USAPA’s measurement criteria and testing procedures for paddle spin compliance ensure that pickleball paddles meet rigorous performance and fairness standards. In short, they evaluate factors such as rebound force1, friction, dimensional accuracy, and surface properties through standardized, reproducible tests. This article explains the technical measurement methods, regulatory benchmarks, and testing protocols that inform product design and quality assessment for USAPA-compliant paddles.

In today’s highly competitive pickleball market, manufacturers must ensure that paddles not only deliver peak performance but also comply with regulatory standards. USAPA (USA Pickleball Association) has developed specific measurement criteria to govern paddle spin compliance—the parameter that dictates a paddle’s ability to impart spin on the ball without compromising safety or fairness. Non-compliance can lead to penalties in competition and result in a diminished reputation among players and retailers.

Compliance officers, product engineers, and quality assurance managers need to understand these measurement parameters to design paddles that meet both performance expectations and stringent regulatory benchmarks. Paddle spin compliance affects game dynamics significantly by influencing rebound force and friction characteristics, which in turn impact accuracy and control. Failing to adhere to these guidelines may lead to inconsistent performance or disqualification in competitive play.

Multiple factors contribute to variations in paddle spin, and understanding these is critical for accurate compliance testing. Key factors include:

• Material Properties: Different materials (such as 3K carbon fiber, 12K carbon fiber, T300, fiberglass, and various composites) have unique tensile strengths and surface properties. These differences affect friction, rebound force, and overall spin dynamics.

• Core Structure: The type of core material—whether polymer honeycomb, Nomex, or aluminum—directly influences the paddle’s stiffness and energy return characteristics, impacting spin.

• Surface Treatment and Texture: The paddle’s surface roughness, treatment coatings, and grip design can alter friction levels, affecting the ball’s spin upon impact.

