In today’s article, we quickly answer the question: How can you diagnose delamination in pickleball paddles? If you squeeze the paddle face and hear a crackly noise or notice gaps and uneven surfaces, there is a high chance that delamination has occurred. This article provides a technical guide for quality control managers and product engineers to identify and address delamination, along with practical test methods and manufacturing process insights.

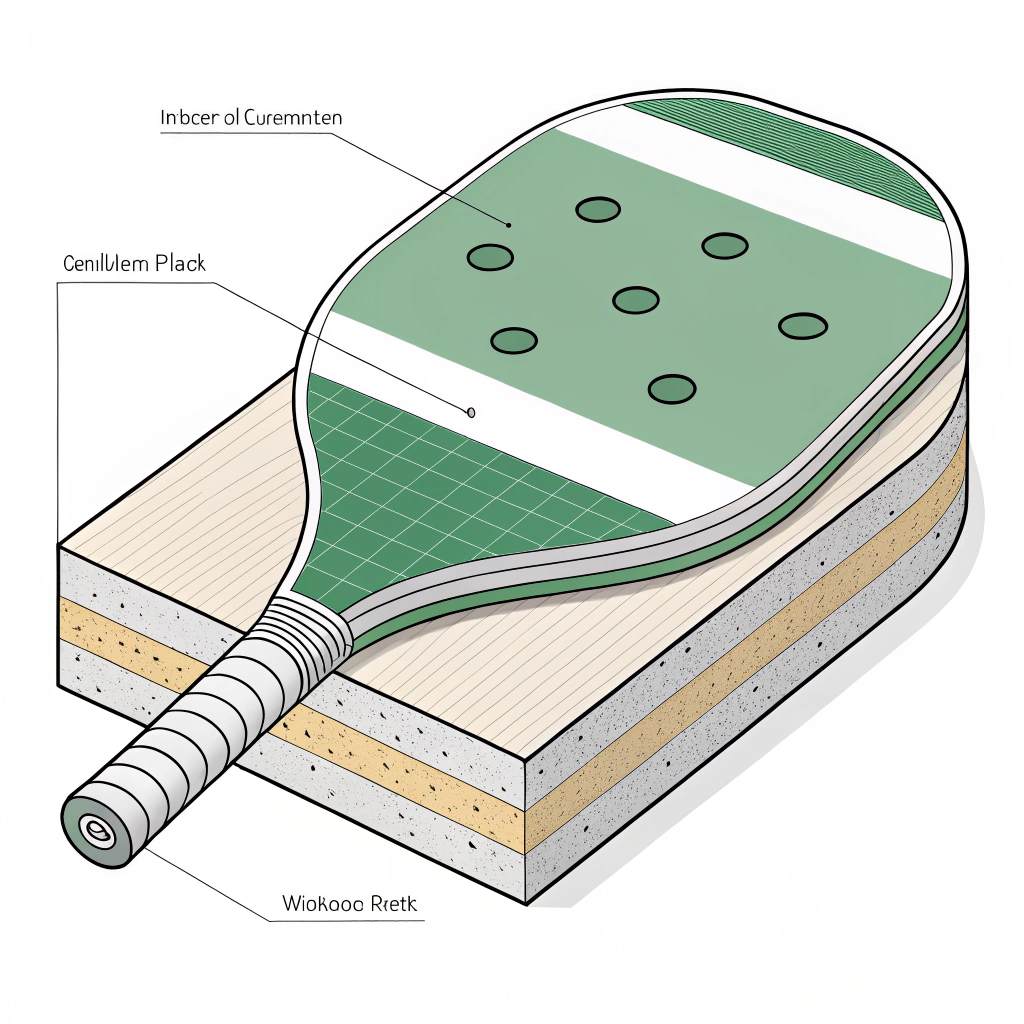

Pickleball paddle delamination is a common manufacturing defect where the layers of a composite paddle separate. This issue can affect both structural integrity1 and performance. For product engineers and quality control managers, early detection is paramount to maintain the durability and reliability of the final product.

Delamination may manifest in several ways: visible gaps, a weak face surface, unexpected sounds when pressure is applied, or even a loose handle. These defects may not be easily detectable during a routine visual inspection, requiring more precise and sometimes physical diagnostic techniques.

