Pickleball is rapidly emerging as one of Europe’s most exciting sports markets, and smart distributors recognize that aligning with high-performance, innovative equipment—such as the paddles from NEX Pickleball—is the key to capturing this growth opportunity. In this article, we explain why Europe’s pickleball trend is gaining traction, how NEX Pickleball’s cutting-edge production techniques and high-quality materials deliver a competitive advantage, and what strategies sports distributors and clubs can employ to tap into this booming market.

Europe’s pickleball market is expanding quickly. With an increasing number of sports clubs, recreational centers, and professional tournaments, the sport’s popularity is driven by its accessibility and fast-paced gameplay. European sports distributors, club managers, and B2B procurement executives are beginning to explore partnerships with suppliers who can provide top-tier, performance-enhancing equipment.

High-performance paddles represent a critical element for market differentiation. Not only do these paddles empower players to compete at their best, but they also provide distributors with a unique selling point to capture and lead an emerging market. As the sport grows, aligning your portfolio with a reputable manufacturer like NEX Pickleball can unlock significant market potential.

At the heart of our competitive edge lies a strict commitment to advanced manufacturing techniques and the use of premium materials. NEX Pickleball employs three primary production processes—hot pressing, cold pressing, and thermoforming1—that ensure every paddle meets high-performance benchmarks.

Our paddles are built using several premium materials:

- Carbon Fiber2: With variants such as 3K, 12K, and T300, carbon fiber paddles cater to various player needs. For instance:

- 3K Carbon Fiber: Offers a balance of strength and flexibility, ideal for achieving high rebound force.

- 12K Carbon Fiber: Boasts a smoother surface and exceptional durability, perfect for competitive advantages.

- T300 Carbon Fiber: Known for its excellent tensile strength, delivering both power and lightweight precision.

- Fiberglass: Provides a wider sweet spot with improved ball control. The E-Glass fiberglass variant ensures elasticity and a quality feel.

- Composite Materials3: Combining carbon fiber with fiberglass or using bamboo core composites offers a balanced mix of strength, lightness, and flexibility that suits players seeking both control and power.

- Core Innovations: Whether using Nomex, Aluminum, or Polymer Honeycomb cores, our paddles are engineered for optimal shock absorption, stability, and a precise hitting feel.

This use of top-tier components not only distinguishes our products but also helps sports distributors deliver superior performance equipment tailored to varying player needs.

