In short, a solid supplier audit1 for pickleball equipment manufacturing must focus on verifying production integrity, quality control, and adherence to industry standards through a detailed checklist covering material quality, production processes, and vendor compliance.

In today’s competitive market, procurement managers and quality control specialists must ensure that their chosen suppliers not only meet but exceed quality expectations. When evaluating a manufacturing partner for high-performance pickleball paddles, factors such as material quality, production processes, and compliance standards become essential. This article provides a comprehensive audit checklist and a step-by-step approach to assess suppliers like NEX Pickleball, ensuring that every product delivers the performance and reliability that end customers demand.

Supplier audit is a systematic evaluation of potential manufacturing partners’ processes, materials, and quality control measures. For a B2B supplier evaluation in the sports equipment industry, especially for high-performance pickleball paddles, there are several critical factors:

• Supplier Audit1: A thorough evaluation of a supplier’s process integrity, quality control measures, and industry certifications.

• Quality Control: Methods and systems in place that guarantee consistent product performance, durability, and safety across every manufactured batch.

• Manufacturing Standards2: Compliance with national and international regulations and industry best practices, ensuring that products remain competitive and reliable.

• Compliance: Meeting both regulatory requirements and internal standards specific to high-performance sporting goods.

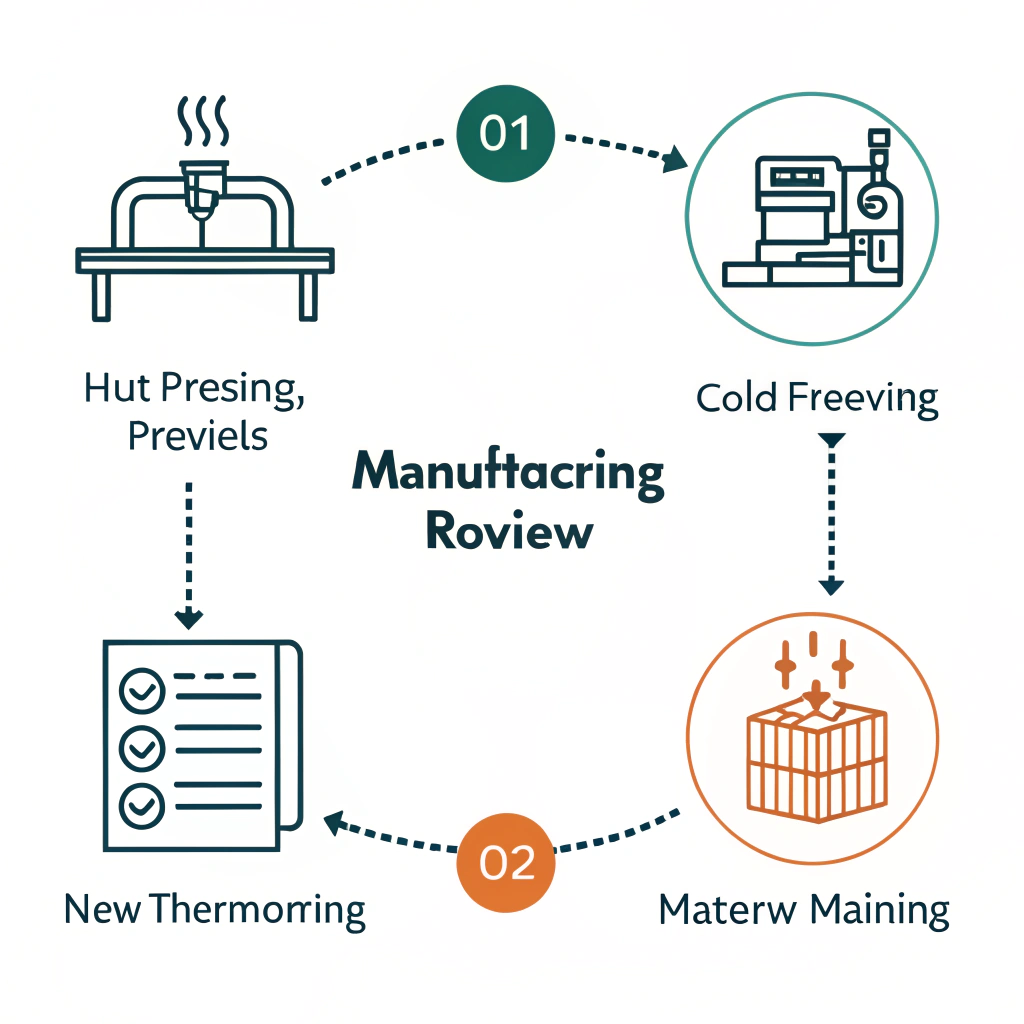

• Production Processes: Various production techniques – such as hot pressing, cold pressing, and thermoforming – directly influence material properties and the final product quality.

