Quick Answer: To create a successful custom pickleball paddle line, you must evaluate and compare production techniques, material options, and OEM manufacturing1 partners carefully while aligning them with your branding goals and market needs.

In today’s competitive sports equipment market, mid-level brand managers and B2B procurement specialists face the challenge of sourcing high-quality, customizable pickleball paddles that meet both performance and branding requirements. As demand for private-label sports equipment grows, it becomes increasingly important to balance technical production details with strong aesthetic differentiation. This article will detail the key production processes, material choices, and strategies to help you successfully launch a custom-branded pickleball paddle line that stands out in the market.

For many brands, the need to create a unique product offering in the pickleball market is driven by two main factors: product performance and brand differentiation. The ideal paddle must not only provide excellent play characteristics—such as power, control, durability, and comfort—but also support your branding strategy with customizable design elements.

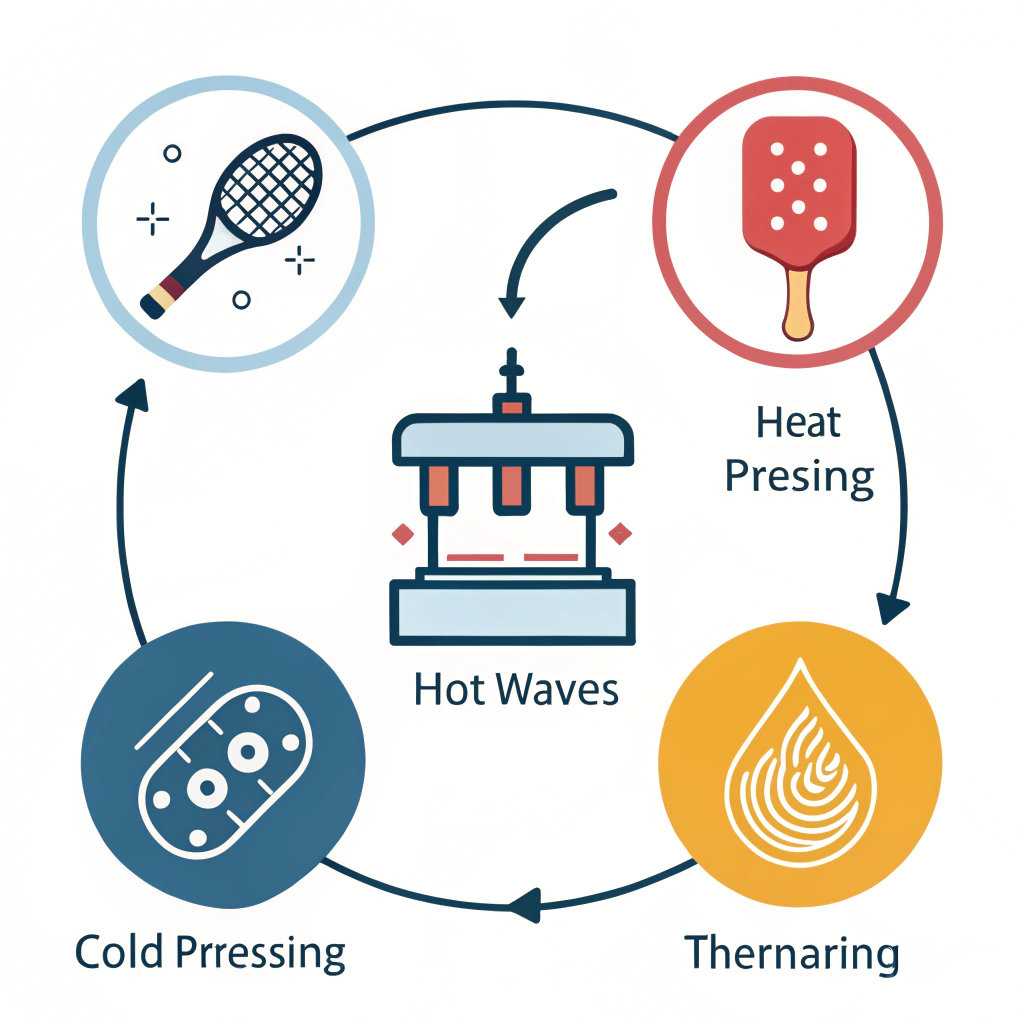

Brand differentiation in a crowded market depends on the consistent quality control of each paddle. Companies like NEX Pickleball, with expertise in OEM manufacturing1 and private-label production, offer advanced production techniques including Hot pressing2, cold pressing, and Thermoforming3. It is vital to understand these processes, as they directly influence the paddle’s performance and overall quality. Businesses which collaborate with such manufacturers enjoy the advantage of tailored solutions that are engineered to meet their specific market demands.

