Quick Answer: Paddle deflection is the degree to which a paddle bends under pressure and directly influences rebound force, ball control, and overall gameplay dynamics. Minimizing unwanted deflection while maintaining a balance between power and precision is crucial for product performance and competitiveness.

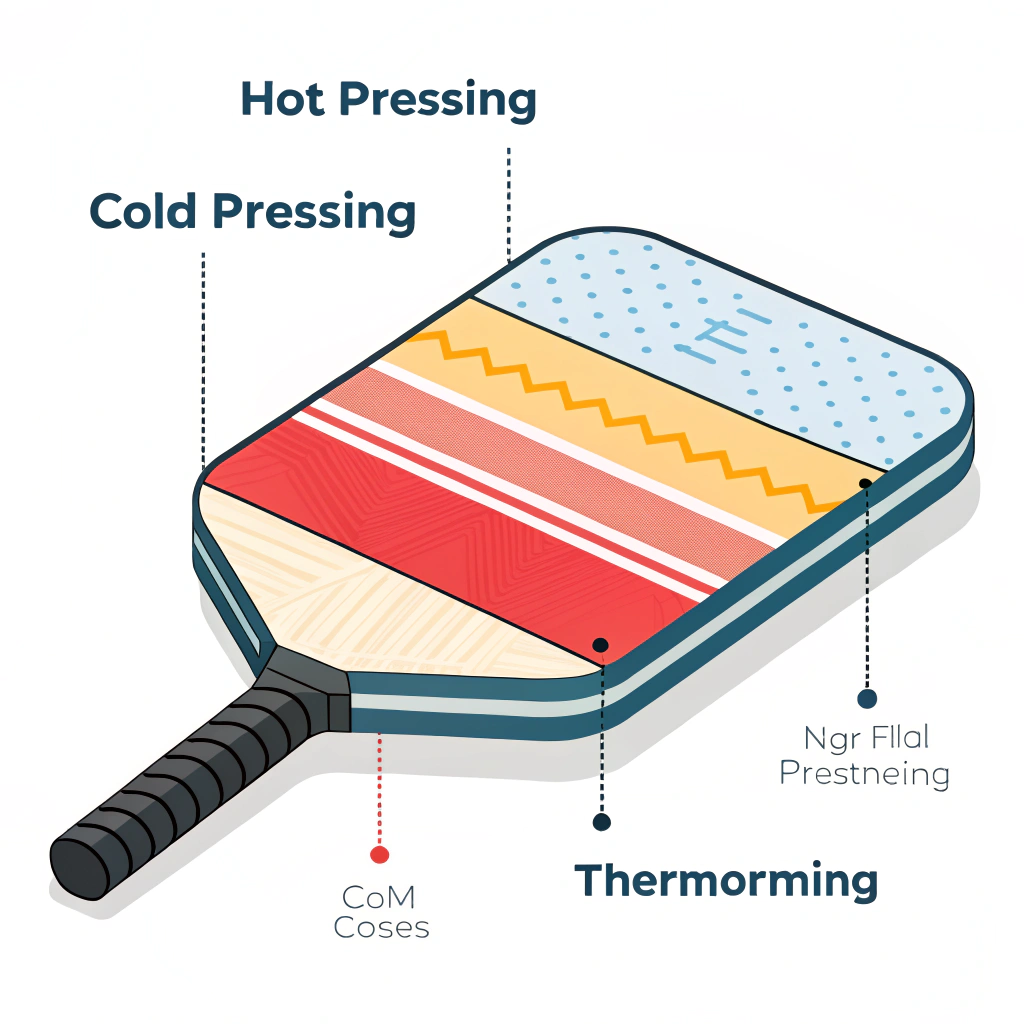

Paddle deflection is one of the most critical engineering parameters in the design and production of high-performance pickleball paddles. It influences how the paddle responds upon ball impact, affecting rebound force, control, and even vibration reduction. In this article, we provide a comprehensive analysis of paddle deflection, examining its root causes, technical implications, and practical solutions drawn from industry-leading production processes like hot pressing, cold pressing1, and thermoforming2.

