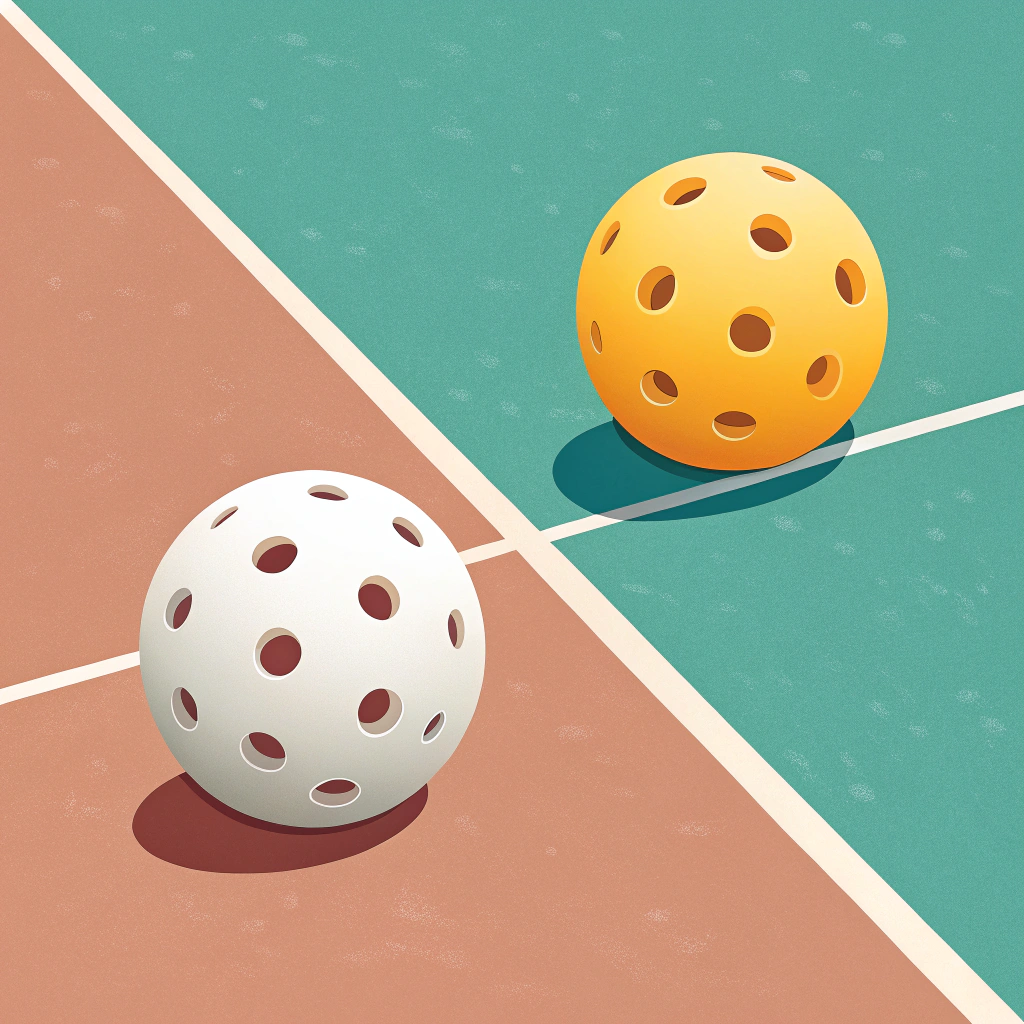

Indoor pickleball balls are typically lighter with softer plastic and larger holes for precise indoor play, whereas outdoor balls feature heavier, harder plastic with smaller holes to withstand wind and rough surfaces. This article thoroughly compares these two varieties to help you make an informed procurement decision for your market needs.

B2B purchasing managers often face the challenge of selecting the right pickleball ball to suit their target customer’s playing environments. The key difference lies in the design parameters: indoor balls are optimized for controlled, precision play on smooth surfaces, while outdoor balls are built to endure unpredictable weather conditions and rougher courts. This decision is not merely about aesthetics—it involves an in-depth technical evaluation of materials, performance durability, safety standards1, and cost-benefit analysis2.

