Advanced graphite pickleball paddles from NEX Pickleball combine high-performance materials and precision production processes to deliver superior durability, responsiveness, and customization for competitive play. In this article, we detail the challenges B2B procurement managers and product developers face and provide solutions through our advanced ODM production1 techniques, including hot pressing2, cold pressing3, and thermoforming4.

B2B procurement managers and sports equipment distributors are continuously looking for innovative and reliable manufacturing partners for premium pickleball paddles. The challenges they face include:

• Procuring paddles that balance fast-paced performance with precise control.

• Ensuring the consistency of quality for bulk orders.

• Customizing designs to meet evolving market demands and branding efforts.

• Navigating the range of advanced materials—such as carbon fiber5 variants, fiberglass, and composite cores—to achieve optimal play performance.

The market demands paddles that not only meet the rigorous standards of competitive play but also provide differentiated benefits in terms of durability, weight balance, and impact resistance.

Several factors contribute to the complexity of sourcing high-performance graphite pickleball paddles:

-

Material Variability:

The range of materials, including various types of carbon fiber (3K, 12K, T300), fiberglass, and composite blends, requires careful selection. Each material has its unique properties affecting durability, control, and rebound performance. -

Production Process Complexity:

The manufacturing techniques such as hot pressing2, cold pressing3, and thermoforming4 directly influence the paddle’s performance characteristics. Small variations in process conditions can lead to differences in paddle strength, responsiveness, and even feel during play. -

Customization Demands:

Modern B2B clients often seek paddles tailored to their specific competitive and branding requirements. Customization involves adjustments in weight distribution, grip ergonomics, and surface textures—all of which require agile production capabilities and precision engineering. -

Quality Control and Consistency:

For bulk procurement, maintaining 100% quality consistency is critical. Minor imperfections due to production process variability can lead to performance issues, thus affecting player satisfaction and brand reputation.

In addressing these challenges, NEX Pickleball leverages advanced production processes and state-of-the-art quality control measures. Below is an in-depth look at how our solutions directly address your procurement concerns:

