A series of innovative Custom Pickleball Paddle Projects1 have achieved viral success by marrying creative design, advanced manufacturing techniques, and cutting-edge marketing strategies. These projects demonstrate that combining customization with quality production can not only enhance brand identity but also drive tremendous market buzz for distributors and retailers.

In today’s competitive sports equipment market, standing out is more critical than ever. Businesses must invest in unique product innovations and tailor-made designs to catch the eyes of consumers and influencers alike. Custom pickleball paddle projects provide a fantastic example of how paddle customization2 can turn an ordinary sports accessory into a viral sensation. Let’s explore the challenges faced by companies, the manufacturing techniques that make these custom paddles unique, and actionable strategies for creating similar successful projects.

Distributors and retail chains often struggle with differentiating their product lines in a market saturated with similar offerings. The pickleball sector is no exception. Many buyers are enticed by performance metrics or price points, but few options are as eye-catching as custom-designed paddles that tell a story. Without innovation, companies risk blending into the background, facing stiff competition from established brands that already have strong market recognition.

Key challenges include:

• The need to incorporate advanced technology into traditional sports equipment.

• Achieving a balance between artistic design and technical performance.

• Convincing stakeholders that investment in customization will yield tangible marketing and revenue benefits.

Several factors make it tough for businesses to launch standout custom paddle projects:

