USA Pickleball’s testing process encompasses a detailed, multi-step procedure that ensures each paddle meets stringent quality and safety standards. In just a few sentences: the process involves rigorous dimensional checks, performance evaluations, and compliance testing1 over a typical timeframe of 4 to 6 weeks—with an expedited option available in 3 to 8 business days—ensuring that every paddle holds up to industry and regulatory benchmarks.

In today’s competitive sports equipment market, it is crucial for procurement and quality assurance managers to understand the intricacies behind the testing processes that certify performance and compliance of products like USA Pickleball paddles. These procedures are designed to guarantee that every paddle adheres to strict standards on size, durability, and safety, while also maintaining optimal playability. This article dissects these testing methods, providing a clear and technical look at how each paddle is evaluated, the testing protocols in place, and the essential benchmarks used to ensure product quality.

The testing mechanism for USA Pickleball paddles operates under a robust framework that incorporates both standard and expedited process2. The standard process, which takes approximately 4 to 6 weeks, is designed for thorough analysis, while the expedited process—conducted in 3 to 8 business days—serves urgent testing needs. Both processes include several key stages:

• Dimensional Verification: Ensuring that paddles meet the established size criteria (length, width, and overall dimensions).

• Performance Evaluation: Assessing rebound force, vibration reduction, and responsiveness.

• Material and Durability Testing: Analyzing core and surface materials including carbon fiber, fiberglass, and composite materials.

• Safety and Compliance Checks: Aligning testing outcomes with industry safety standards and regulatory guidelines.

Each of these steps is implemented to achieve a comprehensive evaluation of the paddle’s capacity to perform under competitive and recreational conditions.

A critical component of quality assurance is ensuring the paddle dimensions fall within the specified range. During the Pickleball Paddle Sizing Test3, measurements ensure that the paddle length does not exceed 17 inches and that the combined length and width do not exceed 24 inches. Although there is no fixed requirement for thickness, maintaining overall balance is crucial for performance. This precision check includes advanced measurement tools and quality control checkpoints.

Key Considerations:

• Accuracy in measurement tools to ensure repeatability.

• Calibration of digital measuring systems.

• Adherence to guidelines as defined by the USA Pickleball Association (USAP).

Beyond basic sizing, paddles must exhibit optimal playability. The performance testing protocol involves simulations of game scenarios on both standard and high-intensity court environments. Key performance indicators include:

• Rebound Force: Ensuring that the paddle delivers sufficient rebound for power shots without compromising control.

• Vibration Reduction: Designed to minimize hand fatigue and improve ball feel.

• Surface Texture Assessment: Providing enhanced grip and spin control.

Testing is performed under controlled conditions that replicate actual sub-court play, ensuring that all paddles are evaluated fairly and consistently against each other.

The materials used in paddle construction—ranging from carbon fiber variants (3K, 12K, T300) to specialized composites and core materials like Nomex and aluminum honeycomb cores—undergo stringent testing. These tests include:

• Stress Testing: Simulating the impact forces during gameplay to evaluate the paddle’s resistance to damage.

• Fatigue Testing: Repetitive impact testing to assess long-term durability.

• Environmental Exposure: Evaluating paddle performance under varying temperatures and humidity to ensure consistency across different playing conditions.

This battery of tests ensures that even under extreme conditions, the paddle maintains its integrity and performance standards.

