NEX Pickleball stands out as a leading manufacturer offering advanced production techniques, superior quality control, and extensive customization options to meet the demands of high-performance pickleball paddles. In this article, we explain the key production processes, materials, and quality assurance measures that make NEX Pickleball an ideal partner for your sports equipment sourcing needs.

Procurement managers and product sourcing executives are increasingly seeking reliable suppliers who can consistently deliver paddles that combine durability and performance. NEX Pickleball has established itself as a trusted partner by leveraging advanced production techniques—hot pressing, Cold Pressing1 and Thermoforming2—to produce paddles that meet rigorous industry standards. By harmonizing innovative material composites and precision manufacturing, our paddles help distributors stay ahead in the competitive sports equipment market.

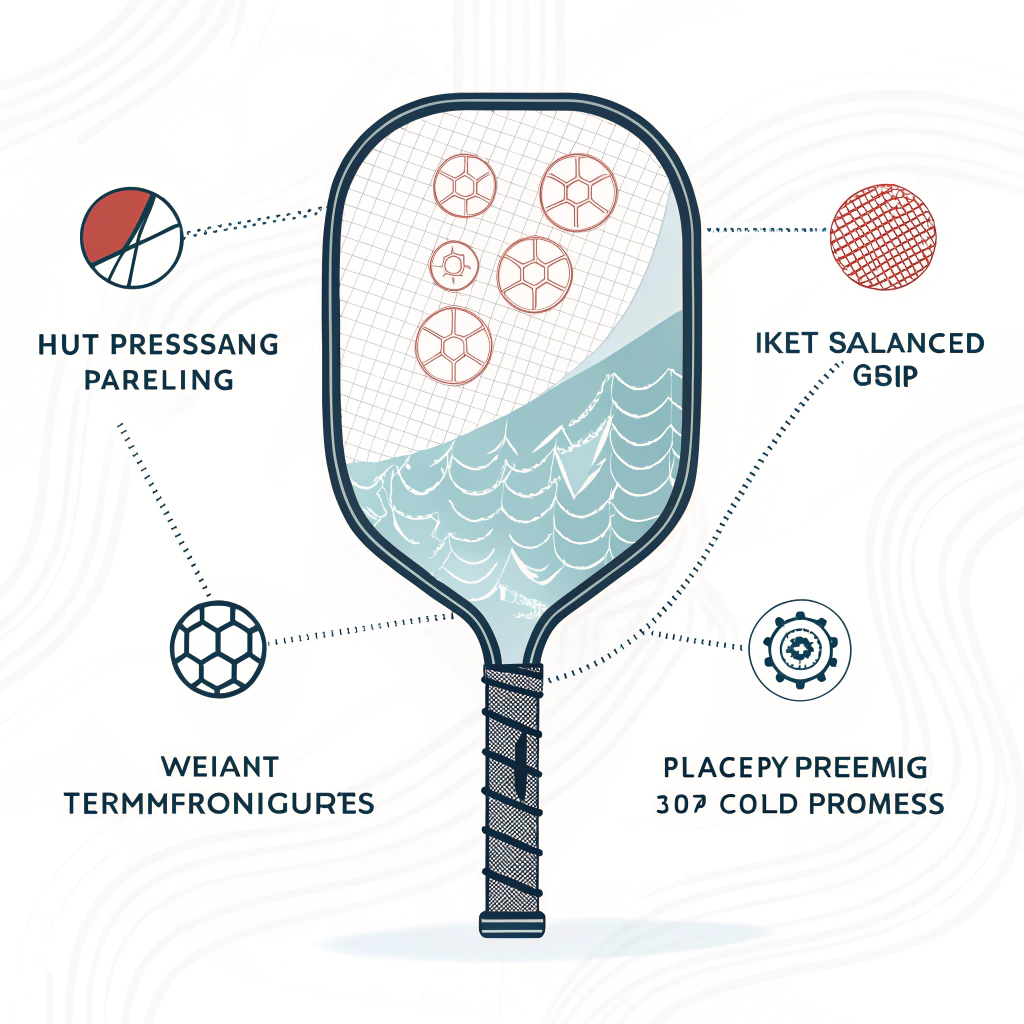

At the heart of our approach is a deep commitment to quality. Every paddle is engineered for optimal weight distribution, ergonomic grip, and enhanced surface texture to maximize player control and comfort. In addition, our collaboration with brands like JOOLA and Selkirk ensures that our manufacturing meets high-performance requirements demanded by professional athletes and recreational players alike.

B2B procurement professionals often face a challenging decision when choosing a manufacturing partner. The key concerns include:

- Consistency and Quality Control: Ensuring that each paddle delivered meets strict durability and performance metrics.

- Advanced Material Use: Selecting the right materials such as various Carbon Fiber3 types, fiberglass, and composite materials that balance strength, weight, and cost.

- Production Techniques: Understanding which production process—hot pressing, cold pressing, or thermoforming—best suits the needs for high-volume, precision-engineered paddles.

