In today’s fast-paced market, sustainable sourcing of pickleball gear is not only about protecting the environment—it is a strategic element to improve supply chain resilience, reduce production costs, and enhance brand reputation. This article explains how eco-friendly material selection, ethical procurement practices, and innovative manufacturing processes can be integrated into your sourcing strategy for pickleball equipment, driving both environmental and business benefits.

Modern procurement specialists and supply chain managers are increasingly challenged by the need to balance cost, quality, and sustainability. The pressure to comply with environmental regulations while satisfying market demands has led to a surge in interest around sustainable sourcing. In the realm of pickleball gear, where performance and durability are paramount, integrating eco-friendly practices can appear complex. However, by understanding the challenges and myths around sustainable sourcing, businesses can make informed decisions that align with both economic and environmental goals.

Many sports equipment suppliers and manufacturers face a dilemma when choosing materials and processing methods that meet both performance requirements and sustainability standards. Traditional sourcing practices might offer cost efficiencies but often lack transparency in material traceability and environmental compliance. Conversely, sustainable sourcing options, while environmentally responsible, might be perceived as more expensive or less efficient due to concerns over production speed and material performance.

Key issues include:

• The perceived higher cost of eco-friendly materials1 and manufacturing techniques.

• Uncertainty about the durability and performance of sustainable options compared to conventional materials.

• Lack of clarity regarding the environmental impact and carbon footprint of production methods.

• Difficulties in aligning innovative production methods with stringent quality controls.

For procurement teams, the challenge is clear—finding manufacturing partners who provide quality, performance, and sustainability without compromise.

The drive toward sustainable sourcing in pickleball gear manufacturing is fueled by several factors:

• Environmental Regulations: Governments globally are enforcing stricter environmental standards. Companies must adhere to these regulations to avoid penalties and promote a green image.

• Consumer Demand for Sustainability: End consumers, including sports enthusiasts and professional players, are increasingly focused on products that have a minimized environmental impact.

• Supply Chain Risk Management: Sustainable sourcing options can reduce reliance on non-renewable resources, helping companies mitigate the risk of supply disruption.

• Efficient Use of Resources: Modern technologies such as thermoforming2 or cold pressing not only enhance material performance but also reduce energy usage and waste, contributing to a lower carbon footprint3.

• Reputation and Market Differentiation: Companies that demonstrate a commitment to ethical procurement4 and environmental responsibility often attract loyalty from both end customers and business partners.

Understanding these drivers helps procurement specialists discern that sustainable sourcing is not merely an environmental trend but a strategic approach designed to secure long-term business viability.

With these challenges and reasons in mind, sustainable sourcing in the pickleball industry can be broken down into actionable steps. Below is a solution checklist and a comparison table that outlines key aspects of sustainable practices:

-

Material Selection:

• Evaluate sustainable materials such as recycled composites, bamboo cores, and eco-friendly polymer honeycomb cores.

• Collaborate with suppliers who provide transparent material origin documentation and lifecycle assessments. -

