Quick Answer: In today's competitive pickleball market, leveraging advanced production techniques and innovative materials is key to enhancing product performance, durability, and market appeal. This article compares the strengths and challenges of various production methods and materials—ranging from hot pressing1 to thermoforming2 and from carbon fibers3 to composite cores—to help B2B procurement managers make informed decisions for expanding their product portfolios.

The global sports equipment landscape is rapidly evolving, driven by high consumer demand and technological innovations. In particular, the pickleball market is experiencing explosive growth thanks to modern production techniques and advanced materials. For B2B procurement managers and product development specialists, choosing the right production process and materials is crucial to securing a competitive edge. This article provides an in-depth comparison of popular production methods and cutting-edge materials used in pickleball paddle manufacturing, along with real-world insight into market trends and buyer priorities.

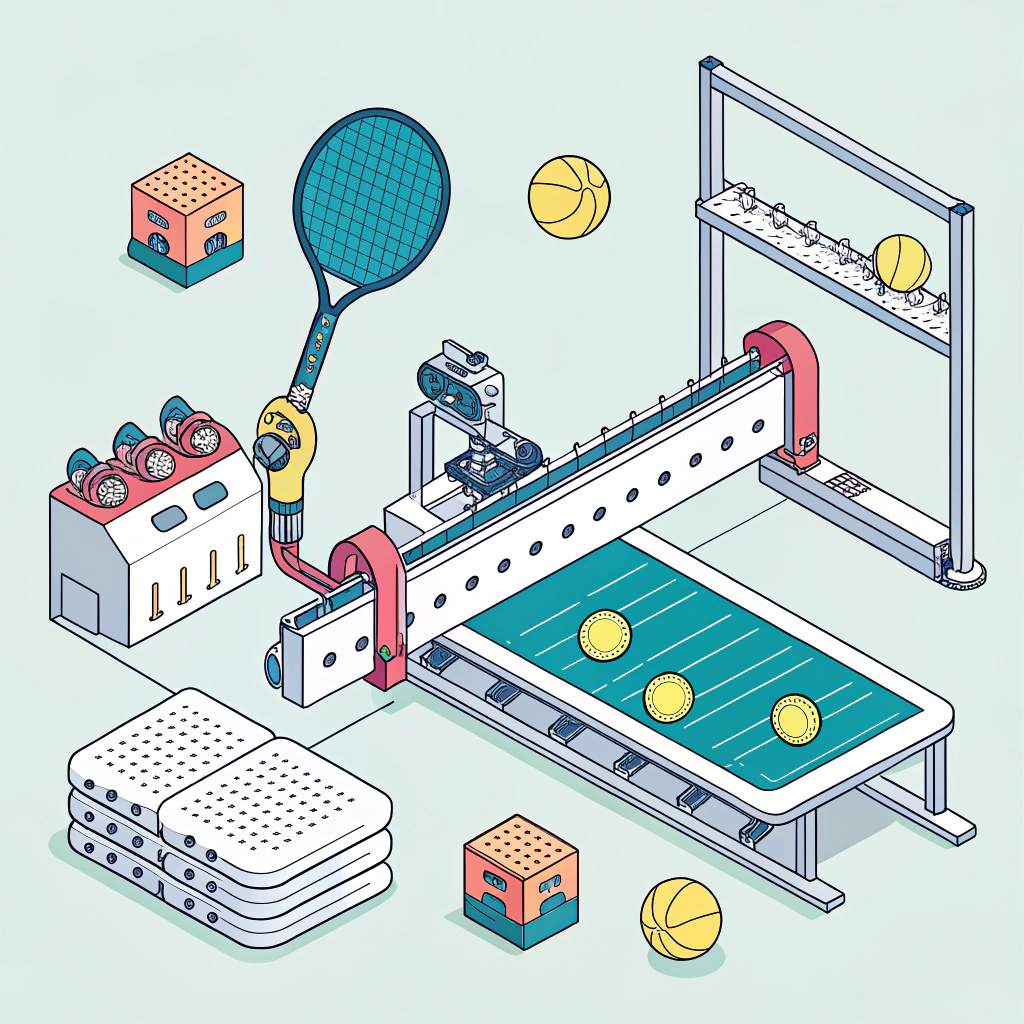

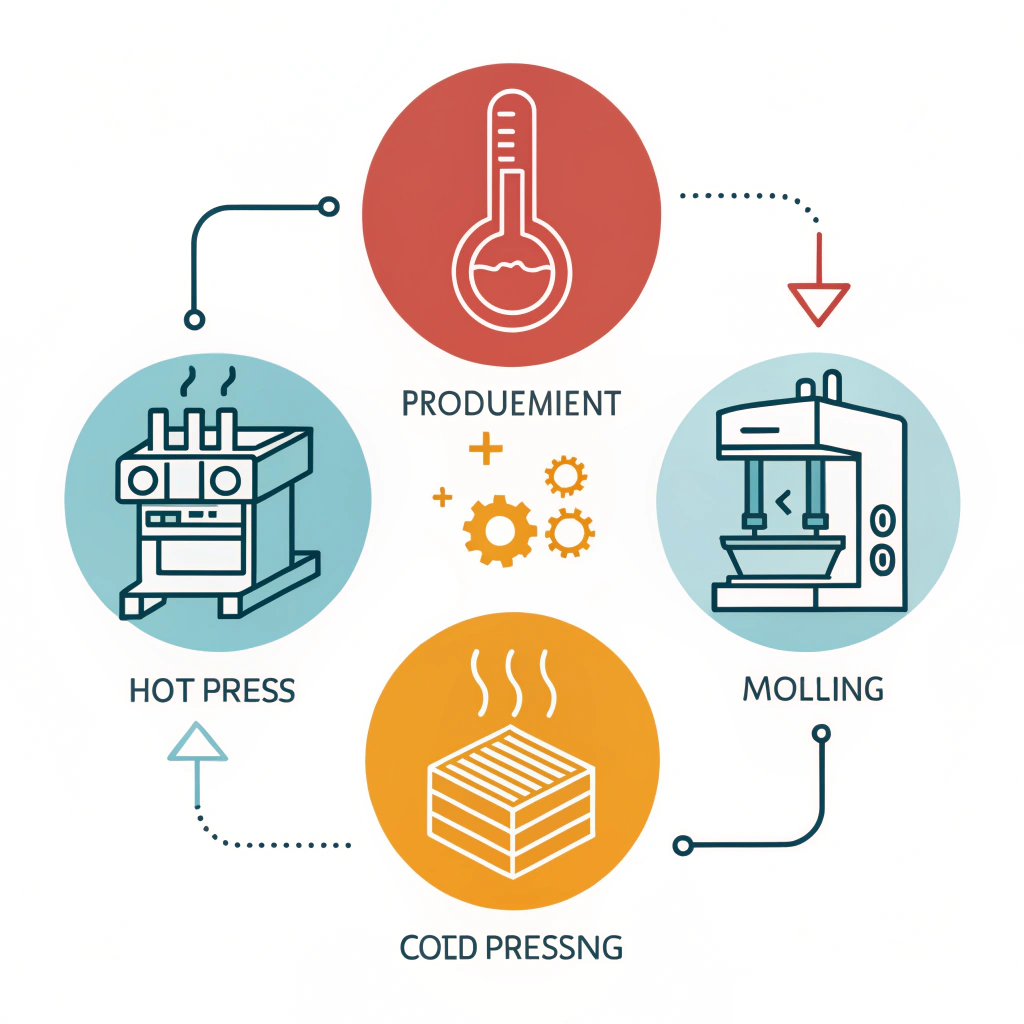

Manufacturers are increasingly turning towards sophisticated approaches to meet rising performance expectations. Three main production techniques are at the forefront: hot pressing1, cold pressing, and thermoforming.

Hot pressing is an efficient and widely adopted method. This technique involves heating the materials and applying pressure to form a paddle with exceptional strength. Here’s an overview:

-

Advantages:

• High production efficiency suitable for large-scale manufacturing.

• Produces paddles with excellent impact resistance and strong structural integrity.