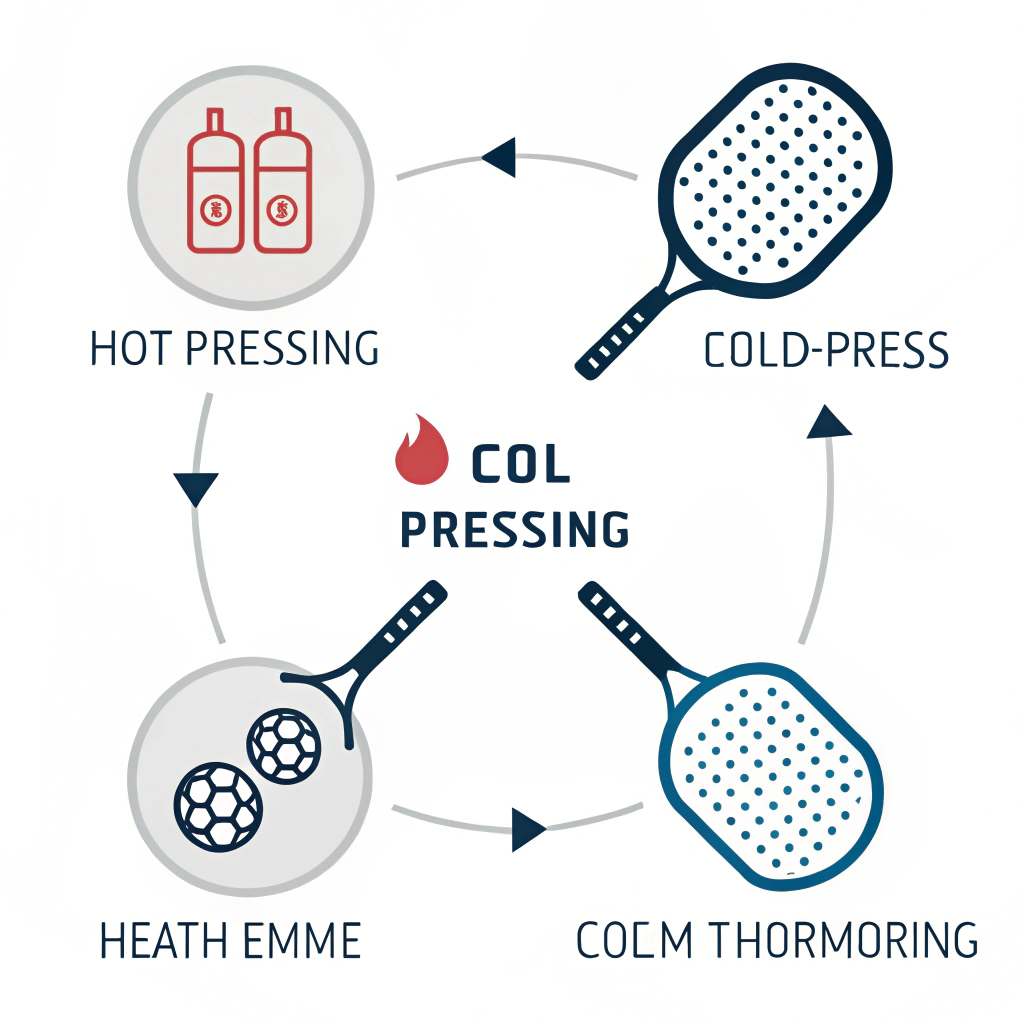

• Manufacturing Process: Production methods like hot pressing, cold pressing, and thermoforming2 not only determine the final shape and balance but also the material consistency and performance attributes, eventually influencing spin compliance.

Understanding these factors helps in refining testing protocols and ensuring that the measured spin characteristics are reliable and aligned with USAPA standards.

USAPA’s measurement criteria define a series of standardized testing procedures that every paddle must undergo to ensure spin compliance. These procedures are critical for verifying that paddles offer fair play conditions and predictable performance across different changes in playing conditions. The primary testing procedures include:

-

Dimensional Verification:

Every paddle must first be inspected for dimensional consistency. Measurements such as paddle face size, thickness, and contour are compared against established thresholds to ensure uniformity and balance. -

Rebound Force Testing:

This test measures the kinetic energy returned to the ball upon impact. Using calibrated equipment, the paddle is struck with a controlled impact, and the rebound speed is recorded. A defined range of rebound force is required to ensure that paddles do not provide an unfair advantage in spin generation. -

Friction Coefficient Measurement3:

By assessing the friction between the paddle's surface and a standardized testing surface, this measurement determines how effectively a paddle can impart spin. The friction coefficient is computed by rolling a weighted test ball over the paddle surface and recording the resistance encountered. -

Spin Transfer Analysis4:

Advanced testing setups evaluate the relationship between the paddle surface properties and ball spin. This involves launching a ball at varying angles and impacts while using high-speed cameras and sensors to measure the resulting spin rate. The data is then compared against USAPA’s acceptable spin ranges. -

Durability and Consistency Checks:

Paddles undergo repetitive stress tests to simulate extended play. These tests evaluate whether the spin characteristics remain consistent over prolonged usage and under varying environmental conditions.

Below is a table summarizing key testing procedures and their associated performance metrics:

| Test Procedure | Key Metrics | Advantages | Limitations |

|---|---|---|---|

| Dimensional Verification | Size, thickness, contour | Ensures consistency & balance | Requires precision tools |

| Rebound Force Testing | Kinetic energy, rebound speed | Quantifies energy transfer; reproducible results | Sensitive to impact conditions |

| Friction Coefficient Measurement | Friction level, surface resistance | Assesses surface grip for optimal spin | May vary with environmental factors |

| Spin Transfer Analysis | Spin rate, impact angle | High-speed and accurate evaluation of spin dynamics | Requires specialized high-speed imaging systems |

| Durability Testing | Performance consistency over time | Validates long-term compliance and resilience | Time-consuming and resource-intensive |

Understanding the parameters that define paddle spin compliance is essential for both product engineers and quality assurance teams. The primary parameters include:

• Rebound Speed: Indicates the paddle’s ability to return energy in the form of ball speed and spin. Variations in rebound speed can signal manufacturing defects or material inconsistencies.

• Friction Coefficient3: Critical for determining the level of grip between the paddle and the ball. This is measured using a friction-testing apparatus that simulates standard game conditions.

• Spin Rate: Measured in revolutions per minute (RPM), the spin rate helps quantify how much rotation is imparted to the ball. This is achieved by recording high-speed sequences during contact tests.

• Material Uniformity: Ensures that every part of the paddle, from the face to the core, has consistent physical properties. Variations in material distribution can affect performance and compliance.

High-precision instruments such as laser micrometers, friction testers, high-speed cameras, and automated impact rigs are essential tools in verifying these metrics. Consistent calibration of these instruments is a vital part of maintaining the validity of the test results.

