Quick Answer: Optimizing weight balance in OEM pickleball paddles requires a precise combination of advanced material selection and production processes—such as hot pressing, cold pressing, and thermoforming1—to create a paddle that maximizes performance, durability, and control while maintaining ergonomic comfort.

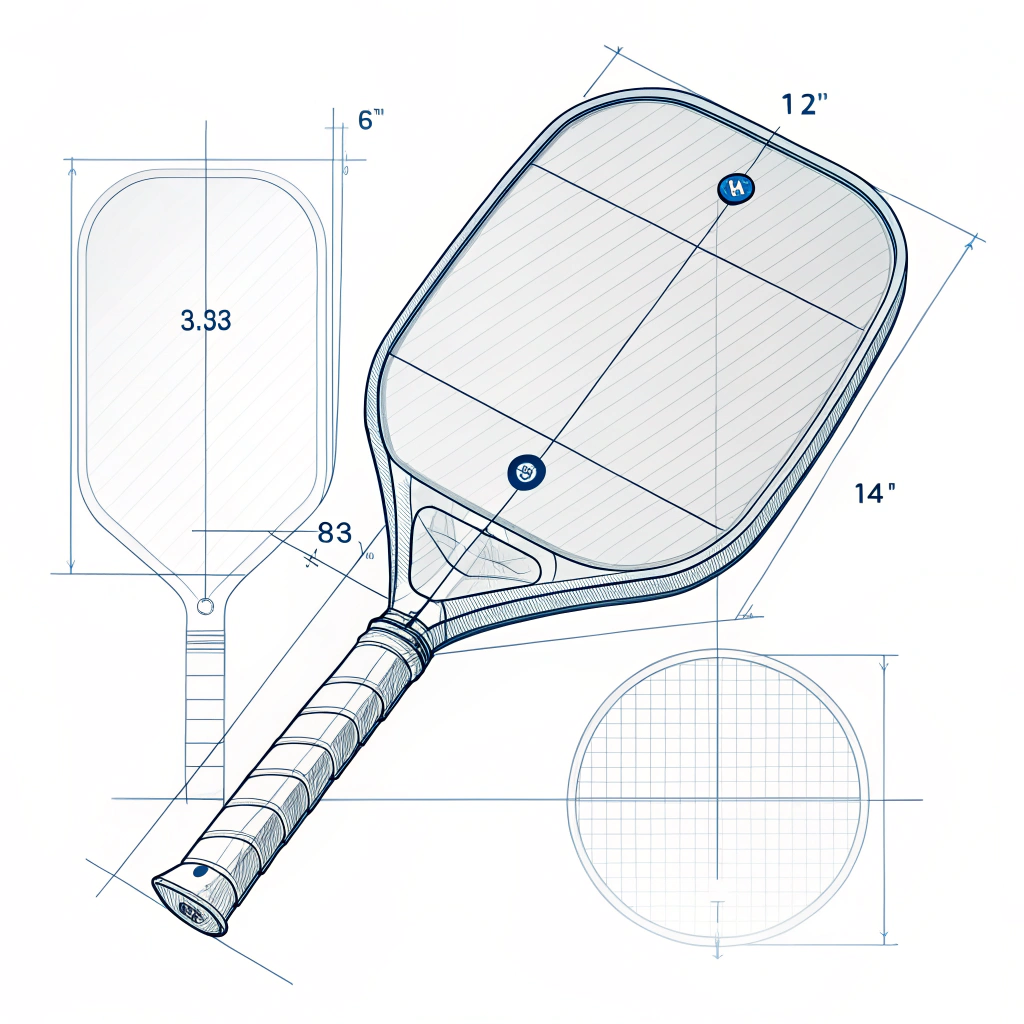

In today’s competitive sports equipment industry, achieving optimal weight balance in pickleball paddles is crucial for superior performance and player comfort. OEM procurement managers and product developers need a comprehensive understanding of how material choices and manufacturing techniques impact paddle weight distribution. This article details the challenges in balancing weight, compares different production processes, and explains how premium materials like carbon fiber2, fiberglass composites3, and various cores contribute to overall paddle quality. Our goal is to provide actionable insights for approaching paddle design that meets both performance and longevity requirements.

