Pickleball paddle certifications are designed to ensure that products meet strict quality, safety, and regulatory standards while complying with industry-specific measurements and testing protocols. In this article, we will explore the certification framework for pickleball paddles, examine key quality assurance standards, and discuss actionable steps for achieving regulatory compliance in a B2B context.

In today’s competitive sports equipment market, quality and compliance are critical. Certification standards1 for pickleball paddles not only assure end-users of a product’s safety and performance but also enable distributors and retailers to confidently procure items that meet regulatory demands. For a procurement manager or quality assurance specialist, understanding these requirements is essential to ensuring that paddles will perform as promised under competition and recreational conditions.

Quality assurance for pickleball paddles involves a range of considerations:

• Ensuring consistency in manufacturing

• Meeting specific regulation requirements

• Guaranteeing player safety

• Upholding competitive fairness

• Enhancing brand credibility

Certification can cover testing protocols, dimensional requirements, material quality, and performance metrics. Adhering to these standards allows manufacturers, such as NEX Pickleball, to deliver paddles that exceed expectations in both recreational and competitive environments.

One of the most basic, yet critical, certification requirements for pickleball paddles involves their dimensions. According to established guidelines, paddles should not exceed 17 inches in length, and the sum of the paddle’s length and width must not exceed 24 inches. This ensures all products used in regulated play maintain a level playing field. These rules also tie directly to maintaining the sport’s competitiveness by ensuring that paddle dimensions contribute to fair play dynamics.

Beyond physical dimensions, performance tests are conducted to evaluate the paddle’s materials and construction quality. The USA Pickleball2 organization, for example, regulates paddle characteristics through the Paddle/Ball Coefficient of Restitution (PBCoR)3 standard. This test helps determine the impact, ball rebound, and overall playing characteristics of a paddle, ensuring that all products used in competitive play are balanced and do not confer any undue advantage.

For companies operating globally, adherence to ISO standards4 is often a critical requirement. ISO (International Organization for Standardization) certifications such as ISO 9001 for quality management systems signal that a manufacturer is committed to consistently meeting customer and regulatory requirements.

Additionally, the CE mark5 on products sold in the European Economic Area (EEA) indicates conformity with health, safety, and environmental protection standards. Manufacturers that invest in CE certification showcase their commitment to stringent safety standards across all production processes, assuring retailers and distributors of minimal liability alongside high product quality.

Different materials used in the construction of pickleball paddles come with their own certifications. For example:

• Carbon Fiber Certifications: When using 3K, 12K, or T300 carbon fiber, each type requires quality checks that focus on tensile strength, durability, and resistance properties.

• Fiberglass Standards: Fiberglass paddles must meet specific elasticity and tensile strength benchmarks.

• Composite Material Verification: When combining materials such as carbon fiber and fiberglass or using unique core options like Nomex honeycomb or aluminum honeycomb, additional testing ensures that the composite meets the required performance criteria.

These certifications help determine the right combination of weight, balance, and performance that players expect while ensuring that all materials comply with regulatory and safety guidelines.

For distributors and retailers, certified pickleball paddles offer several benefits:

• Enhanced product credibility

• Assurance of meeting safety standards

• Reduced risk of liability

• Strengthening consumer trust in the brand

• Facilitating smoother entry into regulated markets

In the B2B context, having high-quality, certified products simplifies procurement decisions. Decision-makers are more confident when quality and safety standards are verifiable through certifications such as ISO, CE, and compliance with USA Pickleball regulations.

Below is a comparative table summarizing key certifications and what each entails:

| Certification/Standard | Key Focus Area | Benefits | Typical Testing Method |

|---|---|---|---|

| ISO 9001 | Overall quality management | Improved process consistency, global market acceptance | Regular audits, process review |

| CE Mark | Health, safety, environmental protection | Ensures compliance with European safety and environmental norms | Product safety tests and compliance assessments |

| USA Pickleball Regulations | Paddle dimensions and performance (PBCoR) | Standardized product performance for fair play | Dimensional measurement, PBCoR testing |

| Carbon Fiber Material Checks | Tensile strength, flexibility, durability | Assures material performance and longevity | Material strength tests, fatigue testing |

| Fiberglass and Composites | Elasticity, durability | Balances power, control, and safety | Impact and elasticity testing |

By leveraging such a table, industry professionals can quickly gauge which certifications are most relevant for their market and ensure that products sourced align with these essential standards.