Adhering to USAPA guidelines means following standardized protocols that have been established through industry consensus and rigorous testing. These guidelines address both the design and the performance aspects of paddle spin compliance:

-

Material Certification:

Manufacturers must document the type and batch of materials used. Certification ensures that only approved materials, which have been proven to align with USAPA’s performance criteria, are utilized. -

Process Validation:

Testing procedures must account for variations introduced by different manufacturing methods. Whether a paddle is produced via hot pressing, cold pressing, or thermoforming, each process is validated and its impact on the paddle’s spin characteristics is documented. -

Repeatability and Reproducibility:

Ensuring that testing results are both repeatable and reproducible across different tests and batches is crucial. This is achieved through standardized testing setups and rigorous quality control processes. -

Documentation and Traceability:

Detailed records of measurement data, calibration certificates, and test conditions must be maintained. This transparency facilitates regulatory reviews and future product improvements.

Comparing the manufacturing techniques, Table 2 highlights the key differences in how production processes can influence paddle spin compliance:

| Production Process | Impact on Spin Characteristics | Key Considerations |

|---|---|---|

| Hot Pressing | Produces strong, high-impact resistant paddles | High production efficiency; may modify material feel |

| Cold Pressing | Preserves material properties for better control | Longer cycle times; precise pressure control necessary |

| Thermoforming | Enables complex designs with consistent material distribution | Longer production time; ideal for custom-made premium products |

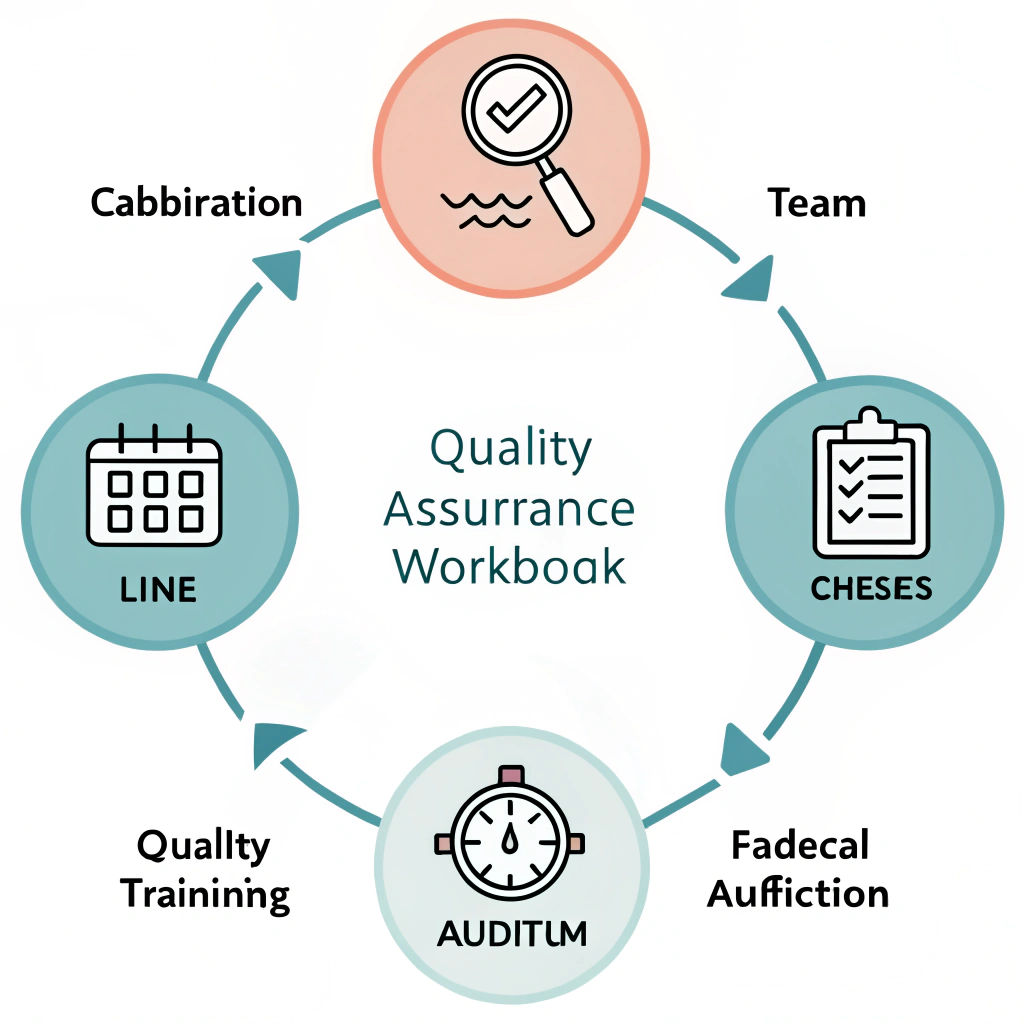

Integrating USAPA measurement criteria into product engineering requires a robust quality assurance strategy. Here are critical steps for implementation:

• Calibration5 of Equipment:

Regular calibration of measurement instruments is essential. This includes routine checks on high-speed cameras, friction testers, and impact rigs to ensure data accuracy.

