Pickleball’s explosive growth is driven by innovative production techniques, evolving market trends, and a shift from recreational play to competitive sport. In this article, we explore how a once modest backyard pastime evolved into a global business opportunity and why advanced manufacturing processes1 are key to delivering high-performance pickleball paddles.

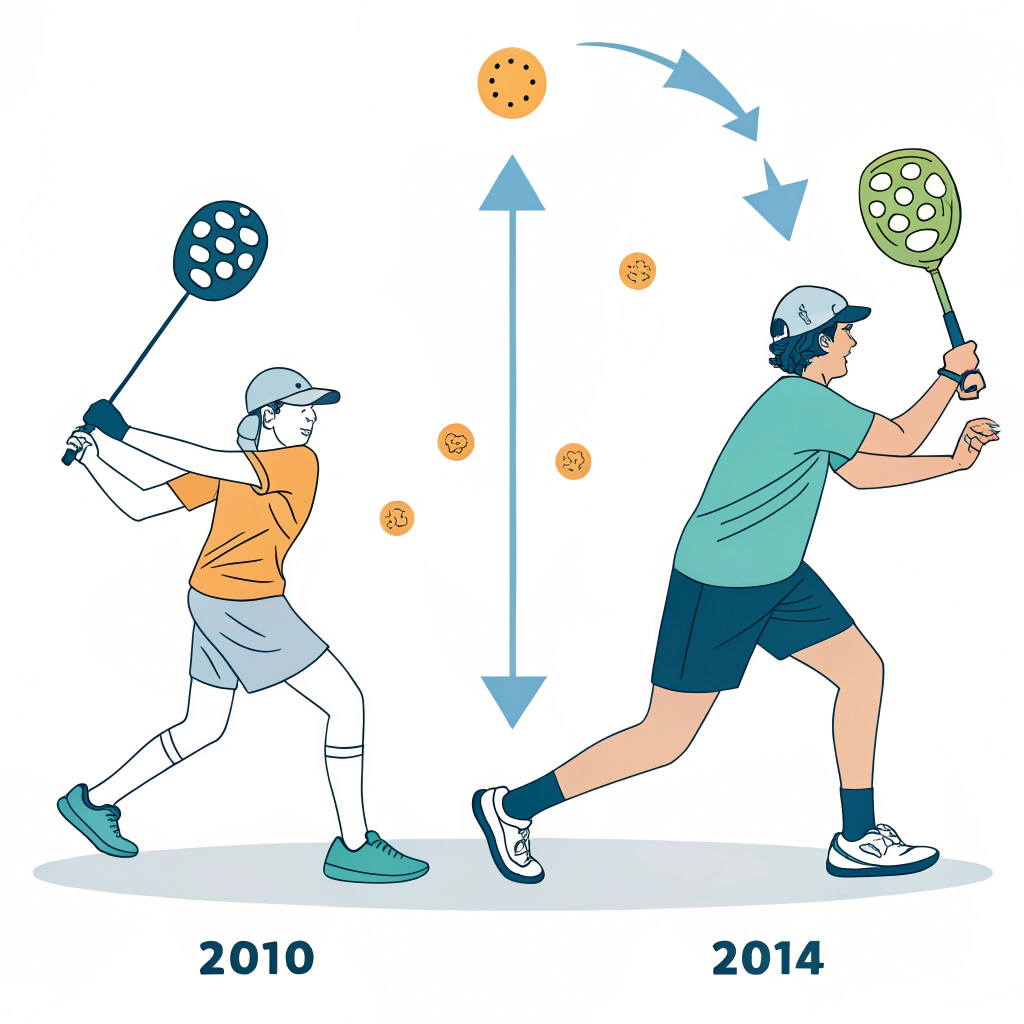

Pickleball started as a simple game and quickly transformed into a dynamic industry. Initially popular in local communities, the sport has surged in demand due to increased media exposure, growing participation, and a shift in consumer lifestyle trends. This evolution demonstrates a clear progression from a recreational game to a multi-million-dollar industry, attracting B2B decision-makers and sports industry executives alike.