Problem Statement and Importance

An imbalanced paddle can compromise a player’s control, swing speed, and overall game performance. In competitive and recreational settings alike, weight balance plays a central role in:

• Enhancing control by ensuring responsiveness during quick changes in direction.

• Reducing player fatigue by optimizing the paddle’s center of gravity.

• Improving durability with even stress distribution on the paddle surface.

The challenge for OEM partners lies in tailoring designs that address these factors while maintaining cost efficiency and production scalability. With diverse materials available and multiple processes in production, a deep dive into each step is essential to guide decision-making.

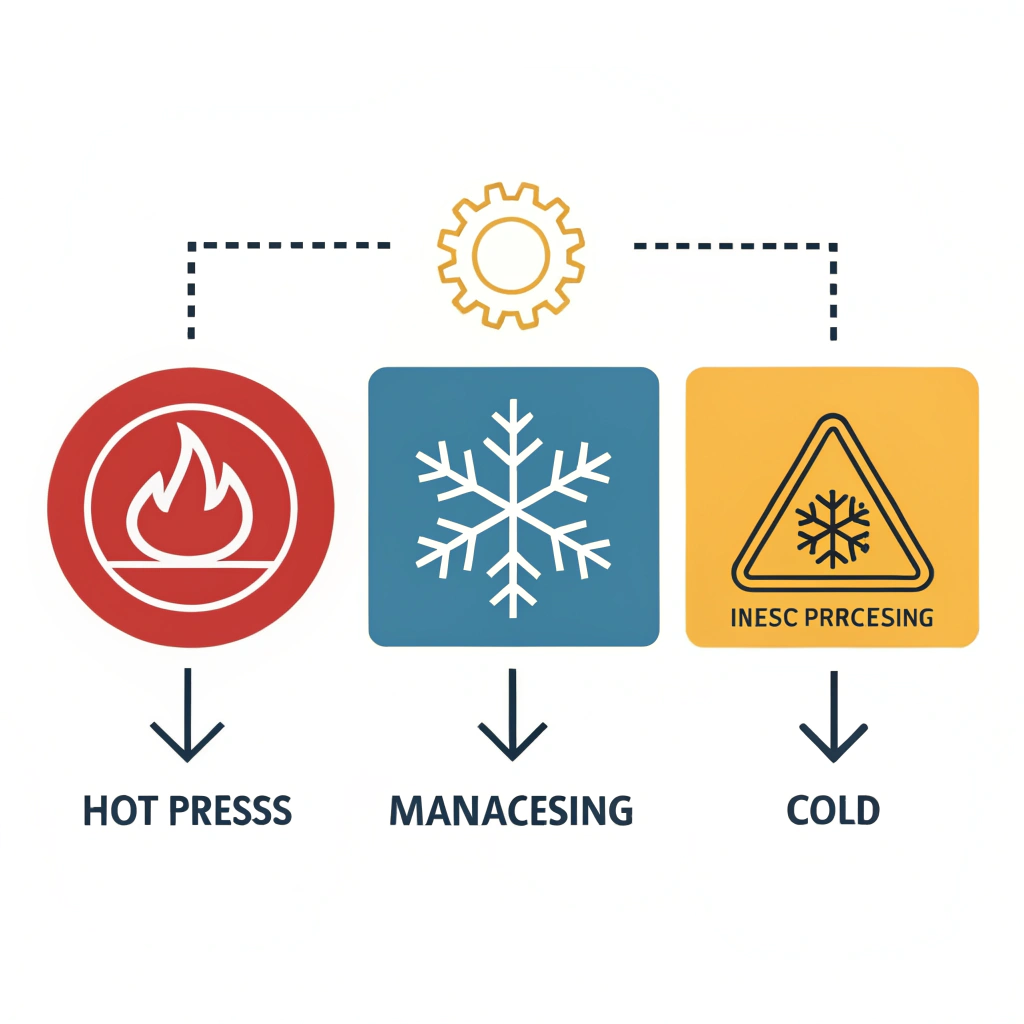

Understanding Production Processes

One of the most critical aspects of paddle manufacturing is the production process. Each method—hot pressing, cold pressing, and thermoforming1—offers unique benefits and limitations, which directly affect the paddle’s weight balance and overall performance.