• Training of Technical Teams:

Engineers and quality control teams should receive intensive training on the standardized testing protocols. Understanding the intricacies of each test is key to maintaining compliance.

• In-line Quality Checks:

Incorporate automated testing modules within the production line. Continuous monitoring allows for immediate identification of deviations from the set performance criteria, reducing waste and ensuring consistent compliance.

• Feedback Loop from Field Data:

Use data gathered from competitive play and laboratory testing to refine measurement processes further. This iterative process helps in identifying potential anomalies early and adjusting manufacturing processes accordingly.

• Documentation and Audits:

Keeping detailed records and periodic audits boosts confidence in the empirical data generated during testing. This documentation is critical not only for internal reviews but also for regulatory compliance verification.

Integrating these strategies can transform the manufacturing process into one that consistently produces paddles meeting USAPA standards and enhances overall product quality.

Consider a situation where a manufacturer identified inconsistencies in paddle spin during competitive play. A comprehensive review of the testing protocols revealed that slight variations in the friction coefficient were responsible. By calibrating the friction measurement setup and adjusting the surface treatment process, the manufacturer achieved uniform spin transfer across all units. The implemented changes brought the product into full compliance with USAPA guidelines, improved performance consistency, and ultimately led to a higher satisfaction level among players. This case highlights the importance of rigorous measurement and the ability to adjust manufacturing processes in real-time.

To summarize, adhering to USAPA’s measurement criteria and testing procedures for paddle spin compliance is critical for ensuring fair play and optimal performance. Manufacturers must pay careful attention to material properties, production methodologies, and detailed testing protocols including rebound force, friction coefficient, and spin rate measurements. By integrating calibrated measurement equipment, standardized testing procedures, and comprehensive quality assurance strategies into the manufacturing process, companies can achieve consistent compliance and maintain a competitive edge in the pickleball market.

For compliance officers, product engineers, and quality assurance managers, it is recommended to:

• Review and update testing protocols regularly to align with evolving standards.

• Invest in high-precision measurement equipment and ensure regular calibration.

• Engage in comprehensive training sessions for technical teams on USAPA guidelines.

• Leverage field data and feedback as part of an ongoing improvement process.

Implementing these recommendations will not only ensure adherence to USAPA’s guidelines but also contribute to the development of high-performance, compliant pickleball paddles that meet the demands of both recreational and competitive play.

People Also Ask

Q1: What does USAPA paddle spin compliance mean?

A1: USAPA paddle spin compliance means that a paddle meets standardized criteria for performance, including acceptable ranges of rebound force, friction, and spin rate, ensuring fairness and consistency in competitive play.

Q2: How is paddle spin measured for USAPA compliance?

A2: Paddle spin is measured using standardized tests such as rebound force testing, friction coefficient measurement, and spin transfer analysis with high-speed imaging to quantify the paddle’s ability to impart spin on the ball.

Q3: Why is dimensional verification important in paddle spin compliance testing?

A3: Dimensional verification ensures that a paddle’s size, thickness, and contour remain consistent, which is crucial for maintaining uniform performance and ensuring that spin characteristics fall within USAPA’s regulatory standards.

-

Rebound Force: Reading this article will provide insight into how kinetic energy is measured upon impact, ensuring that product designs meet performance criteria without compromising fairness. ↩

-

Thermoforming: This explanation covers how thermoforming enables complex designs in manufacturing, balancing production efficiency with high-quality material distribution. ↩

-

Friction Coefficient: Explore this resource to understand how friction is quantified in testing, which is crucial for optimizing paddle grip and spin performance. ↩ ↩2

-

Spin Transfer Analysis: Learn about advanced testing techniques that measure how a paddle imparts spin, helping manufacturers achieve precise control over gameplay dynamics. ↩

-

Calibration: Discover the importance of calibration in ensuring that testing instruments remain accurate, leading to reliable quality assurance and compliance outcomes. ↩