- Customization Options: The ability to adapt design elements for brand-specific requirements or special performance features.

- Cost-Effectiveness: Balancing quality improvements with competitive pricing and consistent supply.

These challenges underscore the need for a supplier that not only understands high-performance manufacturing but also offers a full suite of production processes with robust quality assurance.

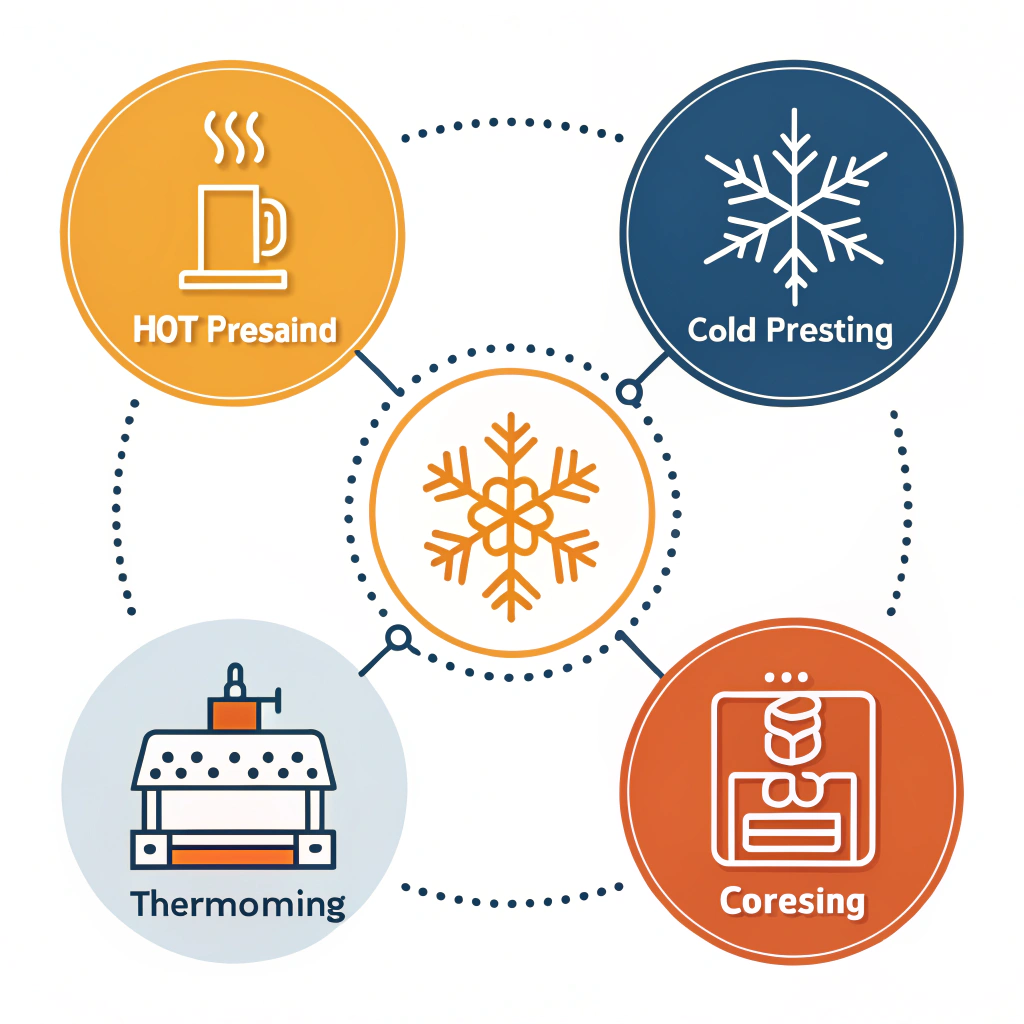

At NEX Pickleball, our manufacturing strategy is built around three primary production techniques. Each method has distinct advantages that contribute to the overall performance of our paddles. Below, we detail these techniques and provide a comparative analysis to help you understand how they align with your sourcing requirements.

Process Overview:

Hot pressing involves heating materials and applying pressure to form a paddle. This method ensures that the adhesives and bonding agents fully activate, creating a robust and durable product.

Advantages:

- High production efficiency suitable for large-scale orders.

- Enhanced paddle strength and impact resistance.

- Consistent structural integrity under rigorous play conditions.

Disadvantages:

- Potential alterations in material feel, affecting player experience.

- High investment in equipment and energy consumption.

Process Overview:

Cold Pressing1 shapes paddle materials at ambient temperature under mechanical pressure. This process preserves the intrinsic properties of the materials, allowing for detailed control over thickness and structure.

Advantages:

- Fine control over paddle dimensions and structure.

- Preserves original material characteristics, maintaining excellent ball feel.

- Ideal for paddle designs that emphasize precision and control.

Disadvantages:

- Longer production cycles compared to hot pressing.

