Pickleball paddle regulations in 2025 are set to challenge traditional manufacturing and material choices. In response to evolving safety standards and compliance requirements, stakeholders must understand emerging trends, key banned models, and their impact on production and supply chains.

Recent regulatory announcements for 2025 have created shifts in how manufacturers, distributors, and buyers view high-performance pickleball equipment. With particular attention to banned paddle models and restricted materials, decision-makers must act quickly to adjust procurement and production strategies. New bans target specific paddle constructions, core thicknesses, and weight ranges that do not meet updated safety and performance guidelines.

Understanding the Impact of Banned Paddle Models1

Regulatory bodies have spotlighted paddles whose design features are now considered non-compliant. For example, certain models from renowned brands such as JOOLA, Gearbox, and ProKennex have been identified for bans based on factors like core construction and material composition. This targeted approach stems from concerns about player safety, performance consistency, and overall quality control.

-

Material Restrictions:

New guidelines focus on the use of specific carbon fiber variants2 and fiberglass compositions. Manufacturers are now required to adhere to stricter standards when sourcing materials like 3K, 12K, and T300 carbon fiber, each with distinct performance metrics. Regulatory bodies emphasize that excessive rebound force or material degradation under pressure can compromise safety. -

Core and Weight Regulations:

The core material of paddles plays a crucial role in absorbing shocks and delivering responsive play. For instance, banned models often exhibit unconventional core thicknesses (ranging from 13mm to 16mm) and weight imbalances that might lead to unexpected impacts during play. -

