Pickleball paddle cores are the heart of paddle performance, with options such as honeycomb1, EVA foam2, and polymer cores3 each offering unique benefits in power, control, and durability to suit different manufacturing and play needs.

In the rapidly growing pickleball industry, understanding the different core materials is crucial for B2B procurement managers, product engineers, and sports equipment distributors. Choosing the right paddle core not only influences the gameplay characteristics—such as responsiveness, shock absorption, and overall feel—but also affects production costs, durability, and the end-user experience. This article provides an in-depth examination of various paddle core materials, comparing their performance characteristics, manufacturing implications, and cost efficiencies to enable better procurement and production decisions.

Every pickleball paddle's performance is greatly influenced by its core material. The core acts as the shock absorber, influences the ball's rebound, and helps define the paddle's weight distribution and balance. For B2B decision-makers, it is essential to understand these materials to select optimal products that offer a strong balance between power and control while being cost-efficient.

Key performance parameters include:

- Shock Absorption: Reducing vibration during gameplay.

- Weight Distribution: Ensuring stability and maneuverability.

- Durability: Sustaining long-term play without compromising performance.

- Manufacturing Complexity: Balancing efficient production with high quality.

Below is a detailed look at the three primary core materials widely used in pickleball paddles today:

The honeycomb1 core is a popular choice among both recreational and competitive players. Its structure consists of a series of hexagonal cells that distribute impact forces evenly over the paddle surface.

• Performance Advantages:

- Enhanced Shock Absorption: The honeycomb architecture absorbs impacts well, reducing strain on the player’s arm.

- Balanced Power and Control: The cellular structure allows for a crisp feel without compromising control.

- Durability: The unique cell pattern helps maintain structural integrity over repeated impacts.

• Common Variants:

- Nomex Honeycomb Core: Made from high-strength polymer, it provides long-lasting durability and softens vibrations.

- Aluminum Honeycomb Core: Offers increased power due to its rigidity, though it might transmit more impact vibrations.

- Polymer Honeycomb Core: Often chosen for recreational paddles, delivering excellent elasticity and a comfortable hitting experience.

EVA foam2 cores have gained popularity for their ability to generate extra power with minimal effort. This material is valued for its lightweight properties and the additional boom it provides when striking the ball.

• Performance Advantages:

- Extra Power Generation: The softness of EVA allows the paddle to store and release energy effectively.

- Improved Comfort: Reduced effort on contact means less stress on joints, making it attractive for extended play sessions.

- Cost Efficiency: EVA cores can be manufactured at a lower cost, making them ideal for budget-friendly paddles.

• Use Cases:

- Recreational Play: Often used in paddles designed for beginners and recreational players.

- Entry-Level Competitions: Provides competitive players with a product that offers power without a heavy price tag.

