The Best Control Pickleball Paddles for Precision (2025) are engineered with advanced materials, precision production techniques, and optimized designs that emphasize a balanced, low-vibration impact for superior control and finesse during play.

In a competitive market where performance matters, selecting the right pickleball paddle for control is crucial. Procurement specialists at sports equipment distributors require a deep understanding of technical specifications, manufacturing methods, and design attributes. This article provides an in-depth guide for decision-makers on choosing high-performance control paddles that deliver exceptional precision, durability, and meeting the high demands of advanced players. At NEX Pickleball, our research and expertise shape paddles that stand out by balancing technical prowess with production innovations.

Control in pickleball translates to precision, stability, and a consistent play response. The following features define the best control paddles:

-

Material Composition:

- Carbon Fiber Variants: Our paddles, using 3K, 12K, and T300 Carbon Fiber1, emphasize a firm yet forgiving surface that enhances ball touch and reduces vibrations.

- Fiberglass Options: E-Glass Fiberglass serves to expand the sweet spot and offers excellent control with a smoother ball feel.

- Composite Synergy: Combinations of carbon fiber and fiberglass, along with bamboo and honeycomb cores, blend durability with precise ball response.

-

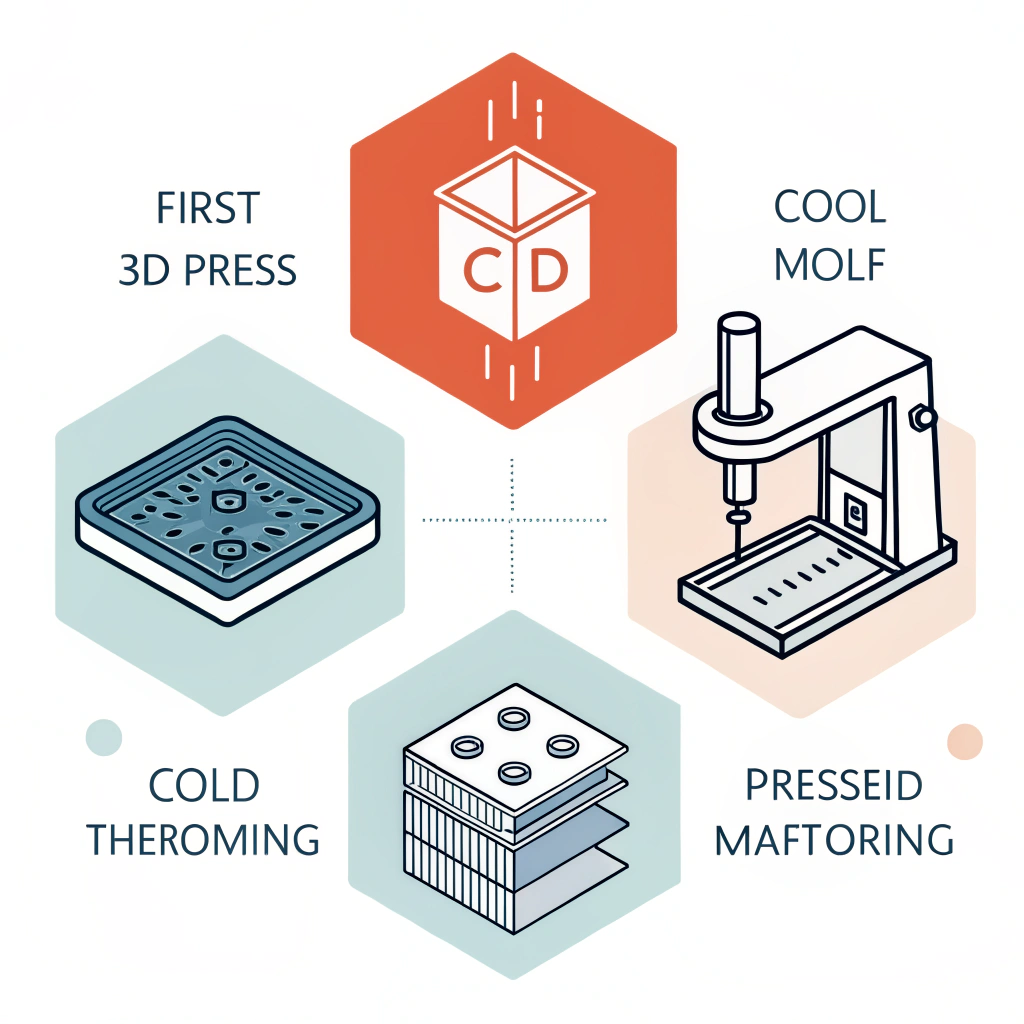

Manufacturing Techniques:

- Hot Pressing: Offers incredible strength and impact resistance.

-

- Cold Pressing2: Preserves the material’s inherent properties and delivers a responsive, controlled touch.

-

- Thermoforming3: Provides intricate designs with tailored weight distribution and responsiveness.

-

Core Material: The type of core used is essential for defining the paddle’s feel:

-

- Nomex Honeycomb4: Designed for high shock absorption.

- Aluminum Honeycomb: Delivers power with balanced precision.

- Polymer Honeycomb: Offers a soft touch and excellent ball control.

-

-

Ergonomic Design: Paddle shapes and grip sizes are optimized to reduce fatigue while aiding in quick directional changes and precise shot execution.

The manufacturing process is a cornerstone in producing control-focused paddles. Different production methods offer distinct performance benefits, impacting the overall control a player experiences. Below is a comparison of the three main production techniques used:

| Production Process | Advantages for Control | Key Considerations |

|---|---|---|

| Hot Pressing | - High production efficiency - Strong build and impact resistance | - May alter material feel slightly - Requires significant equipment investment |