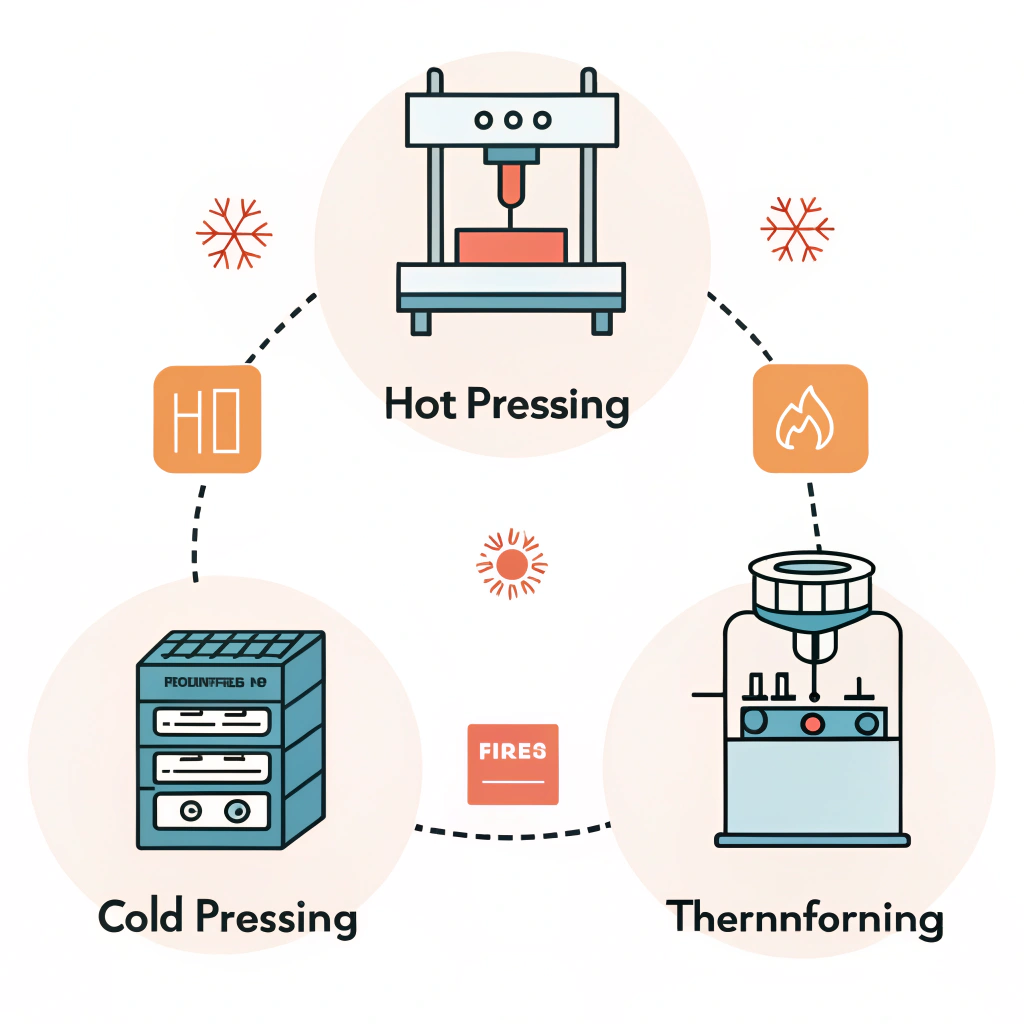

Production Process Challenges:

Modern manufacturing techniques such as hot pressing, cold pressing3 and thermoforming4 require precise calibration to maintain consistency. Deviations in these processes can alter the material properties critical for compliance. High production efficiency must be balanced against the integrity of the paddle's performance and safety features.

Advanced manufacturing methods enable the creation of high-performance pickleball paddles that meet stringent guidelines. Each process—hot pressing, cold pressing, and thermoforming—has unique strengths and challenges when it comes to regulatory compliance.

Manufacturers like NEX Pickleball employ these processes to optimize paddle performance while adhering to updated regulatory demands. Below is a comparison table highlighting these methods:

| Production Process | Advantages | Disadvantages | Compliance Considerations |

|---|---|---|---|

| Hot Pressing | • High production efficiency • Strong, impact-resistant paddles • Ensures structural integrity | • May alter material properties affecting paddle feel • High equipment investment | Must monitor temperature and pressure closely to ensure material stability. |

| Cold Pressing | • Enhanced control over paddle thickness • Maintains material's inherent properties • Improved ball feel and responsiveness | • Longer production cycles • Requires precise pressure control | Optimal for paddles requiring delicate balance of safety and performance. |

| Thermoforming | • Can produce intricate designs • Guarantees precise material distribution • Suitable for complex high-performance materials | • Longer production time • Higher equipment costs | Best for custom or premium paddles; focus on uniformity is key. |

To navigate these challenges successfully, manufacturers and procurement specialists should observe the following guidelines:

• Rigorous Testing: Every paddle must undergo thorough testing for durability, shock absorption, and consistency in weight and balance.

• Material Verification: Ensure all components, especially carbon fiber types and core materials, meet the latest industry standards.

• Process Calibration: Regular audits of hot pressing, cold pressing, and thermoforming processes are crucial. Fine-tuning these methods ensures that the end product remains compliant with 2025 guidelines.

• Custom Manufacturing Options: Consider partnering with manufacturers who offer tailored solutions, such as custom weight distribution and grip optimizations, to meet both performance and regulatory criteria.

Consider a scenario where a leading distributor sourced paddles from a manufacturer that continued traditional production methods without adapting to new guidelines. The result was a surge in returns and legal challenges due to non-compliance. On the contrary, companies like NEX Pickleball have preemptively upgraded their production processes. By integrating advanced technologies, rigorous material testing, and continuous process improvements, these companies have not only ensured compliance but also enhanced player performance through superior product quality.

Recent market surveys indicate that over 65% of distributors are actively reviewing their supply chains to mitigate risks associated with non-compliant pickleball equipment. This proactive approach has driven manufacturers to innovate, focusing on:

• Enhanced durability: Adapting material constructions to reduce vibration and enhance impact resistance.

• Optimized performance: Balancing core thickness and overall weight to suit dynamic player needs.

• Improved aesthetics: Incorporating custom design options without compromising safety standards.

Integrating these factors into a comprehensive quality control framework helps manufacturers maintain the delicate balance between performance and regulation. The adoption of state-of-the-art testing labs and enhanced certification processes is becoming standard practice in the industry.

For B2B decision-makers, understanding these changes is vital for forecasting market trends and managing procurement risks. Regulatory trends are now impacting not just the design and manufacturing of paddles, but also the broader market dynamics. Upcoming bans, specifically targeting certain paddle models, require decision-makers to be more selective about product lines and manufacturers.

| Paddle Model | Core Thickness | Weight |

|---|---|---|

| JOOLA Perseus 14mm MOD TA-15 | 14mm | 8.0-8.5 oz |

| Gearbox Pro Power Elongated | 13mm | 7.8-8.3 oz |

| ProKennex Black Ace Pro | 16mm | 8.1-8.6 oz |

| ProKennex Black Ace XF | 16mm | 8.0-8.5 oz |

The table above provides a snapshot of significant banned models that have come under regulatory scrutiny. Decision-makers should update inventory and procurement lists accordingly to avoid compliance risks in upcoming tournaments and retail distributions.

