Rapid market launch can be achieved by leveraging state-of-the-art manufacturing processes, precise quality control, and tailor-made production solutions. NEX Pickleball exemplifies this approach by ensuring that every custom paddle meets strict performance and durability standards while shortening time-to-market1 for renowned brands.

In today’s fast-paced sports equipment market, companies face enormous pressure to introduce innovative products quickly. For a Canadian sports brand seeking to launch a new pickleball line, the challenge was not only to capture attention in a rapidly expanding industry but also to ensure that the equipment delivered was of high performance and quality. Typically, delays in production, inconsistent quality, and a lack of customization combine to create significant barriers for sports brands aiming to meet market demand.

Traditional manufacturing processes may lead to longer lead times and unpredictable quality outcomes. For supply chain managers and sourcing professionals, these issues translate into lost opportunities and market share. The problem becomes even more acute when the product itself, such as a high-performance pickleball paddle, must satisfy rigorous standards in terms of materials, design innovation, and user comfort.

Several factors contribute to delays and quality issues in conventional manufacturing settings:

- Material Inconsistency: Standard production often struggles with material variability. For instance, using common composites without tailored production techniques can result in paddles with uneven weight distribution and compromised durability.

- Limited Process Flexibility: Traditional methods usually follow a one-size-fits-all approach that does not cater to specialized demand. Paddles designed for high performance require different techniques compared to recreational equipment.

- Supply Chain Fragmentation: Disconnected manufacturing stages, from core material sourcing to final quality assurance, introduce inefficiencies. This fragmentation can delay the feedback loop that is crucial for rapid market response.

- Customization Limitations: When manufacturers rely on rigid production processes, offering custom solutions—such as varying grip sizes and on-demand print options—becomes challenging.

These root causes create a scenario where meeting the fast-paced demands of products like high-performance pickleball paddles seems almost impossible using outdated methodologies.

