The answer to the question “Which core material is optimal for pickleball paddles—EVA foam1 or PP core?” is that both materials have unique benefits. Polypropylene (PP) core2 typically offers enhanced durability and cost efficiency while EVA foam typically delivers superior shock absorption and energy return. The final decision depends on your production priorities, target market, and performance requirements.

In today’s competitive sports equipment industry, product development engineers and B2B procurement managers must thoroughly evaluate material options before integrating them into new pickleball paddle designs. Two popular core materials—EVA foam and Polypropylene (PP) core—each offer distinct advantages that affect paddle performance, durability, production costs, and overall user experience. This article provides a detailed technical comparison of these materials to help you make data-supported decisions.

EVA Foam

Ethylene-vinyl acetate (EVA) foam is known for its excellent shock absorption and energy return characteristics. Its flexible structure reduces impact vibrations, making it well-suited for paddles aimed at providing enhanced comfort and a controlled ball response. Additionally, EVA foam has a relatively soft touch and is often chosen for paddles that emphasize player comfort and finesse.

Polypropylene (PP) Core

PP core materials, made from a tough polymer, are valued for their high durability and resilience under repeated impact. Their rigid structure provides a stable hitting surface with improved weight distribution, often resulting in paddles that offer excellent cost efficiency during production. PP cores are a popular choice for products designed for competitive use where long-term durability and consistent performance are critical.

To facilitate a clear understanding of the differences, the comparison below summarizes key factors:

| Property | EVA Foam Core | Polypropylene (PP) Core |

|---|---|---|

| Shock Absorption | Superior; minimizes vibrations for comfort | Good; effective but typically less cushioning |

| Energy Return | High; enhances ball rebound and responsiveness | Moderate; provides stable energy transfer |

| Durability | Typically lower under extreme impact stress | High; withstands repeated heavy impacts |

| Weight Distribution | Can be adjusted with density variation | Provides consistent weight and balance |

| Production Cost | Higher material cost due to specialized features | Lower cost; more economical in large-scale runs |

| Manufacturing Complexity | Requires controlled molding processes | Simpler processing, beneficial for economies |

| Ideal Audience | Players seeking comfort and precision | Competitive players needing robust durability |

This table highlights that while EVA foam excels in reducing impact shock and enhancing energy feedback, PP core is preferable when durability and cost-effectiveness are paramount. The choice between these two cores ultimately depends on whether the design emphasis is on player comfort or long-term resilience and production efficiencies.

