Pickleball’s explosive growth in North America is creating an significant opportunity for OEM companies1 to leverage advanced manufacturing and innovative materials to capture a booming sports segment.

The North American pickleball market is experiencing an unprecedented surge. With 19.8 million active players in 2024, a year-over-year growth of nearly 45.8% from 2023, and an overall expansion of 311% since 2021, the sport has moved well beyond niche status into mainstream popularity. This market expansion is not merely a trend; it is a strategically significant shift that introduces vast opportunities for OEM companies in the sports equipment industry.

The explosive numbers speak to more than just a rising player base. They hint at the evolving dynamics of consumer behavior, shifting recreational preferences, and a heightened demand for innovative, high-performance products. In particular, the manufacturing of pickleball paddles using advanced production processes and premium materials offers OEMs a chance to differentiate themselves and build strong B2B partnerships.

Several key drivers are boosting pickleball’s growth in North America:

- Broadening Demographics: Traditional sports are making way for new, accessible games that appeal to various age groups and skill levels. Pickleball’s easy-to-learn nature contributes to its rapid adoption.

- Increased Investment in Facilities: With over 68,000 courts nationwide, infrastructure investments—from community centers to dedicated sports complexes—are fueling the sport’s expansion.

- Enhanced Product Quality: Advances in materials such as Carbon Fiber2, Fiberglass3, and optimized paddle cores (Nomex, Aluminum, Polymer) have revolutionized player performance. High-quality paddles now offer enhanced vibration control, improved ball response, and increased durability, which are key selling points in a highly competitive market.

- Technological Advancements: Modern production techniques like hot pressing, cold pressing4, and thermoforming5 ensure superior quality and consistency in paddle manufacture, resonating with both professional athletes and recreational players.

These industry dynamics are not only shaping consumer demand but are also pushing OEMs to innovate and upgrade their manufacturing processes to remain competitive.