The performance of a pickleball ball is directly influenced by its material composition3 and manufacturing process. Let’s break down these aspects:

-

Plastic Composition:

Indoor balls are generally made from softer plastics that allow for a controlled bounce on uniform indoor surfaces. In contrast, outdoor balls use harder plastic that adds durability and resilience in the face of wind and abrasive outdoor surfaces. -

Weight and Density:

Outdoor balls tend to be heavier to counteract wind interference, ensuring a consistent trajectory. Indoor balls, being lighter, permit more accurate ball placement and enhanced rebound control due to the lower impact forces on softer surfaces. -

Hole Configuration:

The number and size of holes in the ball are critical for aerodynamics. Outdoor balls usually sport smaller and fewer holes, reducing air drag and maintaining momentum, whereas indoor balls feature larger and more holes, which help slow down the ball for improved control in enclosed spaces.

Manufacturing methods such as injection molding4 and quality control testing contribute significantly to the final product’s consistency and performance. Manufacturers invest in advanced processes to ensure each ball meets strict performance and safety standards—a crucial factor when comparing indoor versus outdoor balls.

To better understand which type is suited for your market, consider this detailed table comparison:

| Parameter | Indoor Pickleball Balls | Outdoor Pickleball Balls |

|---|---|---|

| Material Hardness | Softer plastic for enhanced control | Harder, more durable plastic for rugged use |

| Weight | Lighter weight for reduced trajectory interference | Heavier to combat the effects of wind |

| Hole Size & Count | Larger, more holes for slower, controlled bounce | Smaller, fewer holes for improved aerodynamic stability |

| Surface Durability | Designed for smooth indoor courts; less wear resistance needed | Engineered to handle rough surfaces and weather extremes |

| Vibration Dampening | Enhanced ball feel with more bounce consistency | May exhibit lower bounce consistency in windy conditions |

| Cost Implications | Typically lower production cost due to fewer durability requirements | Higher production cost due to robust material and design requirements |

This table provides a clear breakdown, allowing you to match each parameter to your specific market's demands. Consider the playing environment, consumer expectations, and price sensitivity when interpreting these features.

Understanding performance differences is vital not only from a user experience perspective but also with regard to industry safety and testing standards.

Both indoor and outdoor pickleball balls undergo rigorous quality control tests to ensure they meet key performance metrics. These tests include:

- Impact Resistance: Essential for outdoor balls facing potential hits on rough surfaces.

- Bounce Consistency: A vital parameter for ensuring game fairness; indoor balls typically excel here.

- Durability under Varying Temperatures: Outdoor balls must maintain performance in fluctuations from cold to hot weather.

Manufacturers may also align with international safety standards, ensuring both product types are certified for professional use in sports clubs and retail environments. Such certifications provide additional assurance to purchasing managers regarding the longevity and reliability of the balls.

From a cost perspective, outdoor balls may have higher production costs due to the need for more durable materials and advanced processing techniques. However, the added expense is offset by their increased lifespan and performance in challenging conditions, representing a better long-term investment in outdoors-heavy markets.

Indoor balls, with their less demanding material requirements, often come with a lower price tag—ideal for facilities or regions primarily focused on indoor sports without compromising on in-game performance. A clear cost-benefit analysis should carefully weigh upfront costs against long-term durability and performance expectations.

The end-use scenario crucially influences product selection. Here’s how indoor and outdoor pickleball balls cater to different market segments:

- Facilities: Ideal for sports clubs, schools, and indoor recreational centers where surfaces are smooth and controlled.

- Player Levels: Suitable for beginners and professionals alike, offering predictable ball behavior and enhanced touch on hard indoor courts.

- Performance: Their design allows for precise control and consistent bounce—a major factor in competitive indoor play.

- Facilities: Best suited for outdoor facilities like community parks, outdoor tennis courts, and sports complexes.

