Quick Answer: Edgeless pickleball paddles provide a sleek design with increased surface area for control and power, while edge guard technology1 paddles offer additional structural protection and durability. Each design has distinct manufacturing requirements and performance benefits that merit careful review based on production processes, materials, and target market needs.

Pickleball paddle design is evolving rapidly as manufacturers strive to meet the demands of professional athletes and recreational players alike. In today’s competitive market, the decision between an edgeless paddle and one featuring edge guard technology1 can significantly affect performance, durability, production efficiency, and ultimately, cost-effectiveness. This article provides a comprehensive technical comparison tailored to product development managers and procurement specialists in the sporting goods manufacturing industry. We will explore the performance differences, manufacturing trade-offs, and overall benefits of both designs, based on our extensive experience at NEX Pickleball.

Modern pickleball paddles are no longer just simple hitting tools; they represent a blend of advanced materials, engineering precision, and innovative design techniques. Two dominant design types are:

- Edgeless Paddle Design: This design eliminates the traditional raised edges, offering a larger hitting surface and a modern aesthetic.

- Edge Guard Paddle Design: This incorporates a protective frame around the paddle edge, which helps preserve the paddle’s integrity during high-impact play while still maintaining performance.

Both designs are driven by the need for improved performance optimization, enhanced durability, and meeting the specific demands of different player segments.

The edgeless design is gaining popularity due to its sleek appearance and performance benefits. Here are some key factors:

- Enhanced Surface Area: With no raised rim or hard edge, the paddle offers a uniform hitting zone, which can lead to improved ball control and spin precision.

- Reduced Interference: The absence of an edge guard minimizes vibration misalignment and eliminates any risk of ball deflection from a protruding edge.

- Modern Aesthetics: Players often favor the contemporary look of edgeless paddles, which can also signify a premium product in the market.

- Performance: Provides improved ball contact consistency, offering players enhanced control in fast-paced environments.

- Weight Distribution: The design allows for more precise center-of-gravity adjustments, supporting balanced play.

- Material Integration: Edgeless paddles benefit from advanced materials like 3K Carbon Fiber2 or T300 Carbon Fiber3, which provide both strength and flexibility.

- Durability Concerns: Without an edge guard, there is a heightened risk of wear and damage from minor impacts.

- Manufacturing Precision: The edgeless design demands tighter tolerances during production, relying heavily on precision techniques like cold pressing or thermoforming4, which can extend production time.

The edge guard paddle integrates a protective element around the paddle’s perimeter. This design accommodates the needs of players looking for extra durability without compromising too much on performance.

- Structural Reinforcement: The edge guard acts as a buffer to absorb shocks from impacts, thereby enhancing the paddle's lifespan.

- Protection Against Wear: Preserves the integrity of the paddle, especially in intense games where repeated impacts are common.

- Versatile Design: Many edge guard paddles use a hybrid approach combining fiberglass with composite materials to balance power and protection.

- Durability and Longevity: The added support minimizes surface wear, making these paddles ideal for prolonged, high-intensity use.

- Production Adaptability: The edge guard can be more forgiving in production variations, allowing manufacturers to use efficient methods like hot pressing, which improves throughput.

- Cost-Effectiveness: In some cases, edge guard paddles may reduce rework and waste in production because the protective edge compensates for minor material inconsistencies.

- Reduced Hitting Surface: The protective edge can slightly reduce the effective hitting zone, potentially affecting ball trajectory and spin.

- Additional Material: Incorporating an edge guard can add a marginal increase in production costs if premium materials are used.

- Aesthetic Perception: Some consumers may perceive the edge guard as less modern compared to the minimalist edgeless design.

When deciding between these designs, several dimensions should be compared. The table below provides a multidimensional analysis:

| Comparison Dimension | Edgeless Paddle | Edge Guard Paddle |

|---|---|---|

| Hitting Surface | Larger, uniform surface for enhanced ball contact | Slightly reduced contact area due to protective edge |

| Durability | Prone to wear without additional edge protection | High durability with built-in shock absorption via edge guard |

| Weight & Balance | Allows optimization of weight distribution for agility | May experience minor weight addition from extra materials |

| Aesthetic Appeal | Modern, sleek design preferred by performance enthusiasts | Traditional look that is preferred for its rugged protection |

| Production Process Compatibility | Requires high-precision methods (e.g., cold pressing, thermoforming) | Can be more compatible with hot pressing for mass production |

| Cost Implications | Potentially higher production costs due to tight tolerances | Can be more cost-effective in large-scale manufacturing |

| Player Preference | Ideal for players prioritizing control and finesse | Suited for markets emphasizing durability and longevity |

This comparison table highlights that the choice between edgeless and edge guard designs ultimately hinges on the targeted player profile and production priorities. High-performance, competitive players may lean towards edgeless paddles for their superior ball control, while a broader market segment focusing on product longevity and cost efficiency may find edge guard designs more appealing.