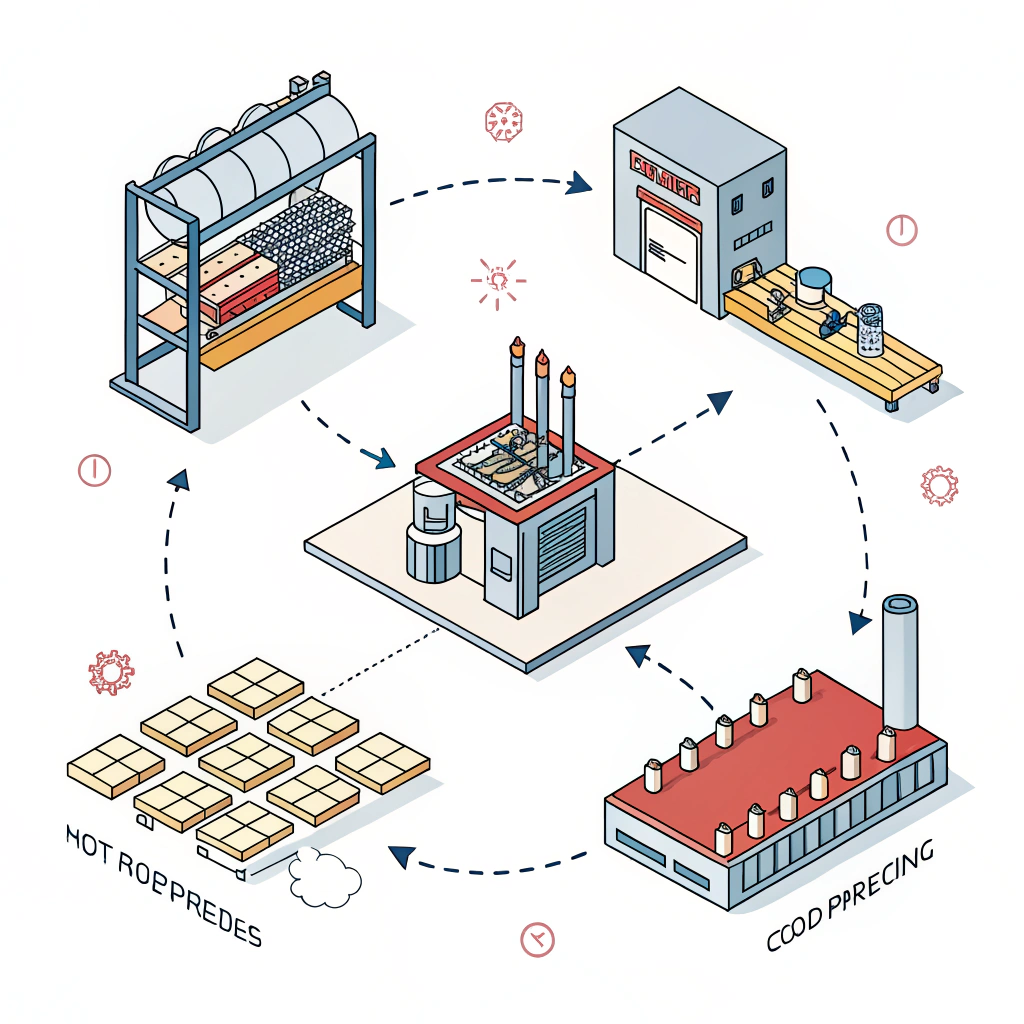

For OEMs considering entry into the North American sports equipment market, understanding production techniques is crucial. NEX Pickleball leverages three main processes that each offer unique benefits and challenges:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | - High production efficiency suitable for large-scale manufacturing. - Produces strong paddles with excellent impact resistance. - Ensures structural integrity for high-performance use. |

- May alter some material properties affecting the paddle’s feel. - High initial equipment investment required. |

| Cold Pressing | - Allows precise control over paddle thickness and structure. - Maintains material properties for better ball control. - Delivers excellent responsiveness. |

- Longer production cycles reduce overall efficiency. - Requires precise equipment for quality control. |

| Thermoforming | - Ideal for creating intricate designs and precise material distribution. - Enhances paddle stability and performance. - Suitable for premium or custom products. |

- Higher equipment costs and longer production times. - Best suited for specialized, high-value products. |

By effectively balancing these techniques, OEMs can cater to diverse market needs—from cost-efficient mass production to customized, high-end products.

The choice of materials dramatically impacts the performance and longevity of pickleball paddles. Advanced materials not only enhance competitive play but also serve as a key differentiator in a crowded marketplace.

- 3K Carbon Fiber: Provides excellent strength and flexibility while reducing vibration. It is ideal for paddles requiring high rebound force and exceptional durability.

- 12K Carbon Fiber: Offers a smoother surface, enhanced hardness, and superior impact resistance, perfect for top-tier competitive play.

- T300 Carbon Fiber: Balances strength and lightweight characteristics, ensuring paddles support both speed and control without compromising durability.

- E-Glass Fiberglass: Balances power and control by offering a wider sweet spot along with excellent ball feel. It is favored for its elasticity and tensile strength, making it a great choice for enhancing ball control.

- Composite Combinations: By combining Carbon Fiber and Fiberglass, OEMs can produce paddles that optimize power, flexibility, and control. Additionally, composites like the Bamboo Core and Honeycomb Core enhance impact resistance and overall paddle resilience.

-

Core Materials: The inner core is crucial to paddle performance:

- Nomex Honeycomb Core: Known for robust shock absorption and durability.

- Aluminum Honeycomb Core: Provides a balanced mix of strength and precision, ensuring optimal weight distribution.

- Polymer Honeycomb Core: Reduces vibration for a more comfortable play experience—perfect for recreational users and beginners.

The detailed attention to raw materials and core design not only leads to superior product performance but also acts as a strong selling point when approaching potential OEM partners who value technical excellence.

For OEM companies in the sports equipment industry, the rising pickleball trend offers a fertile landscape for new business development. As the sport's popularity grows, the following strategic insights are pivotal for capitalizing on this opportunity:

-

Adapting Manufacturing Processes: Investing in advanced production methods such as thermoforming and cold pressing is essential for producing high-performance paddles that appeal to both competitive and recreational players. OEMs that upgrade their production lines to integrate these technologies can benefit from enhanced product quality and operational efficiencies.

-

Material Innovation and Customization: With consumer demand for premium products, OEMs should consider diversifying their material options. Implementing various Carbon Fiber types and specialized composites can create a range of products to meet different market segments. Customization options, such as tailored grip sizes and paddle balance, allow OEMs to offer differentiated products that resonate with brand-conscious consumers and sports organizations.