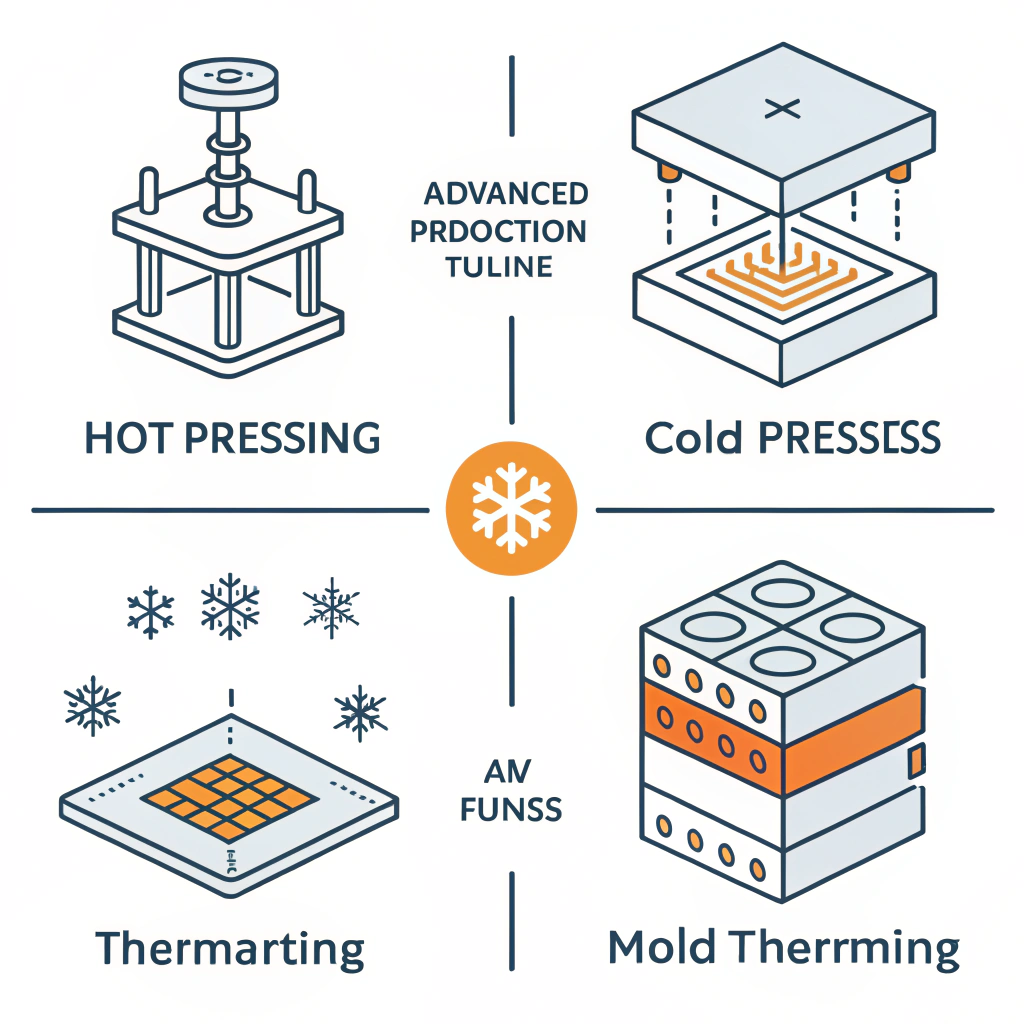

NEX Pickleball has addressed these challenges head-on by integrating advanced production techniques into our manufacturing ecosystem. Our core processes—hot pressing2, cold pressing3, and thermoforming4—are finely tuned to serve different paddle requirements while ensuring rapid and reliable output.

Each production process offers unique advantages tailored to different product needs:

| Production Process | Key Advantages | Limitations |

|---|---|---|

| Hot Pressing | High production efficiency; excellent structural integrity and impact resistance | Potential alteration of material feel; high equipment investment required |

| Cold Pressing | Precise control over thickness; maintains material properties for optimum ball feel | Longer production cycles; demands high-quality pressure control systems |

| Thermoforming | Ability to produce intricate designs with even material distribution; ideal for custom shapes | Extended production time; higher equipment costs |

These processes are not used in isolation. Instead, NEX Pickleball applies them in a complementary manner. For example, paddles that require robust strength and durability leverage 3K Carbon Fiber or 12K Carbon Fiber during hot pressing. In contrast, designs demanding superior ball control may use cold pressing to preserve the material properties essential for performance.

A leading Canadian sports brand partnered with NEX Pickleball to launch a new line of high-performance pickleball paddles. The brand was under pressure to enter the market quickly while ensuring that its offering was both innovative and competitive.

- Speed to Market: With the market rapidly evolving, the brand needed a manufacturing partner who could deliver quality paddles in record time.

- Customization: The paddles required unique design features, including custom grip sizes and on-demand print services, to align with the brand’s identity.

- Quality and Consistency: As a premium sports brand, every paddle had to exhibit top-tier performance, durability, and aesthetic appeal.

- Rapid Prototyping: By utilizing advanced production techniques, we rapidly prototyped paddle designs, giving the brand a tangible product to evaluate early on.

- Custom Production: Through our flexible manufacturing process, customization became a strong selling point. We offered options ranging from diverse core materials—such as Nomex Honeycomb Core5, Aluminum Honeycomb Core, and Polymer Honeycomb Core—to special printing services that allowed on-demand personalization.

- Quality Assurance: Each paddle underwent rigorous testing to ensure it met the highest industry standards. Our production processes ensured a strong bond between performance and durability, offering outstanding feedback from early test users.

- Streamlined Communication: Close coordination with the Canadian sports brand’s product development team helped us adjust designs swiftly, minimizing iterations and accelerating decision-making.

The success of this case study lies in how NEX Pickleball’s comprehensive solution addressed the brand’s need for speed, quality, and customization—all essential elements for a successful market launch.

To ensure that each paddle meets rigorous performance standards and to facilitate rapid market launches, NEX Pickleball focuses on the following areas:

We use premium materials like Carbon Fiber (3K, 12K, T300) and Fiberglass to meet different performance criteria:

- 3K Carbon Fiber is favored for paddles requiring high rebound force.

- 12K Carbon Fiber is ideal for scenarios demanding extreme strength and impact resistance.

- T300 Carbon Fiber strikes a balance between strength and lightweight performance.

- E-Glass Fiberglass provides that extra touch of flexibility and enhanced control during play.

The ability to choose from and combine these materials means that our manufacturing process adapts to the specific demands of each client and product lineup.

The paddle core directly influences factors such as ball control, shock absorption, and overall durability. Our variety includes:

- Nomex Honeycomb Core: Provides excellent shock absorption and ensures durability during high-intensity play.