For decision-makers and technical procurement managers in the sports equipment distribution industry, understanding paddle deflection is essential. The performance of a pickleball paddle heavily depends on how much it deflects when a ball strikes it. Excessive deflection can lead to energy loss and reduced ball speed, whereas a more rigid paddle might provide power but could increase vibration and reduce comfort.

Key challenges include:

- Determining the optimal balance between power and control.

- Understanding how various materials and manufacturing techniques affect the paddle’s stiffness.

- Meeting compliance and performance standards while ensuring player safety and comfort.

Paddle deflection is influenced by several factors:

- Material Properties: The type of material used (e.g., 3K carbon fiber, 12K Carbon Fiber3, fiberglass, composites) plays a significant role. Each material offers varying levels of stiffness, flexibility, and durability.

- Core Construction: The inner core materials such as Nomex Honeycomb4, Aluminum Honeycomb, and Polymer Honeycomb determine how much the paddle will bend during impact.

- Manufacturing Process: Techniques like hot pressing, cold pressing, and thermoforming not only impact the paddle’s surface and finish but also its structural integrity.

Players looking for precision will prioritize paddles with low deflection, as minimized bending results in faster rebound, enhanced ball control, and less energy transfer into vibrations that can lead to player fatigue.

The manufacturing process of a paddle is critical in controlling deflection. NEX Pickleball employs state-of-the-art processes to ensure that the finished products meet high-performance standards.

Hot pressing involves heating the paddle’s material while applying pressure. This process yields:

- High production efficiency.

- Superior impact resistance.

- Enhanced structural integrity.

However, this method may alter certain material properties which can influence the paddle's tactile feel.

Cold pressing uses mechanical pressure at room temperature, preserving the inherent properties of the paddle materials:

- Enables precise control over thickness and structural integrity.

- Maintains the natural elasticity of the composite materials.

- Provides exceptional ball feel and responsiveness.

The trade-off here is a longer production cycle and the increased need for precision equipment.

Thermoforming heats the material to a malleable state before molding:

- Ideal for complex designs and achieving even material distribution.

- Supports the creation of paddles with specific deflection characteristics.

- Perfect for custom-made or premium product lines.

Despite its benefits, thermoforming requires longer production times and higher investments in equipment.