| - Cold Pressing2 | - Precise control over material thickness - Maintains inherent material properties for enhanced touch | - Slower production cycles - Demands precision equipment |

| - Thermoforming3 | - Allows complex shapes - Facilitates even material distribution for optimized performance | - Longer production time - Higher initial costs |

Each method brings unique strengths catering to varied market needs. For premium control-oriented products, cold pressing and thermoforming are often favored to maintain the tactile qualities essential for precision play.

Different grades of carbon fiber play a vital role in achieving dynamic control:

- 3K Carbon Fiber: With a well-balanced mix of strength and flexibility, 3K is ideal for paddles that demand rapid rebound and low vibration.

- 12K Carbon Fiber: Offers a higher thread density for an exceptionally smooth surface and enhanced durability. It is preferred for high-impact and competitive play.

- T300 Carbon Fiber1: Known for its superior tensile strength, T300 is the material of choice for paddles that need to combine light weight with robust performance.

Integrating these carbon fiber materials enables paddles to deliver superior ball control along with consistent feedback on every hit.

Fiberglass provides a controlled flex that enhances the paddle’s overall response, especially during finesse shots:

- E-Glass Fiberglass enhances elasticity and delivers a uniform ball hit.

-

- Composite Materials5: Combining carbon fiber with fiberglass allows for balanced performance, ensuring that the paddle is not only powerful but also well-suited for controlled play. Additionally, using a bamboo core in composites offers a unique lightweight feel with excellent impact resistance.

The core is the foundation of every paddle, directly affecting the control and feel:

| Core Material | Key Benefits | Ideal For |

|---|---|---|

| - Nomex Honeycomb4 | Superior shock absorption and durability | Advanced competitive play |

| Aluminum Honeycomb | Balanced rigidity and power control | Mixed power/control scenarios |

| Polymer Honeycomb | Enhanced elasticity and reduced vibration | Recreational and precision play |

Each core type serves a specific niche, ensuring that buyers can select a paddle that precisely matches their performance needs and the competitive environment.

An optimal paddle design includes tailored grip sizes, weight distributions, and surface textures. Ergonomic enhancements ensure that players maintain a secure hold and minimize fatigue during extended play sessions. The carefully engineered grip surfaces also help with effective spin and accurate ball placement, crucial for a controlled game strategy.