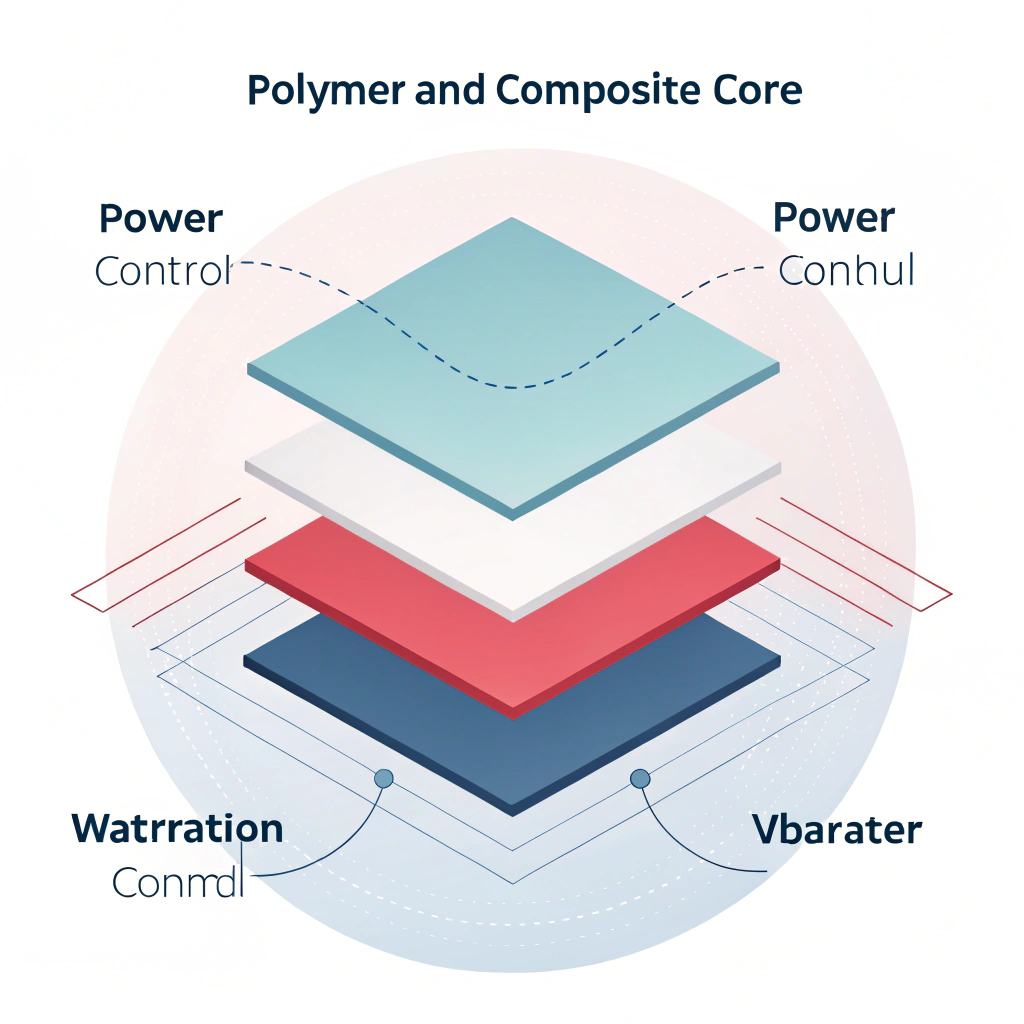

3. Polymer and Composite Cores4

Polymer cores3 are widely regarded as a superior option across multiple levels of play. They are engineered to offer a balanced mix of power, control, and reduced vibration.

• Performance Advantages:

- Balanced Performance: Offers excellent shock absorption and a consistent playing feel.

- Versatility: Suitable for various levels of play, from recreational to competitive.

- Reduced Vibration: Enhanced material properties result in a softer hit, minimizing arm fatigue.

• Composite Options:

- Carbon Fiber and Fiberglass Composite: Combines rigidity and flexibility to maximize both power and control.

- Bamboo and Honeycomb Composite: Incorporates natural materials for a unique balance of lightweight and strength.

To better inform your procurement decisions, consider the following table summarizing the key attributes of each core type:

| Core Type | Key Attributes | Advantages | Disadvantages | Ideal Use Case |

|---|---|---|---|---|

| Honeycomb Core | Hexagonal cell structure | Superior shock absorption, balanced feel, durable | May vary in performance based on material used | High-performance, competitive paddles |

| EVA Foam Core | Soft, lightweight foam | Extra power generation, cost-efficient, comfortable | Reduced control compared to rigid cores | Recreational and entry-level paddles |

| Polymer Core | Engineered polymers | Balanced performance, excellent vibration reduction | Can be more expensive than EVA cores | Versatile use across all skill levels |

| Aluminum Honeycomb Core | Rigid, metallic structure | Increased power, robust | Transmits more vibration | Performance-driven, robust play |

| Composite Cores | Combination of materials (e.g., Carbon/Fiberglass) | Optimized power and control, advanced material properties | Higher production complexity | Premium and custom paddles |

This table provides a quick reference for comparing the essential characteristics of each material. It allows decision-makers to quickly identify which core type aligns with their product requirements, whether that is for high-level competitive play, budget-focused production, or a balanced solution.

How these core materials are integrated into pickleball paddles is also crucial. Let’s explore the three primary manufacturing processes used and their impact on material performance:

Hot pressing involves heating the core material and applying pressure to form it into the paddle shape. This method is favored for its speed and efficiency in producing large quantities.

• Advantages:

- High production efficiency

- Strong impact resistance and structural integrity

• Disadvantages: - May alter intrinsic material properties

- Requires significant upfront investment in equipment

For honeycomb cores, hot pressing can enhance durability by properly bonding the cells, although care must be taken to preserve the material’s natural softness.

Cold pressing shapes the material at room temperature, maintaining the raw properties of the core without thermal alteration.

• Advantages:

- Preserves material flexibility and control

- Allows precise control over thickness and distribution

• Disadvantages: - Longer production cycle increases costs

- Demands high precision equipment

This process is ideal for EVA foam and polymer cores, where maintaining the natural elasticity of the material is critical for optimal performance.

Thermoforming5 uses heat to soften the material before it is molded into shape. This process is especially useful for creating intricately designed paddles with complex material distributions.

• Advantages:

- Enables detailed designs and efficient material use

- Maintains stability and balance in the final paddle

• Disadvantages: - Longer production time can elevate costs

- Higher equipment costs, making it best for premium products

Thermoforming is often applied in the production of high-end composite and polymer core paddles, ensuring an even distribution of materials for optimum performance.

When sourcing pickleball paddles or deciding on the manufacturing process, several factors must be taken into account:

-

Performance Requirements: Assess whether the paddle is targeted at recreational use, competitive play, or intermediate levels. Competitive paddles often prioritize a balance between shock absorption and power, whereas entry-level paddles may rely on simpler, cost-effective core materials like EVA foam.