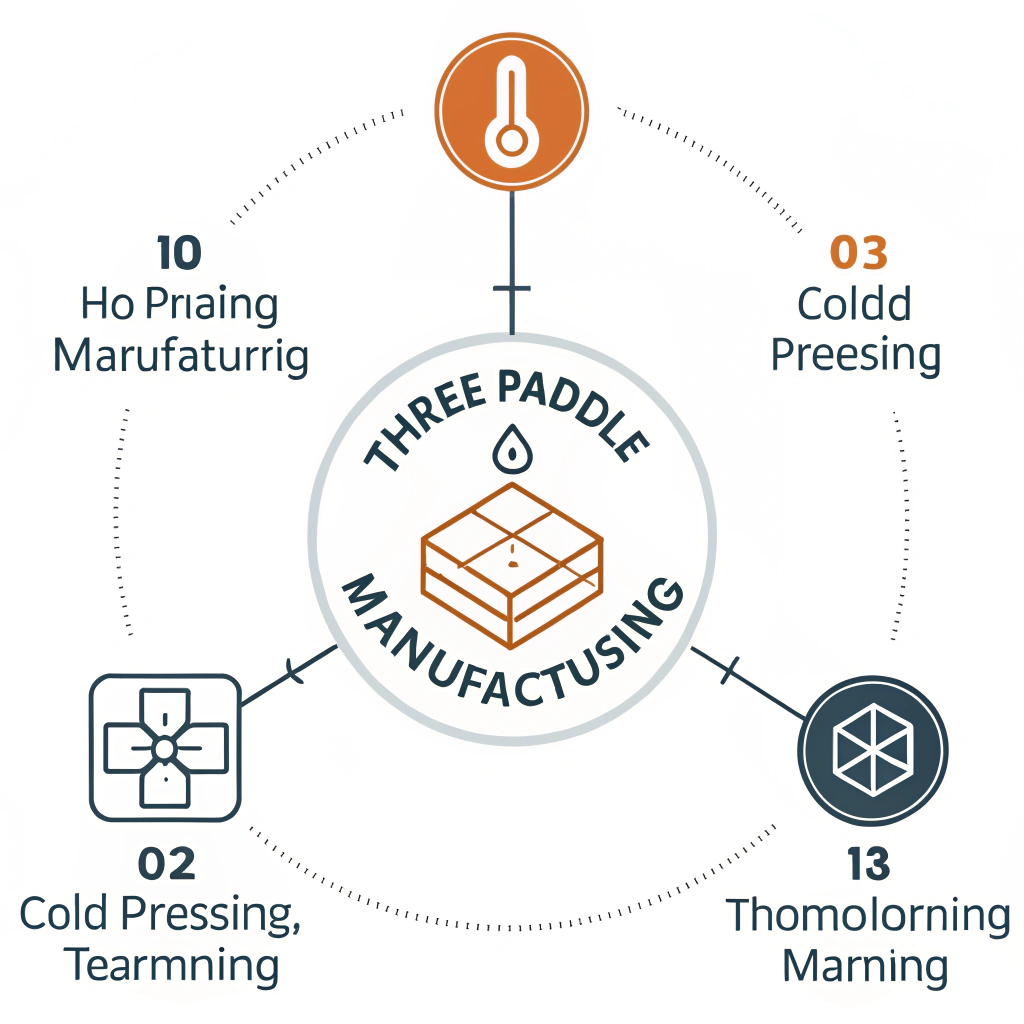

Below is an overview of the three processes:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, structural integrity | Potential alteration of material properties |

| Cold Pressing | Precise control over material properties, excellent ball feel | Longer production cycle, requires precise equipment |

| Thermoforming | Enables complex designs, precise material distribution, custom-made options | Longer production time, higher equipment cost |

Deflection not only has an engineering basis but also a direct influence on gameplay:

- Rebound Force: Lower deflection retains more energy from the ball impact, providing quicker rebound speeds and thus enabling faster gameplay.

- Ball Control and Accuracy: Excessive flex can lead to inaccurate shots. By balancing material stiffness and paddle design, manufacturers improve player control.

- Vibration Reduction: Deflection can introduce unwanted vibrations. Advanced techniques and carefully selected materials help in minimizing these vibrations, leading to a smoother playing experience.

- Player Comfort: A paddle that minimizes harmful vibrations enhances overall comfort, particularly for prolonged play sessions.

Understanding these impacts helps procurement managers select paddles that offer a competitive advantage by ensuring optimal energy transfer and player ergonomics.

deflection test5 is an industry-standard procedure used to measure the degree of bending in a paddle when subjected to a controlled force. Key aspects of the test include:

- Controlled Force Application: The paddle is subjected to an exact force which simulates ball impact conditions during gameplay.

- Measurement of Deformation: Highly sensitive instruments capture the precise amount of deflection, which is then compared against established performance benchmarks.

- Compliance with Rules: The results ensure that the paddle adheres to regulatory limits and maintains consistency across production batches.

This test is vital because it not only confirms the paddle's stiffness but also predicts its overall performance in real-world scenarios. It informs the design process and helps optimize material choice and manufacturing methods.

To achieve the best balance between power, control, and comfort, consider the following solutions and best practices:

-

Material Selection:

- Use 12K Carbon Fiber for paddles that demand high power and durability.

- Opt for Fiberglass when a larger sweet spot and excellent ball control are desired.

- Implement composite materials to combine the strengths of carbon fiber and fiberglass.

-

Core Engineering:

- Choose a Nomex Honeycomb Core for high shock absorption and durability.

- Consider Aluminum Honeycomb Cores for balanced weight distribution and enhanced precision.

- For recreational play and a softer feel, Polymer Honeycomb Cores can be the ideal choice.

-

Optimized Manufacturing Process:

- Deploy cold pressing to maintain material integrity and precise thickness control.