-

Hot Pressing

Hot pressing involves heating and applying pressure to the composite materials. This method ensures strong bonds between fibers and resins.

• Advantages:- High production efficiency suitable for large-scale manufacturing.

- Produces strong, durable paddles with excellent impact resistance.

- Ensures structural integrity, crucial for high-performance play.

• Disadvantages: - The heat can alter some material properties, potentially affecting the paddle’s feel.

- Requires significant investment in specialized equipment.

-

Cold Pressing

Cold pressing is performed at room temperature under high mechanical pressure. This technique is used when precision control over the paddle structure is necessary.

• Advantages:- Maintains the original properties of each material, preserving flexibility and responsiveness.

- Allows for precise control over the paddle’s thickness and surface structure.

• Disadvantages: - The lower production speed can extend manufacturing cycles.

- Demands high-quality, precise pressure control equipment.

-

Thermoforming1

Thermoforming involves heating the paddle materials to their softening point and then forming them into shape using molds, ideal for producing complex designs with intricate material distribution.

• Advantages:- Enables intricate designs with accurate control on weight distribution.

- Maintains stability in paddle performance by ensuring uniform material distribution.

• Disadvantages: - Longer production times and higher equipment costs may result.

- Best suited for premium or custom paddle series.

To visualize the pros and cons of these processes, the table below summarizes their attributes:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency; strong, durable construction; robust bond | Potential alteration in material properties; high equipment cost |

| Cold Pressing | Precise control; retains material properties; excellent feel | Slower production cycle; requires precise control |

| Thermoforming | Intricate design capability; stable material distribution | Longer production time; higher cost for equipment |

Each of these methods can be calibrated to enhance the weight balance of the paddle. For instance, adjusting the pressure and heating time can influence the overall density distribution, ensuring that no segment of the paddle becomes overly heavy or weak. Knowing these details empowers procurement managers and product developers to evaluate OEM partners from a performance perspective.