• Well-suited for high-performance paddles. -

Disadvantages:

• High initial equipment investment.

• Elevated temperatures can sometimes alter material properties that affect the paddle's feel.

Cold pressing uses mechanical pressure at room temperature to shape the paddle. It provides greater control over the paddle thickness and structure, maintaining the original properties of the materials. The term cold pressing4 is used here to denote a fabrication method that preserves the material's inherent characteristics.

-

Advantages:

• Precise control over paddle design and thickness.

• Retains the material's natural feel, offering better control and flexibility for players. -

Disadvantages:

• Longer production cycles compared to hot pressing.

• Requires precise control of pressure with high-quality equipment to ensure product consistency.

Thermoforming involves heating the material to a softened state and then molding it into the desired shape. This method is particularly useful for complex designs and detailed material distribution. Although mentioned earlier, thermoforming2 is revisited here to emphasize its role in producing intricate paddle designs.

-

Advantages:

• Can achieve intricate paddle designs with precise material layouts.

• Results in paddles with excellent stability and performance.

• Suitable for producing premium or custom-designed paddles. -

Disadvantages:

• Longer production times and higher equipment costs.

• Best utilized for products where customized design and performance benefits outweigh production cost concerns.

The following table provides a concise comparison of these three production techniques:

| Production Technique | Key Advantages | Main Disadvantages |

|---|---|---|

| Hot Pressing | High efficiency, strong structure | High investment, material property changes |

| Cold Pressing | Precision in design, natural material feel | Longer cycle, precise equipment required |

| Thermoforming | Intricate designs, stable performance | Higher cost, longer production |

Equally important as the production technique is the selection of advanced materials. Today’s high-performance pickleball paddles benefit from innovations in carbon fiber3, fiberglass, and composite materials.

At our company, different types of carbon fiber are utilized to match a range of performance requirements:

-

3K Carbon Fiber:

Perfect for paddles needing high rebound force and durable performance. Its flexibility and strength are ideal for reducing vibration and increasing longevity. -

12K Carbon Fiber:

This material features a higher thread density than 3K, resulting in a smoother surface and greater hardness. It is preferred in products that demand extreme strength and impact resistance, catering to competitive players. -

T300 Carbon Fiber:

Known for its balanced mix of tensile strength and lightweight performance, T300 is ideal for designing paddles that offer both power and control.

Fiberglass is another popular choice, offering a wider sweet spot and improved ball control through a flexible matrix. Our use of E-Glass Fiberglass ensures that players receive a paddle with excellent elasticity and tactile feedback.

Composite materials that blend carbon fiber and fiberglass combine the best features of both elements. Additionally, modern composites like Bamboo Core Composite and Honeycomb Core materials deliver great impact resistance, comfort, and a unique hitting feel.

The core of a pickleball paddle plays a vital role in balancing weight, control, and vibration absorption. Our core materials include:

-

Nomex Honeycomb Core5:

Renowned for its durability and excellent shock absorption, making it a favorite among competitive players who require sustained performance. -

Aluminum Honeycomb Core:

Offers balanced weight properties, enhancing both power and precise control during fast-paced gameplay. -

Polymer Honeycomb Core:

Known for its superior elasticity and reduced vibration, which appeals especially to recreational players seeking maximum comfort and control.

These material innovations are significant as they provide versatility and customization options for distributors looking to satisfy varied market demands.

Customization has become a critical driver in distinguishing products in a crowded market. With options for varying paddle grip sizes, surface textures, and aesthetic designs, B2B buyers can offer unique products that cater to their customers' specific needs.

-

Player Preferences:

Tailor the paddle’s weight, balance, and grip design to suit players at every skill level. -

Branding Opportunities:

Custom paddle options are ideal for team branding or retail differentiation, adding a significant competitive advantage. -

Production Adaptability:

With advanced production methods like thermoforming, manufacturers can efficiently create custom paddles without sacrificing performance.

Our experience in using on-demand print services enables personalized branding on each paddle, ensuring that the product stands out in the market while maintaining a commitment to quality. Through careful quality control and technical innovations, we meet both standard and bespoke customer needs, merging cost efficiency with high performance.

