Our high-performance custom pickleball paddles enhance your brand identity by combining advanced production techniques1, premium materials, and precise quality control to deliver consistency, durability, and aesthetic appeal—all essential factors for a compelling sports equipment offering.

In today’s competitive sports equipment market, aligning your product portfolio with your brand’s image is crucial. Pickleball paddle design not only affects performance on the court but also serves as a powerful branding tool. For procurement specialists and brand managers, understanding manufacturing techniques, material selections, and customization options is key to making an informed supplier decision.

At NEX Pickleball, our commitment to excellence is underscored by our use of advanced production techniques and premium raw materials. We are recognized as a reliable sports equipment supplier that supports custom paddle manufacturing for retail and competitive use. With our established partnerships—including producing for brands like Joola and Selkirk—our offerings deliver both high performance and a visual narrative that enhances brand identity.

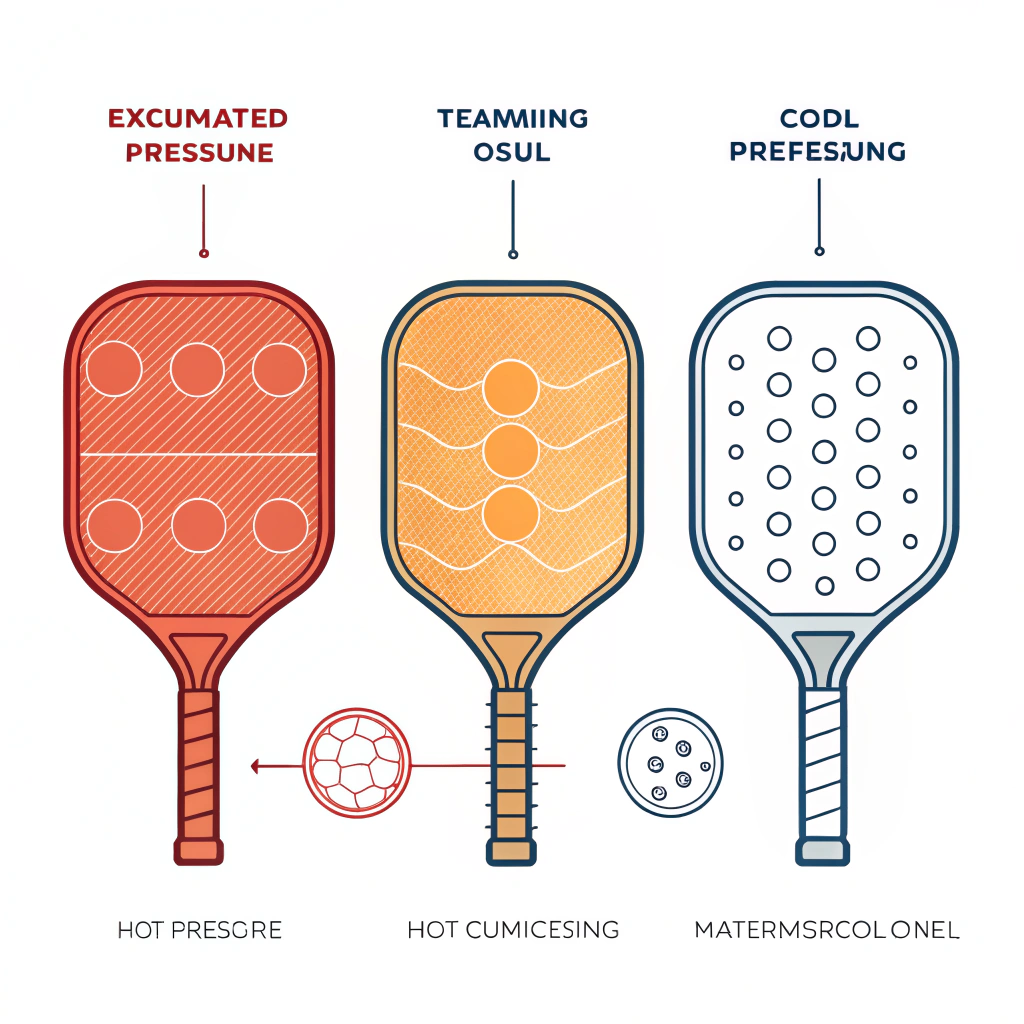

Selecting the ideal manufacturing process for your paddles is a balancing act between performance, durability, and production efficiency. Let’s examine the three main techniques we deploy:

Hot pressing involves applying heat and pressure to shape the paddle. This method is widely used in high-volume production because it delivers robust paddles with excellent impact resistance.

Advantages:

- High Production Efficiency: Suitable for large-scale manufacturing.

- Structural Integrity: Results in a strong, durable paddle ideal for competitive play.

