Our comprehensive OEM1 solution for custom pickleball paddles ensures that every order is executed with precision—from selecting the premium materials to utilizing advanced production processes, such as hot pressing2, cold pressing3, and thermoforming4—to achieve exceptional quality and performance that meets your business requirements.

In today’s competitive sports equipment market, sourcing high-performance pickleball paddles can be challenging. Procurement managers and business owners seeking an OEM partner need to consider production processes, material quality, and turnaround times. At NEX Pickleball, our OEM process is designed to streamline the ordering experience while maintaining superior product performance and durability.

When considering a custom paddle manufacturing partner, it is essential to understand the primary steps involved in the OEM process. This process not only covers material selection and production techniques but also integrates quality control and strict delivery deadlines. Here’s an overview of our OEM process:

- Inquiry and Consultation:

Our expert team begins by engaging with you to understand your specific requirements. This includes design preferences, material choices, core configurations, grip styles, and any customization details. Effective communication at this stage reduces errors later in production. - Sample Development:

Once the requirements are defined, we produce prototype paddles using your selected materials. This step is crucial as it allows you to evaluate the paddle’s performance, shape, weight distribution, and overall feel. Feedback from the sample phase ensures that the final production meets your expectations. - Production Planning:

Based on the approved sample, production planning commences. Our team schedules production runs and allocates resources according to the order magnitude, ensuring consistency and efficiency. - Manufacturing Process:

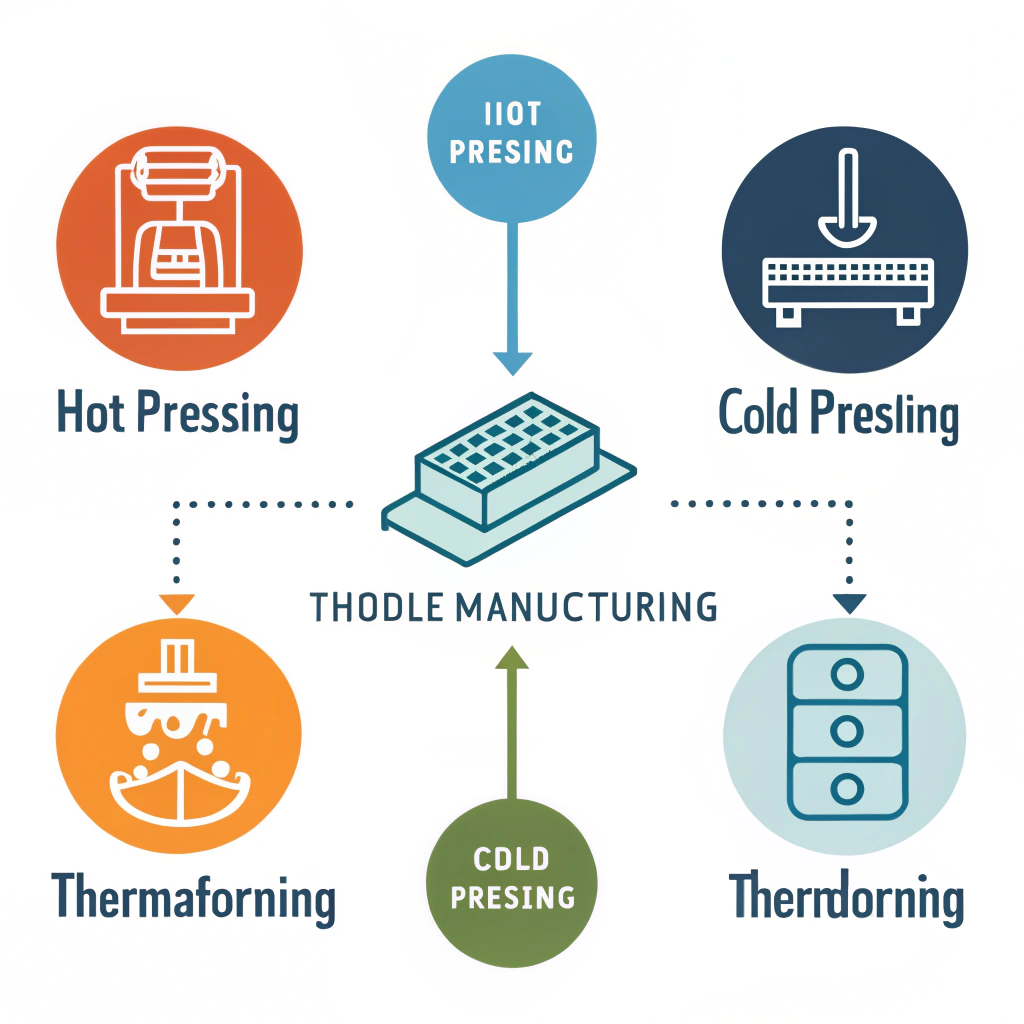

We offer three primary production processes to cater to various performance and design needs:- Hot Pressing2: Rapid manufacturing with high-pressure and heat. This method results in structurally robust paddles with enhanced impact resistance.

