At NEX Pickleball, our advanced manufacturing processes—hot pressing, cold pressing, and thermoforming—combined with premium materials like Carbon Fiber1 and Fiberglass2 ensure paddles that deliver exceptional performance, durability, and comfort. This article details how we overcome industry challenges through precision production and quality craftsmanship, offering a behind-the-scenes look into our techniques and innovations.

In today’s competitive sports equipment market, achieving excellence in pickleball paddle manufacturing is no small feat. Companies must balance high performance with cost efficiency, ensure precision amid complex production processes, and maintain consistent quality. Business buyers and procurement managers often question:

- How can advanced production processes improve product reliability?

- What manufacturing challenges exist in creating high-performance pickleball paddles?

- How do production methods impact the final product’s performance and durability?

These challenges arise from the need to harmonize innovative design, material selection, and production techniques. Variability in materials and process imperfection can lead to inconsistent product performance. NEX Pickleball addresses these challenges by employing rigorous quality control, state-of-the-art production methods, and a deep understanding of material science3.

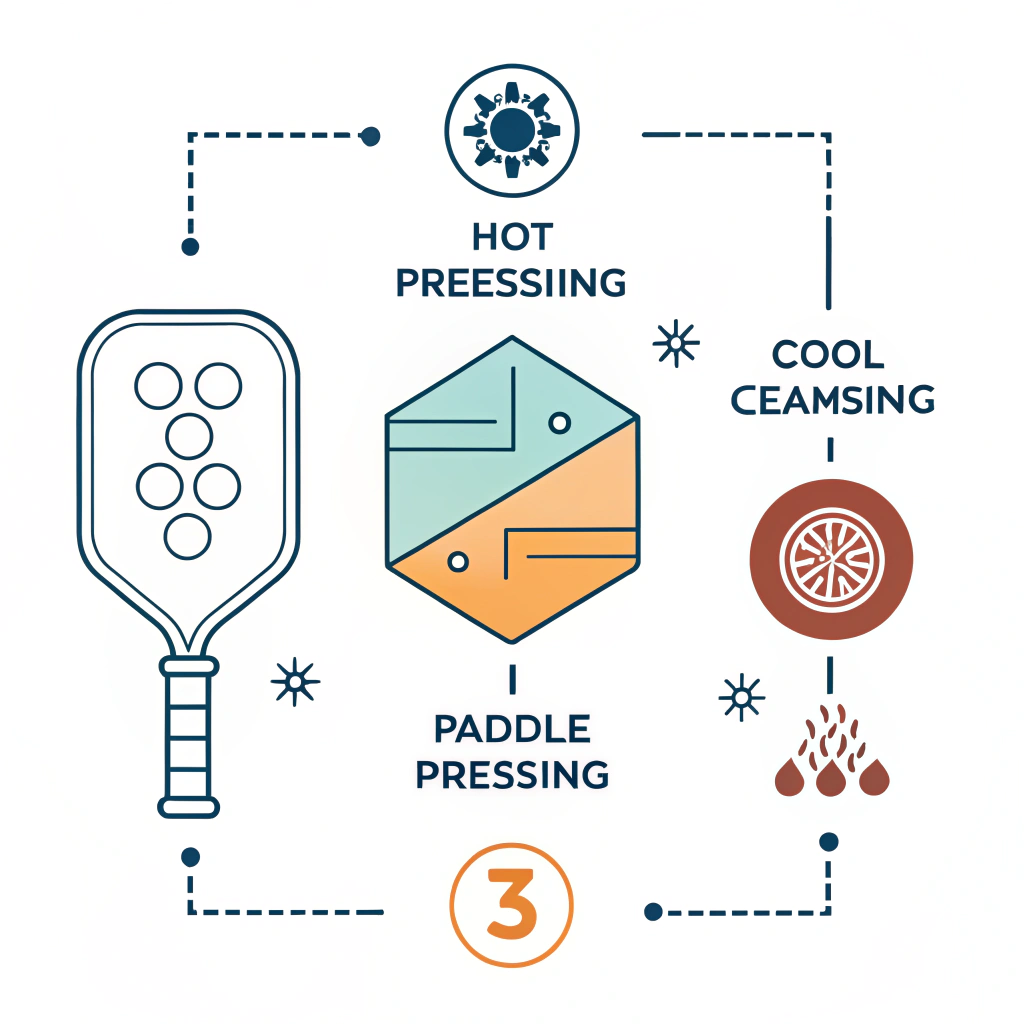

At the heart of our manufacturing excellence is the careful selection of production processes that optimize the properties of each paddle. We utilize three core methods:

- Hot Pressing

- Cold Pressing

- Thermoforming4

Each method offers unique strengths and limitations that we harness to meet diverse customer needs and performance requirements.

Hot pressing involves heating materials and applying pressure to mold them into the paddle’s structure. This modern technique produces paddles that are strong and impact-resistant.

-

Advantages:

- High production efficiency enables large-scale manufacturing.

- Results in a highly durable paddle structure with excellent impact resistance.

- Ensures robust structural integrity for high-performance use.

-

Disadvantages:

- The high temperatures may alter material properties, slightly impacting the paddle’s feel.

- Requires significant investment in specialized equipment.

Cold pressing shapes the paddle materials at room temperature using controlled mechanical pressure. This method maintains material properties offering optimum control and responsiveness.

-

Advantages:

- Retains the natural characteristics of materials, resulting in superior ball control.

- Allows precise control over paddle thickness and structure.

- Enhances flexibility, making the paddle feel more responsive during play.

-

Disadvantages:

- Longer production cycles compared to hot pressing.

- Requires high-precision equipment to maintain pressure consistency.

Thermoforming involves heating the paddle material until it softens enough to be molded into shape using a form or mold. This technique is essential for complex designs that require thickness and intricate patterns.

-

Advantages:

- Creates paddles with refined designs and precise material distribution.

- Enhances the paddle’s stability and performance.

- Ideal for premium products or custom-made orders.

-

Disadvantages:

- Longer production time and higher equipment costs.

- Best suited for specialized, high-end paddle production.

Below is a table summarizing these production processes:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, robust build | High equipment cost, potential alteration of material properties |

| Cold Pressing | Precise control, retains natural material properties | Longer production cycle, requires precise equipment control |

| Thermoforming | Intricate designs, stable performance | Higher production cost and time, ideal for premium or custom orders |

Our commitment to quality is visible not only in our manufacturing processes but also in our choice of advanced materials5. At NEX Pickleball, we use a variety of premium materials, each selected for its specific performance attributes:

-

Carbon Fiber Variants:

- 3K Carbon Fiber: Provides excellent flexibility and rebound force, making it perfect for high-impact environments.

- 12K Carbon Fiber: Offers a smoother surface, greater hardness, and improved durability—ideal for competitive play.

- T300 Carbon Fiber: Known for outstanding tensile strength, balancing power and light weight for peak performance.

-

Fiberglass:

- E-Glass Fiberglass: Known for its elasticity and optimal ball feel, fiberglass paddles offer a balance of power and control with a wider sweet spot.

-

Composite Materials:

- Carbon Fiber and Fiberglass Composite: Merges benefits from both materials for enhanced flexibility and strength.

- Bamboo Core Composite: A lightweight, impact-resistant option delivering a crisp, clear hitting sensation.

- Honeycomb Core: Provides superior shock absorption while reducing vibration, ensuring long-lasting durability.

-

Core Materials:

- Nomex Honeycomb Core: A durable, shock-absorbent polymer core for stable and long-lasting play.

- Aluminum Honeycomb Core: Balances weight for controlled power output suitable for precise gameplay.

- Polymer Honeycomb Core: Favoured for its elasticity and ability to reduce vibration, ideal for beginners and recreational players.

At NEX Pickleball, every step of our production process is tightly controlled. Our expert team continuously evaluates each paddle at every stage—from material selection to final testing—to ensure it meets our exacting standards.

- Rigorous Testing: Each paddle undergoes multiple rounds of testing to measure strength, balance, and vibration control.

- Advanced Technology Integration: We invest in advanced machinery that ensures consistency and precision in every product produced.