-

Cost vs. Quality: While premium materials such as advanced polymers or high-quality honeycomb designs offer superior longevity and performance, they may also come with increased production costs. Balancing budget constraints with desired performance features is critical for B2B procurement managers.

-

Manufacturing Capabilities: The choice of production method (hot pressing, cold pressing, or thermoforming) significantly affects the core material’s performance. Companies need to ensure that their production facilities or partners can handle the nuances of these techniques without compromising quality.

-

Customization Needs: Many modern pickleball paddles are now engineered for specific player needs through custom cores that adjust for weight distribution, balance, and grip. This customization aspect is especially important for products aimed at team branding or specialized competitive requirements.

-

Durability and Longevity: The core material directly influences the paddle’s lifespan. For instance, while EVA cores provide an excellent cost-benefit ratio for recreational use, polymer cores and advanced composite options might be preferable for high-wear competitive environments.

To enhance your product offerings and meet the evolving demands of pickleball enthusiasts, consider the following actions:

- Conduct material trials comparing honeycomb1, EVA foam2, and polymer cores3 to see how each performs under real game conditions.

- Collaborate with production teams to evaluate which manufacturing process aligns with your product quality goals.

- Review market trends and customer feedback to continuously refine your paddle design based on core performance.

- Leverage composite core technology where feasible to combine the benefits of various materials, ensuring a balanced performance profile.

- Consider scalability and future-proofing: As pickleball continues to evolve, investing in advanced materials now could deliver long-term benefits.

A leading sports equipment distributor recently upgraded their paddle portfolio by introducing a hybrid core that combines a polymer honeycomb3 with a layer of EVA foam. This approach resulted in a paddle that offered a balanced mix of power and control without compromising on shock absorption.

The distributor reported:

- A 20% improvement in paddle longevity

- Enhanced feedback from both recreational and competitive players

- Simplified manufacturing processes due to the hybridization of established methods

This case study exemplifies how blending traditional and innovative core materials can deliver a product optimized for both performance and cost efficiency.

Understanding the various pickleball paddle core materials is essential for making informed B2B procurement decisions. The core is a fundamental component that directly affects paddle performance by managing shock absorption, weight distribution, and overall durability. Whether you choose the precise, balanced performance of a polymer core3, the power-boosting characteristics of EVA foam2, or the time-tested reliability of a honeycomb core1, each option has distinct advantages and trade-offs.

By leveraging technical insights and comparative analyses, you can tailor your paddle designs to meet specific market demands. Aligning production processes such as hot pressing, cold pressing, or thermoforming5 with these material choices further enhances the quality and consistency of the final product. For B2B procurement managers and product engineers, these insights provide a roadmap to optimize product performance, maintain competitive pricing, and ultimately deliver superior equipment to the market.

With ongoing innovation in material science and manufacturing techniques, today’s paddle cores are evolving faster than ever. Stay updated with the latest trends, conduct rigorous testing, and continuously seek feedback from both end-users and production teams. These practices will not only improve product quality but also secure a competitive advantage in the increasingly dynamic pickleball market.

Q: What are the different cores for pickleball paddles?

A: Pickleball paddles primarily use cores such as honeycomb cores1 (which can include Nomex, aluminum, or polymer variants), EVA foam cores2 for added power and comfort, and polymer cores3 known for balanced performance and excellent shock absorption. Each core type caters to different performance needs and manufacturing budgets.

Q: Is honeycomb core good for pickleball paddles?

A: Yes, honeycomb cores are excellent for pickleball paddles. Their hexagonal structure provides balanced power and control by enhancing shock absorption and reducing vibrations, making them suitable for players of all skill levels.

Q: What is EVA Core pickleball paddle?

A: An EVA core pickleball paddle uses EVA foam2 as the central material, which enables extra power generation with minimal effort. This type of core is especially popular in recreational and entry-level paddles due to its lightweight nature and cost effectiveness.

-

Honeycomb: Click to learn more about how the honeycomb structure distributes impact force evenly across a paddle’s surface, enhancing shock absorption and durability for competitive and recreational play. ↩ ↩ ↩2 ↩3 ↩4 ↩5

-

EVA Foam: Click to discover the benefits of EVA foam, including its lightweight properties and energy storage capabilities that provide extra power and improved comfort during extended play. ↩ ↩ ↩2 ↩3 ↩4 ↩5 ↩6

-

Polymer Cores: Click to explore how polymer cores deliver a balanced performance with excellent shock absorption and reduced vibration, ideal for versatile paddle use across multiple skill levels. ↩ ↩ ↩2 ↩3 ↩4 ↩5 ↩6

-

Composite Cores: Click to learn about composite cores, which combine multiple materials like carbon fiber and fiberglass to maximize both power and control, and how they can be used to create premium, custom paddles. ↩ ↩

-

Thermoforming: Click to understand how thermoforming works—a heat-assisted molding process that allows for intricate design details and optimal material distribution while maintaining paddle stability. ↩ ↩ ↩2 ↩3