- Player Levels: Often recommended for advanced players who require quick rebound and power in varied weather conditions.

- Performance: The heavier, harder design counters wind and surface irregularities, making them indispensable in outdoor competitions.

When making a decision, consider the predominant playing environment. For buyers serving markets with diverse seasonal conditions, outdoor balls provide reliability, whereas indoor balls excel in environments where control and consistency are merited.

For a B2B purchaser evaluating which pickleball ball to stock or supply, keep the following decision-making guidelines in mind:

-

Assess Customer Demand:

Understand whether your target market uses indoor facilities, outdoor courts, or a combination of both. This helps direct the inventory mix appropriately. -

Review Technical Specifications:

Compare the ball dimensions, weight, material composition, and hole configuration. These technical details are crucial for ensuring the product meets performance expectations. -

Consider Environmental Factors:

Evaluate local weather conditions and facility maintenance standards. Outdoor balls should be prioritized in hotter climates or areas with high exposure to elements, while indoor balls are preferable where surface quality is controlled. -

Evaluate Cost Versus Durability:

Conduct a cost-benefit analysis considering both immediate budget constraints and long-term replacement cycles. Outdoor balls may require a higher initial investment but often result in lower replacement costs over time due to their superior durability. -

Regulatory and Safety Standards:

Ensure that the selected balls comply with any local or international safety certifications. Regulatory compliance adds credibility and ensures product reliability, especially in competitive or high-volume sectors. -

Feedback and Testing:

If possible, obtain samples for practical evaluation or review independent test data. Real-world feedback from players and facility managers can provide invaluable insight into product performance and help mitigate procurement risks.

In summary, the choice between indoor and outdoor pickleball balls hinges on several key considerations: material differences, weight and hole design, environmental durability, cost-effectiveness, and compliance with safety standards. By aligning your choice with the specific demands of your market—whether it’s a controlled indoor environment or a rugged outdoor setting—you can ensure optimal performance and customer satisfaction.

We recommend that purchasing managers carry out a thorough evaluation of their target customer’s needs, consider local environmental factors, and analyze product specifications in detail before making a final procurement decision. Investing in the right product mix not only enhances user experience but also drives customer loyalty and long-term business growth.

Overall, a detailed technical comparison and a well-informed decision-making process are essential. With this comprehensive guide, you now have a clear framework to decide which type of pickleball ball—indoor or outdoor—matches your business objectives and market needs, ensuring both optimal performance and cost efficiency in your sports equipment portfolio.

Q1: How to tell the difference between indoor and outdoor pickleball balls?

A1: Indoor pickleball balls are lighter with softer plastic and feature larger holes for controlled bounce on smooth surfaces, whereas outdoor balls are heavier, made from harder plastic with smaller holes, ensuring enhanced durability and stability in windy or rough conditions.

Q2: Can you use indoor pickleball balls outside?

A2: Although it is possible to use indoor pickleball balls outdoors, it is not recommended. Indoor balls are designed for smooth indoor surfaces, and their performance can be compromised in outdoor settings due to exposure to wind and rough surfaces. For optimal performance, outdoor pickleballs should be used on outdoor courts.

Q3: How do you know if a ball is indoor or outdoor?

A3: One key indicator is the number and size of the holes. Indoor pickleball balls generally have larger, more numerous holes and are made of softer plastic, while outdoor balls have smaller, fewer holes and are constructed of harder, more durable plastic to withstand outdoor conditions.

-

safety standards: Read this article to understand the international and local safety compliance requirements that ensure sports equipment reliability and player protection. ^Return ↩

-

cost-benefit analysis: Click here to learn how to effectively compare upfront costs with long-term durability and performance benefits for better procurement decisions. ^Return ↩

-

material composition: Discover how different materials affect the performance and life span of sports equipment, helping you make informed technical evaluations. ^Return ↩

-

injection molding: Explore the injection molding process and its role in ensuring product consistency and quality control in manufacturing operations. ^Return ↩