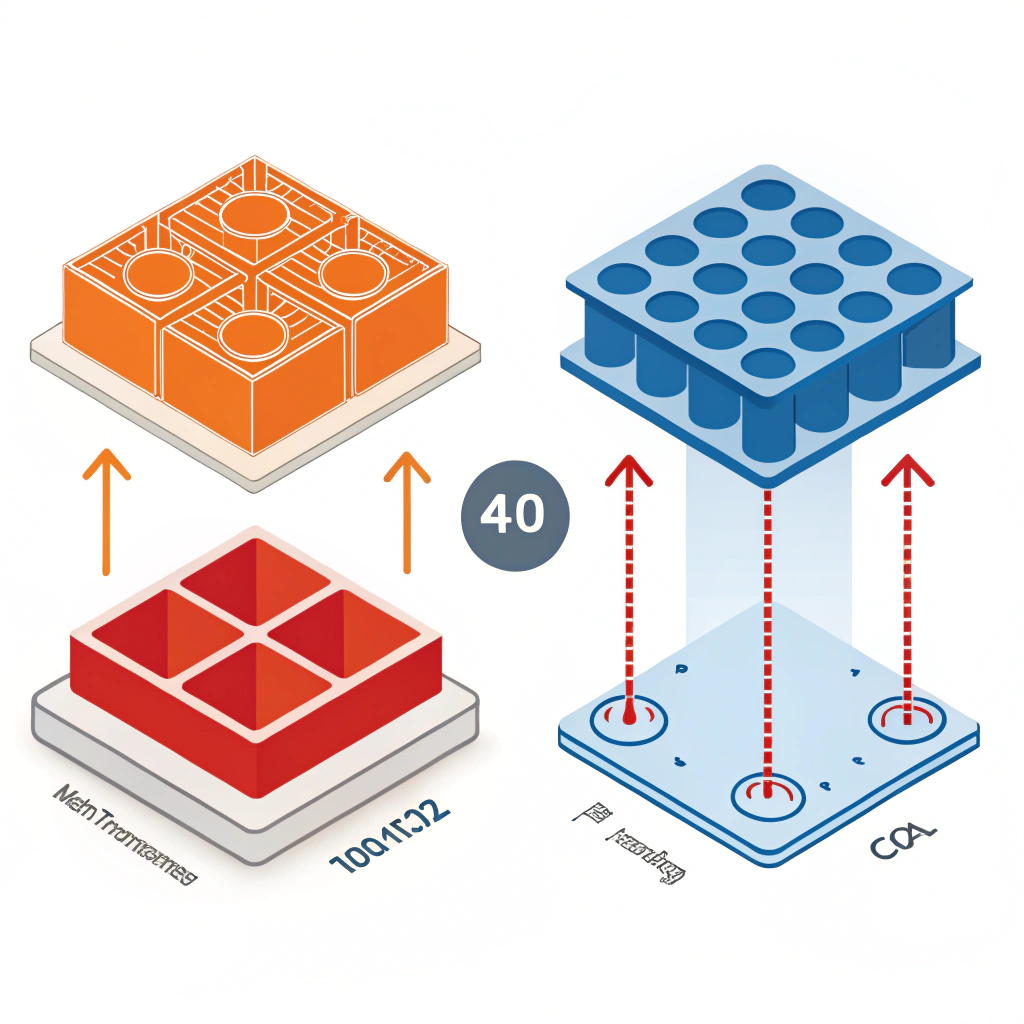

Both EVA foam and PP core materials require distinct production methods, and the chosen manufacturing process can significantly influence paddle performance:

EVA Foam Production

Manufacturing with EVA involves precise control of temperature and pressure during molding. As a result, processes such as hot pressing or thermoforming3 are often deployed to achieve the right balance of softness and structural integrity. This level of control helps maintain the intended shock absorption characteristics while ensuring that any variations in density are fine-tuned to produce optimal performance. However, this technique is more costly and time-consuming, impacting overall production efficiency.

PP Core Production

In contrast, PP cores are typically produced using methods that emphasize speed and consistency, such as cold pressing combined with injection molding4. These processes allow for lower production costs and are easily scalable, making PP a favorite among manufacturers focused on high-volume production. Additionally, the inherent strength of PP lends itself to designs that need to consistently meet demanding impact resistance standards, even over extended playing periods.

When evaluating EVA foam and PP cores, several technical metrics come into play:

-

Shock Absorption:

- EVA foam’s molecular structure absorbs and disperses impact forces. This characteristic is particularly appealing for players who experience frequent and vigorous impacts.

- PP cores, while resilient, are more rigid, leading to a firmer paddle feel that might transfer more vibration to the player’s hand over time.

-

Energy Transfer Efficiency:

- The flexible nature of EVA allows it to compress and then rebound quickly, contributing to better energy return and potentially faster play.

- PP, with its consistent density, offers a stable energy transfer which can benefit players looking for precise ball control and reduced unpredictability during play.

-

Durability and Longevity:

- EVA foam, though excellent for vibration dampening, may deteriorate faster under chronic high-impact scenarios due to its softer state.

- PP maintains its integrity over prolonged use and is less susceptible to wear, making it a more dependable choice in highly competitive environments.

-

Weight and Balance:

- The weight distribution in a paddle is crucial for maneuverability. EVA cores can be engineered to modify paddle weight but require added precision to maintain balance.

- PP cores are naturally stable, providing consistent weight distribution across large production batches, which simplifies quality control and meets stringent performance standards.

Deciding between EVA foam and PP core goes beyond just material properties; it also aligns with targeted use cases.