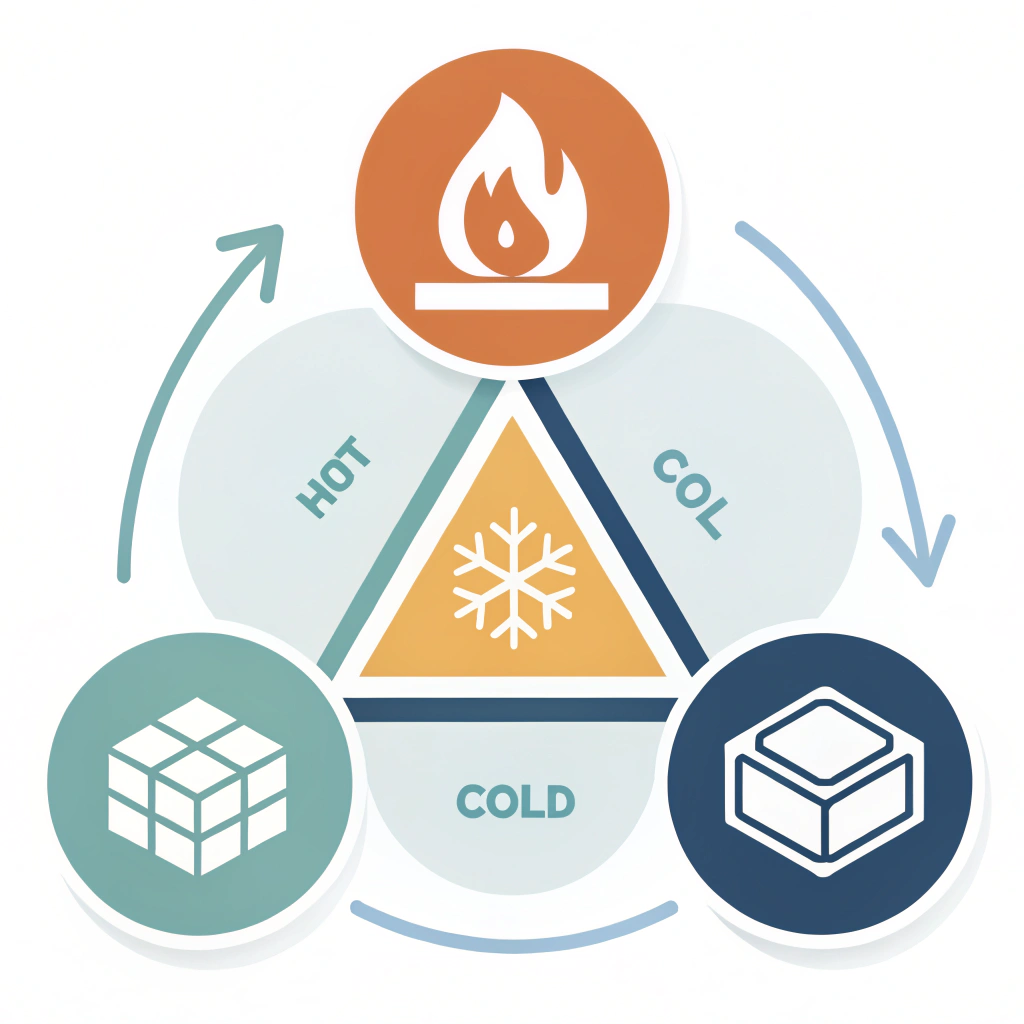

Each production method offers specific benefits tailored to different design and market needs:

-

Hot Pressing2:

This technique heats and compresses raw materials to form robust paddles efficiently.

• Advantages: High production efficiency, strong impact resistance, and excellent structural stability.

• Considerations: Requires significant initial investment and may slightly alter material properties. -

Cold Pressing3:

Conducted at room temperature, this process ensures precise control over paddle thickness and material arrangement, preserving the original properties of the materials.

• Advantages: Superior control, enhanced ball feel, and flexibility retention.

• Considerations: Longer production cycles due to slower processing speeds. -

Thermoforming4:

This method involves heating the composite material to a soft state then molding it using precision molds, ideal for intricate paddle designs.

• Advantages: Allows for complex designs and precise material distribution, enhancing both aesthetic appeal and performance consistency.

• Considerations: Best suited for custom or premium series due to higher equipment costs and extended production time.

Below is a comparative table that summarizes these three production processes:

| Production Process | Advantages | Considerations/Limitations |

|---|---|---|

| Hot Pressing | High production efficiency; excellent strength and durability; robust impact resistance. | High initial equipment investment; potential alteration of material feel. |

| Cold Pressing | Precise material control; superior ball feel; maintains original material properties. | Longer production cycles; requires precision equipment. |

| Thermoforming | Intricate design capabilities; precise material distribution; enhances paddle aesthetics. | Higher production costs; longer processing times; ideal for premium orders. |

At NEX Pickleball, our commitment to using premium materials is evident in every paddle we manufacture. Here’s how our material strategy ensures competitive and durable performance:

-

Carbon Fiber Options5:

We utilize various forms of carbon fiber—3K, 12K, and T300—to cater to different performance needs.

• 3K Carbon Fiber offers flexibility and high rebound, perfect for players needing extra power.

• 12K Carbon Fiber provides a smoother surface and greater hardness, ideal for competitive play.

• T300 Carbon Fiber strikes a balance between strength and lightweight, optimizing both durability and control. -

Fiberglass and Composite Materials:

In addition to pure carbon fiber, blending fiberglass with carbon fiber or using composite materials allows us to enhance ball control and increase the sweet spot area, ensuring a more forgiving experience for enthusiasts at different skill levels. -

Core Material Strategy:

The paddle’s core significantly influences its feel and impact absorption. Our range includes:

• Nomex Honeycomb Core: For superior shock absorption and long-term durability.

• Aluminum Honeycomb Core: Providing an ideal mix of power and precision.

• Polymer Honeycomb Core: Designed for enhanced elasticity, reducing vibrations for a comfortable playing experience.

Each selection offers distinct performance characteristics—allowing our B2B clients to choose the materials best suited to their market niche.

One of the key differentiators of NEX Pickleball as an ODM partner is our robust customization capability. Our clients can specify:

-

Design Details:

Custom paddle designs, including weight, balance, and grip size, ensure that the final product meets both performance and branding requirements. -

Production Process Adjustments:

Depending on the order volume and performance specifications, we offer tailored production methods (i.e., a blend of cold pressing for precision and hot pressing for durability). -

On-Demand Printing and Branding:

We provide on-demand printing services to include custom graphics, logos, and personalized color schemes. This is particularly beneficial for retailers and sports teams looking to enhance their brand identity on the court.

