USAPA-approved pickleball balls must meet strict technical requirements—including precise weight, diameter, bounce, and material durability—ensuring consistent performance in competitive play. In this article, we will examine the regulatory criteria and manufacturing practices necessary for producing a regulation pickleball ball and provide actionable insights for product managers and technical buyers1 in the sporting goods industry.

Understanding the Critical Specifications

Competitive pickleball demands that every ball used on the court maintains a reliable, predictable performance. USAPA standards2 set a rigorous benchmark for manufacturing, quality control3, and performance testing. For technical buyers, it is essential to grasp these specifications to guarantee that any product sourced or developed meets tournament requirements.

Pickleball balls approved by USAPA must conform to guidelines concerning weight, size, bounce consistency, and material composition4. These standards are not arbitrary; they are based on detailed testing and feedback from professional competition—ensuring that every ball delivers a fair and exciting game experience.

Regulatory Compliance and Performance Criteria

One of the primary challenges facing manufacturers is ensuring that the final product adheres exactly to the prescribed technical parameters. Let’s delve into the most critical specifications and the reasoning behind them:

-

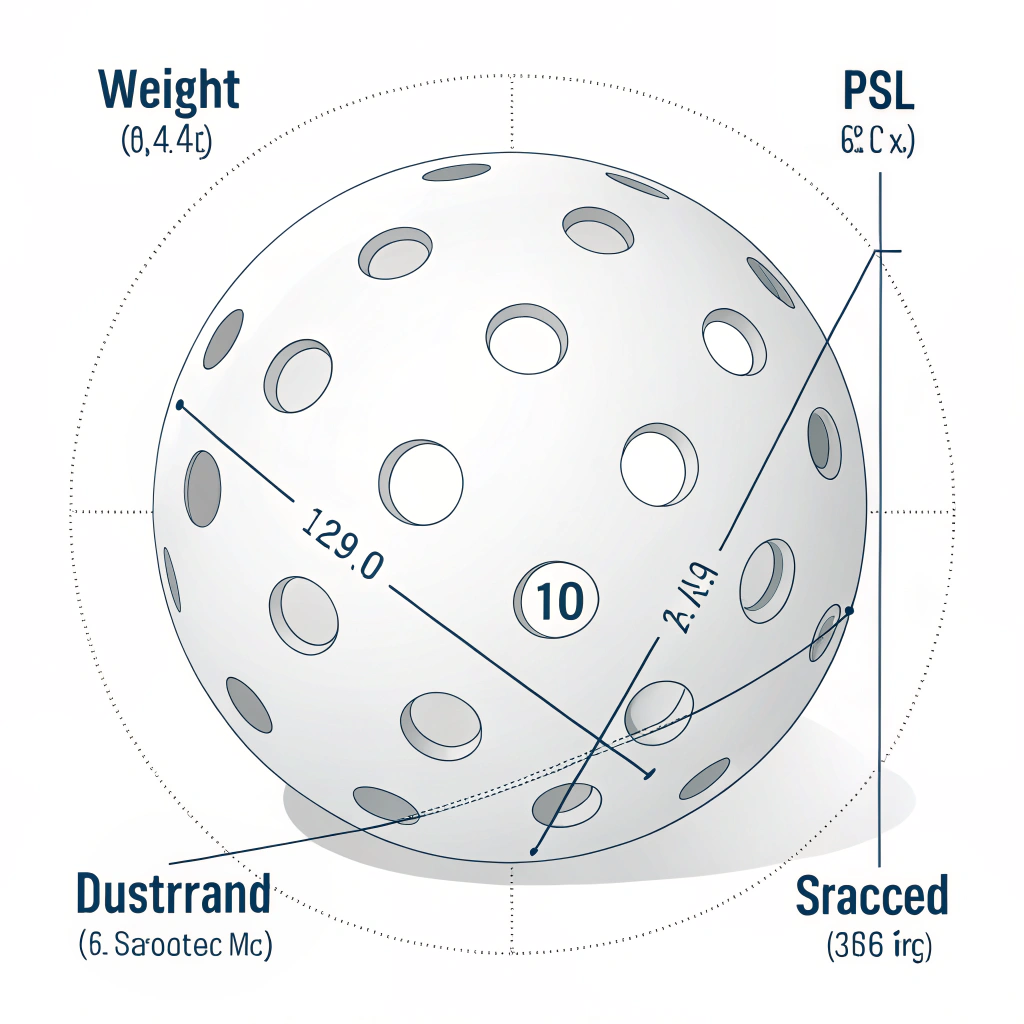

Weight:

USAPA standards require that a pickleball weighs between 0.78oz (22.11g) and 0.935oz (26.51g). This weight range is crucial as it affects the ball’s flight dynamics, rebound force, and overall playability. Heavier balls tend to be preferred for outdoor play because they can better resist wind interference, while slightly lighter balls are more common indoors. -

Diameter and Size Consistency:

Although the weight is heavily regulated, the diameter of the ball also plays an important role. A regulation pickleball typically has a diameter close to 2.87 to 2.97 inches, ensuring uniformity in play. A precise diameter guarantees that the ball rebounds consistently off surfaces, allowing players to anticipate its behavior accurately. -

Bounce and Hardness:

The bounce height and consistency are standard performance metrics established through rigorous testing. A regulation ball must consistently rebound to a specified height when dropped from a predetermined distance on a standardized surface. This requirement ensures that the bounce is reliable, a critical factor in high-stakes tournament play. -

Material Composition and Durability:

The materials used in manufacturing a pickleball ball must balance durability with performance. Typically, high-grade polymer compounds are used to enhance impact resistance while maintaining the necessary elasticity. The surface treatment should allow for optimal flight characteristics and a steady bounce throughout the ball’s service life. Manufacturers often choose materials that minimize deformation under repeated impact, ensuring longevity and sustained performance.

A detailed table below summarizes the primary USAPA compliance specifications:

| Specification | Requirement/Range | Purpose/Impact |

|---|---|---|

| Weight | 0.78oz (22.11g) – 0.935oz (26.51g) | Ensures consistent flight and rebound dynamics. |

| Diameter | ~2.87 – 2.97 inches | Maintains uniformity in bounce and performance. |

| Bounce Height | Consistent rebound meeting testing standards | Guarantees performance predictability on court. |

| Material Composition | High-grade polymer with proper elasticity | Balances durability with playability. |

| Surface Texture | Smooth with controlled grip | Facilitates optimal flight characteristics. |