- Aluminum Honeycomb Core: Balances power and control perfectly, appealing to competitive players.

- Polymer Honeycomb Core: Offers increased elasticity and reduced vibration, making it suitable for recreational and beginner players.

This flexibility in core materials has allowed brands to tailor their products to specific player needs and performance metrics, further enhancing the product’s market appeal.

Customization goes beyond material choice. With our on-demand print services, we allow brands to incorporate personalized designs, logos, and color schemes onto the paddles. This service not only reinforces the brand identity but also creates an emotional connection with end-users. Such custom options have proven essential for brands that aim to stand out in a crowded market, adding further value to the final product.

A significant contributor to the rapid market launch is our streamlined production workflow. From the design phase through quality testing to final packaging, every step is optimized:

- Automated Testing: Our automation systems minimize human error and ensure that every paddle meets strict performance standards.

- Real-Time Quality Monitoring: Continuous monitoring during production helps identify and fix potential issues immediately.

- Efficient Communication: Our integrated project management system keeps our partners informed throughout the production cycle, ensuring transparency and timely updates.

The above measures significantly reduce production lead times, making it possible for our partners to enjoy competitive advantages in the sports equipment market.

The experience with the Canadian sports brand provides several strategic insights that can apply to similar B2B relationships:

- Collaboration is Key: Close, ongoing communication between client and manufacturer is crucial for meeting rapid timelines without sacrificing quality.

- Customization Drives Differentiation: In today’s market, offering tailor-made solutions can set a product apart from standardized competitors.

- Leveraging Advanced Processes: Investing in advanced production techniques not only enhances product performance but also optimizes production speed.

- Quality as a Non-Negotiable: Regardless of market pressures, stringent quality control measures are essential to maintain brand reputation and product reliability.

For suppliers and sourcing managers assessing manufacturing partners, these factors should be evaluated carefully. Making the right partnership decision can mean the difference between launching a product that leads the market and one that fails to meet consumer expectations.

NEX Pickleball’s case study with the Canadian sports brand proves that with the right blend of advanced materials, innovative production techniques, and clear communication, rapid market entry is not only feasible—it is a competitive necessity.

By choosing a partner like NEX Pickleball, decision-makers in the sports equipment industry can rest assured that:

- Production cycles are minimized without compromising on product quality.

- Each paddle is produced with a focus on performance, durability, and authentic customization.

- Advanced manufacturing techniques and real-time quality control work together to deliver products that meet strict performance criteria.

For sourcing managers and sports equipment companies ready to innovate and accelerate their time-to-market, partnering with experienced manufacturers like NEX Pickleball will provide the strategic edge needed in today’s competitive landscape. We invite you to leverage our advanced production capabilities for your next launch and experience the transformative impact of a manufacturing process built for performance and precision.

Q1: What advanced production techniques are used in manufacturing high-performance pickleball paddles at NEX Pickleball?

A1: NEX Pickleball utilizes a combination of hot pressing, cold pressing, and thermoforming. These techniques are chosen to optimize different performance aspects—ensuring high impact resistance, precise control over thickness, and even material distribution for custom designs.

Q2: How does NEX Pickleball enable rapid market launch for sports brands?

A2: Through streamlined production workflows, rigorous quality control, and flexible customization options, NEX Pickleball significantly reduces lead times. This efficiency, combined with advanced techniques and real-time communication with clients, ensures that products meet market demands quickly and consistently.

Q3: What customization options do NEX Pickleball offer for paddle production?

A3: NEX Pickleball provides extensive customization options including varied core materials (such as Nomex, Aluminum, and Polymer Honeycomb Cores), grip size options, design alterations, and on-demand print services. These options allow brands to tailor paddles to specific player needs and market positioning.

-

time-to-market: Click to learn how reducing the time-to-market can provide companies with a competitive edge by accelerating product launches and quickly adapting to market changes. ↩ ↩

-

hot pressing: Click to explore how hot pressing contributes to high production efficiency and structural integrity in products. ↩ ↩

-

cold pressing: Click to understand the benefits of cold pressing in maintaining precise material properties and achieving optimal product performance. ↩ ↩

-

thermoforming: Click to uncover the advantages and limitations of thermoforming techniques in producing intricate, custom designs. ↩ ↩

-

Nomex Honeycomb Core: Click to discover the role of Nomex Honeycomb Core in enhancing shock absorption and durability for high-intensity applications. ↩ ↩