Evaluating a high-performance pickleball paddle is more than just checking its weight or looking at its visual appeal. In essence, it involves a detailed examination of manufacturing processes, material choices, and performance quality to ensure you are investing in a product that meets the highest standards. This article breaks down the technical specifications, production techniques, and quality benchmarks you can rely on when making purchasing decisions.

Evaluating a pickleball paddle for quality and performance can be a complex task due to the numerous factors involved. Procurement managers and product developers in the sports equipment industry must consider the following critical areas:

- Material Selection: Choosing between premium elements such as carbon fiber1, fiberglass, or composite materials2 significantly affects paddle performance.

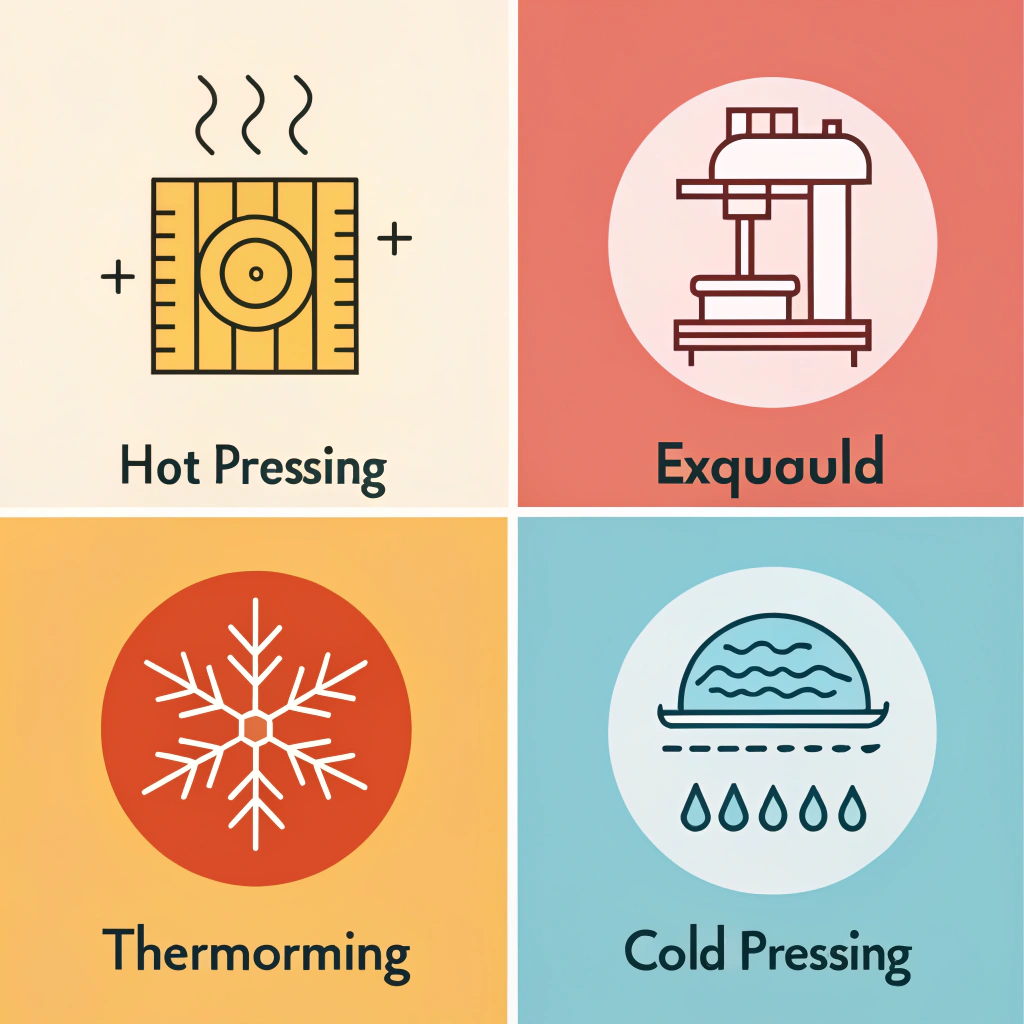

- Production Processes: Techniques like hot pressing, cold pressing3, and thermoforming4 each have unique advantages and limitations that impact the durability and feel of the paddle.

- Performance Metrics: Assessing static weight, swing weight5, and twist weight to determine control, power, and overall playability is vital.