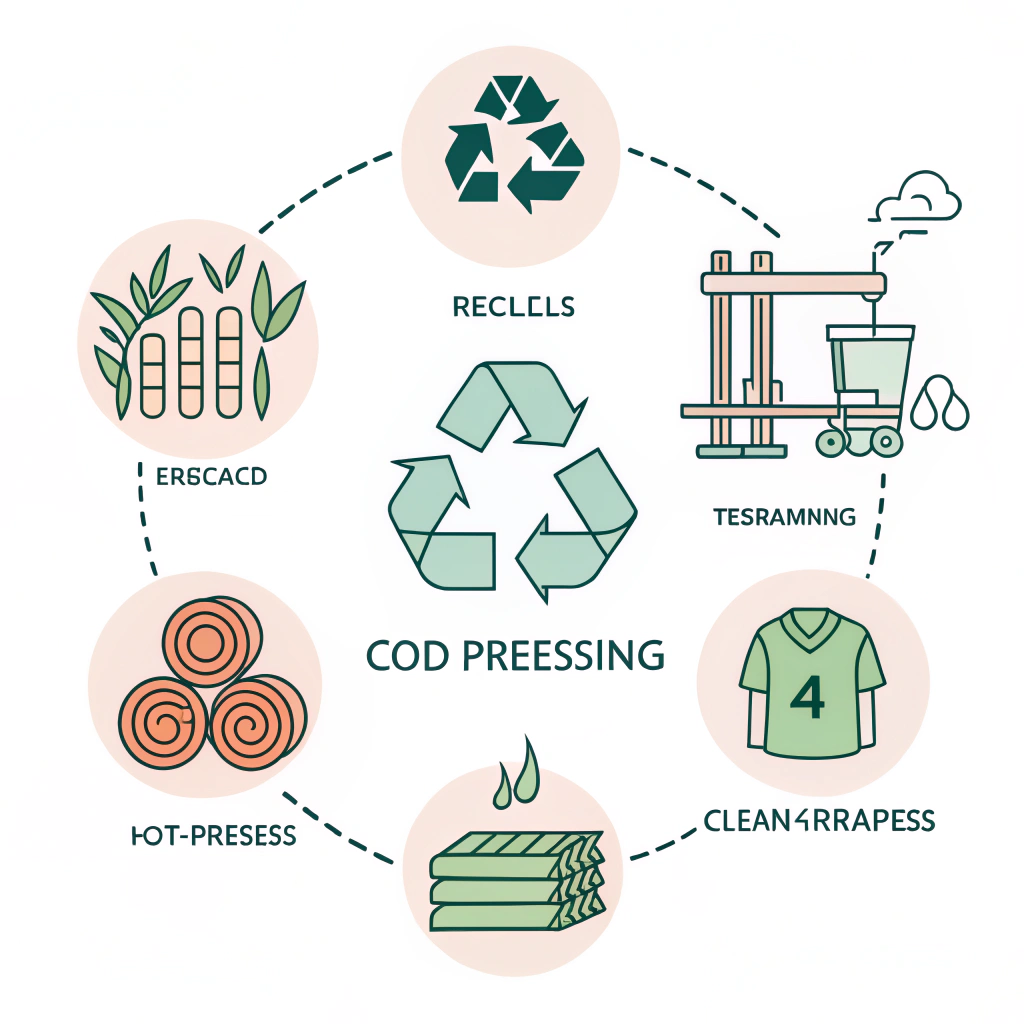

Innovative Manufacturing Processes:

• Implement production techniques like hot pressing, cold pressing, and thermoforming2 that are validated for both performance and reduced environmental impact.

• Regularly assess each process against criteria such as energy consumption and waste production. -

Supplier Evaluation:

• Choose suppliers who comply with global sustainability certifications and environmental standards.

• Request regular traceability reports to ensure that materials are sourced from renewable or responsibly managed resources. -

Data-Driven Decision Making:

• Collect data on product performance, energy usage, and environmental emissions during production.

• Use this information to adjust sourcing strategies to further reduce the carbon footprint3. -

Lifecycle Assessment:

• Incorporate lifecycle assessments5 in product design to identify and minimize ecological impacts at every stage—from material extraction through to end-of-life disposal.

• Use these assessments to continuously improve product designs and production processes.

| Production Process | Advantages | Sustainability Considerations | Performance Impact |

|---|---|---|---|

| Hot Pressing | High production efficiency; results in strong impact resistance. | Requires significant energy input; potential alteration of material properties. | Ideal for high-performance use but may compromise material ‘feel’. |

| Cold Pressing | Precise control over material thickness and structure; maintains original material properties. | Longer production cycle; lower energy usage compared to hot pressing. | Offers improved ball feel and control, suitable for precision designs. |

| Thermoforming | Creates intricate shapes and precise material distribution; excellent surface finish. | Higher equipment costs and longer cycle time; energy-intensive heating process. | Enhances paddle stability and overall performance, best for premium products. |

This table highlights trade-offs procurement specialists must weigh when considering different production methods. Each method offers unique strengths that can cater to various performance and sustainability requirements.

Manufacturers aiming at sustainable sourcing have reported that adopting green manufacturing processes not only reduces energy consumption but also improves product consistency over time. For instance, a case study from a leading sports equipment manufacturer revealed that by switching part of its production to cold pressing, it was able to reduce its overall energy consumption by 15% while maintaining high product quality.

At NEX Pickleball, we integrate similar strategies by leveraging advanced carbon fiber variants—such as 3K Carbon Fiber and 12K Carbon Fiber—to ensure our paddles not only exceed performance standards but also align with sustainable production practices. By investing in production processes that optimize both performance and environmental impact, companies can achieve a competitive advantage while promoting a greener supply chain.