- Impact Resistance: Provides excellent rebound force and shock absorption.

Disadvantages:

- Material Alteration: The high heat may slightly change the material’s inherent properties.

- High Equipment Costs: Requires investment in specialized machinery.

Cold pressing forms the paddle at room temperature by applying mechanical pressure. This technique is essential when precision control and material integrity are critical.

Advantages:

- Precise Control: Allows for accurate control of paddle structure and thickness.

- Material Integrity: Maintains the natural properties of materials, ensuring better touch and feel.

- Enhanced Ball Control: Ideal for designs requiring responsive contact with the ball.

Disadvantages:

- Longer Production Cycles: Lower throughput compared to hot pressing.

- Equipment Demands: Requires precise, high-quality machinery to maintain consistency.

Thermoforming2 involves heating the material to a softening point and shaping it using molds. This method is perfect for creating paddles with intricate designs and uniform material distribution.

Advantages:

- Intricate Designs: Capable of creating complex forms that ensure both durability and aesthetic appeal.

- Stability: Maintains the paddle’s material distribution, contributing to consistent performance.

- Material Versatility: Suitable for a variety of high-performance materials.

Disadvantages:

- Time-Intensive Process: Higher production times may limit output.

- Cost Implications: Involves significant investment in molds and machinery.

Below is a table summarizing the key aspects of each production technique:

| Production Technique | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance | Material alteration, high equipment cost |

| Cold Pressing | Precise control, retains material properties | Longer cycles, requires quality equipment |

| Thermoforming | Intricate design capability, stable structure | Time-intensive, higher production costs |

The performance and branding impact of a pickleball paddle depend heavily on the choice of materials used in its construction. NEX Pickleball leverages an array of premium materials to achieve the perfect balance of power, control, and durability.

Carbon Fiber3 Variants

Carbon Fiber3 is celebrated for its light weight and high strength. We offer several variants:

- 3K Carbon Fiber: Known for its strength and flexibility, it provides high rebound force with excellent durability.

- 12K Carbon Fiber: Delivers a smoother surface and superior impact resistance, making it ideal for competitive play.

- T300 Carbon Fiber: Offers outstanding tensile strength with a balance of performance and light weight.

Fiberglass, particularly E-Glass Fiberglass, is utilized to enhance control while expanding the paddle’s sweet spot. It allows for better ball contact and control, making it ideal for players who seek versatility in performance.

Our composite paddles combine strengths from different materials:

- Carbon Fiber and Fiberglass Composite: Merges the benefits of both materials to offer an exceptional balance between power and control.

- Bamboo Core Composite: Provides a lightweight and impact-resistant base, delivering a clear hitting feel essential for long match durations.

- Honeycomb Core: Offers excellent shock absorption and reduces vibration, ensuring durability across prolonged usage.

The core is a pivotal element in paddle design:

- Nomex Honeycomb Core: Excellent shock absorption and stability for competitive performance.

- Aluminum Honeycomb Core: Balances weight, offering both power and meticulous precision during play.

- Polymer Honeycomb Core: Enhances elasticity and minimizes vibration, providing comfort for extended play sessions.

Consider the following table for an overview of material comparisons and their typical applications:

| Material | Key Benefit | Suitable For |

|---|---|---|

| 3K Carbon Fiber | High strength and durability | High-rebound paddles for aggressive play |

| 12K Carbon Fiber | Smoother surface and extreme durability | Competitive play requiring impact resistance |

| T300 Carbon Fiber | Excellent tensile strength, lightweight | Balanced performance paddles |

| E-Glass Fiberglass | Enhanced ball control and elasticity | Recreational players and wide sweet spot |

| Bamboo Core Composite | Lightweight with excellent impact resistance | Long match durability and custom designs |

| Honeycomb Core (Nomex/Aluminum/Polymer) | Shock absorption and vibration reduction | All-level play ensuring comfort and stability |

Customization is at the heart of modern custom paddle manufacturing4. Today’s sports equipment buyers are not just looking for performance; they also need products that reflect their unique brand identity. At NEX Pickleball, we offer on-demand printing services and customization options that allow clients to specify design elements including color schemes, logos, grip sizes, and weight distribution.

- Brand Cohesion: Customized paddles can be designed to perfectly match your corporate identity, ensuring that every piece of equipment serves as a marketing asset.

- Performance Optimization: With various advanced production techniques and materials, each paddle can be fine-tuned to offer exceptional performance that meets specific athlete needs.

- Market Differentiation: Offering personalized, high-performance equipment helps your company stand out in a crowded market and builds lasting customer loyalty.