- Quality Assurance: Rigorous testing and consistency in production, including custom quality checks and industry-standard benchmarks, ensure that products meet expected standards.

In today's competitive sports equipment market, these factors not only dictate performance but also influence a company’s reputation and distribution success.

One of the fundamental components in paddle evaluation is the material used. Each material option contributes distinct characteristics:

- 3K Carbon Fiber: Renowned for its strength and flexibility, this variant reduces vibration and is perfect for paddles requiring enhanced rebound force.

- 12K Carbon Fiber: With higher thread density, 12K offers a smoother surface, making it ideal for extreme strength and impact resistance—key for competitive play.

- T300 Carbon Fiber: Balances tensile strength and lightweight properties, creating a paddle that is both powerful and responsive.

Fiberglass paddles are valued for their balance between power and control. Some key properties include:

- E-Glass Fiberglass: Delivers excellent elasticity and tensile strength, resulting in a broader sweet spot and superior ball control.

For manufacturers like NEX Pickleball, combining materials can result in significant performance enhancements:

- Carbon Fiber and Fiberglass Composite: Offers an impressive balance of strength, lightness, and flexibility.

- Bamboo Core Composite: Provides a lightweight core with high impact resistance.

- Honeycomb Core: Excellent shock absorption properties contribute to the paddle's durability and reduce vibration.

Each material choice must be evaluated against the intended use and player preference. Often, the application in competitive scenarios leads procurement managers to favor advanced carbon fiber variants for their superior performance and stability.

Manufacturing processes directly influence the final product quality and performance. The three primary production methods include:

Hot pressing utilizes heat and pressure to form the paddle materials.

- Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Superior impact resistance and structural integrity.

- Disadvantages:

- Potential alteration of material properties, which might change the paddle’s overall feel.

- Requires significant investment in specialized equipment.

This method involves shaping the material at room temperature using mechanical pressure.

- Advantages:

- Enhanced precision in controlling thickness and overall structure.

- Maintains inherent material properties, leading to a more responsive and controlled paddle.

- Disadvantages:

- Longer production cycles can reduce overall efficiency.

- Requires exact pressure parameters to ensure consistency, demanding high-quality equipment.

Thermoforming involves heating materials to a softening point and then molding them into shape.

- Advantages:

- Ideal for creating paddle designs with intricate shapes.

- Ensures even material distribution, contributing to a stable and high-performance product.

- Disadvantages:

- Typically involves longer production times and higher associated costs.

- Best suited for premium or custom paddle offerings where cost is justified by performance.

These production processes significantly affect not only the durability but also the performance characteristics of the paddles. In practice, a balanced choice depends on the intended performance outcome and production volume needs.

When evaluating pickleball paddles, it is essential to consider several performance-related criteria:

Static Weight vs. Swing Weight5

- Static Weight: While it gives an overall idea about paddle heft, it can be deceptive.

- Swing Weight & Twist Weight: These metrics better reflect how the paddle will move in play, affecting control and responsiveness.

For instance, a paddle with a static weight between 7 and 9 ounces might seem ideal; however, if the swing weight is too high, it could strain the player’s arm during extended play. On the other hand, too light a paddle might compromise stability and power.

Below is a table summarizing how different production technologies align with various performance attributes:

| Production Process | Impact on Durability | Control & Feel | Efficiency in Production | Ideal For |

|---|---|---|---|---|

| Hot Pressing | Excellent shock absorption; high structural integrity | May alter the natural feel, offering a solid, heavy hit | High production rate, cost-effective for bulk manufacturing | Competitive, high-power play |

| Cold Pressing | Maintains material integrity; moderate durability | Superior control and responsiveness due to precise shaping | Lower efficiency, requires precise control | Requiring refined control and better ball feel |

| Thermoforming | Produces intricate designs; high-end performance | Provides balanced distribution, ensuring consistent play | Longer cycles, higher associated costs | Custom and premium product segments |

An effective evaluation should consider these dynamics to match the performance expectations of both recreational and competitive players.

When integrating these manufacturing and material insights into a procurement decision, industry professionals should perform the following actions:

- Review Technical Specifications: Ensure that the paddle meets all specified performance metrics, including weight, balance, and material composition.

