Consistent design in pickleball OEM manufacturing1 is essential for ensuring high performance, durability, and brand reliability. It requires a careful balance of advanced production processes, material selection, and quality control strategies that drive both product excellence and manufacturing efficiency.

In the competitive world of pickleball, where precision and performance go hand in hand, maintaining design consistency during OEM production is paramount. Not only does it minimize defects and enhance product reliability, but it also strengthens your brand reputation. Manufacturers like NEX Pickleball have mastered the art by integrating advanced techniques such as hot pressing, cold pressing, and thermoforming2 while leveraging premium materials like carbon fiber3, fiberglass, and composite cores.

Many procurement managers and product developers face challenges in ensuring uniform quality across large-scale production. Variations in design and material performance can lead to inconsistencies that compromise the paddle's playing characteristics—affecting both control and power. This is particularly crucial in pickleball paddles where even the slightest deviation in design can alter ball response, impact vibration, and overall user experience.

Inconsistent design can result from:

- Variability in the manufacturing process.

- Fluctuations in the quality of raw materials.

- Inadequate quality control measures.

- Inefficient production techniques that fail to maintain structural integrity.

These issues not only reduce performance but also increase the risk of customer dissatisfaction and higher warranty claims.

To overcome these challenges, it is vital to conduct a thorough analysis of the factors affecting design consistency in OEM manufacturing. Key aspects include:

-

Production Process Techniques:

- Hot Pressing: Offers high production efficiency and strong paddles with excellent impact resistance. However, it requires heavy investment and sometimes alters material properties.

- Cold Pressing: Delivers precise control over paddle thickness and retains material properties, but has longer production cycles.

- Thermoforming: Enables crafting of complex, intricate designs, though it is time-consuming and typically reserved for premium products.

-

Material Selection:

- Carbon Fiber Variants (3K, 12K, T300): Each type offers specific performance attributes such as rebound force, durability, and tensile strength.

- Fiberglass and Composite Materials: Provide a balance between power and control, enhancing both the sweet spot and overall ball feel.

- Core Materials (Nomex, Aluminum, Polymer Honeycomb): Impact how the paddle responds to shock and vibration, crucial for player comfort and product longevity.

-

Quality Control and Testing:

- Moving beyond traditional trial and error, integration of digital inspections and advanced QC measures ensures that every paddle meets strict performance standards.

- Emphasis on ergonomic design and precise weight distribution is key to achieving consistent hitting performance.

-

Manufacturing Equipment and Expertise:

- Using automated machinery with pressure control can significantly reduce human error.

- Skilled technicians and engineers must collaborate to fine-tune each step of the process to maintain product uniformity across batches.

Procurement managers and OEM coordinators can implement the following strategic solutions to ensure superior design consistency:

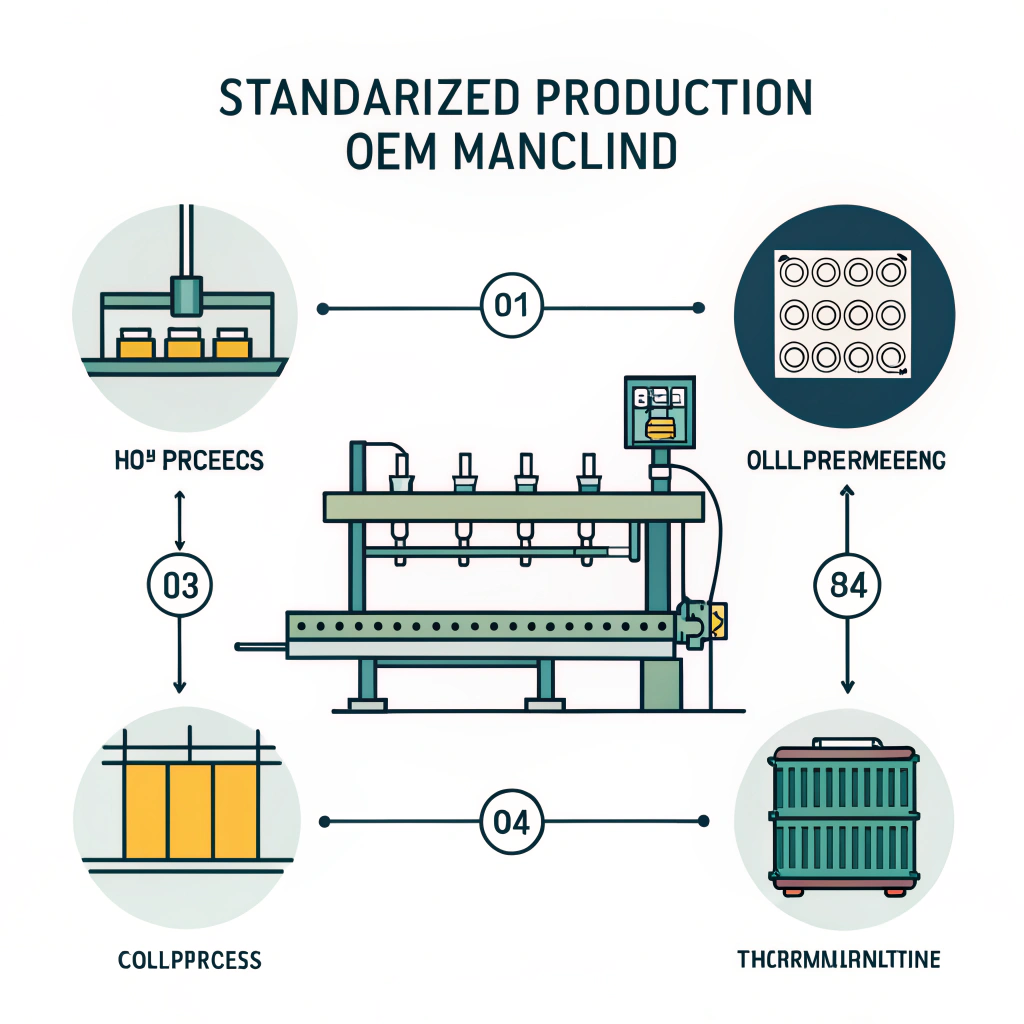

Standardization is the backbone of reliable manufacturing. Establish clear production protocols that outline the specific methods and quality benchmarks to be met during:

- Hot Pressing: Ensure temperature and pressure settings are calibrated consistently, and equipment is routinely serviced.

- Cold Pressing: Adopt precise measurement tools to control paddle thickness with minimal variation.

- Thermoforming: Use customized molds to guarantee that complex designs are replicated reliably across production runs.

Incorporate stringent quality control measures by:

- Setting up checkpoints after each production phase.

- Utilizing both manual inspections and automated sensors.

- Conducting batch testing to monitor for deviations in performance attributes like rebound force and vibration reduction.

Implementing a regular QC audit schedule ensures that any deviations are detected early, and corrective measures are applied before further production.

Modern manufacturing technologies can significantly reduce inconsistencies:

- Digital Manufacturing Solutions4: Employ computer-aided design (CAD) systems and computer numerical control (CNC) machines for precision work.

- Sensors and IoT Integrations5: Use real-time monitoring tools to track temperature, pressure, and material properties during the manufacturing process.

- Data Analytics: Utilize performance data to continuously refine production parameters and improve consistency over time.

Choosing the right materials is fundamental:

- Carbon Fiber: Select the appropriate variant based on performance needs. For example, 3K carbon fiber is beneficial for high rebound force, whereas 12K provides superior hardness and longevity.

- Composite Options: Materials like bamboo core composites or a mix of carbon fiber and fiberglass deliver a balanced performance, essential for targeted play styles.

- Core Materials: Decide on the core type based on players’ feedback and specific game scenarios—Nomex or Aluminum for stability versus Polymer for enhanced vibration control.

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency; excellent impact resistance | High investment; possible alteration of material feel |

| Cold Pressing | Precise control; retains material properties | Longer production cycles |

| Thermoforming | Allows complex designs; maintains material stability | Higher equipment cost; slower production speed |

Consistent product enhancements require a feedback mechanism:

- Solicit input from professional players and recreational users to gauge paddle performance.

- Integrate feedback into the design iteration process to address any emerging inconsistencies.