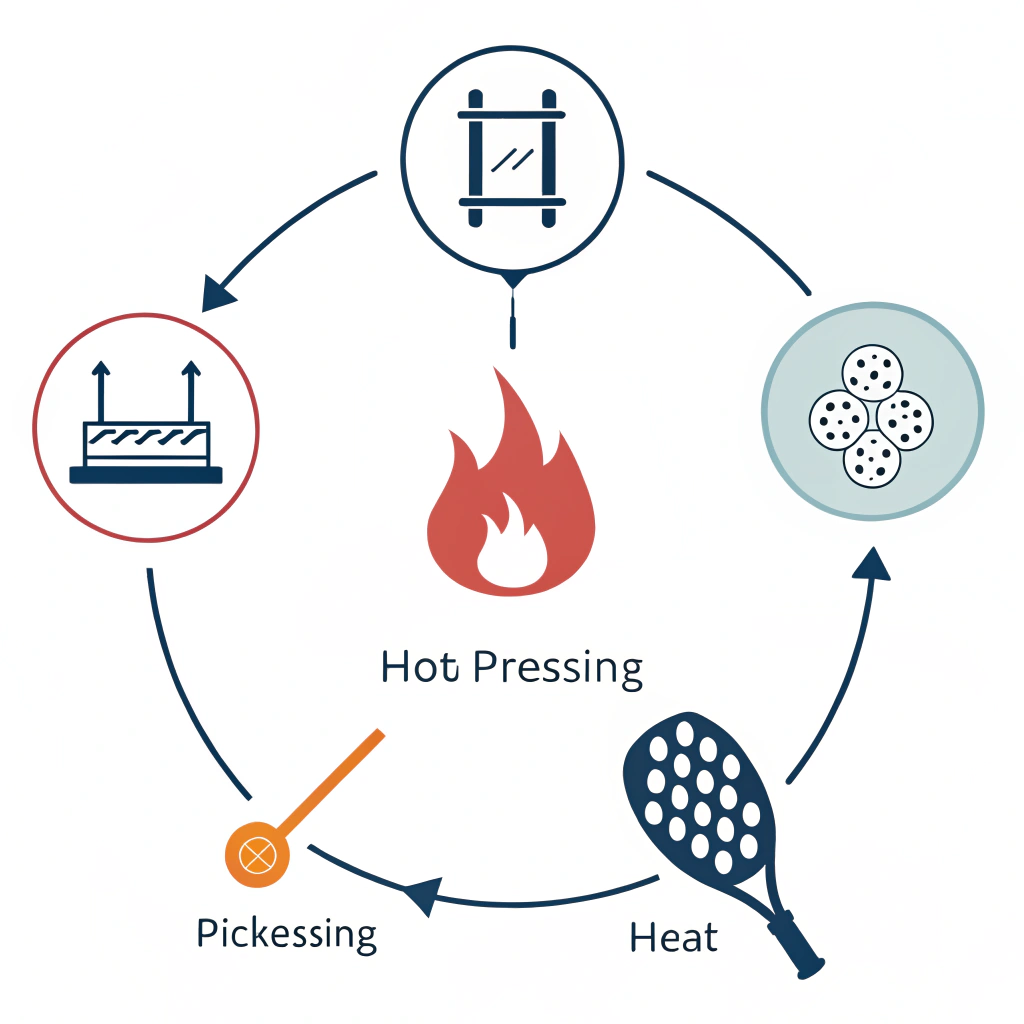

At NEX Pickleball, we integrate robust certification and quality-control procedures along each stage of the manufacturing process. Let’s break down how specific production techniques contribute to meeting the certification standards:

Hot pressing involves heating and applying high pressure to form the material.

• Advantages:

– High production efficiency

– Enhanced impact resistance and structural integrity

• Disadvantages:

– Possible alteration of material sensitivity (affecting paddle feel)

– High initial cost due to equipment needs

Hot pressing is ideal for producing paddles that are robust enough for competitive play. A product manufactured under this process is routinely subjected to safety tests verifying its compliance with established quality standards.

Cold pressing shapes materials at room temperature through controlled, mechanical pressure.

• Advantages:

– Preserves the material’s natural properties

– Offers more precise control over structure and thickness

• Disadvantages:

– Longer production cycles compared to hot pressing

– Requires superior quality control mechanisms

This technique ensures that the paddle retains its responsive feel, crucial for maintaining performance metrics that support regulatory compliance.

Thermoforming allows manufacturers to create complex paddle designs by heating materials until they soften, then molding them into shape.

• Advantages:

– Facilitates intricate design patterns and precise material distribution

– Delivers products with consistent performance characteristics

• Disadvantages:

– Higher production costs and longer cycle times

Thermoforming helps in creating paddles tailored for specific performance targets, ensuring that every prototype meets a standardized quality benchmark before moving forward in production.

These production processes are not only integral to manufacturing high-performance pickleball paddles but also ensure that products comply with established dimensions, material integrity, and durability standards. Stringent quality controls at each step facilitate the certification drafting process and assure both B2B customers and retail partners.