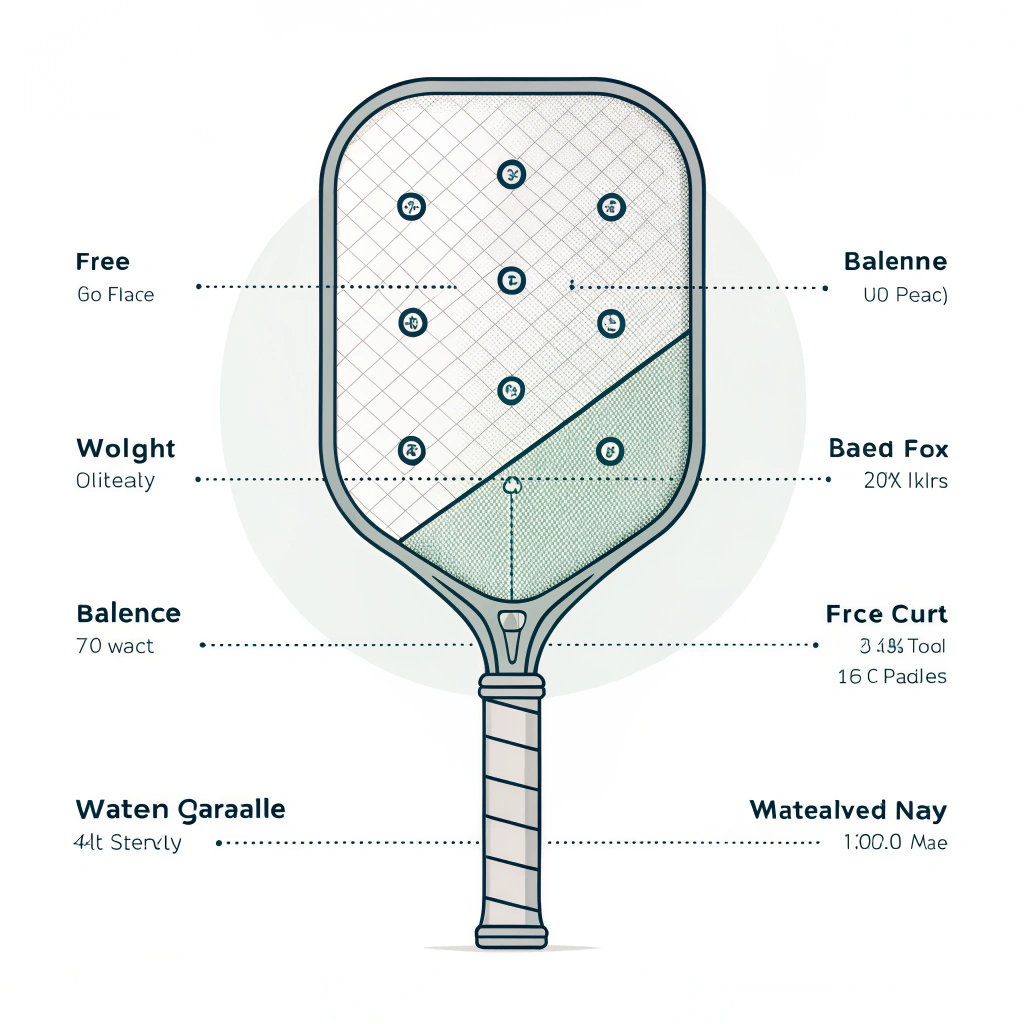

Role of Material Selection in Weight Balance Optimization

When designing OEM pickleball paddles, materials play an equally critical role as production processes. Below, we explore how various high-grade materials contribute to optimized weight balance:

- Carbon Fiber2

Carbon fiber materials are at the forefront of paddle technology due to their strength and lightweight properties. At NEX Pickleball, we utilize various types:- 3K Carbon Fiber: Offers excellent strength and flexibility with a high rebound force. It is ideal for ensuring that the paddle remains responsive while effectively absorbing shocks.

- 12K Carbon Fiber: With a higher thread density, it provides a smoother surface, increased hardness, and greater durability, making it suitable for high-impact competitive play.

- T300 Carbon Fiber: Known for its exceptional tensile strength, it delivers a balanced performance of weight savings and rigidity.

Each type of carbon fiber has a distinctive impact on weight balance. For instance, while 12K may add a bit more weight, it equally reinforces the paddle’s structure. Deciding on the right blend depends on the targeted player demographic and game style.

-

Fiberglass Composites3 and Composite Materials

Fiberglass paddles, particularly those made from E-Glass Fiberglass, offer an excellent compromise between power and control. The material’s flexibility allows for a wider sweet spot, which contributes to more uniform weight dispersion across the paddle’s surface.- Composite Structures: By combining carbon fiber with fiberglass, manufacturers can harness the strengths of both. This composite approach brings together the durability and lightness of carbon fiber with the flexibility and control of fiberglass, leading to superior performance in competitive environments.

-

Core Material Technologies

The core of the paddle is pivotal for determining the hitting feel and overall balance. Different core materials contribute uniquely:- Nomex Honeycomb Core4: Provides excellent impact absorption and durability, ensuring a stable weight distribution even under intense play.

- Aluminum Honeycomb Core: Balances weight effectively to offer both strength and precision, making paddle strikes more reliable.

- Polymer Honeycomb Core: Known for enhanced elasticity and reduced vibration, this option yields a comfortable, balanced performance, particularly beneficial for recreational players.

By carefully selecting core materials, OEM partners can tailor the paddle’s weight characteristics to achieve a precise balance between power, control, and comfort.

Balancing Weight with Advanced Engineering Techniques

The optimization process doesn’t stop at choosing the right materials or production methods. Precision Engineering5 and quality control measures are integral in ensuring that every paddle meets strict performance criteria. Here are several key factors in this process:

• Ergonomic Design: Implementing ergonomic grip and shape designs helps maintain an ideal weight distribution that reduces stress on the player’s wrist and forearm.

• Customized Weight Distribution: Using modern production techniques like thermoforming allows for intricate weight placement management, ensuring that excess material does not concentrate at any specific part of the paddle.

• Quality Control: At NEX Pickleball, each paddle is subject to rigorous testing procedures to ensure that manufacturing consistency translates into optimal paddle performance. This includes dynamic testing on balance, flexibility, and material fatigue.