Historically, the transformation of pickleball reflects broader consumer trends where active lifestyles and social sports have merged with high-performance equipment demands. As seen with other sports innovations, early adoption in niche markets allowed specialized manufacturers to experiment with new materials and production techniques. This, in turn, unlocked opportunities for improved product performance and longevity.

The global pickleball market is expanding rapidly due to several driving factors:

- Increased Participation: More recreational and competitive players fuel demand.

- Media and Sponsorship: Growing television coverage and sponsorship deals are attracting significant investments.

- Innovative Product Offerings: The integration of advanced materials such as carbon fiber and fiberglass has elevated paddle performance, providing manufacturers with a competitive edge in quality and innovation.

These trends have created a robust environment for manufacturers to scale their production and explore international partnerships. With market saturation on the horizon in traditional sports, stakeholders are turning to pickleball as a fertile ground for revenue growth.

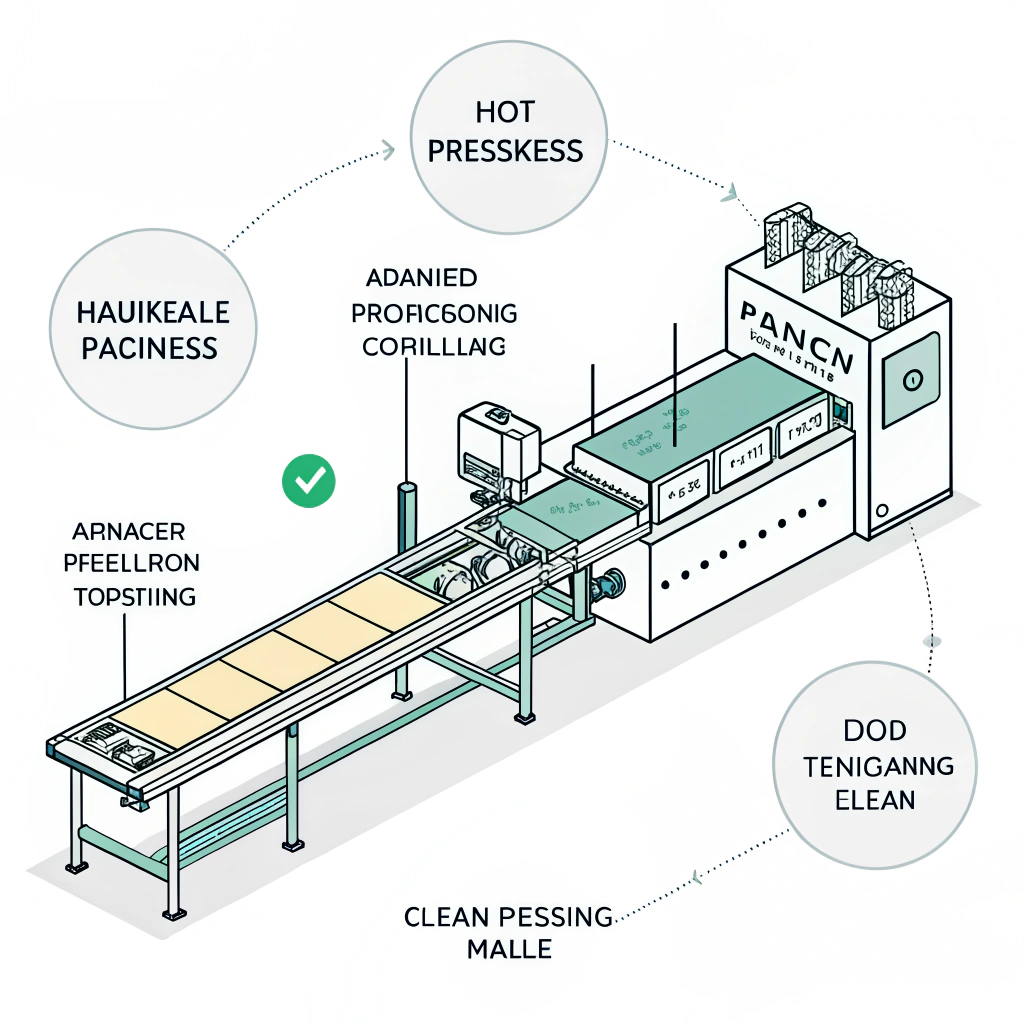

The manufacturing of pickleball paddles is a testament to modern production technology. Manufacturers like NEX Pickleball leverage advanced production processes including hot pressing2, cold pressing, and thermoforming3 to produce paddles that meet high-performance standards.

| Production Technique | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | - High production efficiency - Superior structural strength - Excellent impact resistance | - Can alter material properties - Requires high equipment investment |

| Cold Pressing | - Provides precise control over paddle structure - Preserves inherent material qualities - Enhances ball feel and responsiveness | - Slower production cycle - Needs high-quality precision equipment |

| Thermoforming | - Allows complex and intricate designs - Ensures precise material distribution - Improves paddle stability | - Longer production process - Higher equipment costs |

Each method has its benefits and trade-offs, leaving the choice dependent on the desired balance between efficiency, product performance, and cost. This trend toward using cutting-edge production processes not only improves product durability but also offers tailored solutions for competitive and recreational players alike.

The continuous drive for innovation is evident in the materials and design of pickleball paddles. Manufacturers now utilize a variety of premium materials, each catering to different player needs and performance criteria.