At NEX Pickleball, quality assurance is integrated into every step of our production process. Rigorous testing ensures that each paddle meets the highest standards of:

- Strength and Durability: Confirmed through controlled impact and rebound tests.

- Vibration Reduction: Special surface treatments and core designs help absorb shocks, translating to better ball control.

- Material Integrity: All materials undergo strict evaluation to ensure that their properties remain consistent post-manufacturing.

For B2B buyers, these quality control measures are a guarantee of product performance, ensuring reliability and durability for large-scale deployments.

For businesses focusing on premium equipment procurement, understanding the trade-offs between production efficiency and ultimate paddle performance is key. By investing in high-precision manufacturing techniques such as cold pressing and thermoforming, companies can achieve paddle designs that maintain material integrity and deliver exceptional control.

- Hot Pressing:

- Best for rapid production but may slightly alter paddle feel.

- Cold Pressing:

- Offers the best material preservation for superior control.

- Thermoforming:

- Allows custom designs with detailed attention to material distribution, catering to players who require the highest precision.

A detailed decision matrix comparing these factors helps procurement specialists align their product choices with market demands. The matrix below summarizes the technical trade-offs:

| Factor | Hot Pressing | Cold Pressing | Thermoforming |

|---|---|---|---|

| Production Speed | High | Moderate | Low |

| Material Integrity | Moderate | High | High |

| Control and Precision | Good | Excellent | Excellent |

| Cost Efficiency | High (economies scale) | Moderate to High | High (premium costs) |

This matrix can be used as a reference tool during procurement meetings to justify production choices and align technical specifications with business objectives.

For sports equipment distributors and procurement specialists, choosing the right control pickleball paddle involves a nuanced evaluation of materials, production techniques, and ergonomic designs. The best control paddles for precision in 2025 are those that successfully combine:

- Advanced carbon fiber and composite material technologies.

- Optimized production processes such as cold pressing and thermoforming.

- Ergonomic designs enhanced by a rigorous quality control framework.

NEX Pickleball’s unique position as a leading manufacturer ensures that every paddle is tailored to deliver superior control, longevity, and performance consistency. When considering procurement, focus on paddles that not only meet design specifications but also demonstrate proven performance metrics in controlled testing environments.

We recommend that stakeholders review technical datasheets, conduct comparative evaluations, and consider on-demand customization options available through our services. As market demands for precision and control continue to evolve, staying aligned with advanced production technologies will be key to gaining a competitive edge.

-

What pickleball paddle has the best control?

The Vatic Pro Prism is noted for its high spin and control, delivering excellent build quality at an accessible price. Its balance of advanced materials and precise manufacturing makes it a top contender for players seeking both performance and affordability. -

Are thicker pickleball paddles better for control?

Thicker core paddles typically absorb more ball impact, providing a larger margin for error. This absorption enhances finesse shots, making them well-suited for drives, dinks, and resets during gameplay. -

What is the best pickleball paddle for advanced players?

For advanced players prioritizing both control and power, paddles like the JOOLA Vision CGS 16 are designed with an elongated, lightweight design that improves reach and precision, making them ideal for sophisticated offensive strategies.

-

[T300 Carbon Fiber]: Click to explore the properties of T300 Carbon Fiber, its superior tensile strength, and why it is favored for high-performance paddles. ↩ ↩2

-

[Cold Pressing]: Click to read an article on how cold pressing preserves material properties and contributes to enhanced control through precise thickness regulation. ↩ ↩2

-

[Thermoforming]: Click to learn how thermoforming enables complex paddle designs with tailored weight distribution for optimal performance. ↩ ↩2

-

[Nomex Honeycomb]: Click to understand the benefits of Nomex Honeycomb in shock absorption and its application in high-impact sporting equipment. ↩ ↩2

-

[Composite Materials]: Click to discover how combining different materials, such as carbon fiber and fiberglass, achieves a balanced performance in paddle construction. ↩