- Examine Process Certifications: Verify that the manufacturer adheres to industry standards and quality control measures. Using cutting-edge technology helps maintain consistency across production batches.

- Sample Testing: Procure samples for real-world testing to ensure that the paddle performs as expected under competitive conditions. Understanding both static and dynamic performance is essential.

- Client Feedback and Case Studies: Analyze data from case studies or customer feedback to determine long-term durability and performance reliability. Collaboration with suppliers like NEX Pickleball, which supports custom production specifications, can prove highly beneficial in tailoring products to specific requirements.

A robust quality assurance process typically includes:

- Mechanical Stress Tests: Evaluate the paddle’s resistance to impact and vibrations.

- Player Feedback Trials: Use feedback from experienced players to assess the paddle’s handling and control.

- Consistency Checks: Ensure each production batch meets stipulated standards in both material quality and performance metrics.

These practices help in confirming that the production process—whether hot pressing, cold pressing, or thermoforming—has been executed to the highest standard.

Consider a scenario where a sports equipment distribution company is in the decision comparison phase. They need to choose between paddles manufactured via cold pressing and those using thermoforming techniques. By evaluating the core differences, the following points emerge:

- Cold Pressed Paddles: These offer exceptional control due to the preservation of material properties. Their precise manufacturing allows for a refined feel, which is essential in sports where control dominates gameplay. However, for players who require robust and powerful hits, the slight lag in production efficiency might be a drawback.

- Thermoformed Paddles: These provide balanced performance, especially for players who desire a mix of power and control. They benefit from intricate design features that enhance material distribution. Despite the longer production times and higher costs, the exquisitely designed paddle often results in superior performance during high-pressure competitive matches.

Companies are often drawn to a balance—in many batches, combining manufacturing techniques and composite materials yields paddles that offer both impressive power and precise control. This balance ultimately influences bulk purchasing decisions in B2B scenarios, where consistency and performance are key.

In conclusion, to make an informed purchasing decision regarding pickleball paddles:

- Ensure detailed assessments of both material choices (such as carbon fiber variants, fiberglass, and composite cores) and production processes (hot pressing, cold pressing, and thermoforming).

- Use comprehensive testing protocols to evaluate performance metrics including static weight, swing weight, and twist weight.

- Compare supplier capabilities and certifications to guarantee consistency and durability.

- Consider case studies and real-world testing data to support your selection process.

For procurement managers and product developers, adopting this multi-dimensional evaluation approach will facilitate confidence in supplier selection and ultimately result in a higher-performing product. If you are evaluating new suppliers or comparing product ranges, consider conducting pilot testing and leveraging cross-reference standards with established industry benchmarks.

By focusing on these critical factors, you can ensure that the paddles you procure meet the rigorous expectations of competitive play while aligning with your company’s standards for quality and reliability.

-

How to judge a pickleball paddle?

Pickleball paddle evaluation involves checking not only its weight classification—midweight, lightweight, or heavy—but also understanding how the paddle's design affects control and power. This means reviewing performance metrics such as swing weight and twist weight, which offer a better representation of playability than static weight alone. -

How do you evaluate pickleball paddles?

Evaluation should consider both the static weight (ideally within 7.5 to 8.3 oz) and dynamic factors such as swing weight and twist weight. These metrics describe how the paddle moves during play and can better indicate its performance characteristics beyond just the weight. -

How do you pick a good pickleball paddle?

Choosing a good paddle involves balancing power and control. Heavier paddles may boost power, while lighter ones enhance control and maneuverability. It is important to select a paddle weight that allows for easy swinging while minimizing strain on the arm during extended play.

-

Carbon Fiber: Click to read more about how carbon fiber's high strength-to-weight ratio and vibration reduction properties are critical for advanced product design. ↩ ↩

-

Composite Materials: Click to explore the advantages of composite materials in combining multiple fibers to optimize strength, flexibility, and overall performance. ↩ ↩

-

Cold Pressing: Click to learn about the cold pressing process, which maintains material integrity by shaping products at room temperature for enhanced precision. ↩ ↩

-

Thermoforming: Click to understand thermoforming, a method that uses heat to mold materials into complex shapes while ensuring even distribution and consistent quality. ↩ ↩

-

Swing Weight: Click to discover why swing weight is a pivotal metric in evaluating a paddle’s maneuverability and balance, directly impacting player control. ↩ ↩ ↩2