-

Strategic Partnerships and Branding: Collaborating with established brands like NEX Pickleball can be an effective way for OEMs to enter the market. Leveraging the reputation and technical expertise of a leading manufacturer enhances credibility and lowers the barrier to market entry. These partnerships can also open doors to co-branded initiatives that capitalize on current market trends.

-

Market Research and Competitive Analysis: Staying informed through market studies, industry benchmarks, and consumer feedback is essential. OEMs should continuously analyze competitors’ strategies and production innovations while aligning their production capabilities with the evolving needs of the sport. For example, understanding the nuances of fiberglass versus carbon fiber in paddle performance provides a competitive edge in product design.

To help summarize, consider the following table which outlines key opportunities against production and material considerations for OEMs:

| Focus Area | Key Strategy | Expected Outcome |

|---|---|---|

| Advanced Production Techniques | Invest in thermoforming and cold pressing methods | Enhanced product quality and operational efficiency |

| Material Diversification | Use a mix of 3K, 12K, and T300 carbon fibers, plus fiberglass | Broader product range catering to diverse market needs |

| Customization and Innovation | Offer custom grips, balance, and design options | Increased customer satisfaction and brand loyalty |

| Strategic Partnerships | Collaborate with established industry leaders | Accelerated market entry and elevated brand credibility |

| Market Intelligence | Monitor trends and competitor strategies | Proactive adaptation to market changes and customer demands |