For businesses looking to procure certified pickleball paddles, here are actionable steps to help navigate the certification maze:

-

Define the Certification Requirements:

Clarify whether you need ISO, CE, and/or region-specific standards like USA Pickleball regulations. Investigate which certifications are mandated in your target market to ensure alignment with local regulations. -

Assess Manufacturer Credentials:

Request detailed information regarding the manufacturer’s certification history and quality control processes. Look for recognized certifications like ISO 9001 and independent testing reports. -

Review Testing Protocols:

Inquire about the testing protocols used during production. For example, check if the manufacturer adheres to the Paddle/Ball Coefficient of Restitution (PBCoR) standard and if dimensional stability tests (17-inch maximum length and combined 24-inch limit) are consistently met. -

Examine Material Certifications:

Ensure that the materials used (carbon fiber, fiberglass, and composite materials) have undergone rigorous certification. Ask for documentation verifying quality and performance parameters. -

Leverage Customization Options:

If your market demands unique product features, opt for manufacturers that offer customization while still ensuring all products adhere to necessary safety and quality regulations. -

Regular Audits and Quality Assessments:

Look for manufacturers committed to ongoing quality improvement and who subject their production processes to regular audits. This commitment to quality ensures that every batch of paddles meets industry standards. -

Consult Industry Experts:

Engage with industry experts or certification bodies to get updated insights on evolving standards. For global markets, staying informed about any regulatory changes is key to remaining compliant.

A structured approach to verifying certification quality not only supports regulatory compliance but also boosts confidence in the procurement process.

Industry data consistently shows that certified equipment yields fewer safety concerns and higher customer satisfaction. Distributors who invest in certified products see improved market performance due to reduced return rates and enhanced customer loyalty. For instance, paddles tested under stringent conditions—and displaying reliable quality metrics—are favored in competitive environments and attract better pricing tiers.

Case studies from companies like NEX Pickleball demonstrate that rigorous certification processes contribute to an overall reduction in manufacturing defects and better user satisfaction. By following the detailed testing and certification protocols, manufacturers can not only abide by current standards but also adapt quickly to evolving industry requirements.

Moreover, data from market surveys indicate that adherence to certification requirements can result in up to a 20% increase in market acceptance, due largely to enhanced trust from retailers and end-users. Such figures underline the importance of a robust compliance system in maintaining a competitive edge.

In summary, certifications for pickleball paddles serve as a vital tool in assuring quality, safety, and market competitiveness. By tightly integrating internationally recognized standards such as ISO standards4, CE mark5 and USA Pickleball regulations into the manufacturing process, companies like NEX Pickleball are able to produce paddles that meet stringent quality assurance protocols.

For procurement managers and quality assurance specialists, the key takeaways are:

• Verify that the paddle’s dimensions adhere to regulatory limits.

• Ensure that performance and safety testing, including PBCoR, are rigorously applied.

• Rely on internationally recognized quality management certifications like ISO 9001 and CE certificates for market acceptance.

• Engage with manufacturers that demonstrate transparency and robust testing protocols.

• Keep abreast of industry trends and changes in certification standards for continuous compliance.

Taking these actionable steps will help you make informed purchasing decisions and maintain product quality throughout your distribution network. Certification is not just a legal requirement—it is a vital component of brand reliability and competitive market positioning.

-

What are the requirements for a pickleball paddle?

Answer: Pickleball paddles must adhere to specific dimensional limits, such as a maximum length of 17 inches and a combined length and width not exceeding 24 inches. These standards ensure consistent performance and fair play. -

Are pickleball paddles regulated?

Answer: Yes, pickleball paddles are regulated through standards like the Paddle/Ball Coefficient of Restitution (PBCoR) to maintain competitive balance and ensure the product meets safety and quality criteria. -

What is the USA Pickleball paddle test?

Answer: The USA Pickleball paddle test evaluates paddle dimensions—ensuring that the paddle does not exceed the approved size limits—and assesses performance characteristics. It confirms that the paddle is compliant with established measurement and performance standards.

-

Certification standards: Click to learn how standardized certification criteria help businesses ensure product safety, quality, and regulatory compliance through clearly defined testing and measurement processes. ↩

-

USA Pickleball: Click to explore the role of USA Pickleball in establishing sport-specific guidelines and performance metrics that ensure fair play and safety in pickleball equipment. ↩

-

Paddle/Ball Coefficient of Restitution (PBCoR): Click to discover more about how the PBCoR test measures a paddle’s performance characteristics to ensure balanced play and competitive fairness. ↩

-

ISO standards: Click to understand the importance of ISO certifications in managing quality and consistency, which are critical for gaining global market acceptance. ↩ ↩2

-

CE mark: Click to learn how the CE mark signifies compliance with European health, safety, and environmental protection requirements, bolstering product credibility. ↩ ↩2