- Monitor key performance indicators (KPIs) such as production yield, defect rate, and customer returns to adjust processes in real time.

At NEX Pickleball, design consistency is the cornerstone of manufacturing high-performance pickleball paddles, especially for renowned brands like Joola and Selkirk. Consider the following practices that have contributed to their success:

- Collaborative Engineering: NEX Pickleball’s engineering team collaborates closely with product designers to fine-tune materials and production processes. This holistic approach ensures all aspects—from paddle thickness to core density—are optimized.

- Advanced Testing Facilities: Every paddle is rigorously tested for parameters such as weight distribution, vibration absorption, and surface texture. The data collected during these tests feeds directly into the production process, allowing for continuous adjustments.

- Use of Premium Materials: Through a judicious choice of premium materials (T300 carbon fiber, E-Glass fiberglass, and Nomex honeycomb cores), NEX Pickleball ensures that every paddle meets the high standards required for both competitive play and recreational use.

This comprehensive approach has not only improved production consistency but has also significantly enhanced brand reliability, making NEX Pickleball a trusted partner in the industry.

While striving for design consistency, several precautions need attention:

- Environmental Factors: Changes in temperature and humidity can affect material behavior during both hot and cold pressing. Ensure controlled environments during key production stages.

- Equipment Calibration: Regular calibration of machinery is essential. Even minor deviations can lead to significant design differences over large production runs.

- Training and Skill Development: Invest in training programs for technicians and production staff to ensure they are adept with the latest technologies and quality standards.

- Supply Chain Coordination: Work closely with material suppliers to secure high-quality raw materials regularly. Establish long-term partnerships to benefit from consistent material quality.

Manufacturers should not only focus on the production stage but also on post-production inspections to align every paddle with the specified design requirements.

Design consistency in OEM pickleball paddle production is not just about achieving uniform aesthetics, but it is a key driver of performance. By standardizing production processes, applying rigorous quality control, leveraging advanced technologies, and optimizing material selection, procurement managers and product developers can achieve superior consistency that enhances both durability and on-court performance.

Action recommendations:

- Revisit production processes and identify areas where standardization can minimize variability.

- Invest in advanced quality control tools and continuous improvement systems.

- Strengthen partnerships with suppliers to ensure the quality of raw materials.

- Engage with industry experts for regular process audits and updates on best practices.

Adopting these strategic solutions will ensure that your OEM production processes not only meet but exceed the expectations of high-performance performance standards, cementing a strong long-term partnership with your manufacturing providers.

Q: Does thickness matter in pickleball?

A: Yes, the thickness of a pickleball paddle plays a crucial role in balancing power and control. Thinner paddles typically offer greater pop and power due to their reduced weight, enhancing agility. Conversely, thicker paddles provide better control and consistency, making them suitable for players who prefer precision.

Q: How to get consistent in pickleball?

A: Consistency in pickleball starts with having a minimal, controlled motion during play. Efficient movement and a stable, well-designed paddle contribute significantly to delivering consistent shots. Focusing on proper technique and using paddles engineered for uniform performance can further enhance consistency.

Q: What makes expensive pickleball paddles better?

A: Higher-end pickleball paddles often incorporate advanced materials like carbon fiber and fiberglass, along with precise manufacturing processes. These materials provide improved power, control, and reduced vibration. The overall quality of construction and rigorous testing also contribute to the superior performance seen in expensive paddles.

-

OEM manufacturing: Click to read an article that explains how Original Equipment Manufacturing drives integrated production strategies and enhances brand value in B2B markets. ^Return ↩

-

Thermoforming: Click to learn about the thermoforming process, its benefits in creating complex designs, and its applications in high-performance manufacturing. ^Return ↩

-

Carbon fiber: Click to explore comprehensive insights into carbon fiber variants, their properties, and why they are crucial for advanced material applications in performance products. ^Return ↩

-

Digital Manufacturing Solutions: Click to understand how digital manufacturing solutions like CAD and CNC improve precision and efficiency in modern production environments. ^Return ↩

-

IoT Integrations: Click to discover how IoT integrations are revolutionizing real-time monitoring and quality control in manufacturing processes. ^Return ↩