Advanced negotiation strategies for sourcing high-performance pickleball equipment are essential for procurement managers aiming to balance quality, cost, and supplier reliability. In today’s competitive B2B environment, understanding supplier production capabilities, contract terms, and market trends is key to securing favorable deals with manufacturers like NEX Pickleball.

Procurement professionals in sports equipment distribution face a complex process when selecting pickleball suppliers. With the market rapidly growing and evolving, several issues arise:

• Balancing leading-edge technology with cost control

• Evaluating supplier production capacity and quality assurance processes

• Negotiating comprehensive contract terms that protect both parties

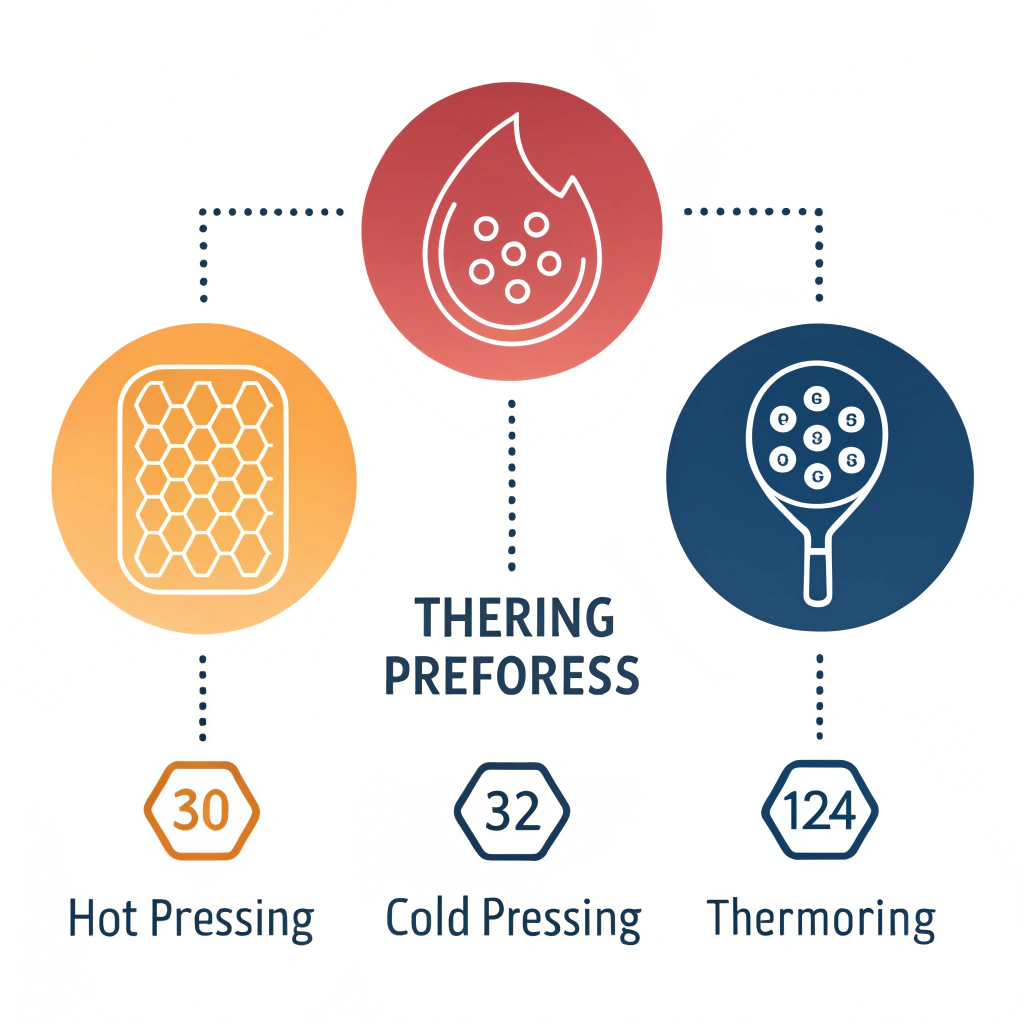

In addition, when dealing with advanced production techniques—like hot pressing1, cold pressing2, and thermoforming3 used by manufacturers such as NEX Pickleball—negotiators must appreciate the nuances in each process to match product performance with business needs.

The pickleball market is experiencing significant growth. With estimates showing a market value of USD 2.2 Billion in 2024, expected to reach USD 9.1 Billion by 2034, and growing at an impressive CAGR4 of 15.3%, procurement managers should recognize:

• The increasing demand for equipment, especially paddles and balls

• Intensified competition driving both price sensitivity and quality demands

• The need for robust supplier evaluation processes to secure a strategic advantage

Understanding the underlying reasons for negotiation complexities with pickleball suppliers can help in devising effective strategies. Key factors include:

-

Diverse Material Options:

Manufacturers use a range of premium materials such as carbon fiber5 (3K, 12K, and T300), fiberglass, and composite materials. Each offers unique benefits regarding durability, flexibility, and performance. Negotiators must understand these technical details to weigh cost vs. performance effectively. -

Production Process Variability:

Methods such as hot pressing lead to high production efficiency and strong impact resistance, cold pressing offers precision in thickness and control over the paddle’s feel, and thermoforming allows for intricate designs but requires more extended production times.Recognizing these factors allows procurement professionals to ask the right questions in negotiations and align terms with their quality and delivery expectations.

-

Supplier Relationship Complexity:

Long-term partnerships with suppliers require clear agreements on quality assurance, lead times, and contingency plans. The complexity of maintaining relationships while ensuring cost control often leads to intricate contract negotiations. -

Market Trends and Competitive Pressure:

Rapid market expansion and technological innovation demand that procurement managers stay updated with emerging trends and adjust negotiation tactics accordingly.