- Review Current Inventory: Audit existing products to identify any that may face regulatory challenges in 2025.

- Engage with Manufacturers: Work closely with suppliers to ensure they have updated their production processes and material sourcing strategies.

- Train Procurement Teams: Ensure that teams are aware of the latest guidelines and can identify potential compliance pitfalls.

- Plan for Change: Develop contingency plans to transition to compliant products without disrupting supply chains.

The banned paddle trends in 2025 highlight the importance of proactive decision-making and strategic planning. B2B stakeholders must leverage comprehensive insights into manufacturing processes, material science, and regulatory trends to steer their organizations toward profitable and compliant operations.

• Innovate Production Techniques: Invest in advanced manufacturing methods that can offer high levels of control and consistency. Technologies like precision cold pressing and thermoforming enable manufacturers to meet new guidelines without compromising quality.

• Enhance Quality Control: Implement systematic testing processes and continuous training for quality assurance teams. Reliable quality control mechanisms not only satisfy regulatory requirements but also boost the overall reputation of the product line.

• Strengthen Supplier Partnerships: Building robust relationships with trusted suppliers who understand the intricacies of modern regulation is vital. A transparent supply chain ensures that each component adheres to strict quality and compliance standards.

By aligning production capabilities with strict compliance measures, manufacturers such as NEX Pickleball are well-positioned to lead the industry through these regulatory changes. The focus on high-performance materials, advanced production methods, and proactive quality control ensures that businesses can continue to innovate while meeting industry standards.

Manufacturers who anticipate and adapt to these changes will not only avoid disruptions but also capitalize on opportunities to improve product performance and market reach. As the industry evolves, concerted efforts toward regulatory compliance and innovation will be key drivers of success.

The evolving regulatory landscape for pickleball paddles in 2025 is both a challenge and an opportunity. By understanding the detailed nuances of banned models, material restrictions, and production process adjustments, B2B decision-makers can make informed choices that protect their supply chains and drive future growth. Continuous innovation in manufacturing processes, stringent quality control, and strategic supplier engagement are essential for navigating these changes. Embracing these strategies today ensures that tomorrow’s products are not only compliant but also superior in performance and durability.

People Also Ask

Q1: What paddles are banned in pickleball in 2025?

A1: Banned pickleball paddles in 2025 include models such as JOOLA Perseus 14mm MOD TA-15, Gearbox Pro Power Elongated, ProKennex Black Ace Pro, and ProKennex Black Ace XF. These restrictions focus on core thickness and weight specifications to ensure player safety and compliance with regulatory standards.

Q2: Why are the Joola Gen 3 paddles banned?

A2: The Joola Gen 3 paddles have been banned primarily due to a clerical error in their registration process. Although they remain acceptable in open play, tournament directors who opt to enforce the ban must do so strictly, highlighting the complexities of regulatory oversight.

Q3: What is the #1 rated pickleball paddle?

A3: The #1 rated pickleball paddle varies by source, but current market evaluations have highlighted models like JOOLA Perseus Pro IV and JOOLA Hyperion Pro IV 16mm among the top contenders. Rankings depend on performance metrics, quality standards, and user feedback in competitive settings.

-

Banned Paddle Models: Reading this article clarifies the reasons behind the banning of specific paddle models, exploring the key design and performance factors influencing regulatory decisions. ↩ ↩

-

specific carbon fiber variants: Reading this article provides insights into the different carbon fiber types used in paddle manufacturing, their performance characteristics, and the regulatory impact on material sourcing. ↩ ↩

-

cold pressing: Reading this article explains the cold pressing technique, highlighting its advantages in preserving material integrity and ensuring consistent product quality under regulatory demands. ↩ ↩

-

thermoforming: Reading this article offers a deeper understanding of the thermoforming process in manufacturing, its benefits for precise material distribution, and its role in meeting compliance standards. ↩ ↩