Manufacturing Processes and Quality Control

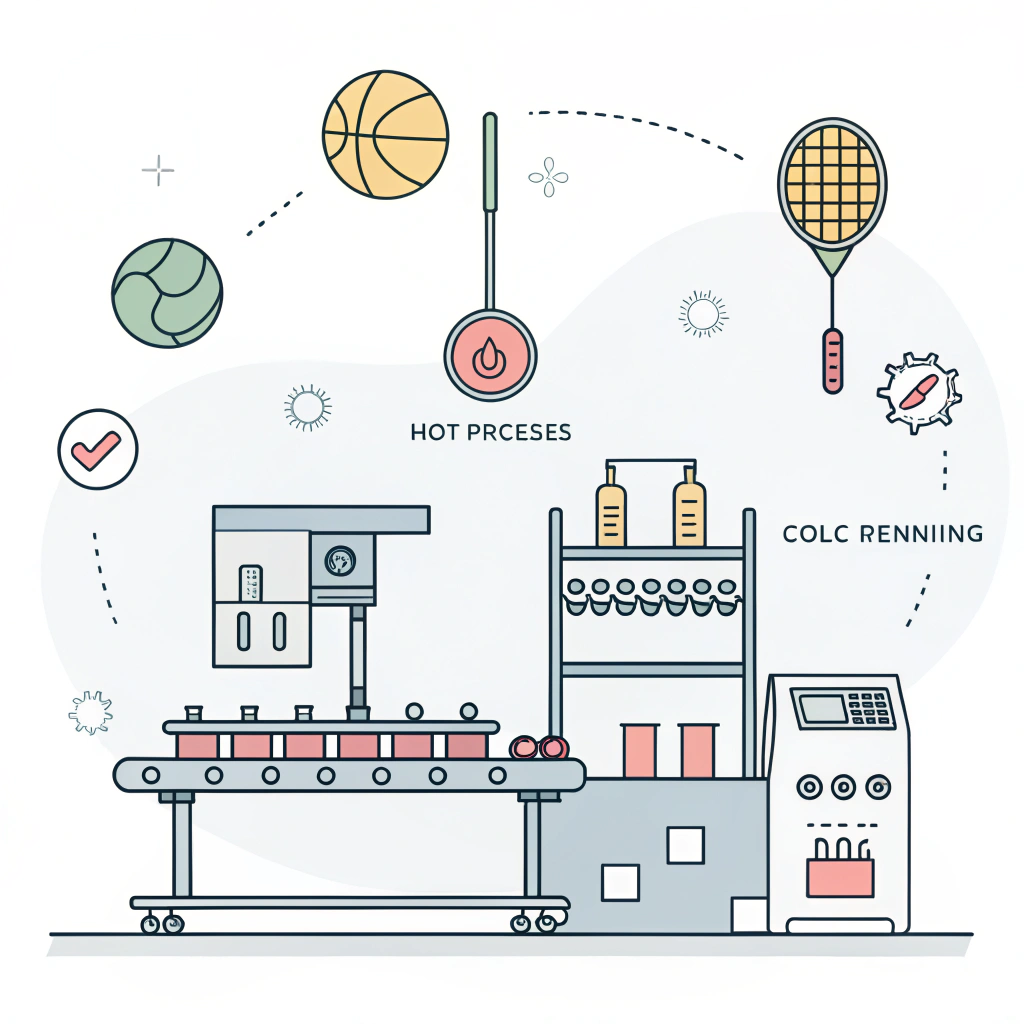

Achieving USAPA approval involves rigorous quality control at every step of the production process. Manufacturers must balance production efficiency with the precise handling of materials. Several advanced production techniques are typically employed:

• Hot Pressing: This technique involves heating the polymer material and applying pressure to mold the ball, resulting in a durable product with consistent performance.

• Cold Pressing: Used typically for enhanced control over the material’s final density and surface finish, cold pressing helps preserve the material’s intrinsic properties and ensure uniform performance.

• Thermoforming5: In situations where intricate designs or specific material distribution are required, thermoforming provides the precision necessary to meet stringent standards.

These methods allow manufacturers to fine-tune the final characteristics of the ball, ensuring that even minor variations in the production process do not adversely affect performance. Quality control teams use standardized testing protocols—including drop tests, bounce assessments, and durability trials—to guarantee every ball meets USAPA criteria before it is approved for tournament play.

Challenges and Considerations in the Compliance Process

Despite the clarity of these specifications, several challenges can complicate the production process:

a. Environmental Influences:

Temperature and humidity can affect material properties during production, posing a challenge for quality control. Manufacturers must use controlled environments to maintain consistency in the material behavior and final product performance.

b. Material Variability:

Variations in polymer compounds or inconsistencies in surface treatments could lead to slight deviations from the ideal specifications. This necessitates rigorous, ongoing quality audits during production.

c. Production Scale:

For high-volume production, maintaining uniform standards across all batches is challenging. Automated production lines with precise control mechanisms are required to ensure that every ball produced matches the required performance indicators.

d. Comparative Performance:

In the competitive world of pickleball, players often compare ball performance based on detailed characteristics like rebound consistency and flight behavior. For technical buyers, understanding how different manufacturing methods affect these factors is essential to making informed procurement decisions.

Manufacturers who are committed to meeting these challenges will typically invest in advanced production technologies and robust testing methods. This approach not only ensures compliance with USAPA standards but also fosters trust among distributors and end-users.

A Comparative Look: USAPA Standards vs. Industry Benchmarks

While USAPA sets specific guidelines, it is helpful to compare these standards against industry benchmarks and performance trends. The following table provides a side-by-side look at how USAPA-approved balls measure against general industry expectations:

| Criterion | USAPA-Approved Standard | General Industry Expectations |

|---|---|---|

| Weight | 22.11g – 26.51g | Similar range; slight variations for customized use |

| Diameter | ~2.87 – 2.97 inches | Often matches standard for consistency |

| Bounce Consistency | Rigid testing for specific rebound heights | Varies based on experimental design and testing rigs |

| Material Durability | High-grade polymers with controlled elasticity | Can range from general-use to high-performance grades |

| Production Techniques | Emphasis on hot pressing, cold pressing, thermoforming | Diverse methods; quality highly dependent on process control |

This comparison highlights that while the industry may accommodate a range of manufacturing practices, adherence to USAPA standards ensures that the product is optimized for competitive play and meets rigorous quality control benchmarks.