When your products are closely aligned with your brand identity, every aspect—from the paddle’s grip to its overall balance—reinforces your brand promise. This integration not only boosts consumer confidence but also enhances the overall perception of quality and innovation. Such strategic product alignment can lead to improved market positioning, increased consumer trust, and long-term business growth.

Quality Control5 and Supplier Evaluation

Ensuring consistent quality is non-negotiable, particularly in sports equipment manufacturing. At NEX Pickleball, rigorous testing protocols are implemented at every stage of production. Each paddle undergoes comprehensive checks to confirm material properties, structural integrity, and performance under stress conditions.

- Precision Testing: We use state-of-the-art equipment to test the paddle’s balance, weight distribution, and impact resistance.

- Material Verification: Every batch of raw materials (be it carbon fiber, fiberglass, or composites) is inspected to meet premium standards.

- Performance Trials: Real-world testing scenarios ensure that paddles perform consistently in competitive play.

- Customization Consistency: Custom designs are verified to align with client specifications, ensuring that every branded element meets quality expectations.

This commitment to quality not only minimizes the risk of production errors but also builds a strong, reliable partnership with clients. When evaluating suppliers, consider their quality control protocols, production process transparency, and consistency in delivering on custom requirements.

If your decision-makers are in the solution comparison phase, here are actionable recommendations to finalize your supplier evaluation:

-

Assess Production Techniques:

Evaluate the strengths and weaknesses of manufacturing processes like hot pressing, cold pressing, and thermoforming. Choose the process that aligns with your performance standards and production volume needs. -

Examine Material Options:

Align the material properties (carbon fiber variants, fiberglass, composite options) with your target market's performance needs. For high-level competitive play, premium materials like 12K Carbon Fiber or T300 might be ideal; for recreational players, a balance with fiberglass or polymer cores may be preferable. -

Understand Customization Possibilities:

Ensure the supplier can meet your branding requirements with on-demand printing and design personalization options. This enhances the marketability of your products and bolsters overall brand loyalty. -

Review Quality Control Practices:

Confirm that the supplier has stringent testing measures and quality assurance protocols. This is crucial for long-term performance and consistency across batches. -

Request Samples and Case Studies:

Prior to full-scale procurement, ask for product samples and review case studies or data supporting the performance claims of the paddles. This step helps in verifying that the supplier’s capabilities match your expectations.

By following these recommendations, procurement specialists and brand managers can make an informed decision, ensuring that the chosen supplier not only meets performance criteria but also elevates the overall brand image.

In an ever-evolving market, the right pickleball paddle design becomes a key differentiator for your brand. By leveraging advanced production techniques, superior materials, and robust quality control, NEX Pickleball offers a unique blend of performance and customization. These paddles do more than just excel on the court—they become emblematic of your brand’s commitment to excellence and innovation.

Investing in high-performance, custom-designed paddles is a strategic decision that can dramatically reinforce customer loyalty and market differentiation. We encourage you to evaluate these factors critically and partner with a manufacturer who aligns with your standards. Your next-generation sports equipment could very well define the future of your brand.

Q: How do advanced production techniques impact paddle performance?

A: Advanced production techniques like hot pressing, cold pressing, and thermoforming ensure that each paddle is manufactured to precise design specifications. They affect the paddle’s strength, balance, and durability while preserving optimal material properties for enhanced performance on the court.

Q: What are the benefits of using carbon fiber over fiberglass in paddle manufacturing?

A: Carbon fiber offers superior strength, low weight, and high rebound force, making it ideal for competitive play. In contrast, fiberglass provides enhanced ball control and a wider sweet spot, which is typically favored by recreational players. The choice depends on the desired balance of power versus control.

Q: Why is customization important in pickleball paddle design for brand identity?

A: Customization allows brands to incorporate their logos, color schemes, and specific design attributes into the paddles, creating a unique, branded product. This not only differentiates the product in the market but also reinforces the company’s identity and commitment to quality and innovation.

-

advanced production techniques: Reading about advanced production techniques provides insights into innovative manufacturing processes that improve product performance, durability, and aesthetic quality—essential for strategic sourcing decisions. ↩

-

Thermoforming: Exploring thermoforming helps you understand how heat and molds are used to create intricate and uniform designs, offering a competitive edge in both customization and production efficiency. ↩ ↩2

-

Carbon Fiber: Delving into carbon fiber variants explains the benefits of this high-strength, lightweight material, including its impact on performance and durability, which are critical for competitive sports equipment. ↩ ↩2

-

custom paddle manufacturing: Learning about custom paddle manufacturing shows how tailored production processes can be aligned with brand identity, enabling personalized products that enhance market differentiation. ↩

-

Quality Control: Understanding quality control protocols is key to ensuring consistent product excellence and reliability, which are paramount for maintaining high standards in competitive manufacturing and supplier evaluation. ↩