- Apply thermoforming methods for custom prototypes with intricate design requirements.

- Use hot pressing for large-scale production while carefully calibrating the process to maintain material properties.

-

Rigorous Testing:

- Implement a robust deflection test procedure to ensure that each paddle meets performance benchmarks.

- Use data collected from testing to refine and optimize paddle design continuously.

-

Feedback Loop:

- Establish a continuous improvement process that incorporates feedback from professional players.

- Analyze performance data and tweak material/paddle design to enhance gameplay performance continually.

These solutions can be integrated into the production process to offer paddles that meet both technical performance criteria and the expectations of competitive players.

At NEX Pickleball, we leverage our expertise in material science and manufacturing to produce paddles that excel across multiple performance dimensions. Here’s how we manage deflection:

- Advanced Material Combinations: By combining T300 Carbon Fiber with fiberglass or bamboo core composites, our paddles achieve the ideal balance between stiffness and flexibility. This combination helps to optimize rebound force and reduce vibrations.

- Precision Production Techniques: Our production lines utilize state-of-the-art cold pressing and thermoforming methods. These processes ensure a precise control over the paddle’s structure and deflection characteristics.

- Comprehensive Testing: Every paddle produced undergoes a rigorous deflection test. The data collected helps us to fine-tune our processes, ensuring that every batch meets our strict performance standards.

The result is a paddle that not only complies with the highest industry standards but also provides players with superior control, power, and comfort during play.

While controlling paddle deflection is critical for improving performance, there are several limitations and considerations to keep in mind:

- Material Variability: Different batches of carbon fiber or fiberglass may have slight variations, affecting consistency. Quality control measures must be diligently applied.

- Process Trade-Offs: Each manufacturing process has its strengths and weaknesses. Selecting a process requires balancing production efficiency with the desired paddle characteristics.

- Cost Implications: Advanced materials and precise manufacturing methods can increase production costs. It is important to assess cost-to-performance ratios when choosing production techniques.

- Player Preferences: The ideal balance of deflection may vary among players. Customization options allow players to select paddles tailored to their specific performance needs, whether for aggressive gameplay or finely tuned control.

Understanding these constraints further solidifies the importance of ongoing research, testing, and collaboration with end-users during the product development cycle.

In summary, paddle deflection is a key determinant of gameplay performance in pickleball. By understanding and controlling deflection through careful material selection, advanced production techniques, and rigorous testing protocols, manufacturers can deliver paddles that offer both high power and precise control.

Actionable recommendations for decision-makers:

- Evaluate the technical specifications and deflection test results during the procurement process.

- Consider the balance between production efficiency and material performance given your target market.

- Work with OEM partners who can offer customization options to meet the diverse needs of professional and recreational players.

These strategies will help you make informed decisions and ensure that the products you distribute or use are at the forefront of performance excellence.

People Also Ask

Q: How does pickleball paddle thickness affect performance?

A: Thicker paddles generally offer more power due to a larger sweet spot and increased weight, which can be beneficial for aggressive play. Conversely, thinner paddles provide better control and maneuverability, making them ideal for players focused on precision.

Q: What is the deflection test in pickleball?

A: The deflection test measures the extent to which a paddle deforms when a controlled force is applied. This test is crucial for determining the paddle’s stiffness, which directly impacts playability, performance, and compliance with game regulations.

-

cold pressing: Reading the article will help you understand the room-temperature mechanical pressing process that preserves natural material properties and ensures precise thickness control. ↩

-

thermoforming: Reading the article will explain how heating materials to a malleable state allows for complex molding processes and custom manufacturing solutions. ↩

-

12K Carbon Fiber: Reading the article will provide insights into the unique properties of 12K carbon fiber and how it contributes to high-performance, durable composite designs. ↩

-

Nomex Honeycomb: Reading the article will detail how Nomex Honeycomb core structures enhance shock absorption and maintain lightweight durability in paddle design. ↩

-

deflection test: Reading the article will illustrate the industry-standard testing methods used to measure paddle bending under load and its impact on performance. ↩