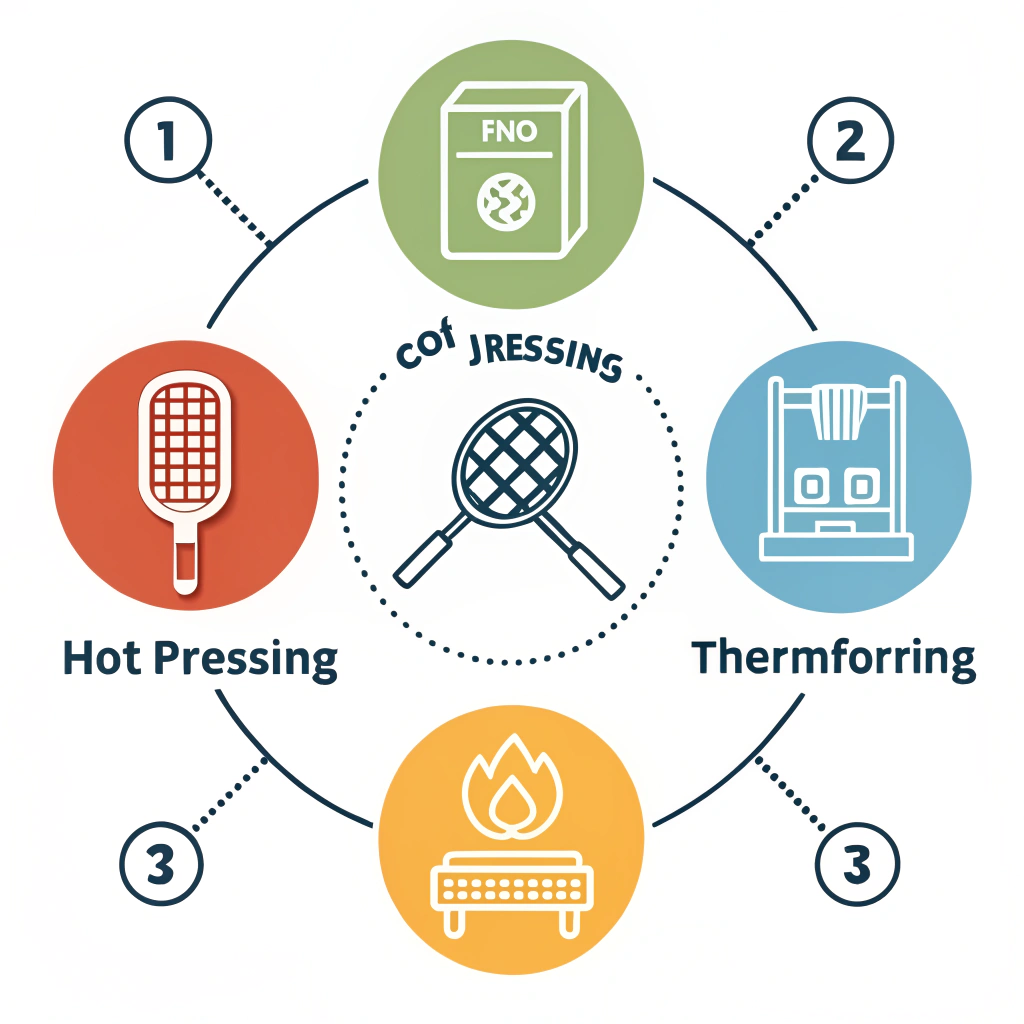

The production methods used in manufacturing these paddles have a significant impact on the testing requirements. For instance, NEX Pickleball’s production processes—hot pressing, cold pressing, and thermoforming4—each introduce unique characteristics in the final product. Understanding these processes is essential for aligning testing protocols with manufacturing realities.

| Production Process | Key Characteristics | Impact on Testing |

|---|---|---|

| Hot Pressing | High production efficiency, strong impact resistance | May alter material properties; tests focus on structural integrity |

| Cold Pressing | Precise control of material structure | Emphasizes ball feel and precise dimension measurements |

| Thermoforming | Intricate design possibilities and custom shapes | Requires detailed tests for stability and material distribution |

Explanation:

- Hot Pressing: Results in robust paddles with enhanced impact resistance, necessitating rigorous structural and endurance testing.

- Cold Pressing: Maintains natural material properties more effectively through precise mechanical pressure, making it essential to test for dimensional accuracy and tactile performance.

- Thermoforming: Balances design complexity with performance; here, stability and consistency across different materials are paramount.

This table demonstrates how production techniques dictate specific aspects of the testing procedures, ensuring that each paddle not only meets but exceeds quality assurance benchmarks.

All tested paddles are subjected to compliance checks in line with USA Pickleball Association (USAP) and relevant regulatory bodies. This ensures that every paddle on the market is safe for use and performs according to customer expectations. Compliance testing generally covers:

• Material Safety: Certification that materials used are free from hazardous substances.

• Performance Standards: Verification that impact resistance, ball rebound, and vibration dampening fall within acceptable ranges.

• Dimensional Consistency: Ensuring all paddles conform to size regulations for competitive play.