The choice of production process plays a crucial role in determining the quality and performance of pickleball paddles. At NEX Pickleball, our manufacturing techniques are tailored to optimize the distinct characteristics of both designs.

- Application: Often employed for edge guard paddles where a robust and durable structure is needed.

- Advantages: High production efficiency, excellent impact resistance, and structural stability.

- Disadvantages: The high temperatures involved can slightly alter material properties, which might affect the feel for edgeless designs.

- Application: Suited for edgeless paddles where precise control over the material’s thickness and structure is essential.

- Advantages: Maintains the inherent material properties, ensuring a consistent and responsive ball feel.

- Disadvantages: Longer production cycles and the need for more sophisticated pressure control mechanisms can increase manufacturing time and costs.

- Application: Ideal for paddles with intricate shapes or when custom designs are required.

- Advantages: Allows for complex, precise molding that supports both edgeless and selective edge guard designs.

- Disadvantages: Requires a longer processing time and can be costlier, making it more suitable for premium or custom orders rather than mass production.

Manufacturers need to balance these process trade-offs to ensure the final product meets the performance, durability, and cost targets. The choice of process also directly impacts the paddle’s final quality control metrics critical for market acceptance.

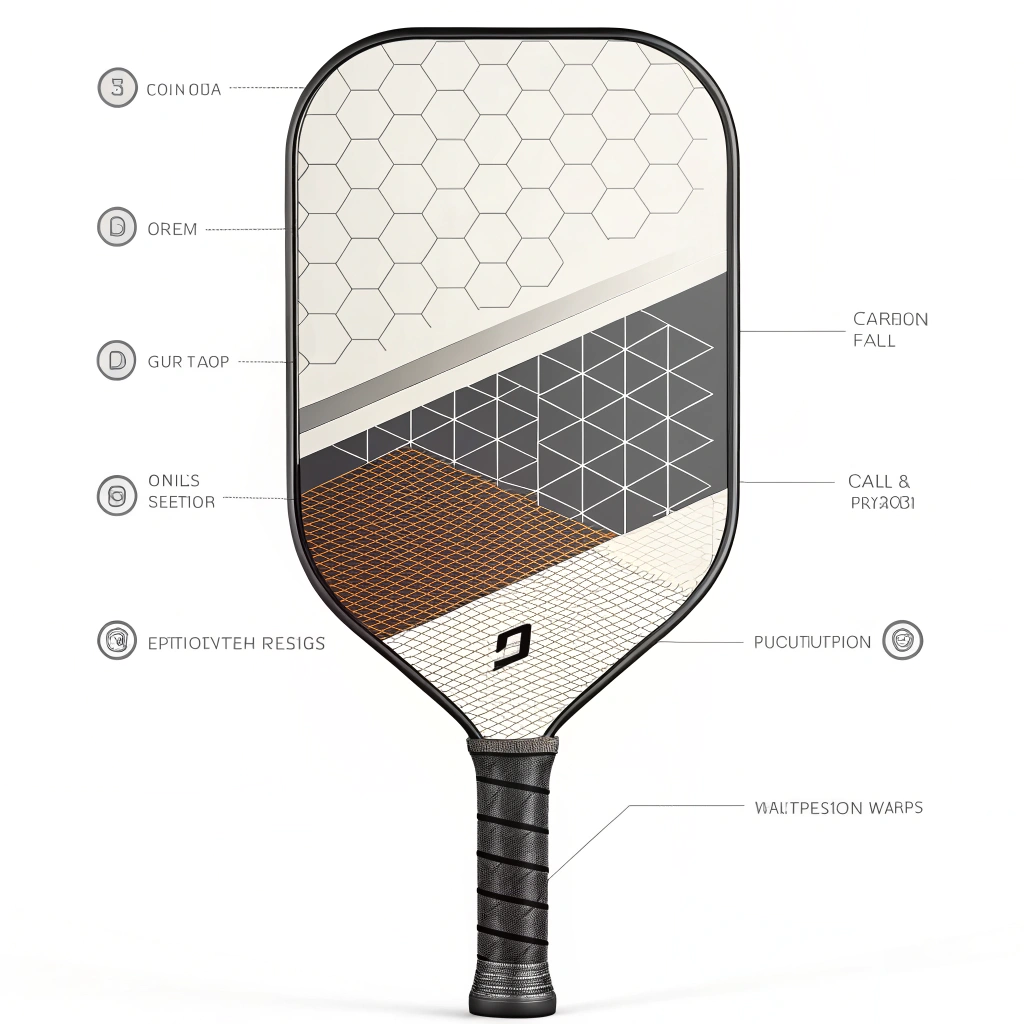

The underlying materials used in paddle construction are paramount. At NEX Pickleball, we use various materials to achieve the desired performance characteristics for both edgeless and edge guard paddles:

- Carbon Fiber Variants (3K, 12K, T300): These materials offer exceptional strength-to-weight ratios, vital for edgeless designs where minimizing deflection and maximizing precision are key.

