A leading way to evaluate a Chinese manufacturer of pickleball paddles is to compare their production capabilities, material choices, and quality control through direct metrics such as production efficiency, technology processes, and cost effectiveness.

In the competitive world of sports equipment sourcing, specifically for pickleball paddles, procurement managers must make informed decisions. Choosing the right Chinese manufacturer involves a deep understanding of the production techniques used as well as the materials involved. This article provides a detailed comparison of key production processes and materials to consider when evaluating potential partners. It outlines how advanced techniques such as hot pressing1, cold pressing2, and thermoforming3 affect the performance, durability, and cost of paddles. With a technical yet practical perspective, this guide will assist you in making an optimal sourcing decision.

Procurement managers often face a dilemma when selecting a manufacturing partner for pickleball paddles. The decision must balance quality, production capability, lead time, and pricing. Key questions include: How do production processes influence paddle performance? Which materials offer the best balance of power and control? And how do manufacturing methods align with cost efficiency in bulk production? Addressing these concerns is critical, as the chosen supplier will impact both your competitiveness and customer satisfaction in the market.

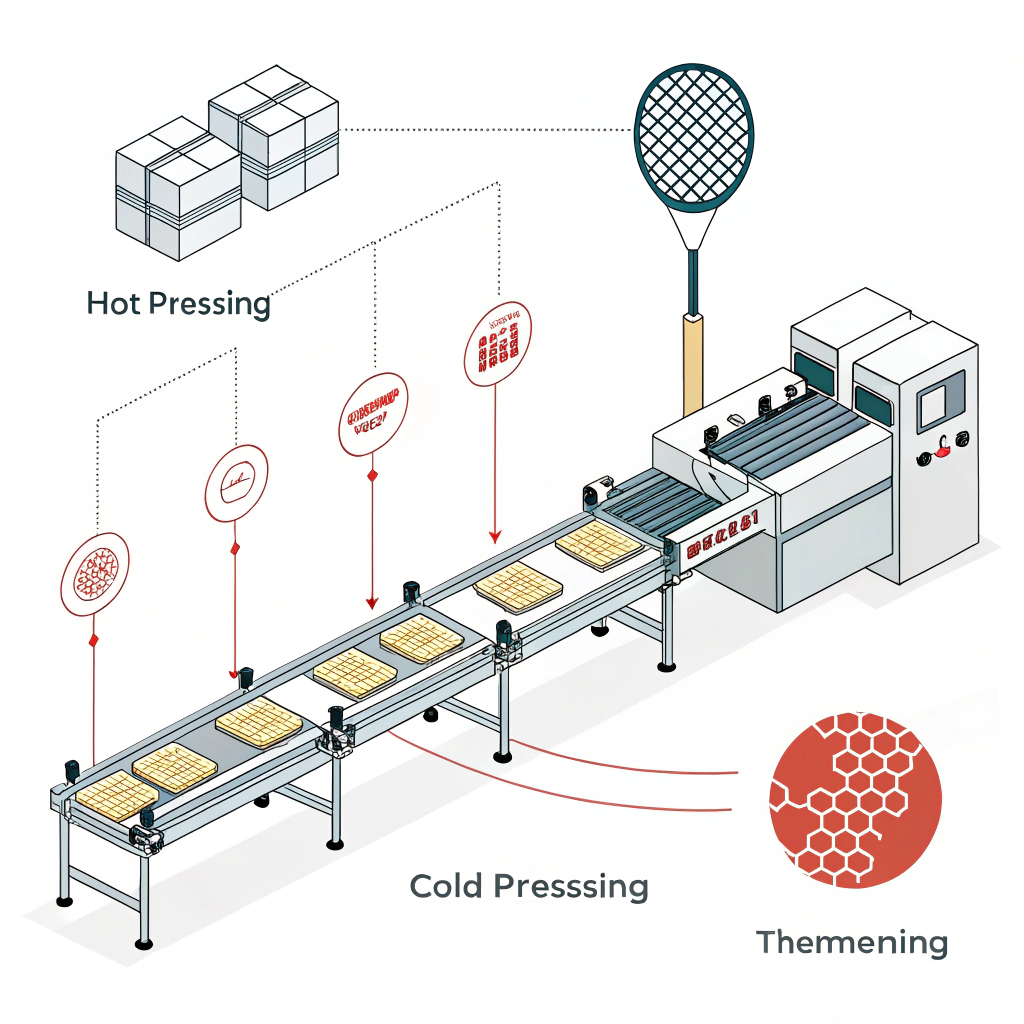

Understanding the various production techniques is essential for evaluating a manufacturer. Chinese manufacturers typically use three main processes for paddle production. Here’s a comparative table to quickly review these methods:

| Process | Advantages | Disadvantages | Ideal Application |

|---|---|---|---|

| Hot Pressing | High production efficiency; strong impact resistance; robust paddles with excellent structural integrity | May alter some material properties affecting the feel; high equipment investment | High-performance paddles for competitive play |

| Cold Pressing | Precise control over thickness and structure; preserves inherent material properties; excellent ball response | Longer production cycles; requires advanced and precise pressure control | Custom paddle designs for niche market segments |

| Thermoforming | Enables intricate designs and precise material distribution; maintains paddle stability throughout | Longer production times; higher costs due to advanced mold and equipment requirements | Premium, custom-made paddles with complex designs |

Each process has its own merits. A manufacturer using hot pressing1 might deliver paddles with excellent impact resistance ideal for high-level performance, while cold pressing2 ensures precise shaping and retaining the natural feel of materials. Thermoforming3 is best for manufacturers focused on premium, custom designs.

The choice of material is just as important as the production process. Each material contributes uniquely to paddle performance:

-

- 3K Carbon Fiber provides high strength and flexibility, essential for paddles that require a high rebound force.

- 12K Carbon Fiber offers a higher thread density, increased hardness, and enhanced durability—ideal for competitive play.

- T300 Carbon Fiber is balanced in strength and weight, suitable for paddles requiring precision and speed.

-

Fiberglass:

- Known for its wider sweet spot and enhanced durability, fiberglass paddles provide a balance between power and control. E-Glass, in particular, offers excellent elasticity and tensile strength.

-

- Carbon Fiber and Fiberglass Composite blends the benefits of both fibers, delivering a product that is both lightweight and robust.

- Bamboo Core Composite delivers a lightweight yet impact-resistant solution for players looking for a crisp hitting contact feel.

- Honeycomb Core and its variations (Nomex, Aluminum, Polymer) offer different characteristics from vibration reduction to enhanced shock absorption.

When evaluating a manufacturer, consider the diversity and quality of materials they work with. NEX Pickleball manufacturers, for instance, incorporate a variety of premium materials along with strict quality control that ensures each paddle meets high performance and durability standards.

The manufacturing process doesn't stop at production; quality control is equally critical. Advanced testing protocols and rigorous quality checks help to ensure the final product meets international standards. When evaluating a supplier, ask for details on:

- Inspection and Testing Procedures: Ensure that each paddle undergoes thorough testing for strength, elasticity, and balance.

- Production Consistency: A reliable manufacturer must have a track record of consistent product quality across large production runs.

- Technological Integration: Modern production facilities use advanced machinery that guarantees precision and reliability, which is key for meeting strict performance standards.

An experienced manufacturing partner will be transparent about their quality control measures and ready to discuss how they meet industry benchmarks.

