performance gameplay. For companies like NEX Pickleball, dedicated to advanced production techniques and superior quality, such detailed inspections are an essential part of ensuring the final product exceeds customer expectations.

We encourage procurement specialists to integrate these detailed steps into their quality control protocols to streamline decision-making and build stronger partnerships with trusted suppliers. A commitment to rigorous quality inspections not only enhances product performance but also strengthens market reputation and fosters customer loyalty.

Q: What to look for when purchasing pickleball paddles?

A: When purchasing pickleball paddles, key factors include the paddle shape, core material, face material, handle length, weight, and grip size. These aspects determine the paddle’s performance, impact resistance, and comfort during play.

Q: How to tell the quality of a pickleball paddle?

A: The quality of a pickleball paddle can be judged by examining the core thickness and material, paddle shape, face layup and materials, weight distribution (static, swing, and twist weights), and the construction method used (such as cold pressed, thermoformed, or floating core).

Q: What are the regulations for a pickleball paddle?

A: Pickleball paddle regulations generally specify that paddles must not exceed a certain length (typically around 17 inches) and that the combined length and height should not surpass 24 inches to meet official guidelines.

-

carbon fiber: Click here to learn about the properties and applications of carbon fiber in high-performance manufacturing. ↩ ↩ ↩2

-

composite materials: Click here to explore how composite materials are engineered to deliver balanced performance and enhanced durability in sporting equipment. ↩ ↩

-

Nomex Honeycomb Core: Click here to understand the benefits of using Nomex Honeycomb Core for strength and lightweight construction in paddle manufacturing. ↩ ↩ ↩2

-

hot pressing: Click here to read about the hot pressing process, its advantages, and challenges in achieving consistent material performance. ↩ ↩ ↩2

-

thermoforming: Click here to discover the thermoforming process and how it enables the creation of intricate paddle designs while preserving material integrity. ↩ ↩ ↩2