- Fiberglass: Provides a balance of flexibility and control, making it an excellent choice for edge guard paddles that need an extra layer of impact resistance.

- Composite Materials: By combining carbon fiber and fiberglass, or integrating a bamboo core or honeycomb core, we achieve an optimal blend of performance and durability. These composites ensure that paddle design is not just a matter of surface area, but an integrated engineering feat.

- Nomex honeycomb5: Selecting the proper core material can dramatically enhance shock absorption and player comfort.

The material choices also influence the production processes. For example, advanced composites might require thermoforming to achieve the right structural integrity, and selecting the proper core material (like Nomex honeycomb5) can dramatically enhance shock absorption and player comfort.

Several real-world scenarios underscore the decision between edgeless and edge guard designs:

-

Competitive Play vs. Recreational Use:

Competitive players often require a paddle that maximizes control and ball response. Here, the edgeless design offers a distinct advantage, ensuring that every shot benefits from maximum surface contact and precision. Conversely, recreational markets might favor edge guard paddles, which are more robust and can tolerate a wider range of usage conditions. -

Production Efficiency and Cost Management:

Our analysis shows that while edgeless paddles may incur higher production costs due to the demands of cold pressing and precision molding, they can command a premium price in the competitive sporting goods market. Edge guard paddles, on the other hand, benefit from hot pressing techniques that deliver efficient mass production and lower per-unit costs, making them appealing in cost-sensitive segments. -

Customizability and Market Differentiation:

With the growing trend towards customization in sporting goods, manufacturers can leverage both designs to create distinct product lines. For instance, a premium series using edgeless paddles can target high-end markets with customizable weight, balance, and grip size. Meanwhile, an edge guard series can be marketed for its durability and reliability—attributes highly prized by clubs and recreational facilities.

A practical recommendation for procurement specialists is to consider your target market’s priorities. If your buyers are performance-driven professionals, an edgeless design may deliver the extra edge in gameplay. If durability and cost management are more important to your clientele, the edge guard design might be the smart choice.

Our detailed comparison demonstrates that both edgeless and edge guard pickleball paddles come with distinct advantages and challenges. The edgeless design offers an expanded hitting area, superior ball control, and modern aesthetics but requires high-precision manufacturing and may have durability concerns. In contrast, the edge guard design provides enhanced structural protection, improved production efficiency, and cost benefits but sacrifices a small portion of the paddle’s active surface area.

For product development managers and procurement specialists evaluating these options:

- Consider edgeless designs if your focus is on premium performance and targeting competitive athletes.

- Opt for edge guard designs when durability, production efficiency, and cost-effectiveness are paramount.

- Evaluate your manufacturing capabilities to determine which production process (hot pressing, cold pressing, or thermoforming) best aligns with your design priorities.

Ultimately, the successful adoption of either paddle design hinges on aligning production strategies with market expectations. At NEX Pickleball, our commitment to advanced materials, rigorous quality control, and innovative manufacturing techniques ensures that our paddle designs meet the highest standards of performance and durability. We encourage you to assess your target market needs carefully and choose the design that best fits your portfolio, ensuring a competitive edge in the rapidly expanding pickleball market.

-

What are the main differences between edgeless and edge guard pickleball paddles?

Edgeless paddles offer a larger, uninterrupted hitting surface for better control, while edge guard paddles include a protective frame that enhances durability and impact resistance. -

How do production processes vary between these two paddle designs?

Edgeless paddles often require high-precision manufacturing like cold pressing or thermoforming to maintain material integrity, whereas edge guard paddles can be efficiently produced using hot pressing, which streamlines production and reduces costs. -

Which paddle design offers better performance for competitive players?

Competitive players may prefer edgeless paddles for their enhanced control and larger hitting area, though the choice ultimately depends on factors like material quality and production precision.

-

edge guard technology: Click to read more about the principles behind incorporating protective edges in paddle design, enhancing product durability and performance. ↩ ↩ ↩2

-

3K Carbon Fiber: Click to learn how 3K Carbon Fiber contributes to optimal strength-to-weight ratios and improved paddle performance. ↩ ↩

-

T300 Carbon Fiber: Click to explore the benefits of T300 Carbon Fiber in providing flexibility and durability in high-performance paddles. ↩ ↩

-

thermoforming: Click for an overview of thermoforming processes, including its advantages in achieving complex, precise paddle designs. ↩ ↩ ↩2

-

Nomex honeycomb: Click to understand how Nomex honeycomb structures enhance shock absorption and overall paddle integrity. ↩ ↩ ↩2