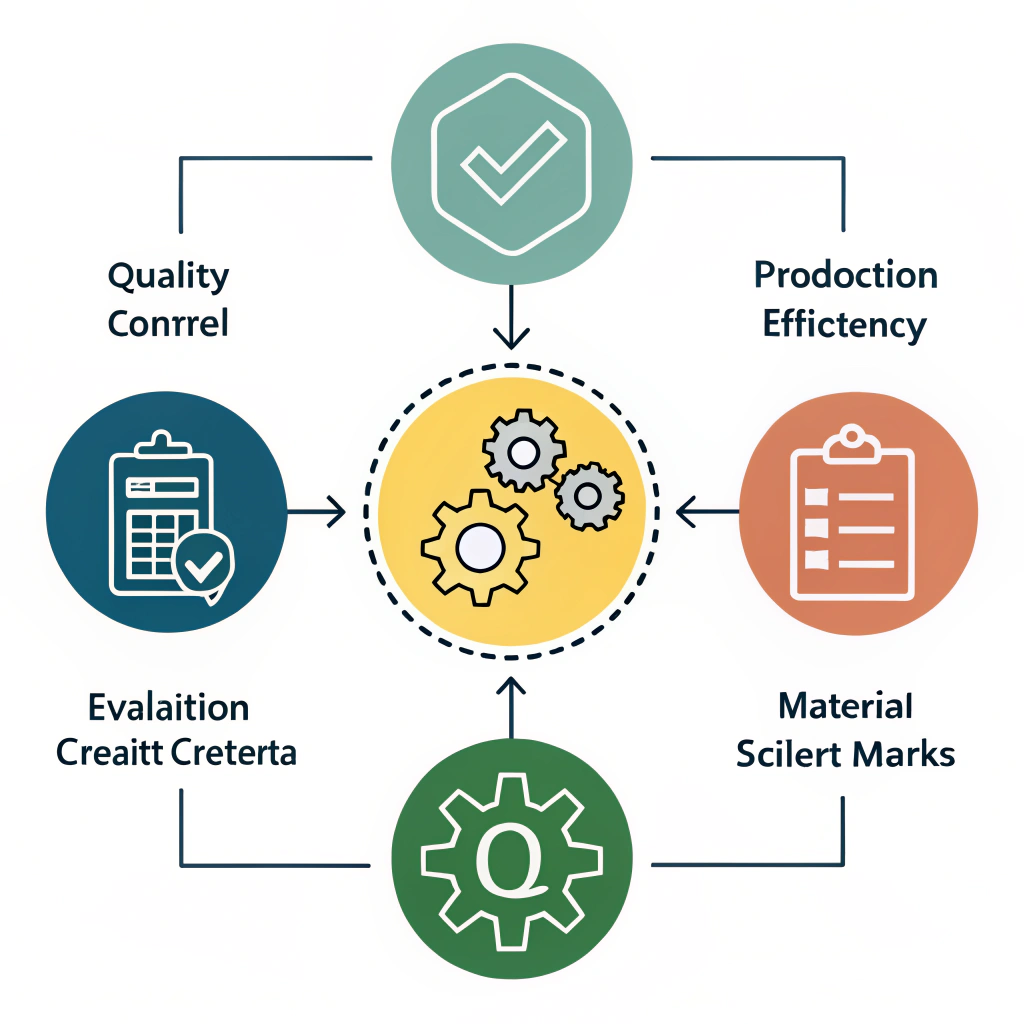

When selecting a manufacturing partner for pickleball paddles, here are some key evaluation criteria:

-

Production Capabilities:

- What production processes are available (e.g., hot pressing, cold pressing, thermoforming)?

- How do these processes enhance the performance and durability of the paddles?

-

Material Sourcing and Options:

- Which premium materials (carbon fiber variants, fiberglass, composite options) are offered?

- Are there customization options available for different player needs?

-

Quality Control Systems:

- What inspection and testing protocols are implemented?

- How often are quality control procedures updated and audited?

-

Cost Efficiency and Pricing Models:

- How does scale affect pricing? Can the manufacturer offer competitive prices for bulk orders?

- What are the cost trade-offs between different production techniques?

-

Lead Time and Delivery Precision:

- What production timelines are typical for each process?

- Does the manufacturer have a reliable supply chain to ensure on-time delivery?

Below is a summarizing table to visualize these criteria:

| Evaluation Criteria | Key Questions | Importance |

|---|---|---|

| Production Capabilities | Which processes are used? How do they affect durability and performance? | Ensures paddles meet competitive standards |

| Material Options | What materials are available? Are customization options provided? | Offers flexibility to meet player preferences |

| Quality Control | What testing processes are in place? How consistent is production? | Guarantees product reliability and safety |

| Cost Efficiency | What is the pricing structure? Are there benefits to bulk orders? | Critical for pricing strategy and ROI |

| Lead Time | What are the production and delivery timelines? | Impacts inventory management and market timing |

Consider a scenario where a sports equipment distribution company is deciding between two manufacturing partners. Supplier A offers a mix of hot pressing1 and cold pressing2 processes with a focus on carbon fiber materials. They boast rapid production cycles but require a higher initial investment in setup. Supplier B specializes in thermoforming3 and composite materials, offering highly customizable paddles with a premium finish, but with longer lead times.