The integration of these advanced techniques ensures that OEM products not only meet but exceed competitive standards. Innovations such as tailored pre-press setups and controlled mold engineering increase the confidence that every unit produced will maintain consistent quality and performance — a critical factor for companies offering branded sports products to the market.

Practical Solutions and Implementation Strategies

To ensure improved weight balance in OEM pickleball paddles, consider the following actionable strategies:

-

Collaborative Design Reviews

Work closely with your manufacturing partner to review the paddle design. This involves examining:- Material composition and the respective benefits of carbon fiber versus fiberglass.

- Core material options (Nomex, aluminum, polymer) based on the intended user experience.

- Production process modifications that can better control the distribution of weight.

-

Data-Driven Testing

Implement a series of tests focused on weight distribution, impact resistance, and vibration reduction. This data can support design modifications to further optimize the paddle’s performance:- Use dynamic balance assessments.

- Record performance data to address any discrepancies in manufacturing.

- Utilize user feedback during prototype testing to identify subtle weight imbalances.

-

Production Process Optimization

Align the manufacturing process with the desired performance outcomes. For instance, if a lightweight paddle with high responsiveness is the goal, emphasize cold pressing techniques:- Regular calibration of pressing machines can help maintain consistency.

- Adjust heat and pressure variables during hot pressing to avoid unintended weight disparities.

- Explore advanced thermoforming methods where premium paddles require complex design features.

-

Continuous Improvement and Innovation

Keep abreast of the latest trends in manufacturing and materials technology. Innovations in carbon fiber composites or new core materials may offer further opportunities to optimize weight balance without compromising durability or cost-efficiency.

Conclusion and Recommendations for OEM Buyers

To achieve the ideal weight balance in OEM pickleball paddles, a finely tuned combination of materials, production processes, and quality control is imperative. By understanding the strengths and limitations of hot pressing, cold pressing, and thermoforming, procurement managers and product developers are better positioned to select OEM partners that deliver both performance and reliability. Leveraging advanced materials such as high-grade carbon fiber, fiberglass composites, and optimized core structures will ensure that each paddle meets the high demands of today’s competitive sports market.

As you move forward in your procurement journey, we recommend that you:

• Engage directly with manufacturers about their production methods.

• Request detailed data on material properties and production consistency.

• Test prototypes under realistic conditions to validate performance metrics.

Ultimately, the decision will hinge on achieving a balance that not only meets performance criteria but also supports long-term durability and brand reputation. By prioritizing these elements, businesses can secure a competitive edge in the evolving market for high-performance sports equipment.

People Also Ask

Q: How do manufacturing processes affect paddle weight balance?

A: Manufacturing processes like hot pressing, cold pressing, and thermoforming determine the density and distribution of materials. Each method influences how heat and pressure are applied, which in turn affects the paddle’s center of gravity and overall balance.

Q: How can the type of carbon fiber influence paddle performance?

A: Different carbon fibers (3K, 12K, T300) offer varying strengths, flexibility, and weight properties. These differences affect the paddle’s rebound force, durability, and responsiveness—key factors in achieving optimal weight balance.

Q: What are the benefits of combining carbon fiber and fiberglass composite in paddle construction?

A: Combining carbon fiber with fiberglass leverages the strength and lightweight properties of carbon fiber along with the flexibility and wider sweet spot provided by fiberglass. This composite approach ensures superior control, improved balance, and enhanced durability.

-

thermoforming: Reading the article will provide insights into the heat-based shaping process used to form complex designs and optimize material distribution in manufacturing. ↩ ↩2 ↩3

-

carbon fiber: Reading the article will explain the benefits of carbon fiber, including its high strength-to-weight ratio and contribution to enhanced durability. ↩ ↩2

-

fiberglass composites: Reading the article will provide a deeper understanding of fiberglass composites and how they combine flexibility and strength to improve overall performance. ↩ ↩2

-

Nomex Honeycomb Core: Reading the article will clarify how Nomex honeycomb cores enhance impact absorption and contribute to optimized weight distribution. ↩

-

precision engineering: Reading the article will help you discover how precision engineering techniques ensure consistent quality and superior performance in manufacturing processes. ↩