The production process is one of the most critical considerations since it establishes the paddle’s performance characteristics. Let’s look at the three main processes and compare their benefits and limitations:

Hot pressing involves heating the paddle materials and applying pressure to form a solid, durable structure.

- Advantages:

- High production efficiency for large volumes.

- Creates robust paddles with excellent impact resistance.

- Ensures strong structural integrity for high-performance play.

- Limitations:

- Some material properties may change slightly, potentially altering the paddle’s feel.

- Significant initial investment in specialized equipment is required.

Cold pressing shapes the paddle material at room temperature using mechanical pressure, offering precision in control over thickness and structure.

- Advantages:

- Superior precision in controlling the paddle’s structure.

- Preserves material integrity for an enhanced feel and responsiveness.

- Ideal for designs targeting excellent ball control.

- Limitations:

- Longer production cycles may limit efficiency.

- Demands high-quality equipment for precise pressure management.

Thermoforming heats the paddle material to its softening point, allowing it to be molded into complex shapes.

- Advantages:

- Facilitates intricate brake designs and fine-tuned material distribution.

- Enhances paddle stability and performance.

- Suitable for premium and custom-made paddles.

- Limitations:

- Higher equipment costs and extended production times can raise the final price.

- Better suited for customized premium products rather than high-volume output.

To provide a clearer comparison, consider the following table summarizing these production methods:

| Production Process | Key Advantages | Limitations | Best For |

|---|---|---|---|

| Hot Pressing | Efficiency, strong structure, high impact resistance | Alters feel, high initial investment | High-volume, performance-based paddles |

| Cold Pressing | Precise thickness control, preserves material properties | Longer production cycles, high precision equipment | Paddles prioritizing control & feel |

| Thermoforming | Intricate design capability, stability | Longer time & higher cost, premium segment | Customized, premium paddle lines |

Each method offers a distinct balance between production efficiency and product quality, making it essential for your procurement strategy to match the process with your specific product vision and market expectations.

Alongside production techniques, the materials used in manufacturing the paddle paves the way for performance characteristics and brand appeal. The right material selection enhances player experience by balancing power, control, and durability. Below is an overview of the key material choices:

Carbon Fiber4 Variants

- 3K Carbon Fiber:

Known for its strength and flexibility, this material gives a great rebound force while minimizing vibration—a perfect option for players who require durability in fast-paced play. - 12K Carbon Fiber:

With a higher thread density, this fiber provides a smoother surface and enhanced impact resistance. It is especially useful for competitive players looking for extreme strength. - T300 Carbon Fiber:

Renowned for its superb tensile strength, the T300 option strikes an excellent balance of weight and performance, ensuring both durability and responsiveness.

- E-Glass Fiberglass:

Offers a balanced approach by delivering enhanced elasticity and excellent ball control. Compared to carbon fiber, fiberglass paddles provide a more generous sweet spot for recreational players and those seeking ease of use.

- Carbon Fiber and Fiberglass Composite:

Combining the best attributes of both fibers, this composite provides a well-rounded performance ideal for players looking for both power and control. - Bamboo and Honeycomb Cores:

- Bamboo Core Composite: Provides a lightweight yet impact-resistant option that offers a clear hitting feel for long-lasting play.

- Honeycomb Core: Exhibits superior shock absorption and reduced vibration, ensuring durability during intense gameplay.

The paddle’s core plays a significant role in defining its strength and user experience. Options like Nomex Honeycomb ensure robust shock absorption, while Aluminum Honeycomb cores deliver balanced weight distribution for an optimized play style. These materials not only contribute to the paddle’s physical properties but also reinforce the brand promise of consistent, high-quality performance.

By selecting the right material, you directly influence the product’s market differentiation. High-performance pads that leverage advanced materials can be effectively branded as premium offerings, appealing to both recreational players and competitive athletes.