- Tailored Production: Custom paddle options are available, allowing for specific adjustments in design, weight, balance, and grip size, catering to individual requirements for business branding or team needs.

- Proven Track Record: As a leading manufacturer working with brands like Joola and Selkirk, our paddles have been field-tested in competitive environments, underscoring our manufacturing excellence.

Real-life production data show that paddles produced through our combined approach excel in terms of durability and performance consistency. Business buyers have praised our focus on quality and innovation, which positions us as a reliable supplier in the global sports equipment arena.

Our manufacturing approach is backed by years of experience and continuous innovation. The integration of advanced production techniques results in paddles that not only meet but exceed industry standards. Our dedication to quality translates into products that provide enhanced gameplay experience, ensuring that every paddle delivers precision, balance, and reliability.

For procurement managers and business buyers evaluating pickleball manufacturing sources, consider the following key points when assessing potential suppliers:

-

Evaluate Production Capabilities:

Assess the variety and precision of production processes such as hot pressing, cold pressing, and thermoforming. Confirm that the production methods align with your quality and performance requirements. -

Verify Material Quality:

Superior materials like Carbon Fiber1 and Fiberglass2 are fundamental to high-performance products. Understand the specific benefits of each material and their application in enhancing paddle performance. -

Examine Quality Control Protocols:

Ensure that the supplier has stringent quality assurance measures in place. Multiple testing phases and advanced technological integration are indicators of a supplier's commitment to product excellence. -

Consider Customization Options:

Tailored production that allows for design modifications is an essential consideration, especially if the end product needs to align with your company’s branding and customer preferences. -

Industry Expertise and Collaboration:

A supplier with established partnerships, such as those with Joola and Selkirk, demonstrates industry credibility and technical competence. Their proven track record in high-stakes competitive environments can be a significant advantage.

By focusing on these areas, business buyers can ensure that they partner with a manufacturing leader capable of delivering products that meet the stringent demands of today's pickleball enthusiasts.

NEX Pickleball’s commitment to manufacturing excellence is evident in our blend of modern production methodologies, premium material selection, and rigorous quality assurance. For those in the sports equipment industry, these factors translate into reliable products that support peak performance and durability in competitive settings.

We invite business buyers and procurement managers to consider these advanced manufacturing techniques when evaluating potential suppliers. Our precision-focused approach combined with a deep understanding of material science positions us as a trusted partner ready to deliver high-performance pickleball paddles. To learn more about our production processes or to explore custom paddle options, please reach out to our team for a personalized consultation.

Q: Why are people suddenly obsessed with pickleball?

A: Pickleball’s rising popularity can be largely attributed to the COVID-19 pandemic. With its accessibility and the ability to be played outdoors, the sport quickly became a favorite among diverse age groups, including former tennis players and casual athletes looking for a new, low-impact way to stay active.

Q: Who were the founders of pickleball?

A: Pickleball was founded in the summer of 1965 by Joel Pritchard, Bill Bell, and Barney McCallum on Bainbridge Island, Washington. The name “pickle ball” reportedly was coined by Joan Pritchard, drawing a playful reference to the idea of a “pickle boat” in crew races where leftovers come together as a team.

Q: Why do older people love pickleball so much?

A: Pickleball offers an ideal combination of physical exercise and social engagement for older adults. It helps improve quickness, agility, and balance while providing opportunities for fresh air, friendly competition, and community interaction—benefits that are both mentally and physically rejuvenating.

-

Carbon Fiber: Click to read about the properties, manufacturing techniques, and performance benefits of carbon fiber materials in high-performance sports equipment. ↩ ↩ ↩2

-

Fiberglass: Click to explore how fiberglass is used in manufacturing for improved elasticity and balance in sports products. ↩ ↩ ↩2

-

material science: Click to discover how material science principles are applied to optimize performance, quality, and innovation in manufacturing processes. ↩ ↩

-

Thermoforming: Click to learn more about thermoforming, a process essential for molding complex designs with precision in sports equipment manufacturing. ↩ ↩

-

advanced materials: Click to understand the role of advanced materials in enhancing product performance and durability in competitive sports gear. ↩ ↩