The following actionable strategies have proven effective when negotiating with high-performance pickleball equipment suppliers:

It is essential to request detailed information on the supplier’s production processes. Ask specific questions about:

• The production techniques used (e.g., hot pressing, cold pressing, thermoforming)

• Quality control measures and testing protocols

• Customization options and production lead times

A table outlining production processes may help compare and contrast supplier offers:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | Efficient, strong structural integrity | May alter material properties, equipment cost |

| Cold Pressing | Precise control, excellent ball feel | Longer production cycles, requires precision |

| Thermoforming | Complex designs, precise material distribution | Extended production time, higher equipment cost |

This table not only facilitates internal decision-making but can also serve as a discussion point during supplier negotiations.

Using up-to-date market data in negotiations can strengthen your negotiating position. For instance, referencing the recent growth projections in the pickleball market provides context when discussing pricing and supply chain terms.

Key data points to reference include:

• The market's growth trajectory from USD 2.2 Billion in 2024 to USD 9.1 Billion in 2034

• Product segments, particularly the dominance of equipment such as paddles and balls

• The rising importance of performance-enhancing materials and production innovations

This data not only justifies your cost-control goals but also demonstrates that you are a knowledgeable partner who understands industry trends.

Rather than a purely adversarial negotiation, approach supplier discussions as a partnership opportunity. Steps to foster this include:

• Establishing clear communication channels for discussing quality expectations, order volumes, and future growth opportunities

• Discussing flexible contract terms that allow for adjustments as market conditions evolve

• Exploring collaborative opportunities such as on-demand printing services for custom paddle designs, which can lead to mutually beneficial innovation

By building strong supplier relationships, you can negotiate better terms, secure priority production, and even get exclusive access to new product developments.

Detailed contract terms can protect both parties. Focus on:

• Quality assurance clauses: Specify acceptable quality parameters, such as production precision and product durability.

• Cost and pricing adjustments: Ensure there is room for negotiation based on order volume and market fluctuations.

• Delivery and lead time commitments: Clarify penalties or discounts related to delayed shipments or urgent orders.

• After-sales support: Establish terms for warranty, maintenance, and technical support, which are critical for long-term supplier reliability.

A well-drafted contract acts as a safety net during challenging market conditions and helps maintain quality standards. Highlighting case studies or data from previous successful negotiations with NEX Pickleball can also provide concrete examples of effective terms in action.

Before entering negotiations, preparation is key. Consider these action items:

• Research the supplier’s background, production process details, and track record in quality assurance.

• Prepare a list of questions and clarifications regarding material quality, production techniques, and delivery timelines.

• Develop a negotiation script that includes potential concessions in exchange for longer-term commitments or benefits.

• Analyze prior negotiation outcomes and adjust strategies accordingly. This includes reviewing case studies where similar negotiation strategies yielded successful contracts.

Gathering internal stakeholders, such as quality assurance experts or production supervisors, to review technical aspects and market data further enhances your discussion points.

By adopting these advanced negotiation strategies, procurement managers in sports equipment distribution can expect several benefits:

• Reduced overall costs without compromising on the quality of the pickleball equipment

• Enhanced supply chain reliability due to clear production and delivery parameters

• Strengthened long-term supplier relationships that foster mutual growth and innovation

• Competitive market positioning by aligning with reputable manufacturers like NEX Pickleball

Ultimately, a well-negotiated contract sets the stage for continued innovation and success. Companies can achieve a competitive edge by sourcing high-performance, durable paddles that meet the exacting standards of today’s pickleball players.

In conclusion, advanced negotiation strategies are vital when sourcing high-performance pickleball equipment. To summarize:

- Analyze supplier production capabilities thoroughly, using detailed comparisons and tables to guide decision-making.

- Leverage robust market data to ground your negotiations in current trends and future growth expectations.

- Embrace a partnership approach that prioritizes mutual benefits, flexibility, and long-term success.

- Focus on contract details including quality assurance, pricing adjustments, and delivery commitments to safeguard your interests.

- Prepare comprehensively for negotiation meetings by gathering relevant technical and market data and involving key internal stakeholders.

For procurement managers evaluating high-performance pickleball suppliers, these strategies will help you secure competitive pricing, robust quality standards, and reliable supplier relationships. The right approach not only improves cost control but also positions your company strongly in an increasingly dynamic market.

Q: What is the market for pickleball?

A: The pickleball market is rapidly expanding, valued at around USD 2.2 Billion in 2024 and expected to reach USD 9.1 Billion by 2034, growing at a CAGR of approximately 15.3%. This growth is largely driven by increasing demand for equipment, particularly paddles and balls, as the sport gains widespread popularity.

Q: What sporting goods would one purchase if looking to play pickleball?

A: Essential items for pickleball include a paddle, a ball, and appropriate athletic shoes. For court play, additional items like boundary markers might also be necessary.

-

hot pressing: Click here to understand hot pressing techniques, its impact on material properties, and its role in boosting production efficiency. ↩ ↩

-

cold pressing: Click here to explore cold pressing technology, highlighting its precision and the resulting control over product quality. ↩ ↩

-

thermoforming: Click here to discover how thermoforming works in molding intricate designs and the trade-offs regarding production time and cost. ↩ ↩

-

CAGR: Click here to gain insight into CAGR (Compound Annual Growth Rate) and how it's used to forecast market trends and business performance. ↩ ↩

-

carbon fiber: Click here to learn about the various grades and applications of carbon fiber in manufacturing, focusing on durability and performance benefits. ↩ ↩