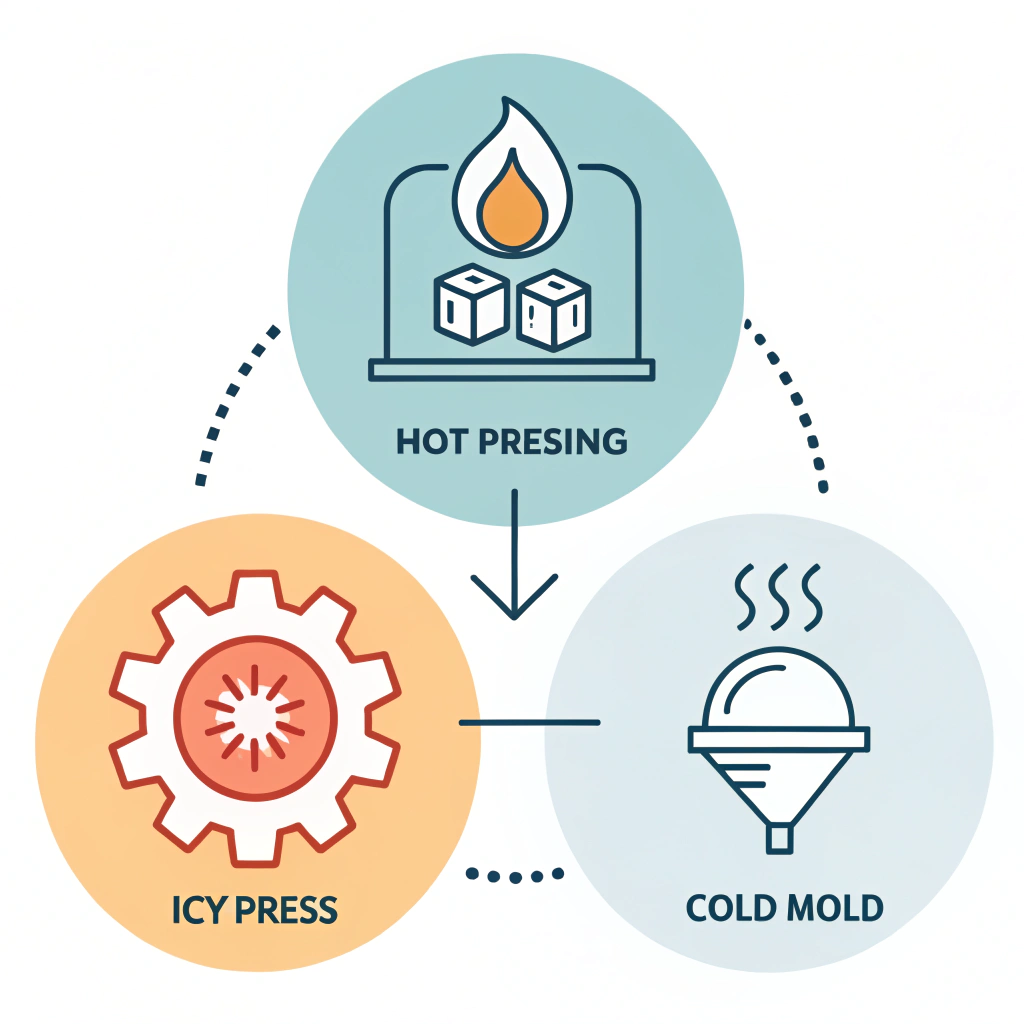

An efficient and innovative manufacturing process is the backbone of any high-performance sports equipment. NEX Pickleball leverages three distinct techniques to deliver paddles that meet exacting standards:

- Process: Materials are heated and pressed into shape.

- Advantages:

- High production efficiency suitable for scaling.

- Produces paddles with excellent impact resistance.

- Maintains structural integrity under high-performance conditions.

- Disadvantages:

- Potential alterations to material feel.

- High initial investment in machinery.

- Process: Uses mechanical pressure at room temperature to shape paddles.

- Advantages:

- Provides precision in thickness and geometry.

- Preserves the inherent material properties.

- Enhances ball control and responsiveness.

- Disadvantages:

- Slower production cycles.

- Demands high-precision equipment and control.

- Process: Involves heating materials to a softening point followed by forming in molds.

- Advantages:

- Allows for intricate design and uniform material distribution.

- Results in stable paddles that enhance on-court performance.

- Ideal for premium and custom orders.

- Disadvantages:

- Requires longer production times.

- Involves higher equipment costs.

Below is a comparative table summarizing the three processes:

| Process | Key Advantage | Main Disadvantage | Ideal For |

|---|---|---|---|

| Hot Pressing | Efficient mass production with strong impact resistance | May affect material feel; high machinery cost | High-performance, durable paddles |

| Cold Pressing | Precise control over structural dimensions | Longer production cycle | Paddles requiring high ball feel |

| Thermoforming | Intricate design with even material distribution | Longer production time; premium cost | Custom-made and premium paddles |

This table demonstrates how each process is uniquely positioned to meet different customer needs, empowering distributors to make informed product choices tailored to their market segments.

For European sports distributors and club managers, integrating a new product line into your existing portfolio involves both market analysis and strategic supplier selection. Here are concrete steps and strategies that can support your decision-making process:

Understanding the rapid rise of pickleball in Europe is essential. Here are a few action points:

- Gather regional sports participation data.

- Monitor growth trends at local clubs and sports centers.

- Engage with local pickleball associations to get firsthand insights.

When assessing potential suppliers, consider the following:

- Product Quality: NEX Pickleball’s use of advanced materials and rigorous testing protocols ensures every paddle meets international performance standards.