-

In Supplier A’s case:

- Faster turnaround could be beneficial for high-volume orders.

- Use of 3K Carbon Fiber and 12K Carbon Fiber paves the way for high-performance but may compromise on the tactile feel of the paddle.

- Suitable for clients who need durability and quick delivery.

-

In Supplier B’s situation:

- Custom design options mean the paddles can be tailored to specific market demands.

- More intricate production techniques result in a higher cost per unit.

- Ideal for niche markets or premium product lines where customization and design complexity are paramount.

As a procurement specialist, you need to weigh whether your priority is high-volume production or premium customization. Understanding these differences is crucial in matching supplier capabilities with your company’s strategic objectives.

To sum up your decision-making process, follow these actionable steps when assessing a Chinese manufacturer for pickleball paddles:

- Request detailed documentation on production processes and quality control protocols.

- Compare material options and inquire about customized solutions if you target a specific player niche.

- Analyze cost structures, considering both production efficiency and potential setup investments.

- Arrange factory visits or request virtual tours to witness production firsthand.

- Evaluate lead times and delivery schedules, ensuring they align with your market demands.

These insights will arm you with the necessary information to make a robust and confident sourcing decision.

Selecting the right manufacturing partner in China for pickleball paddles requires an in-depth analysis of both production techniques and material choices. By comparing methods like hot pressing1, cold pressing2, and thermoforming3, and by evaluating material quality—from various types of carbon fiber to advanced composites—you can ensure a match with your business needs and market strategies. Coupled with stringent quality control and cost efficiency measures, this comprehensive approach positions you to choose the best supplier for competitive, high-performance pickleball paddles.

People Also Ask

Q1: What is the best pickleball paddle made in China?

A1: The best pickleball paddle made in China is one that integrates advanced materials, such as high-quality carbon fiber and fiberglass, with precise manufacturing techniques like hot pressing and thermoforming. Leading manufacturers, recognized for their robust quality control and innovative production processes, consistently deliver paddles designed for optimal performance and durability.

Q2: What to look for when purchasing pickleball paddles?

A2: When purchasing pickleball paddles, key factors include paddle shape, core material, face material, handle length, paddle weight, and the grip design that fits the player’s hand size. These elements are critical in ensuring a balance between power, control, and comfort, matching the specific play style and performance needs of the user.

Q3: Which pickleball paddles are not made in China?

A3: Several high-quality pickleball paddles are manufactured in the USA, such as the Gamma 405 Graphite Pickleball Paddle from Pennsylvania, PROLITE Stealth GS2 Carbon Fiber Pickleball Paddle from Wisconsin, and Paddletek Bantam Carbon Fiber Pickleball Paddles from Michigan.

-

hot pressing: Click here to read about the hot pressing process, which explains its advantages in enhancing production efficiency and impact resistance while discussing potential trade-offs in material properties. ↩ ↩ ↩2 ↩3 ↩4

-

cold pressing: Click here to understand cold pressing, a technique that allows for precise control over material thickness and structure, preserving the innate qualities of the raw materials. ↩ ↩ ↩2 ↩3 ↩4

-

thermoforming: Click here to explore thermoforming, a process that enables manufacturers to create intricate and stable paddle designs using advanced molding techniques. ↩ ↩ ↩2 ↩3 ↩4

-

Carbon Fiber: Click here to learn about carbon fiber, its different variants (such as 3K, 12K, and T300), and why it is essential for achieving high performance in sports equipment manufacturing. ↩ ↩

-

Composite Materials: Click here to read about composite materials, their role in combining different fibers for optimal performance, and how they impact durability and weight in paddle design. ↩ ↩