Understanding these aspects lays the foundation for a robust audit strategy. For instance, evaluating the production process details can reveal potential risks in material performance. Are there risks due to material degradation from repeated heating cycles in hot pressing? How does cold pressing maintain a paddle’s responsiveness and durability compared to thermoforming? Answering these questions is paramount in supplier audit.

A detailed audit of suppliers such as NEX Pickleball should start with a look at the production processes. Let’s break down the three major manufacturing methods frequently used in producing high-performance pickleball paddles:

Hot pressing involves applying heat and pressure to bond materials. This method is known for high production efficiency and structural integrity. However, it may affect the tactile feel of the paddle if the heat alters some material properties.

• Advantages:

– High production throughput

– Superior impact resistance

– Enhanced structural integrity

• Disadvantages:

– Potential alteration of material properties

– Requires significant investment in specialized equipment

Cold pressing shapes the paddle at room temperature. This process provides better control over the paddle’s thickness and ensures that the materials’ inherent properties are preserved, leading to excellent ball feel and responsiveness.

• Advantages:

– Precision control over structural dimensions

– Preservation of material qualities

– Enhanced player comfort and control

• Disadvantages:

– Slower production cycle

– Requires precise and high-quality pressure control systems

Thermoforming heats the materials to their softening point before forming them into complex shapes. This makes it ideal for creating paddles with tailored thickness distributions and intricate designs.

• Advantages:

– Customizable designs

– Precise material distribution

– Maintains paddle stability

• Disadvantages:

– Longer production times

– Higher equipment and maintenance costs

Each process must be audited for consistency in output, equipment maintenance, and process control, ensuring that each paddle produced meets the required quality and performance benchmarks.

