In summary, while both pickleball paddles1 and padel rackets2 share some material similarities, they differ significantly in design, production techniques, and gameplay performance. This article provides an in-depth side-by-side technical comparison to help B2B buyers understand which product fits your market strategy and customer profiles best.

Both pickleball paddles and padel rackets are crafted with high-performance materials and advanced manufacturing processes, but they serve different game dynamics and player needs. Pickleball paddles are typically lighter, emphasizing precision, control, and reduced vibration, whereas padel rackets are thicker, more powerful, and designed with enhanced strength to support a different style of play.

At NEX Pickleball, our expertise in manufacturing high-quality pickleball paddles—often using premium materials such as carbon fiber3, fiberglass, and advanced composite structures—demonstrates our commitment to performance as well as durability. In contrast, padel rackets, primarily used in “paddle tennis” markets in America, are designed to meet a different demand profile, with thicker bodies and additional features such as hard foam centers and specialized perforations for enhanced power.

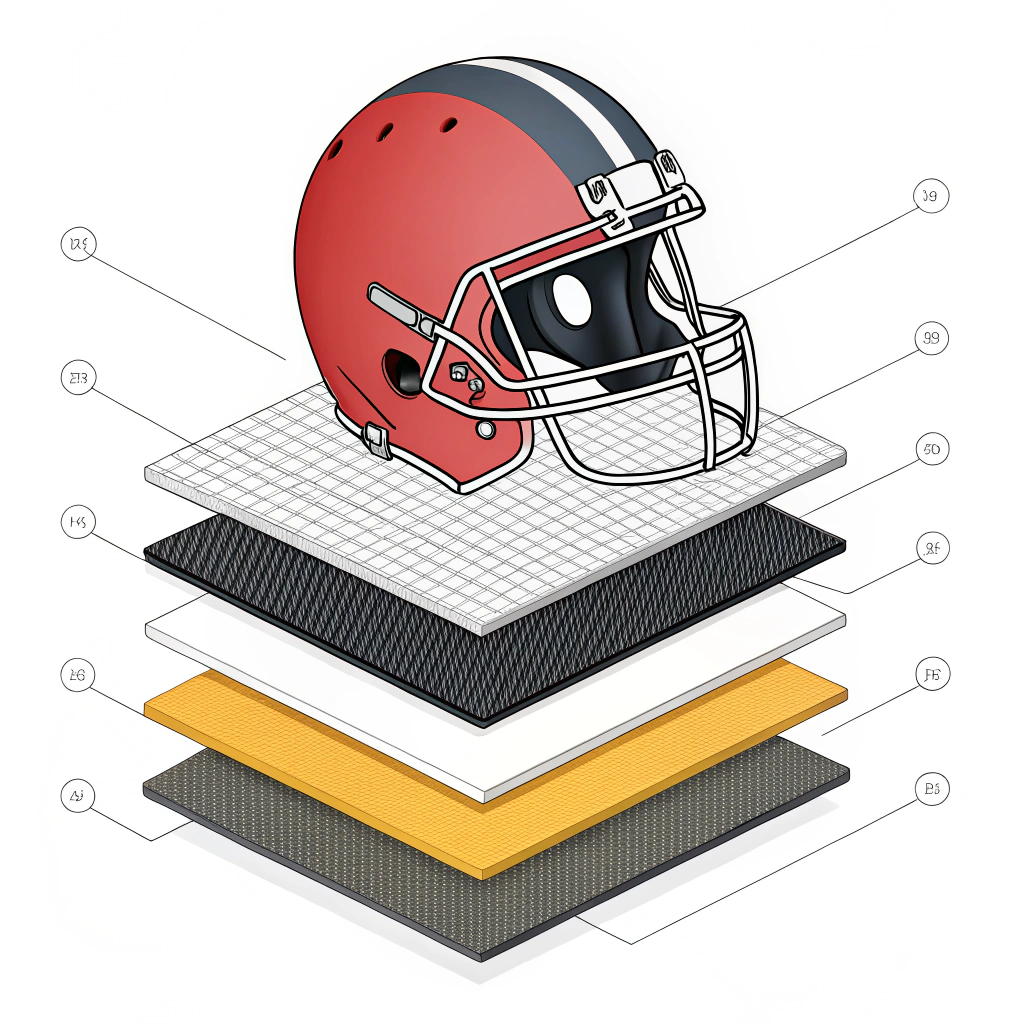

An essential factor in understanding the differences lies in the choice of materials and production processes. Both products typically use carbon fiber and fiberglass, yet the selection differs based on desired performance outcomes.