Additionally, the occurrence of delamination can indicate underlying manufacturing problems. Issues such as improper bonding during the hot pressing2, cold pressing, or thermoforming3 processes can cause the materials (e.g., carbon fiber, fiberglass, composite cores) to separate under stress. Preventing or immediately addressing these issues is essential for preserving product quality and customer trust.

Understanding the root causes of delamination in pickleball paddles is critical. Several factors may contribute to this defect:

-

Material Incompatibility

When combining different materials such as carbon fiber and fiberglass or when using varied composite structures, the bonding process becomes more complex. If the adhesive or pressing technique is not suited for the particular combination, separation can occur. -

Inadequate Production Processes

- Hot Pressing: While this process offers high production efficiency and strong impact resistance, excessively high temperatures or pressure can alter material properties, leading to weak bonding between layers.

- Cold Pressing: This method preserves the materials’ inherent properties but offers less bonding efficiency if the pressure is not controlled precisely.

- Thermoforming: Although ideal for intricate designs and precise material distribution, longer cycle times and the need for higher equipment investments can lead to inconsistencies in product quality.

-

Improper Adhesive Selection or Application

The choice of adhesive and its application process are fundamental. If the adhesive does not properly cure or fails to bond the layers under the operational pressures, delamination issues may occur. -

Environmental and Handling Factors

Exposure to high humidity, sudden temperature changes, or mechanical stresses during handling and storage may accelerate the delamination process, particularly if the paddle materials were not cured or sealed properly.

Each of these factors plays a role in the overall integrity of the pickleball paddle. Detailed analysis and control at every stage— from material selection to production process— are required to mitigate delamination risks.

To prevent customer dissatisfaction and reduce production costs, it is essential to detect delamination early. Below are some effective diagnostic methods:

- Surface Examination:

Look for any visible cracks, indentations, or irregularities on the paddle surface. A continuous, smooth surface is a sign of good material bonding. - Squeeze/Press Test:

Gently press or squeeze the paddle face. Listen for crackling or popping sounds, which indicate that internal layers have separated. - Shake Test:

Hold the paddle firmly and give it a gentle shake. Any movement or rattling sound inside the paddle often signals that some components have detached.

- Ultrasonic Testing4:

Ultrasonic waves can be sent through the paddle to detect any internal fractures or voids. This non-destructive technique provides a detailed internal health report. - Thermal Imaging5:

Differences in thermal conductivity between properly bonded material and delaminated areas can highlight problem spots. Thermal imaging cameras capture these variations effectively. - Adhesive Integrity Testing:

Specialized equipment may be used to test the bond strength of adhesives between layers. Monitoring these parameters during production is integral to maintaining quality.

To better summarize the detection methods, refer to the following table:

| Diagnostic Technique | Key Indications | Likely Issue | Recommended Action |

|---|---|---|---|

| Surface Examination | Visible cracks, gaps, or indentations | Poor adhesive bonding | Re-assess material bonding methods |

| Squeeze/Press Test | Crackling sounds upon pressing | Delaminated layers | Optimize pressing temperature/pressure |

| Shake Test | Rattling or internal movement | Loose internal components | Adjust material curing process |

| Ultrasonic Testing | Inconsistent wave propagation | Internal voids/delamination | Incorporate regular ultrasound checks |

| Thermal Imaging | Uneven temperature distribution | Improper material bonding | Double-check adhesive application |

Using these diagnostic techniques allows quality control teams to pinpoint delamination early in the manufacturing process, ensuring that products meet durability and performance standards.