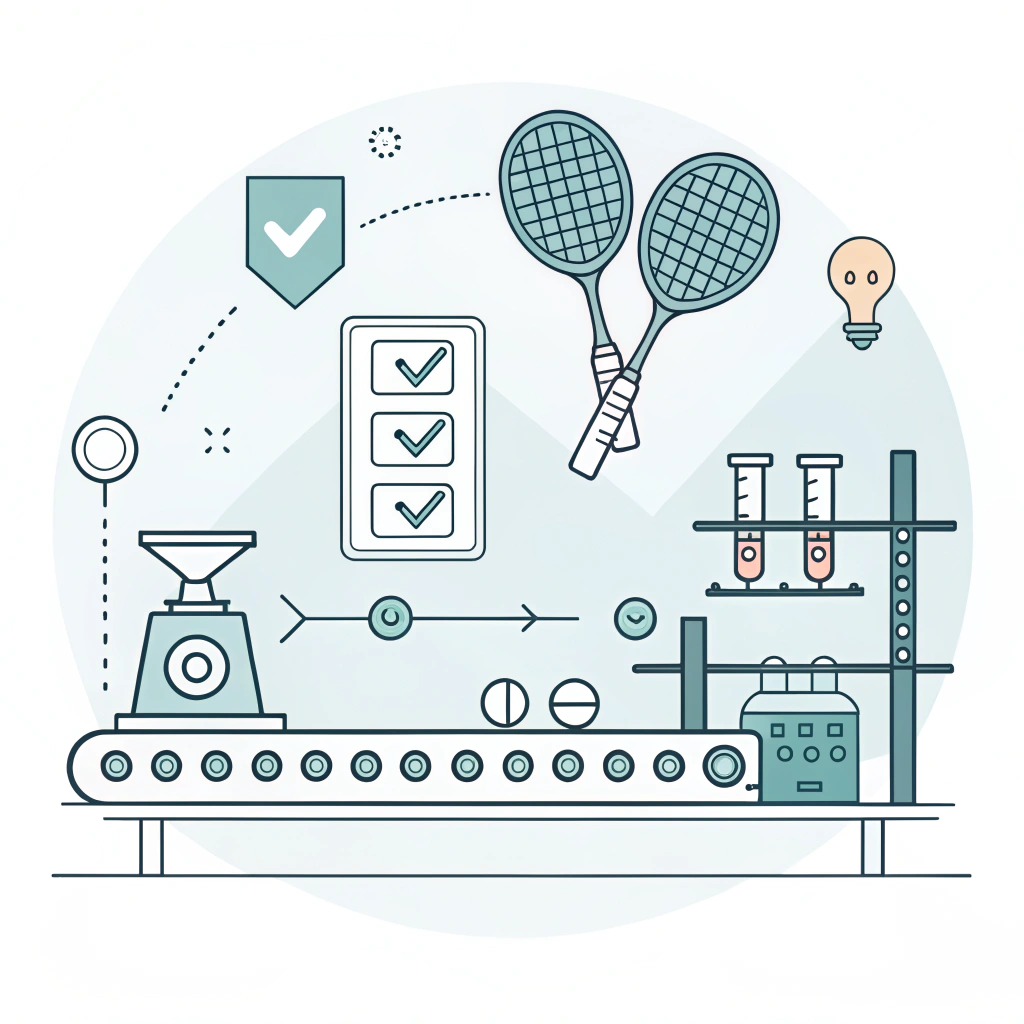

Consistency is critical for high-performance sports equipment. Each paddle produced undergoes rigorous quality control to ensure that the final product meets the highest standards in strength, flexibility, and durability. By integrating advanced techniques such as precision hot pressing, cold pressing, and thermoforming, alongside thorough testing protocols, manufacturers can secure large volumes of reliable products destined for diverse markets.