-

Pickleball Paddles:

- Carbon Fiber Variants:

- 3K Carbon Fiber: Offers flexibility and strength with excellent rebound force.

- 12K Carbon Fiber: Provides a smooth, durable surface with enhanced hardness for competitive play.

- T300 Carbon Fiber: Balances tensile strength with low weight.

- Fiberglass: Enhances ball control and comfort due to its elasticity.

- Composite Materials: Use combinations such as Carbon Fiber & Fiberglass composites, or bamboo cores for lightweight strength.

- Carbon Fiber Variants:

-

Padel Rackets:

- Constructed using robust composites that incorporate carbon fiber or fiberglass.

- Typically exhibit thicker construction with a hard foam center.

- Feature perforated surfaces to optimize aerodynamic impact and power delivery.

The manufacturing process plays a crucial role in the final product’s performance. Here’s how each process is applied:

| Production Process | Pickleball Paddles | Padel Rackets |

|---|---|---|

| Hot Pressing4 | Used for creating high-strength, durable paddles. Involves heating and applying pressure for excellent impact resistance. | Occasionally used but less common due to the need for controlled material thickness. |

| Cold Pressing | Maintains material properties for superior control, perfect for ergonomic designs and balanced weight distribution. | Rarely applied; padel rackets rely on foam cores which require more controlled and uniform pressing. |

| Thermoforming5 | Ideal for complex design geometries and uniform material distribution, suitable for premium paddles. | Utilized for creating thicker, more impactful rackets with intricate internal foam structures. |

The differences in these processes ensure that each product is optimized for its intended use. For instance, hot pressing can improve the paddle’s impact resistance but might slightly affect the tactile feel, which is less of an issue in rapid, high-force padel play.

The design of these sports products is tailored to meet distinct gameplay needs:

-

Pickleball Paddles:

- Tend to be lighter and more ergonomically balanced to maximize control and reduce fatigue.

- The design focuses on reducing vibration for precise ball striking.

- Core Materials: Commonly use Nomex honeycomb, aluminum honeycomb, or polymer cores. Each core type affects weight, shock absorption, and hitting feel differently.

-

Padel Rackets:

- Are generally heavier with a thicker build, promoting powerful swings and robust impact performance.

- Designed to deliver high torque, making them effective for fast-paced ball games.

- Typically incorporate foam centers that contribute to the racket’s increased durability and power without overly compromising maneuverability.

-

Pickleball Paddles:

- Feature specially treated surfaces to enhance grip and control on the ball.

- The precise surface texture and treatment ensure players can produce spin and accuracy.

-

Padel Rackets:

- Often come with perforated surfaces, which help reduce drag and provide a unique play feel.

- The thicker surface area contributes to a more powerful hit but can reduce the finesse compared to the lightweight pickleball counterpart.

Both products emphasize ergonomics to reduce player strain:

- Pickleball Paddles generally offer a variety of grip sizes to suit different hand sizes, ensuring optimal comfort during extended play.

- Padel Rackets, due to their design aimed at increased power, must balance grip comfort with the challenge of managing a heavier racket.

For B2B buyers, the production method and customization options are critical factors in your procurement strategy.

At NEX Pickleball, our production processes such as hot pressing, cold pressing, and thermoforming are continuously optimized to ensure efficiency and superior quality. Each paddle undergoes rigorous testing to meet global standards for strength, ball feel, and durability.

-

Pickleball Paddles:

- We offer custom options that allow for adjustments in design, weight, balance, and grip sizes. This is vital for clients looking to provide a tailored solution to varying player levels—from recreational to competitive.