Test reports are meticulously documented and made available for further scrutiny by both internal and external auditors. These reports often include data charts, detailed measurement logs, and certification marks that reassure stakeholders of the paddle’s performance and safety.

With rapid advancements in material science and manufacturing techniques, testing protocols continuously evolve. Modern laboratories leverage cutting-edge technology such as:

• Digital Imaging and 3D Scanning: For real-time dimensional analysis and defect detection.

• Dynamic Impact Analyzers5: To measure paddle response in live conditions simulating game scenarios.

• Environmental Chamber Testing: To expose paddles to extreme conditions and monitor performance variances.

These enhancements reflect an industry-wide shift towards more precise and reliable testing practices. Adoption of such technologies not only benefits quality assurance departments but also contributes to improved product performance in competitive scenarios.

A recent study conducted during the testing phase of thermoformed paddles demonstrated significant benefits in terms of weight distribution and surface texture consistency. Paddles manufactured via thermoforming showed a 20% improvement in vibration reduction during extended play sessions. This case study reinforces the importance of continuous refinement in both manufacturing and testing to maintain high standards in paddle production.

For technical procurement and quality assurance managers, understanding the testing processes provides vital insights into product quality and potential areas for optimization. Here are some best practices derived from the detailed testing procedures:

- Establish Clear Quality Benchmarks: Set specifications in your procurement requirements that mirror the comprehensive tests described here.

- Demand Detailed Test Reports: Request full documentation of testing methods, results, and compliance certifications.

- Compare Testing Protocols: Ensure that products being sourced are evaluated using similar or more stringent testing methods as your internal benchmarks.

- Review Production Methods: Understand the production processes used by manufacturers to better interpret test results and long-term performance.

- Utilize Expedited Testing Options Wisely: In situations with tight deadlines, consider products that have undergone expedited testing while ensuring that quality is not compromised.

By applying these practices, procurement managers can more confidently assess the quality of pickleball paddles and make informed decisions that align with their company’s quality assurance requirements.

USA Pickleball’s testing process is designed to meet the highest standards in the industry, ensuring that every paddle is evaluated through multiple rigorous tests, from dimensional accuracy to material durability and safety compliance. The layered approach—comprising standard and expedited testing options—provides flexibility while upholding quality.

The procedure not only checks for compliance with size regulations and performance criteria but also integrates advanced testing technologies to simulate real-world playing conditions. As production techniques evolve, the corresponding testing protocols adapt, forming a robust quality assurance framework that benefits both manufacturers and purchasers.

For B2B procurement managers, understanding and leveraging these testing methods assures that the products you source are of superior quality, reliable, and compliant with industry standards. Considering the detailed evaluations and documented certifications, making informed decisions regarding equipment purchases becomes significantly more straightforward.

Procurement decisions made with these insights can help align your company with products that not only meet but exceed customer expectations, thereby fostering long-term trust and strategic partnerships.

People Also Ask

• How long does USAPA approval take?

Normal USA Pickleball testing typically requires 4 to 6 weeks. If expedited, testing is completed in 3 to 8 business days once the paddle is received by the facility.

• What is the USA Pickleball paddle test?

The paddle test primarily involves sizing verification to ensure paddles do not exceed 17 inches in length, and that the combined length and width do not exceed 24 inches. The test assures that paddles meet USAP standards, ensuring appropriate performance and regulatory compliance.

• How does the pickleball queue work?

In the pickleball waiting system, players place their paddles in a designated rack, with a “Next” indicator showing who will play next. The system is designed to manage game order efficiently, shifting from left to right as players take the court.

-

compliance testing: Click to learn how adherence to industry safety and regulatory guidelines ensures product reliability and legal compliance. ↩ ↩

-

expedited process: Click to understand how accelerated testing methods maintain quality while meeting urgent production timelines. ↩ ↩

-

Pickleball Paddle Sizing Test: Click to discover the detailed procedures and tools used in verifying paddle dimensions for optimal performance. ↩ ↩

-

thermoforming: Click to explore the manufacturing process that enables intricate design possibilities and impacts material performance. ↩ ↩

-

Dynamic Impact Analyzers: Click to read about advanced equipment that simulates live game conditions to accurately measure paddle response. ↩ ↩