Before transitioning to sustainable manufacturing processes, procurement specialists should consider the following best practices:

• Evaluate Total Cost of Ownership:

While sustainable materials and processes might have a higher upfront cost, the reduction in regulatory risk, improved brand reputation, and lower long-term operational costs often justify the investment.

• Engage in Joint R&D Efforts:

Collaborate with manufacturing partners to drive innovation in eco-friendly materials and processing methods. Joint R&D can help customize products that meet both performance and sustainability benchmarks.

• Monitor and Report Performance:

Establish benchmarks for production energy use, waste generation, and material efficiency. Regular performance monitoring helps in identifying areas for improvement and adjusting procurement strategies.

• Compliance with Regulations:

Stay updated with international environmental standards and ensure that suppliers adhere to certifications such as ISO 14001. This helps in mitigating regulatory risks and ensures ethical sourcing practices.

• Customer-Centric Innovations:

Leverage consumer feedback to refine product designs and sourcing strategies. When customers see a clear commitment to sustainability, it strengthens market position and loyalty.

Transitioning to more sustainable production methods often involves implementing technologies that use energy more efficiently and generate less waste. For example, thermoforming2 enables the production of paddles with complex designs that distribute materials in a way that minimizes waste during the formation stage. Although this process may involve longer production times and higher upfront equipment costs, the resulting reduction in material waste and improved product longevity can offset these factors over time.

Additionally, using a combination of production processes—like merging hot pressing with elements of cold pressing in a hybrid approach—can balance efficiency with sustainability. The integration of renewable energy sources into production lines further enhances the green credentials of the manufacturing process.

To summarize, sustainable sourcing in the pickleball market demands a thoughtful approach that balances technical performance with environmental responsibility. The key takeaways include:

• Sustainable sourcing is essential for compliance, risk management, and meeting modern consumer expectations.

• Evaluate innovative production processes (hot pressing, cold pressing, thermoforming) according to both performance and environmental impact.

• Establish clear criteria for supplier evaluation, focusing on material traceability, lifecycle assessments, and certification adherence.

• Leverage data-driven insights to optimize production and continuously reduce the carbon footprint.

• Invest in R&D and collaborate with suppliers to drive innovations that support sustainability without compromising product quality.

Procurement specialists are encouraged to assess their current supply chain practices and consider integrating these sustainable measures into their strategies. Not only does this approach result in a more resilient and efficient supply chain, but it also aligns with global trends toward responsible manufacturing and consumption. In an increasingly competitive market, the dual focus on performance and sustainability can be a significant differentiator that drives both profitability and positive environmental impact.

For businesses in the pickleball gear market, the journey toward sustainable sourcing is not just a trend—it is an essential evolution that fuels long-term success.

People Also Ask

Q1: What are the main benefits of sustainable sourcing in pickleball gear manufacturing?

A1: Sustainable sourcing in pickleball gear manufacturing offers benefits such as improved regulatory compliance, reduced energy consumption, lower environmental impact, enhanced brand reputation, and a resilient supply chain through the use of eco-friendly materials and production methods.

Q2: How can companies ensure material traceability in their sustainable sourcing efforts?

A2: Companies can ensure material traceability by partnering with suppliers who provide transparent documentation, using lifecycle assessments, and implementing certification standards such as ISO 14001, which together support ethical procurement and accurate tracking of material origins.

Q3: What production processes are most effective for reducing the carbon footprint in pickleball paddle manufacturing?

A3: Production processes such as cold pressing and thermoforming, combined with renewable energy integration, have proven effective in reducing the carbon footprint while maintaining the high performance required for pickleball paddles.

-

eco-friendly materials: Learn about sustainable materials that minimize environmental impact while meeting performance standards. ↩︎ ↩

-

thermoforming: Discover the thermoforming process, which involves shaping heated plastics into complex forms to balance efficiency with eco-friendly production. ↩︎ ↩ ↩2 ↩3

-

carbon footprint: Understand how to measure and manage the carbon footprint to reduce environmental impact and support sustainability initiatives. ↩︎ ↩ ↩2

-

ethical procurement: Explore ethical procurement practices that ensure transparency, fairness, and sustainability in supplier relationships. ↩︎ ↩

-

lifecycle assessments: Read about lifecycle assessments to evaluate and minimize the environmental impact of products from creation to disposal. ↩︎ ↩