-

Padel Rackets:

- Although customization is available, the manufacturing processes are more complex due to the need to combine foam, composite materials, and perforations. Decisions here involve balancing between power delivery and control.

| Feature | Pickleball Paddle | Padel Racket |

|---|---|---|

| Material Composition | Carbon fiber variants, fiberglass, composites | Mainly robust composites with thick foam center |

| Production Processes | Hot pressing, cold pressing, thermoforming | Thermoforming and controlled molding for thicker builds |

| Weight & Balance | Lighter with ergonomic grip design | Heavier, designed for increased power and impact |

| Design Features | Smooth surface with enhanced ball control | Perforated surface with thicker body for durability |

| Customization | High level, including design and grip customizations | Available but more complex due to integrated foam structures |

Understanding these differences is essential for making an informed decision on which product aligns best with your market strategy. The choice will depend on your target audience’s preferences and the specific performance attributes required for their sporting activities.

Recent studies in the sports equipment market have highlighted a trend towards niche performance specifications. Buyers are increasingly looking for products that offer a precise balance between control and power. High-performance paddle sports require both durability in production and innovation in materials. For instance, the enhanced rebound force provided by 3K and T300 Carbon Fiber in pickleball paddles is a game-changer for competitive players seeking precision and reduced vibration.

-

Pickleball Paddles:

- Players benefit from a paddle that focuses on finesse and control. The slight differences in core materials such as Nomex or polymer honeycomb significantly influence the paddle’s feel, contributing to accuracy during rapid exchanges.

-

Padel Rackets:

- Designed for high-impact play, the additional weight and thickness enhance power, making them suitable for players who rely on strong, decisive hits. However, this can sometimes come at the expense of fine ball control.

For procurement managers or distributors, understanding these technical and performance differences can guide your product line strategy. Consider the following:

- Identify the specific needs of the local market and player demographics.

- Analyze the performance data and feedback from players at various skill levels.

- Factor in the production efficiency and potential customization options to meet client-specific requirements.

- Balance inventory between high-performance, customizable products and standardized models that cater to mass markets.

In conclusion, the decision between investing in high-performance pickleball paddles or padel rackets requires careful consideration of design specifications, production processes, material quality, and market trends. For distributors aiming to meet the demands of a diverse clientele:

• Pickleball paddles are optimal if your focus is on delivering precise control, reduced vibration, and high customization options.

• Padel rackets, on the other hand, cater to markets where players demand a more powerful, impact-resistant product with unique design features like a perforated surface and thicker build.

By comparing advanced materials such as carbon fiber and fiberglass, and understanding the different production processes like hot pressing, cold pressing, and thermoforming, you can make a well-informed procurement decision. Our technical comparisons and market analyses are designed to support your strategic business choices, ensuring you invest in products that enhance gameplay performance and meet customer expectations.

Ensure that your next step involves understanding your customer base, assessing the performance aspects of each product, and aligning these with your sourcing strategy. Whether you are expanding your product line or introducing new sports equipment to your distribution channels, the in-depth details provided here serve as a comprehensive guide.

-

What is the difference between a padel paddle and a pickleball paddle?

The main difference lies in design and material characteristics. Padel paddles tend to be thicker with a hard foam center and perforated surfaces, while pickleball paddles are lighter with specialized surface treatments aimed at reducing vibration and improving control. -

Can you use a padel racket for pickleball?

No, padel rackets are not interchangeable with pickleball paddles. Despite similarities in materials such as carbon fiber or fiberglass, padel rackets have distinct design features—thicker bodies, altered head sizes, and differing balance—that make them unsuitable for pickleball play. -

What is padel called in America?

In America, padel is often referred to as “paddle tennis,” reflecting its similarities to traditional tennis while also highlighting the unique paddle design used in the sport.

-

pickleball paddles: Reading this article will help you understand the design, material, and performance aspects of pickleball paddles, ensuring you select products that meet market demands. ↩

-

padel rackets: Click to learn how padel rackets differ in design and manufacturing, influencing power delivery and overall play experience. ↩

-

carbon fiber: Explore how carbon fiber is used in sports equipment manufacturing, its benefits in enhancing strength while reducing weight, and its role in product performance. ↩

-

Hot Pressing: Learn about the hot pressing process, including how it uses heat and pressure to enhance material strength and durability in product manufacturing. ↩

-

thermoforming: Discover the process of thermoforming, its applications in creating complex shapes, and how it contributes to the structural integrity of high-performance equipment. ↩