- Cold Pressing3: Provides precise control over thickness and texture while preserving the intrinsic properties of the material.

- Thermoforming4: Suitable for paddles demanding intricate designs and uniform material distribution.

- Quality Control and Testing:

Every paddle undergoes rigorous testing to confirm that all performance metrics—such as durability, balance, and vibration reduction—meet industry standards. We use advanced inspection techniques to ensure each paddle maintains its premium quality. - Packaging and Timely Delivery:

Post-production, the paddles are carefully packaged to avoid any damage during transport. Our logistics team ensures that orders are delivered on time, meeting the commitments promised during the initial consultation.

The choice of a manufacturing process directly affects the paddle’s performance and durability. Below is a summarized comparison of the three primary production methods we employ:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | - High production efficiency - Superior impact resistance - Ensures structural integrity for high-performance use | - Potential alteration of material properties - Requires investment in high-temperature equipment |

| Cold Pressing | - Precise control over dimensions - Maintains material’s intrinsic properties - Enhanced ball feel and responsiveness | - Longer production cycles - Requires precise pressure control with sophisticated machinery |

| Thermoforming | - Allows intricate design details - Uniform material distribution - Ideal for custom shapes and premium finishes | - Longer production time - Higher equipment costs |

Each of these methods is chosen based on the design requirements and performance expectations you have for your custom paddles.

A significant aspect of our manufacturing process is our careful selection of materials. The performance characteristics of a pickleball paddle are largely driven by the materials used in its construction. Here are some of the premium materials we work with:

- Carbon Fiber Variants:

- 3K Carbon Fiber: Renowned for its strength and flexibility, this material is perfect for paddles that need high rebound force and vibration reduction.

- 12K Carbon Fiber: Offers a smoother surface and greater hardness due to its higher thread density, ensuring exceptional durability.

- T300 Carbon Fiber: Balances strength and light weight, ideal for paddles that combine power with maneuverability.

- Fiberglass Options:

- E-Glass Fiberglass: Provides excellent elasticity and tactile feedback, ensuring a broader sweet spot for improved ball control.

- Composite Materials:

- Carbon Fiber and Fiberglass Composite: Merges the strengths of both materials, delivering a balance between power and control.

- Bamboo Core Composite: Known for its lightweight characteristics and impact resistance, offering clear hitting feedback.

- Honeycomb Core5: Utilizes high-density polymers to offer superb shock absorption, reducing vibrations and increasing paddle longevity.

By using these premium materials, we ensure that every paddle not only meets high-performance standards but also offers durability in competitive play.

Quality control is the cornerstone of our OEM manufacturing process. At every stage, from sample development to final production, we implement a series of strict quality tests to verify product reliability and consistency. Here’s how we manage quality assurance:

- Rigorous Testing Protocols:

We simulate real-game conditions to assess the paddle’s performance, ensuring that each product can withstand repetitive high-impact scenarios. - Material Inspection:

Our team conducts thorough checks on raw materials. Carbon fiber, fiberglass, and composite materials are tested for strength, consistency, and durability before being approved for production. - Continuous Improvement:

Feedback from prototypes and customer reviews is used to fine-tune our production processes. This continuous cycle of improvement ensures that every batch of paddles is of the highest quality.

Quality control is not just about meeting standards—it is about continuously exceeding them, ensuring that the final product serves both recreational and competitive players with excellence.

For businesses looking to establish a long-term partnership or require custom branding, our onboarding process is designed to be smooth and efficient. Here’s what sets our onboarding process apart:

- Tailored Consultations:

We work directly with decision-makers to understand your specific requirements, from design nuances and grip sizes to color schemes and additional printing options on the paddle surface. - Flexible Order Quantities:

Whether you’re placing a small initial trial order or a large-scale production run, our processes are scalable without compromising quality. - Custom Branding Options:

Our on-demand printing services allow you to incorporate your branding on the paddles, creating a unique product that stands out in the marketplace. - Clear Communication Channels:

Regular updates throughout the production cycle provide transparency and build trust. Our dedicated account managers are always on hand to address any queries or adjustments you might need.

This personalized approach ensures that your OEM order aligns perfectly with your business's branding and performance demands, offering you a competitive edge in the sports equipment market.

Consider the case of a leading sports equipment distributor who partnered with us to revamp their pickleball paddle line. They required paddles that could endure rigorous training sessions and competitive tournaments. By selecting the 12K Carbon Fiber variant combined with a Nomex Honeycomb Core, we were able to engineer a product that offered superior durability and court performance.

The distributor reported the following improvements after switching to our custom OEM paddles:

- A 20% reduction in paddle breakage incidents during intense usage.