-

For High-Performance Competitive Play:

Manufacturers seeking paddles for professional-level competition might favor EVA foam if the priority is on shock absorption and rapid energy return. However, it is essential to balance against the increased production costs and the possibility of reduced long-term durability under extreme conditions. -

For Mass Production and Recreational Use:

When production efficiency and consistent durability are paramount, PP core materials offer a cost-effective and reliable solution. Competitive players and organizations that demand long-lasting performance at scale tend to gravitate toward PP cores, as these materials better withstand the repeated impacts common in extended play sessions. -

Hybrid Designs:

In some cases, manufacturers are exploring hybrid core designs5 that blend EVA and PP characteristics to optimize performance. Such designs can leverage the cushioning benefits of EVA while using PP components to reinforce structural integrity and balance. This approach requires careful material integration but may ultimately offer the best of both worlds for versatile player needs.

To illustrate, consider a case where a manufacturer used a composite core that incorporated EVA for shock absorption in the central region while lining the periphery with PP for reinforcement. This design provided excellent control and comfort, as evidenced by extended play testing and positive feedback from professional athletes.

When integrating these core materials into your paddle manufacturing process, keep the following factors in mind:

-

Material Consistency:

Maintaining consistent material quality is critical, especially with EVA foam, where slight variations in density can have significant performance effects. -

Environmental Factors:

Temperature and humidity during both the manufacturing process and actual gameplay can alter the physical properties of the core materials. PP cores typically offer more stability under varied environmental conditions. -

Customization and Branding:

With the flexibility of EVA, there are more opportunities for brands to innovate in paddle customization, such as modifying core thickness for a tailored player feel. On the other hand, PP cores may limit certain design flexibilities but offer a robust structural base for custom graphic overlays and on-demand printing. -

Quality Control:

Implement rigorous testing protocols that simulate real-world impacts to ensure that the chosen core material meets performance expectations over its lifespan. This involves both lab-based testing and pilot production runs.

Selecting the appropriate core material for your pickleball paddles is a balance of technical consideration, cost constraints, and targeted performance outcomes. EVA foam cores offer excellent shock absorption, energy return, and a comfortable feel—well-suited for high-performance play where player feedback is paramount. In contrast, PP cores excel in durability, cost efficiency, and ease of manufacturing, making them an ideal choice for products designed for long-term, heavy-duty use.

In summary, here are the key takeaways:

• Choose EVA foam if your goal is to maximize player comfort and enhance high-speed energy transfer, especially in paddles tailored for precision control.

• Opt for PP core if durability, production consistency, and cost efficiency are your primary concerns, particularly for high-volume manufacturing and competitive endurance.

• Consider hybrid designs that exploit the advantages of both materials if your product strategy allows for innovative engineering solutions.

Ultimately, the optimal choice will depend on your specific product positioning, market demands, and manufacturing capabilities. It is advisable to run pilot tests and consult with material specialists to ensure that your final product meets both performance and economic expectations. An informed decision in this area can significantly enhance your product’s performance in the market, bolster brand reputation, and improve overall customer satisfaction.

People Also Ask

Q1: What is the main performance difference between EVA foam and PP core in pickleball paddles?

A1: EVA foam generally offers superior shock absorption and rapid energy return for enhanced player comfort, whereas PP core provides robust durability, consistent structural integrity, and better cost efficiency.

Q2: How do manufacturing processes differ for paddles using EVA foam versus PP core?

A2: Paddles with EVA foam typically require controlled processes like hot pressing or thermoforming for optimal cushioning, while PP cores are manufactured using simpler methods such as cold pressing, which supports high-volume, cost-effective production.

Q3: Which core type is recommended for competitive play in terms of durability and cost-effectiveness?

A3: PP core is often recommended for competitive play due to its high durability and economical production process, though EVA foam may be chosen if superior shock absorption and energy return are prioritized.

-

EVA foam: Read this article to understand the composition, properties, and applications of EVA foam in sports equipment manufacturing, including its benefits for shock absorption and energy return. ↩

-

Polypropylene (PP) core: Explore detailed insights on Polypropylene cores, including their chemical properties, durability, and cost efficiency in high-volume production. ↩

-

Thermoforming: Learn about thermoforming processes, which involve shaping materials under heat and pressure, and how they are applied in producing materials with precise structural characteristics. ↩

-

Injection molding: Discover the injection molding process, its advantages in scalability and consistency, and its role in efficient production for durable products. ↩

-

Hybrid core designs: Understand the concept of hybrid core designs that combine different materials to optimize product performance, along with techniques for effective material integration. ↩