Implementing Best Practices for Sourcing and Development

For B2B buyers, particularly those in product management and technical sourcing, ensuring regulatory compliance in your supply chain is a critical decision factor. Here are a few recommended best practices:

-

Supplier Audits:

Before partnering with a manufacturer, conduct thorough audits to verify that their production processes align with USAPA standards. This includes examining their testing protocols, employee training certifications, and equipment certifications. -

Prototype Testing:

Request sample products and conduct your own performance tests. Measure critical specifications like weight, diameter, and bounce consistency. Independent testing not only verifies compliance but also gives you insight into potential performance variances under different environmental conditions. -

Transparent Reporting:

Work with suppliers who offer detailed production reports and compliance certificates. Transparency builds trust and facilitates continuous improvement in product quality. -

Comparative Analysis:

Align your procurement process with industry benchmarks by comparing your supplier’s product specifications against both USAPA standards and peer products in the market. Tools such as detailed specification tables and performance tests can support your decision-making process. -

Continuous Feedback:

Stay connected with end-users and professional players to gather feedback on ball performance. This real-world input can be instrumental in fine-tuning future production runs and ensuring that each batch of balls remains competitive and compliant.

By following these best practices, technical buyers can ensure that their products not only comply with regulatory standards but also deliver the high-performance characteristics that advanced players demand.

Conclusion and Actionable Recommendations

Ensuring that pickleball balls meet USAPA standards involves a careful balance between advanced manufacturing techniques, rigorous quality control, and continuous feedback from real-world usage. For distributors and manufacturers alike, understanding the detailed technical criteria—from weight and diameter to material composition and bounce performance—is essential for product success.

As a final takeaway, here are the actionable steps to ensure compliance and optimal product performance:

• Verify that your product specifications align precisely with USAPA standards.

• Invest in modern production techniques like hot pressing, cold pressing, and thermoforming to ensure consistent quality.

• Implement robust quality control procedures, including prototype testing and standardized performance tests.

• Maintain transparent communication with suppliers by requesting detailed compliance reports and certificates.

• Engage with the end-user community to gather continuous feedback and refine product performance over time.

By adopting these strategies, you not only uphold regulatory standards but also position your product to be competitive in a rapidly evolving market. Continuous attention to technical detail and quality assurance will help ensure that your pickleball balls are ready for high-level tournament play and meet the evolving expectations of both players and distributors.

People Also Ask

Q: What pickleballs are approved for tournament play?

A: The approved pickleballs for tournament play are those that adhere strictly to USAPA specifications. One popular example is the Dura Fast-40, which features a patented hole pattern machined into a single seamless piece to deliver perfect bounce, speed, and superior flight characteristics.

Q: What is a regulation pickleball ball?

A: A regulation pickleball ball must weigh between 0.78oz (22.11g) and 0.935oz (26.51g) and meet standardized criteria for size, bounce, and material performance. Although players may prefer slightly different weights for indoor versus outdoor play, the official USAPA guidelines do not differentiate between the two.

-

technical buyers: Click here to learn about the role and expectations of technical buyers in the sporting goods industry, including how they evaluate product specifications and regulatory compliance. ↩ ↩

-

USAPA standards: Read this article to understand the comprehensive guidelines that govern manufacturing, performance testing, and compliance in competitive pickleball production. ↩ ↩

-

quality control: This article explains quality control practices crucial for ensuring consistent production and maintaining regulatory standards in manufacturing. ↩ ↩

-

material composition: Explore this resource to gain insight into the importance of material composition in product durability and performance for sporting goods. ↩ ↩

-

thermoforming: Discover detailed information on thermoforming processes and how this manufacturing technique enhances precision and quality in product fabrication. ↩ ↩