- Enhanced customer satisfaction due to improved ball control and reduced vibration.

- Faster turnaround time from order placement to delivery, owing to our streamlined production workflow.

This case underscores the importance of selecting the right materials and manufacturing processes in achieving optimal product performance and operational efficiency.

Timelines are critically important when placing an OEM order. At NEX Pickleball, we ensure that every order is managed within a clearly defined schedule, without compromising on quality. Here is an overview of our production timeline:

| Stage | Description | Typical Duration |

|---|---|---|

| Inquiry & Consultation | Initial discussion and requirement gathering | 1-2 weeks |

| Sample Development | Prototype creation and testing | 2-4 weeks |

| Order Confirmation | Finalizing design and production parameters | 1 week |

| Production Run | Full-scale manufacturing using selected processes | 4-6 weeks (may vary) |

| Quality Control Testing | Rigorous testing to ensure product meets performance criteria | 1 week |

| Packaging & Delivery | Final packaging and logistics arrangement | 1-2 weeks |

By adhering to these timelines, we guarantee that every product shipment reaches you on schedule, making it easier for you to meet market demands and customer expectations.

When evaluating a supplier for custom paddle manufacturing, it is essential to consider how well they align with your quality, performance, and communication standards. Here are some key benefits of partnering with NEX Pickleball:

- Advanced Manufacturing Techniques:

Our use of sophisticated processes like hot pressing, cold pressing, and thermoforming ensures that every product achieves peak performance. - Material Expertise:

With a deep understanding of materials—from various carbon fiber types to specialized composites—we offer tailor-made solutions that meet diverse performance criteria. - Quality Assurance:

Our rigorous testing regime guarantees that your paddles are not only reliable but also deliver a superior playing experience. - Efficient Communication:

Our dedicated account managers offer ongoing support and clear updates throughout the manufacturing process, so you always know where your order stands. - Customization Flexibility:

Whether it’s custom branding, specific grip designs, or tailored paddle dimensions, our production process is adaptable to your unique needs.

For a procurement manager or business owner, these benefits translate into a streamlined production cycle, reduced risk of product failure, and ultimately, a competitive advantage in the market.

Choosing the right OEM partner for your pickleball paddle orders is an important decision that can significantly affect your product’s market success. At NEX Pickleball, we combine advanced production techniques, premium materials, and a customer-focused approach to help you achieve the best possible outcomes. As you evaluate your options, consider the following actionable recommendations:

- Review our detailed production process timeline to ensure it fits your market deadlines.

- Assess the benefits of different manufacturing methods and select the one that best aligns with your performance requirements.

- Engage in thorough consultation and sample evaluation to tailor the final product to your specifications.

- Prioritize quality control measures to minimize any risks related to product durability and performance.

- Leverage our customization options to enhance your brand’s visibility and product distinctiveness.

By following these recommendations, you can secure a reliable, efficient, and quality-assured manufacturing process that propels your product line ahead of the competition.

What is a good beginner pickleball set?

While a good beginner pickleball set typically focuses on affordability and ease-of-use, custom OEM orders like ours are designed for high-performance and competitive play. For entry-level play, you might consider more economical options, but our focus remains on premium quality and durability, which are ideal for businesses targeting professional players and active markets.

How does pickleball serving order work?

The pickleball serving order follows a structured guideline where players line up according to their scores. Although our discussion centers on OEM manufacturing, understanding the game's structure can help tailor paddle designs to optimize performance during critical gameplay moments. For detailed rules, we recommend consulting official pickleball guidelines.

What is a good pickleball rating for a beginner?

Pickleball ratings typically start at 1.0 for beginners and progress up to 5.5+ for advanced players. While this rating system is important for players selecting equipment, our custom paddles are engineered to meet the demands of advanced play, ensuring performance and durability across all skill levels.

-

OEM: Reading this article will help you understand the benefits and processes of Original Equipment Manufacturing in the sports industry, providing insight into customized production and quality assurance practices. ^Return ↩

-

hot pressing: Reading this article will provide insights into the hot pressing process, a method involving high heat and pressure to mold materials, ensuring structural strength and enhanced impact resistance. ^Return ↩ ↩2

-

cold pressing: Reading this article will explain the cold pressing technique, emphasizing its precision in material handling and preservation of intrinsic characteristics, resulting in optimal texture and thickness control. ^Return ↩ ↩2

-

thermoforming: Reading this article will offer a comprehensive overview of thermoforming, a process that leverages heat to shape materials into intricate designs and consistent compositions, ideal for custom products. ^Return ↩ ↩2

-

Honeycomb Core: Reading this article will shed light on Honeycomb Core technology, which uses high-density polymers to optimize shock absorption and vibration reduction, crucial for product durability in high-performance applications. ^Return ↩