When creating a private-label product, aligning technical manufacturing details with market expectations is key. For brands looking to establish their own pickleball line, partnering with a reliable OEM manufacturer like NEX Pickleball provides significant competitive advantages:

-

Customization: OEM partners offer tailor-made solutions—from grip size and surface texture to paddle shape and weight distribution. This flexibility is critical for developing products that resonate with niche market segments.

-

Quality Control: Advanced production techniques ensure each paddle undergoes rigorous testing, aligning with the high standards your brand promises.

-

Cost Efficiency: Streamlining production through established manufacturing processes such as hot pressing, cold pressing, or thermoforming helps in maintaining a balance between product excellence and cost competitiveness.

-

Define Your Product Vision:

Outline your target market, desired performance characteristics, and branding elements. Consider how customization will enhance player experience. -

Evaluate Production Processes:

Examine the comparative benefits of Hot pressing2, cold pressing, and Thermoforming3. Use the provided table as a guide to match production capabilities with your product needs. -

Select Material Combinations:

Choose materials that provide the desired balance of power, control, and durability. Advanced composites and premium carbon fibers can elevate your paddle’s performance. -

Partner with a Trusted OEM:

Leverage the experience and production expertise of reliable partners like NEX Pickleball to ensure your product meets international quality and performance standards. -

Emphasize Customization in Branding:

Use design elements, from color choices (think innovation with unique hues like pink for standout appeal) to grip customization, to create a product that aligns perfectly with your brand identity. -

Implement Rigorous Quality Control:

Ensure every paddle undergoes detailed quality tests to deliver consistent performance across your line—a key requirement for long-term brand loyalty.

In summary, launching a custom pickleball paddle line requires a deep understanding of manufacturing processes, material science, and product customization. By carefully evaluating production methods such as Hot pressing2, cold pressing, or Thermoforming3, and pairing them with high-quality materials like various forms of Carbon Fiber4, fiberglass, and advanced composites such as Composite Materials5, you can position your brand at the forefront of the sports equipment market.

For B2B decision-makers, the strategic selection of an OEM partner that provides end-to-end solutions—ranging from production excellence to custom design—serves as a significant differentiator. The outlined steps offer a robust framework for creating paddles that not only perform at high levels but also embody your brand’s identity.

Your next step is clear: integrate these insights into your procurement strategy, partner with an established manufacturer, and launch a pickleball paddle line designed for performance and market impact. By doing so, you ensure that your product offering will resonate with both recreational and professional players, ultimately driving your brand’s success in a rapidly growing market.

Q: How to make your own pickleball lines?

A: Creating your own pickleball line starts with designing the product layout, marking court dimensions, and ensuring proper measurements are taken. While the detailed steps involve marking from the net and measuring the appropriate sidelines and baselines, the key takeaway is that a precise and methodical approach ensures the best results.

Q: Can I create my own paddle for pickleball?

A: Yes, there are countless ways to design and create a custom pickleball paddle. You can choose from various design elements such as colors, graphics, and even personalized quotes to make it unique. Advanced OEM partners enable you to bring these custom designs to life while ensuring high performance.

Q: What is the best material for a pickleball paddle to be made of?

A: The ideal material depends on the intended play style. Graphite or high-performance carbon fiber typically offers superior handling and feel, while fiberglass tends to enhance power due to its flexibility. Your choice should align with your target market’s preferences and performance demands.

-

OEM manufacturing: Click to learn about the strategic benefits of partnering with original equipment manufacturers, including streamlined production processes, quality control, and cost efficiency for building custom product lines. ↩ ↩ ↩2

-

Hot pressing: Click to explore how hot pressing works, its advantages in producing robust and high-impact resistant products, and considerations for equipment investment and material changes. ↩ ↩ ↩2 ↩3 ↩4

-

Thermoforming: Click to understand the thermoforming process, how it enables complex designs, its suitability for premium products, and the trade-offs regarding production time and cost. ↩ ↩ ↩2 ↩3 ↩4

-

Carbon Fiber: Click to delve into carbon fiber technology, its benefits in strength and flexibility, and why it is a favored material for high-performance sports equipment. ↩ ↩ ↩2

-

Composite Materials: Click to learn about composite materials, how they combine different fibers for balanced performance, and their role in enhancing both durability and playability in sports products. ↩ ↩ ↩2