- Manufacturing Efficiency: Different processes may offer benefits depending on scale and customization needs.

-

- As the OEM partner4 for renowned brands like Joola and Selkirk, our reliability is well-proven in the market.

Distributors can benefit from various partnership opportunities:

- Exclusive Distribution Agreements5: Secure a competitive edge by becoming the sole distributor for a region.

- Co-branding Initiatives: Enhance your market presence by featuring customized designs and logos.

- On-Demand Print Services: Cater to local market trends with personalized paddle designs, reinforcing your brand’s commitment to innovation.

Implementing high-performance equipment in your distribution chain requires aligning your logistics and inventory management with supplier capabilities:

- Integrate real-time order tracking.

- Coordinate with production teams to manage custom orders effectively.

- Develop strong after-sales support to enhance customer satisfaction.

For sports distributors and club managers, the benefits of offering NEX Pickleball’s high-performance paddles extend beyond product quality:

- Enhanced Player Performance: High-tensile strength, superior ball control, and reduced vibration improve overall player experience, which can translate into more loyal customers for your clubs or retail outlets.

- Brand Differentiation: Featuring state-of-the-art materials and innovative designs sets your product portfolio apart in a competitive market.

- Market Leadership: Early adoption of emerging trends positions your business as a forward-thinking leader, ready to capture new market segments quickly.

Distributors who invest in high-performance, innovative paddle technology can better meet the evolving needs of both recreational and competitive players, thereby anchoring their position in a lucrative and growing market.

Europe’s pickleball market offers tremendous potential, largely driven by a renewed focus on sports innovation and performance. NEX Pickleball stands at the forefront with its advanced manufacturing processes, premium materials, and customer-centric approach. The combination of these factors has secured our position as the OEM partner for established brands and continues to attract new partnerships in European markets.

For European sports distributors, club managers, and B2B procurement professionals:

- Consider the long-term benefits of stocking high-performance paddles that have been engineered using rigorous quality controls.

- Evaluate supplier partnerships that provide both technological innovation and market agility.

- Act decisively to capture the expanding pickleball trend and ensure your organization remains competitive and forward-thinking.

By partnering with a proven market leader like NEX Pickleball, you can drive sales, enhance brand loyalty, and meet the growing demand for top-quality sports equipment. Explore opportunities for exclusivity, customization, and co-branding that empower your business to lead in an evolving sports landscape. Now is the time to invest in equipment innovation and secure your position in Europe’s emerging pickleball market.

Q: What drives the growing popularity of pickleball in Europe?

A: European players are drawn to pickleball due to its accessibility, fast gameplay, and excellent social and competitive aspects, which have rapidly increased the sport’s appeal across clubs and recreational centers.

Q: How do high-performance paddles improve competitive play?

A: High-performance paddles, especially those made from premium carbon fiber and advanced composite materials, offer superior power, precise control, and reduced vibration, which collectively enhance player performance during competitive play.

Q: What distinguishes the manufacturing processes for pickleball paddles?

A: Manufacturing processes such as hot pressing, cold pressing, and thermoforming each provide unique benefits—ranging from high production efficiency to precision control and customized designs—ensuring that paddles meet both high durability and exact performance specifications.

-

thermoforming: Read the article to understand how thermoforming works as a manufacturing process, offering detailed insights into its benefits and challenges for producing high-performance sports equipment. ↩ ↩

-

Carbon Fiber: Click to learn more about carbon fiber’s role in sports equipment manufacturing, including its variants and how its properties can enhance performance and durability. ↩ ↩

-

Composite Materials: Discover how composite materials combine different substances for optimal strength, lightness, and flexibility, and why they are critical in advanced paddle designs. ↩ ↩

-

OEM partner: Explore the concept of an OEM partner in the manufacturing industry, and how such partnerships drive innovation and reliability in sports equipment markets. ↩ ↩

-

Exclusive Distribution Agreements: Gain insights into exclusive distribution agreements and how they benefit B2B relationships by providing competitive advantages and market differentiation. ↩ ↩