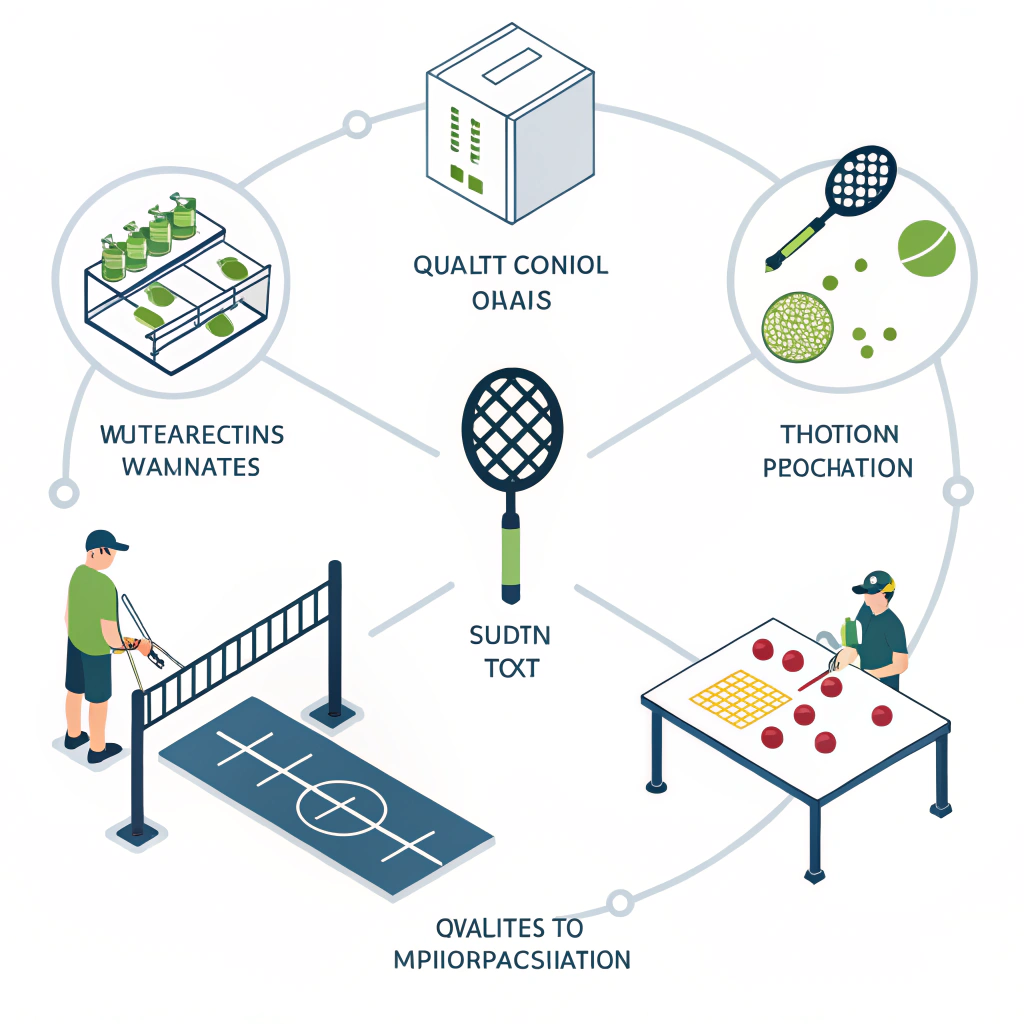

Quality control is a critical factor in ensuring the continued success of any manufacturing operation, especially in a competitive field like pickleball. At NEX Pickleball, every paddle undergoes rigorous testing procedures to validate its strength, flexibility, and playability. OEMs looking to capitalize on the pickleball boom must implement comprehensive quality control systems, which include:

- Pre-production Material Assessments: Regular testing of raw materials such as carbon fiber variants and core composites.

- In-line Inspection Processes: Continuous monitoring during each production phase to ensure consistency.

- Post-production Testing: Detailed evaluations, including performance simulations, to ensure that the final products meet or exceed customer expectations.

Looking forward, trends indicate that technological advancements will continue to shape the landscape of paddle manufacturing. With ongoing research into new composite materials and automated production processes, OEMs that invest in innovation today are likely to reap significant rewards in the near future.

The future of pickleball technology also holds promise for further customization. Innovations such as on-demand printing for personalized designs and ergonomic enhancements are becoming more mainstream, appealing to both the amateur and professional segments. Keeping pace with these developments is essential for OEMs hoping to maintain a competitive edge.

The surge in pickleball's popularity in North America presents a dynamic opportunity for OEMs. By leveraging advanced production techniques, material innovations, and strategic partnerships, companies can position themselves to deliver high-performance, market-leading products.

To capitalize on this growth, consider the following actionable insights:

- Upgrade your production processes to incorporate advanced methods like cold pressing and thermoforming.

- Diversify your material portfolio by exploring different types of carbon fiber and composite options.

- Prioritize quality control systems to ensure that every product maintains the highest performance standards.

- Explore strategic partnerships with established brands to enhance credibility and market reach.

- Stay abreast of market trends and consumer feedback to continuously adapt and improve product offerings.

The North American pickleball market is not a fleeting trend—it represents a significant shift in recreational sports with promising long-term potential. For OEMs, this is the moment to innovate, invest, and set the stage for sustained growth in a rapidly expanding industry.

-

What are the growth statistics for pickleball?

The pickleball market has witnessed impressive growth with around 19.8 million active players in 2024, a year-over-year increase of approximately 45.8%, and an overall growth of 311% since 2021. Additionally, there are over 68,000 courts nationwide, underlining the sport’s rapid expansion. -

Is pickleball declining in popularity in the USA?

Pickleball is far from declining. In fact, participation has seen a dramatic increase—from 4.2 million American players in 2020 to 13.6 million in 2023—indicating exponential growth rather than a downturn in popularity. -

What is the fastest growing sport in North America?

Pickleball stands out as the fastest growing sport in North America with a remarkable increase of 171.1% in participation from 2018 to 2022, making it the clear leader in rapid sports growth.

-

OEM companies: Click here to read about Original Equipment Manufacturers and how they play a crucial role in product development and supply chain management in the sports equipment industry. ^ ↩

-

Carbon Fiber: Click here to explore the advantages of Carbon Fiber, including its strength-to-weight ratio and applications in high-performance manufacturing. ^ ↩

-

Fiberglass: Click here to understand how Fiberglass contributes to product durability and performance, and why it's a favored material in sports equipment manufacturing. ^ ↩

-

cold pressing: Click here to learn about cold pressing, a precision manufacturing process that maintains material integrity and enhances product performance. ^ ↩

-

thermoforming: Click here to discover thermoforming, a technique used to shape materials into complex designs with consistent quality in advanced manufacturing processes. ^ ↩