This quality control approach contributes to several benefits:

-

Customer Satisfaction:

High-quality products reduce the risk of returns and hold strong appeal in a competitive market. -

Market Reputation:

Offering consistent, reliable paddle performance builds long-term trust among retailers and end consumers, which is essential for B2B success. -

Innovation Cycle:

Continuous improvements based on performance feedback allow companies to adapt rapidly to market changes and maintain a strategic advantage.

Given the solution comparisons discussed above, here are some actionable recommendations tailored for procurement managers and product development specialists:

-

Evaluate Production Techniques Based on Scale and Product Needs:

For retailers and distributors focusing on high-volume orders, hot pressing offers efficiency and robustness. Conversely, if the focus is on premium, custom-designed products, investing in thermoforming or cold pressing might yield better market differentiation. -

Select Materials to Align With Target Player Experience:

Balance current trends by offering a mix of carbon fiber variants, fiberglass, and modern composites. Depending on your customer base’s competitive level, a combination strategy can ensure both durability and enhanced gameplay performance. -

Leverage Customization for Brand Differentiation:

Utilize on-demand printing and custom paddle options to offer unique solutions tailored to local market preferences. This not only augments brand value but also provides a personal touch that can sway buyer decisions during the procurement process. -

Prioritize Quality Control and Long-Term Performance:

Strong quality control measures not only assure product reliability but also contribute positively to customer loyalty and brand reputation. Investing in advanced testing and production equipment will yield long-term operational benefits and cost savings. -

Keep an Eye on Market Trends:

With the pickleball market expected to grow exponentially (valued at USD 2.2 Billion in 2024 and projected to reach USD 9.1 Billion by 2034), adapting production capabilities and material selections is paramount. B2B procurement managers should partner with suppliers who demonstrate agility and technological prowess to ensure they remain competitive in a booming market.

In summary, the advancement of production techniques such as hot pressing, cold pressing, and thermoforming, along with an innovative mix of materials like carbon fiber, fiberglass, and composite cores, is revolutionizing pickleball paddle manufacturing. For B2B procurement managers, understanding these methods and materials is crucial to making informed decisions. By aligning product performance with market demands and leveraging customization opportunities, retailers can secure a strong competitive advantage. The insights and recommendations detailed above provide a clear pathway for selecting high-performance, durable, and market-responsive pickleball paddles to enhance your product portfolio.

Investing in advanced production processes and state-of-the-art materials not only ensures product consistency and reliability but also drives market differentiation. As the pickleball market continues to expand rapidly, partnering with manufacturers who combine technical excellence with innovative customization options will be key to long-term success in this dynamic industry.

What is the pickleball market trend?

The pickleball market is experiencing remarkable growth, with a valuation of USD 2.2 Billion in 2024 and projections reaching USD 9.1 Billion by 2034, growing at a CAGR of 15.3%. The demand for high-performance equipment, particularly paddles and balls, is fueling this expansion.

What is the marketing strategy of pickleball?

Effective marketing strategies for pickleball often involve leveraging digital platforms. Companies typically use Google Ads and social media platforms like Facebook, Instagram, and YouTube to reach engaged audiences and enthusiasts with targeted search and display campaigns.

What is the most popular pickleball brand?

While several brands are notable, some of the leading names in the industry include Franklin, Joola, Onix, Paddletek, ProXR, Selkirk Sport, and Vulcan Sporting Goods, along with top retailers like Pickleball Central.

-

hot pressing: Read this article to understand how hot pressing utilizes heat and pressure to achieve high production efficiency and enhanced material bonding, crucial for large-scale manufacturing. ↩ ↩2

-

thermoforming: Explore this resource to learn about thermoforming processes that mold heated materials into complex, precise designs, offering customization in manufacturing. ↩ ↩2

-

carbon fibers: Discover in-depth information on carbon fiber properties and its applications in high-performance sports equipment manufacturing, enhancing strength and reducing weight. ↩ ↩2

-

cold pressing: Learn about cold pressing techniques that maintain the natural properties of materials and provide precise control over design and paddle thickness. ↩

-

Nomex Honeycomb Core: Click here to read about the benefits of Nomex Honeycomb Core, known for its durability and excellent shock absorption, essential for maintaining paddle performance under stress. ↩