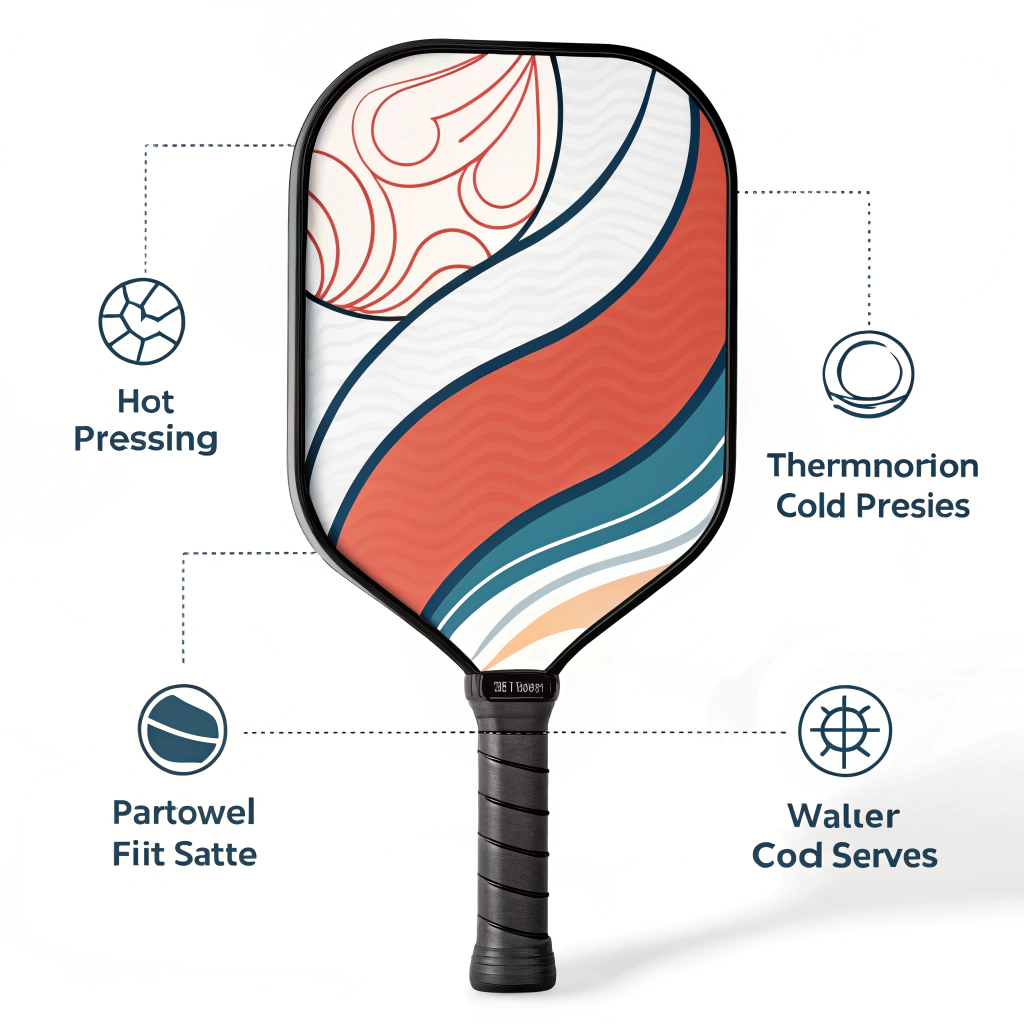

• Uniformity in Production: Standard manufacturing processes like hot pressing and cold pressing often result in uniform products, making it difficult for a brand to highlight innovation.

• Limited Customization Options: Many factories stick to proven methods without exploring advanced techniques or creative material blends.

• Marketing Communication Gaps: Even when innovative designs are available, poor communication of the product’s benefits and unique selling points can fail to capture the audience's attention.

• Cost Concerns: Customization often entails higher production costs. Retailers may hesitate if the return on investment (ROI) is unclear.

Understanding these root causes sets the stage for developing a robust solution that not only enhances product appeal but also incorporates strong factory expertise and modern manufacturing techniques.

One of the prime reasons behind viral success is the intelligent use of advanced production processes. At NEX Pickleball, we leverage our expertise in hot pressing3, cold pressing4 and thermoforming5 to produce paddles that not only perform exceptionally on the court but also captivate potential customers.

This process involves heating materials to form solid paddles under pressure. Its advantages include high production efficiency and excellent impact resistance, making it ideal for producing durable high-performance paddles. However, the process may slightly alter the natural feel of materials, a trade-off many competitive projects willingly accept for the strength it offers.

Cold pressing preserves the material’s inherent properties, ensuring better control and ball feel. It is particularly beneficial for designs that demand precise thickness management and ergonomic balance. Although it takes longer than hot pressing, the level of precision it offers is invaluable when creating unique custom projects that need to demonstrate both performance and aesthetic appeal.

The thermoforming process allows for complex shapes and designs. Heating the materials to a softening point and molding them into intricate forms enables us to realize custom patterns and textured surfaces that stand out visually. This process is perfect for custom paddles aimed at making a strong visual and functional statement in viral projects.

These processes not only provide product strength and durability but also allow for creative customization that can be an essential driver of viral marketing success.

The following attributes have proven essential in categorizing a custom paddle project as a viral success:

-

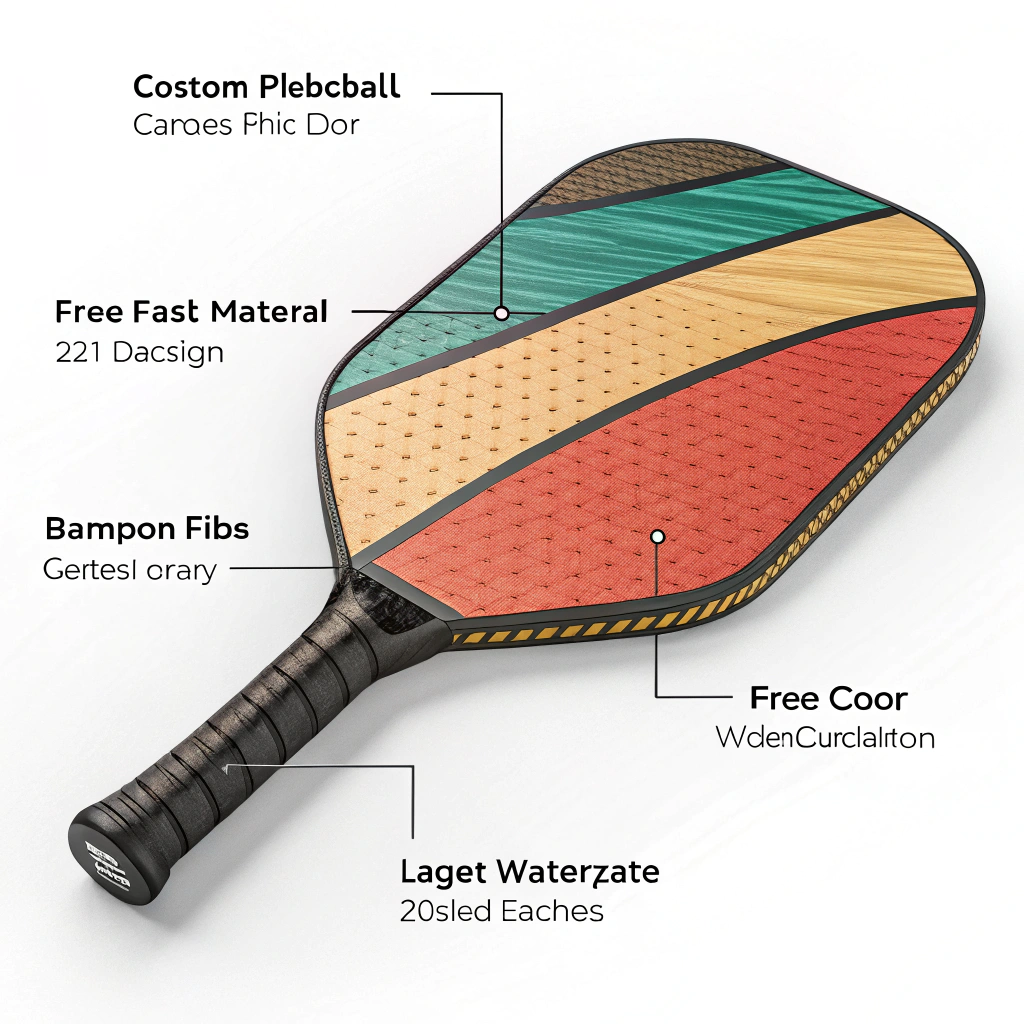

Innovative Material Combinations:

Mixing materials such as 3K, 12K, and T300 carbon fibers with E-Glass Fiberglass or Bamboo Core Composites can produce paddles that offer a balanced mix of power, durability, and control. These innovative combinations not only improve performance but also give each paddle a distinct look and feel. -

Unique Design Elements:

Incorporating custom prints, intricate surface textures, and bold color schemes can capture the imagination of both players and audiences on social media. Using print-on-demand services, designs can be tailored to reflect a brand’s identity, political campaign, or sporting event, making them conversation starters in the digital age. -

Advanced Custom Production Options:

With techniques that allow for personal choice regarding grip sizes, core materials, and exterior textures, brands can offer limited editions, artist collaborations, or even interactive design processes. These options lead to a heightened sense of exclusivity and collectability, encouraging both players and influencers to share their unique finds.

Below is a table summarizing the core customization features and their respective production processes:

| Customization Feature | Production Process | Key Benefits |

|---|---|---|

| Innovative Material Mix | Hot Pressing / Thermoforming | Enhanced strength and unique visual appeal |

| Enhanced Aesthetic Designs | Thermoforming | Intricate shapes and bold color options |

| Personalized Grip and Core Options | Cold Pressing | Precise control and tailored player experience |

| Custom Print on Demand | Combined Processes | Unique, limited edition aesthetics |

Many successful custom paddle projects started with a problem-solving approach. Here are two case studies that exemplify how customization can drive market buzz and deliver strong ROI.

A leading sports equipment distributor partnered with a renowned graphic artist to launch a limited-edition series of paddles. The collaboration blended visually striking designs with the technical benefits of a T300 Carbon Fiber framework and Polymer Honeycomb Core. The project followed these key steps:

• Initial brainstorming to identify shared values between the brand and the artist.

• Prototyping using thermoforming to achieve intricate textures coupled with personnalized print-on-demand designs.

• Iterative market testing where early feedback helped refine aesthetics and performance metrics.

• A coordinated social media campaign that leveraged influencer partnerships and viral marketing strategies.

In just three months, the series sold out 80% of its initial production run, fueled by online buzz and influencer endorsements. The project's success lay in its seamless integration of advanced manufacturing with a creative marketing narrative.