-

Carbon Fiber Variants:

- 3K Carbon Fiber: Offers flexibility and strength, reducing vibration and enhancing rebound force.

- 12K Carbon Fiber: Provides a smoother surface with increased hardness and durability for extreme play.

- T300 Carbon Fiber: Balances high tensile strength with lightweight attributes, offering superior control.

-

Fiberglass Options:

- E-Glass Fiberglass: Known for excellent elasticity and ball control, making it ideal for achieving a wider sweet spot.

-

Composite Materials:

- Carbon Fiber with Fiberglass Composite: Combines power and control.

- Bamboo Core Composite: Delivers a lightweight feel with high impact resistance.

- Honeycomb Core: Provides superior shock absorption, reducing vibration during play.

-

Core Innovations:

- Nomex Honeycomb Core: Excellent for shock absorption and long-term stability.

- Aluminum Honeycomb Core: Balances weight perfectly for power and precision.

- Polymer Honeycomb Core: Ideal for reducing vibrations while preserving elasticity for a comfortable play experience.

Manufacturers not only focus on material innovations but also on ergonomic designs that optimize weight distribution, grip comfort, and surface texture. Custom paddle options now allow B2B clients to specify design elements such as weight, balance, and grip size tailored to their market needs. Such flexibility is crucial in catering to diverse consumer bases and differentiating product offerings in competitive markets.

For sports industry executives and decision-makers, the evolving landscape of pickleball offers significant supply chain and B2B trade opportunities. The integration of advanced production techniques means manufacturers are better positioned to meet both mass-market demand and the increasing customization requests from sports organizations.

- Scalability and Efficiency: Advanced manufacturing processes such as hot pressing allow for high-volume, cost-effective production while maintaining consistent quality standards.

- Customization Capabilities: Tailored paddle options enable businesses to differentiate their product portfolios and strengthen brand loyalty.

- Quality Assurance: Rigorous testing protocols ensure each paddle meets high performance, durability, and safety standards, reducing the risk of product recalls and warranty issues.

- Global Reach: Manufacturers based in strategic locations, such as Jiaxing, Zhejiang, leverage robust international supply chains, simplifying both logistics and trade compliance for partners across borders.