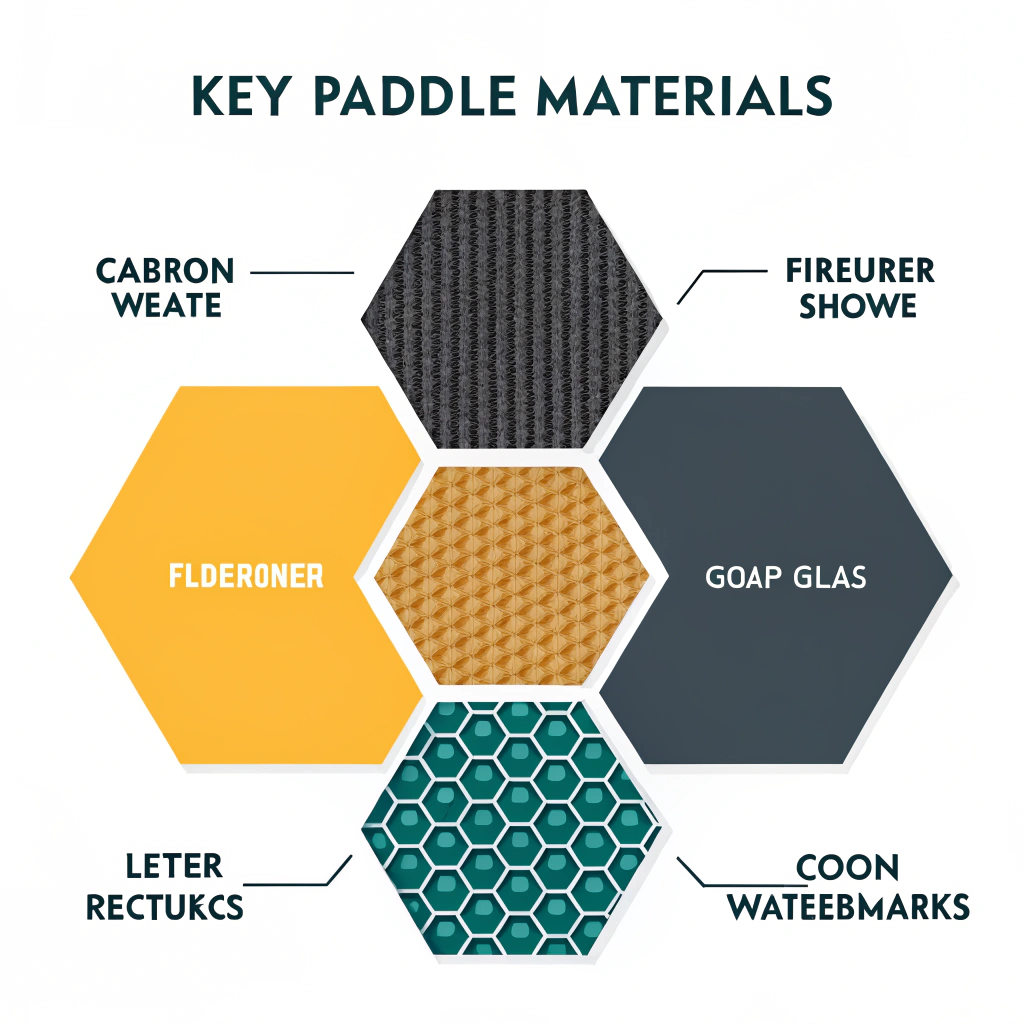

Material quality is a cornerstone of any manufacturing process audit. Evaluating what goes into a paddle offers a clear perspective on potential weaknesses and strengths of the supplier’s output. Consider the following materials:

NEX Pickleball uses varying types of carbon fiber, such as 3K, 12K, and T300, each bringing unique performance benefits.

• 3K Carbon Fiber: Offers strength and flexibility, reducing vibration and enhancing durability.

• 12K Carbon Fiber: Provides a smoother finish and greater hardness, suitable for more competitive play.

• T300 Carbon Fiber: Balances strength with lightweight performance, ideal for high-level play.

Fiberglass paddles deliver an excellent balance between power and control due to their inherent flexibility and larger sweet spot. The use of E-Glass Fiberglass ensures improved elasticity and tensile strength, enhancing control over each strike.

The combination of materials, such as carbon fiber and fiberglass composites, or a Bamboo Core Composite4, offers a balance of power, control, and durability. Core materials, including Nomex Honeycomb5, Aluminum Honeycomb, and Polymer Honeycomb cores, are critical:

• Nomex Honeycomb Core: Known for shock absorption and long-term durability.

• Aluminum Honeycomb Core: Balances weight distribution for improved power and control.

• Polymer Honeycomb Core: Offers reduced vibration and better elasticity for enhanced comfort.

These materials’ quality directly affects the paddle’s performance metrics such as rebound force, vibration reduction, and overall durability, making them essential audit points during supplier evaluation.

To simplify the supplier evaluation process, procurement professionals can utilize a comprehensive checklist tailored for pickleball paddle manufacturing. Below is an example of a structured table detailing key audit criteria:

| Audit Area | Evaluation Criteria | Key Considerations |

|---|---|---|

| Production Process | Consistency and process control during hot pressing, cold pressing, and thermoforming | Evaluate efficiency, potential impacts on product feel and quality |

| Material Quality | Type and grade of carbon fiber, fiberglass, and composite materials used | Verify certifications and material test results |

| Core Materials | Certification and performance metrics of Nomex, Aluminum, and Polymer honeycomb cores | Look into shock absorption, weight balance, and long-term durability |

| Quality Control | In-line inspection processes, batch testing, and end-of-line product inspections | Frequency of testing and adherence to industry standards |

| Equipment & Maintenance | Availability of modern, well-maintained production equipment | Review maintenance logs and equipment calibration records |

| Compliance and Certification | Adherence to international sports equipment standards and certifications | Check for certifications from bodies like USA Pickleball or ISO |

| Customization Capabilities | Availability of on-demand print options and custom design options | Evaluate flexibility to meet specific client branding requirements |

Using this audit checklist ensures a methodical review of all potential risk factors and quality indicators, enabling procurement professionals to make risk-mitigated decisions.