Another project focused on offering customers an interactive tool to design their own paddles online. With a commitment to both innovation and customer engagement, the distributor provided detailed options for paddle core materials, surface textures, and color schemes. The factory used cold pressing techniques to ensure that every custom paddle met precision specifications while retaining a high degree of personalization.

Key differentiators included:

• Real-time design previews that allowed customers to visualize their choices.

• On-demand printing that ensured each paddle was truly unique.

• A streamlined back-end production process that integrated with digital order systems.

The result was a viral trend among pickleball communities, where user-generated designs were shared widely on social media. This case study underscores how factory-level innovation and digital transformation can work in tandem to drive both sales and brand loyalty.

For businesses considering a foray into custom paddle projects, here are some essential insights:

• Leverage Advanced Manufacturing: Choosing the right combination of hot pressing, cold pressing, and thermoforming processes can significantly influence the product’s performance and aesthetic appeal.

• Embrace Material Innovation: Experiment with different combinations of carbon fibers, fiberglass, and core materials to create paddles with exceptional attributes tailored to target markets.

• Prioritize Customization Options: The ability to offer custom prints and personalized design options sets your product apart from competitors and fosters an emotional connection with consumers.

• Integrate Marketing and Manufacturing: Collaborate closely between production teams and marketing experts to ensure that the innovative features of the paddle are communicated effectively both online and offline.

• Monitor and Iterate: Use market feedback and performance data to continuously refine product offerings, ensuring they remain at the cutting edge of both design and functionality.

These practices provide not just enhanced performance and durability but also a roadmap for creating a viral hit that resonates with modern consumers and influencers.

Custom pickleball paddle projects that go viral are more than just a trend—they represent a fusion of technology, design, and strategic marketing. Companies that position themselves at the intersection of these elements will likely see significant benefits in both brand differentiation and market share growth.

For purchasing managers and business development directors exploring innovative product differentiation, consider:

- Conducting a detailed feasibility study to assess customization potential for your current product lines.

- Partnering with manufacturers who are experts in advanced production methods and are willing to experiment with creative design techniques.

- Initiating pilot projects that involve artist collaborations or interactive customer experiences to gauge market response.

By following these actionable steps, businesses can harness the power of Custom Pickleball Paddles to drive brand awareness, energize sales, and create memorable products that generate buzz both on and offline.

Remember, in a world where customization is king, a unique product not only meets performance expectations but also becomes a storytelling vehicle that propels your brand toward viral success.

Q: What makes custom pickleball paddles go viral?

A: Custom pickleball paddles often go viral due to their innovative designs, unique material combinations, and engaging marketing strategies. The use of advanced manufacturing techniques like hot pressing, cold pressing, and thermoforming enables the production of paddles that not only perform well but also capture consumer attention.

Q: How can advanced production techniques improve paddle customization?

A: Advanced production techniques such as thermoforming allow for intricate and personalized designs, while cold pressing ensures precise control over material properties. These methods help create paddles that are both visually appealing and technically superior, making them attractive for custom projects and viral marketing.

Q: What are the benefits of integrating custom print on demand in paddle manufacturing?

A: Integrating custom print on demand allows for unique design variations and limited-edition releases, which can enhance a product’s market appeal. It also provides flexibility in branding and personalization, leading to improved customer engagement and a stronger overall brand identity.

-

Custom Pickleball Paddle Projects: Read more about how innovative, tailor-made products can drive market buzz and differentiate your brand in a competitive landscape. ↩ ↩

-

paddle customization: Learn how personalized design and production techniques can transform ordinary sports equipment into unique selling propositions that capture consumer interest. ↩ ↩

-

hot pressing: Discover the benefits of hot pressing, a production process that uses heat and pressure to enhance material durability and performance in manufacturing. ↩ ↩

-

cold pressing: Explore how cold pressing preserves material integrity and contributes to superior product control and precision in custom manufacturing. ↩ ↩

-

thermoforming: Understand how thermoforming enables complex designs and shapes, offering a versatile approach to creating visually striking and high-performance products. ↩ ↩