Our agile production strategy means that no matter the order size or complexity, we can deliver solutions that are finely tuned to market demands. This flexibility not only meets diverse client needs but also gives you the competitive edge needed in today’s fast-paced sports equipment market.

For ODM production, rigorous quality control is essential to guarantee performance and durability for every paddle that leaves the factory. NEX Pickleball employs several robust measures:

-

Pre-Production Testing:

Materials are tested for tensile strength, elasticity, and durability prior to the production run. This ensures that only the highest quality materials are used. -

In-Process Control:

Our advanced processing equipment continuously monitors production parameters such as temperature and pressure. In critical processes like thermoforming4, this step is crucial for maintaining design consistency and paddle performance. -

Post-Production Inspection:

Every single paddle undergoes thorough testing for structural integrity, proper weight distribution, and optimal ball feel. This final check ensures that the end product adheres to the premium standards required by competitive players.

These quality control protocols not only optimize product performance but also significantly reduce the risk of production defects—all crucial for meeting the demands of bulk orders and commercial distribution.

Several industry players have successfully partnered with NEX Pickleball, leveraging our expertise in ODM production. Here are some examples of our performance-driven approach:

- Enhanced Player Performance:

Analysis from competitive play shows that paddles designed with advanced materials and precision processes exhibit a noticeable improvement in ball control and reduced vibration. - Bulk Procurement Efficiency:

Our existing B2B partners report shorter lead times and reduced rework frequency, thanks to our efficient production flow and stringent quality control measures. - Customization Impact:

Clients using on-demand printing for team branding have observed an increase in product engagement and market differentiation, making these paddles more attractive to both recreational and professional players.

Customer testimonials and data studies underline that our rigorous production processes and premium material selection have a direct impact on player performance—a competitive advantage that stands out in the crowded sports equipment market.

In summary, NEX Pickleball offers advanced, customizable ODM production for graphite and high-performance pickleball paddles. By leveraging state-of-the-art production techniques, a wide range of premium materials, and comprehensive quality control measures, we are uniquely positioned to meet the demands of modern B2B procurement managers and product developers.

Our combined approach of:

• Addressing material and design complexities,

• Utilizing the right mix of production processes,

• And embracing customization,

ensures that our clients get a product that not only meets but exceeds market standards.

For procurement managers and sports equipment distributors looking for a reliable ODM partner, choosing NEX Pickleball means investing in a product that delivers on durability, performance, and customization—all backed by data and industry expertise.

If you are in the solution comparison phase and evaluating your next ODM partner for high-performance pickleball equipment, we invite you to reach out and explore our robust manufacturing capabilities. Let us help you turn your product vision into a competitive advantage in the market.

People Also Ask

Q1: How does NEX Pickleball ensure the quality of its carbon graphite paddles?

A1: NEX Pickleball maintains strict quality control through pre-production material testing, in-process monitoring using advanced equipment, and thorough post-production inspections. This multi-step quality assurance process ensures consistent high performance and durability for every paddle.

Q2: What are the advantages of advanced production techniques like hot pressing and thermoforming?

A2: Advanced production techniques such as hot pressing and thermoforming offer benefits including high production efficiency, superior structural integrity, and the ability to create intricate designs. Hot pressing provides robust impact resistance while thermoforming enables precise material distribution for customized, high-performance paddles.

Q3: Can I get custom-designed pickleball paddles for bulk procurement orders?

A3: Yes, NEX Pickleball offers extensive customization options including design adjustments, tailored weight distribution, grip size variations, and on-demand printing services. This allows clients to create paddles that meet their specific performance and branding needs for bulk procurement.

-

[ODM production]: Click to learn more about original design manufacturing processes that optimize production scalability and product customization in B2B environments. ↩ ↩

-

[hot pressing]: Click to explore how hot pressing uses thermal compression to enhance material strength and structural integrity in manufacturing. ↩ ↩ ↩2 ↩3

-

[cold pressing]: Click to understand the benefits and applications of cold pressing techniques in preserving material properties and achieving precision in production. ↩ ↩ ↩2 ↩3

-

[thermoforming]: Click to read about thermoforming processes that leverage heat and molding for creating detailed and high-performance components. ↩ ↩ ↩2 ↩3 ↩4

-

[carbon fiber]: Click to discover the properties and advantages of carbon fiber in producing lightweight, durable, and performance-enhancing sports equipment. ↩ ↩ ↩2