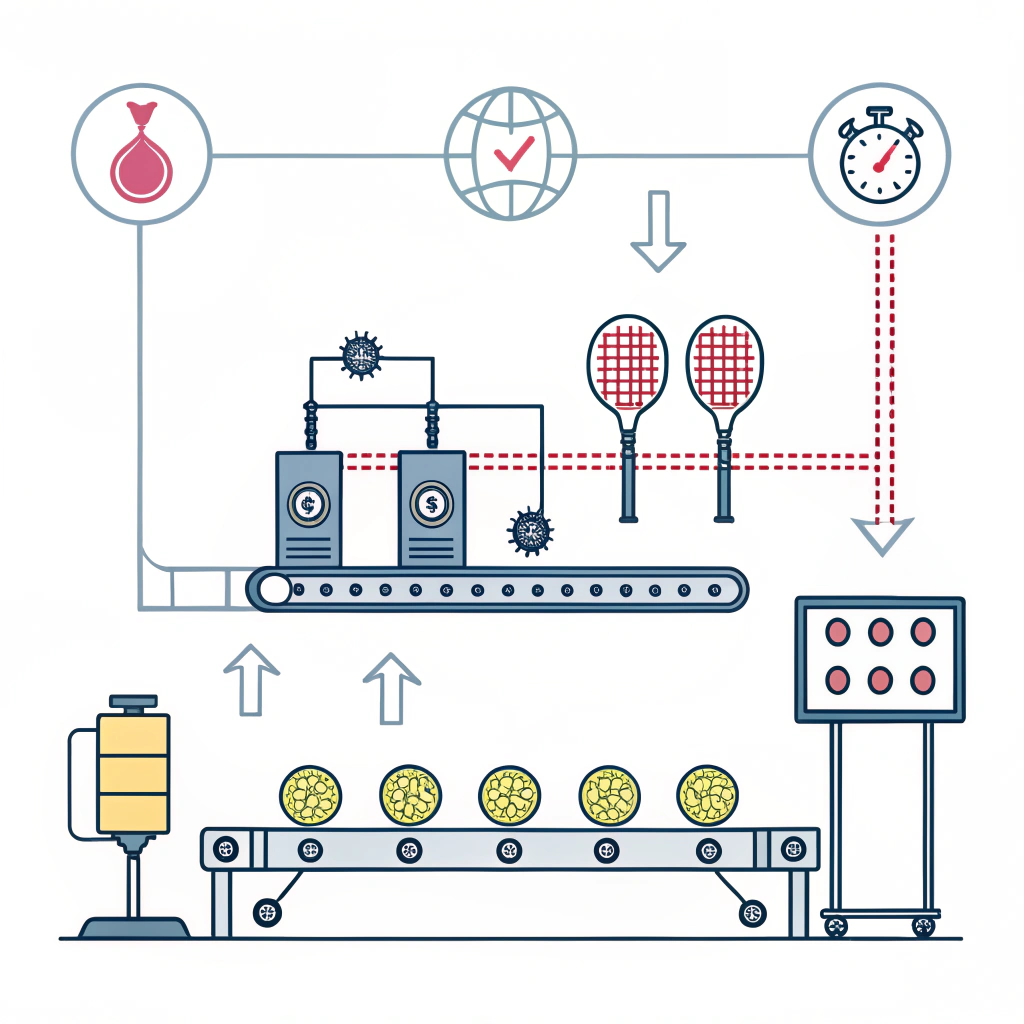

Once delamination is detected, the next step is to identify corrective measures within the manufacturing process. Here are some recommended adjustments:

- Temperature and Pressure Control:

Implement tighter controls over the pressing processes. In hot or thermoforming presses, precise temperature settings ensure that the adhesive cures properly without degrading the material. - Adhesive Quality Improvement:

Research and possibly trial new adhesives that are compatible with both carbon fiber and fiberglass composites. Ensure that the chosen adhesive suits the curing process and environment. - Uniform Material Preparation:

Consistent material quality is key. Ensure all composite layers are prepared to specified tolerances. This enhances the bonding process by providing uniform substrates for the adhesive.

- Regular Equipment Calibration:

Days of continuous production can misalign machines. Regular calibration of pressing equipment minimizes operational variances, ensuring each paddle is manufactured under optimal conditions. - Operator Training:

Train production staff to recognize the early signs of delamination during in-process inspection stages. Early recognition can prevent large-scale production of defective paddles. - Implementing In-line QC Checks:

Introduce quality checks at various process stages—post-adhesion, post-pressing, and pre-packaging—to catch defects early.

Collect data from in-line inspections and post-production tests to identify trends in defect rates. Use this data to adjust both production techniques and material sourcing decisions. A feedback loop from quality control to the engineering team is essential for continuous improvement.