Several case studies underline the importance of rigorous supplier audits. For instance, a sports distributor once encountered significant issues when a supplier failed to maintain consistent quality during the thermoforming process, resulting in paddle warping and reduced durability. A comprehensive audit at that stage could have revealed lapses in equipment maintenance or insufficient process control.

Risk mitigation steps include:

• Conducting regular, on-site audits rather than solely relying on self-reported data from suppliers.

• Requesting detailed process documentation and quality control certificates.

• Using third-party auditors for independent verification, particularly for high-stakes procurement decisions.

• Establishing clear corrective action protocols in the event of quality deviations.

These steps not only help in assessing supplier reliability but also support building a strong long-term partnership with manufacturers who maintain robust production protocols.

After completing the audit, procurement professionals should compile their findings into a comprehensive report. This report forms the basis for a final decision that considers both performance data and any identified risks.

Actionable Recommendations:

- Schedule Regular Audits: Establish a quarterly or biannual audit routine to ensure ongoing compliance and consistency.

- Develop a Supplier Scorecard: Use a scorecard derived from the checklist to quantitatively compare different suppliers.

- Engage in Open Communication: Foster a transparent relationship with suppliers to quickly address any emerging issues.

- Invest in Third-Party Verification: When necessary, partner with independent quality control bodies to validate compliance.

By integrating these practices into your supplier evaluation process, you build confidence in your supply chain and ensure that your end consumers receive products that meet the highest standards of performance and durability.

In summary, auditing suppliers in the pickleball paddle manufacturing industry demands a thorough evaluation of production processes, material quality, and compliance standards. A detailed checklist helps ensure that every aspect of the production—ranging from advanced production techniques like hot pressing, cold pressing, and thermoforming, to the application of premium materials such as various grades of carbon fiber and fiberglass—is meticulously reviewed. This systematic approach not only reduces risk but also enhances the likelihood that your chosen supplier will deliver high-performance paddles meeting both industry standards and customer expectations. For procurement managers aiming to secure reliable manufacturing partners, these strategies form the bedrock of a successful supplier audit.

People Also Ask

• What to look for when buying a used pickleball paddle?

When purchasing a used pickleball paddle, focus on the level of wear. Check for scratches, chips, or cracks which can affect gameplay quality. Ensuring that the paddle maintains structural integrity is crucial for safe and effective play.

• What's better, a 13mm or 16mm pickleball paddle?

Modern trends favor a 16mm paddle due to its enhanced power generation and improved control stemming from advanced thermoforming techniques. Compared to the traditionally stiffer 13mm models, 16mm paddles tend to provide a better balance between power and control.

• Who certifies pickleball paddles?

Certification for pickleball paddles is primarily managed by USA Pickleball, which collaborates with numerous equipment manufacturers. This certification process ensures that manufacturers adhere to stringent industry standards and best practices in equipment testing.

-

Supplier Audit: Click to learn how systematic evaluations of supplier processes and quality measures can significantly reduce operational risks and improve supply chain efficiency. Back to Supplier Audit ↩ ↩2

-

Manufacturing Standards: Click to understand the key national and international benchmarks that ensure product quality and regulatory compliance in manufacturing industries. Back to Manufacturing Standards ↩

-

Thermoforming: Click to explore the thermoforming process, its advantages, challenges, and its impact on product design and quality. Back to Thermoforming ↩

-

Bamboo Core Composite: Click to read about the innovative use of bamboo core composites in manufacturing, examining their benefits in terms of strength, durability, and sustainability. Back to Bamboo Core Composite ↩

-

Nomex Honeycomb: Click to discover the properties of Nomex honeycomb cores, including their exceptional shock absorption and durability, which make them a preferred choice in high-performance products. Back to Nomex Honeycomb ↩