By understanding these supply chain strengths, companies can better strategize their procurement and partnership decisions to align with future market trends. For instance, light-weight yet durable paddles made with advanced composite materials4 are highly sought after by competitive teams, offering a clear competitive advantage.

| Business Factor | Benefits | Considerations/Challenges |

|---|---|---|

| Production Efficiency | High volume, cost-effective | High initial investment in equipment |

| Customization Capabilities | Competitive differentiation | Requires agile and flexible production systems |

| Quality and Performance | Reliable product performance | Continuous quality control and rigorous testing |

| Global Supply Chain | Simplified logistics and trade | Compliance with international trade regulations |

Looking ahead, the pickleball industry is poised for continuous expansion. As participation continues to grow worldwide, manufacturing innovations will drive further improvements in paddle performance and customization. B2B partners must keep an eye on:

- Emerging Materials: Continued research may yield new composites that offer even better performance characteristics.

- Automation in Production: Integration of automation technologies5 can reduce production times and enhance precision while lowering overall costs.

- Sustainability: Environmental concerns could steer manufacturers toward eco-friendly materials and production techniques, appealing to a broader consumer base.

- Digital Integration: The use of data analytics and smart manufacturing systems will better track quality, performance, and consumer preferences, leading to further market segmentation and targeted offerings.

Businesses looking to invest in the pickleball market should consider these trends as indicators of the future competitive landscape. Supporting innovation in supply chain and production technology not only increases product value but also builds strategic resilience in a rapidly evolving market.

The evolution of pickleball from a local recreational activity to a leading global sport is a clear example of how market trends, consumer demands, and advanced production techniques converge to create substantial business opportunities. For B2B decision-makers, understanding these shifts is critical for strategic investment and partnership decisions.

Key takeaways include:

- Pickleball’s growth is fueled by increasing participation, media exposure, and technological innovation.

- Advanced production techniques like hot pressing, cold pressing, and thermoforming are central to manufacturing high-performance paddles.

- Innovative materials such as various types of carbon fiber, fiberglass, and composite cores significantly enhance product performance.

- Customized solutions and rigorous quality control systems provide competitive differentiation in the B2B arena.

- Future market trends point toward automation, sustainability, and digital integration as key drivers of success.

For businesses and investors, now is the time to evaluate supply chain partnerships and consider integrating advanced manufacturing capabilities to capture the growing demand in the pickleball market. Embracing these opportunities can lead to stronger global market positioning and sustainable growth.

Q1: How did pickleball evolve from a recreational game to a competitive sport?

A1: Pickleball evolved due to growing participation, media exposure, and advancements in equipment manufacturing. As community interest grew, manufacturers began using innovative materials and production techniques to improve paddle performance, making the sport more competitive and attracting sponsors and investors globally.

Q2: What role do advanced production techniques play in the performance of pickleball paddles?

A2: Advanced production techniques such as hot pressing, cold pressing, and thermoforming are crucial for optimizing paddle performance. They ensure precise material distribution, enhance durability, and allow for customization. These processes help in reducing vibrations, increasing rebound force, and achieving an optimal balance between power and control.

Q3: Why is investing in modern pickleball paddle manufacturing a strategic move for B2B firms?

A3: Investing in modern paddle manufacturing is strategic because innovative production processes allow for scalability, customization, and consistent quality control. These factors are key to meeting the growing global demand, differentiating product offerings, and securing long-term competitive advantages in the rapidly expanding pickleball market.

-

advanced manufacturing processes: Reading the article will explain how modern production techniques are revolutionizing pickleball paddle manufacturing and improving performance standards. ↩ ↩

-

hot pressing: Explore details on how hot pressing improves production efficiency and product durability through high-pressure techniques. ↩ ↩

-

thermoforming: Learn how thermoforming technology enables complex paddle designs with precise material distribution. ↩ ↩

-

advanced composite materials: Understand the benefits of using advanced composite materials in achieving lightweight and durable sports equipment. ↩ ↩

-

automation technologies: Discover how automation technologies are streamlining production, improving precision, and lowering manufacturing costs. ↩ ↩