To illustrate the production process adjustments, see the following summary table:

| Process Adjustment | Purpose | Expected Outcome | Implementation Step |

|---|---|---|---|

| Temperature/Pressure Calibration | Ensure optimal adhesion | Improved layer bonding | Regular machine maintenance |

| Improved Adhesive Selection | Enhance compatibility with composite materials | Reduced risk of delamination | R&D and supplier evaluation |

| Operator Training Program | Early defect recognition | Lower production error rate | Scheduled training sessions |

| In-line Quality Checks | Continuous defect monitoring | Immediate action on production issues | Introduce multi-stage QC inspections |

These adjustments not only mitigate the immediate issue of delamination but also support long-term product reliability and customer satisfaction.

Recent internal studies in our production facilities have shown that a slight reduction in pressing temperature during hot pressing can significantly reduce the rate of delamination. For example, when we adjusted the temperature by 5°C and ensured tighter pressure control, the number of defects dropped by over 30% in trial runs.

Similarly, implementing ultrasonic testing on a sample of 500 paddles allowed us to detect 95% of early-stage delamination defects before they reached the final product assembly stage. These data points validate the importance of precise production controls and advanced diagnostic techniques in preventing composite failure.

Manufacturers like NEX Pickleball have turned these insights into actionable improvements in our production lines. By continuously monitoring and adjusting our process parameters, we ensure that every paddle delivers the high performance and long-lasting durability our clients expect.

Quality control in manufacturing is not just about inspection but involves a continuous process of improvement, feedback, and adjustment. This commitment to excellence has helped us remain a trusted partner in the sports equipment industry, and it continues to drive our innovation.

To summarize, diagnosing and preventing delamination in pickleball paddles requires a comprehensive understanding of both the materials and the production processes. Quality control managers and product engineers should:

• Identify physical signs of delamination through simple tests like the squeeze, shake, and visual examination tests.

• Utilize advanced diagnostic methods, including ultrasonic testing and thermal imaging, for more detailed analysis.

• Implement targeted production process adjustments focusing on temperature, pressure, and adhesive application to mitigate risks.

• Collect and analyze production data to create a continuous improvement loop.

For quality control managers looking to maintain high manufacturing standards, incorporating these diagnostic and preventative measures into regular quality assurance protocols is highly recommended. Doing so not only ensures product reliability but also builds long-term customer trust and competitive advantage in an increasingly demanding market.

By focusing on both detection techniques and process enhancements, companies can effectively address the challenges posed by paddle delamination. These actions have direct impacts on reducing production waste, increasing efficiency, and ultimately delivering superior products to customers.

If you are facing issues with paddle defects in your manufacturing process or need further guidance in fine-tuning your quality controls, consider reaching out to our technical support team. At NEX Pickleball, our advanced techniques and industry expertise help drive better product reliability for businesses and athletes worldwide.

-

How to tell if a pickleball paddle is delaminated?

When you press or squeeze the paddle face and detect a crackly or popping sound, it usually indicates that the layers have separated, suggesting delamination. -

How can you tell if your pickleball paddle is bad?

Key signs include a loose bumper or edge guard, internal movement when shaken, visible indentations or cracks on the paddle face, a loose handle, and symptoms of delamination. -

What is the average life of a pickleball paddle?

Typically, pickleball paddles can last between 1 to 3 years. Casual players may enjoy optimal paddle performance for up to 3 years before significant wear occurs.

-

structural integrity: Reading the article can help you understand how the strength and stability of a structure impact its overall performance and reliability in demanding applications. ↩ ↩

-

hot pressing: Reading the article can provide insights into this high-temperature and high-pressure bonding method used in composite manufacturing to enhance material adhesion. ↩ ↩

-

thermoforming: Reading the article can help you explore how heating and reshaping techniques are used in production to achieve complex designs while ensuring material integrity. ↩ ↩

-

ultrasonic testing: Reading the article can introduce you to this non-destructive evaluation technique, which uses ultrasonic waves to detect internal flaws in composite materials. ↩ ↩

-

thermal imaging: Reading the article can explain how capturing temperature differences helps detect inconsistencies in material bonding and overall product quality. ↩ ↩