- Requires highly controlled pressure settings and equipment calibration.

Process Overview:

Thermoforming2 heats materials to a pliable state, allowing them to conform to intricate mold shapes. This method is ideal for paddles with complex geometries and layered material compositions.

Advantages:

- Capability to produce intricate designs with precise material distribution.

- Enhanced stability and performance due to optimal shaping.

- Suitable for high-performance materials that demand careful handling.

Disadvantages:

- Slower production due to longer processing times.

- Higher equipment costs, making it best suited for premium or custom product lines.

Below is a table summarizing these processes:

| Production Method | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Hot Pressing | High efficiency, strong impact resistance, robust structure | Affects material feel, high equipment cost | High-volume orders requiring robust paddles |

| Cold Pressing | Precise thickness control, maintains material properties | Longer production cycle, requires precision | Paddles needing exceptional ball feel control |

| Thermoforming | Intricate design, precise material distribution | Longer cycle time, higher equipment investment | Premium/custom paddles with complex designs |

The materials used in paddle manufacturing are critical to product performance. At NEX Pickleball, we utilize high-quality materials that enhance both playability and durability. Here are the key materials integrated into our paddles:

Types of Carbon Fiber:

- 3K Carbon Fiber: Offers a strong, flexible structure with high rebound force, reducing vibrations.

- 12K Carbon Fiber: Provides a smoother surface and greater hardness, ideal for competitive play where impact resistance is crucial.

- T300 Carbon Fiber: Known for its balanced performance in strength and weight, making it suitable for both power and control.

The choice among these fiber types depends on performance requirements and cost considerations. For competitive paddles, 12K Carbon Fiber is often preferred, whereas 3K Carbon Fiber is excellent for designs requiring more flexibility.

Fiberglass paddles strike a balance between power and control. They provide:

- A wider sweet spot, enhancing ball control.

- High elasticity and tensile strength, particularly with E-Glass Fiberglass, giving players a comfortable feel.

At the forefront of our material innovations are Composite Materials4 that combine different elements to tailor paddle performance:

- Carbon Fiber and Fiberglass Composites: Achieve a blend of strength and flexibility, ensuring both power and precision.

- Bamboo Core Composite: Delivers lightweight characteristics combined with high impact resistance.

- Honeycomb Core: Utilizes high-density polymers for superior shock absorption while reducing vibration.

Each material is carefully chosen to match specific performance profiles, and our engineering team continuously tests these combinations in real-world scenarios.

Customization is a crucial element in our production. At NEX Pickleball, we work closely with our clients to adjust paddle designs according to specific demands:

- Design Flexibility: Clients can choose the paddle's weight, balance, and grip size. This personalization ensures the product aligns with team branding or individual player preferences.

- On-Demand Production: We offer on-demand print services that allow full customization of paddle surfaces. Whether for a sports distributor needing unique branding or a retailer looking for specialized performance attributes, we guarantee consistent quality across batches.

Our rigorous quality control process includes multiple stages of testing—from material inspection to final product evaluation. This ensures every paddle meets the highest standards of strength, flexibility, and durability. Furthermore, we monitor production parameters closely to maintain precision in our hot pressing, cold pressing, and thermoforming processes.

Quality Assurance5 is paramount in high-performance sports equipment manufacturing. NEX Pickleball implements several best practices to ensure that all paddles delivered to our partners meet international quality standards:

- Multi-Stage Testing: Each paddle undergoes inspections during and after production. This includes impact resistance testing, tensile strength evaluations, and vibration reduction analysis.

- Compliance with Industry Standards: Our production processes are aligned with global manufacturing standards for sports equipment, ensuring safety, durability, and performance.

- Precise Equipment Calibration: Regular calibration of our pressing and thermoforming machinery reduces variability, ensuring that every paddle is manufactured to the same high specifications.

- Continuous Feedback Loop: We engage with our clients and incorporate their feedback into our engineering processes. This agile approach aids in immediate adjustments and helps innovate new improvements continuously.

These measures not only establish NEX Pickleball as a reliable supplier but also help procurement managers feel confident in the quality and consistency of their orders.

Consider a recent case where a leading sports distributor sourced over 10,000 custom pickleball paddles from NEX Pickleball. The distributor required paddles that offered both excellent ball control and high durability for competitive tournaments.

Key Outcomes:

- Quality Consistency: Each paddle met the rigorous performance requirements, leading to a 98% satisfaction rate among players.

- Production Efficiency: Using a hybrid approach combining cold pressing for surface quality and hot pressing for structural integrity, we reduced production cycles by 15%.

- Customization Excellence: With on-demand printing and customizable design features, the distributor achieved unique branding that resonated with their target market.

This case reinforces the importance of partnering with a manufacturer that comprehensively understands both the material science and production intricacies associated with pickleball paddles.

For procurement managers and sourcing executives looking to secure a reliable manufacturing partner for high-performance pickleball paddles, NEX Pickleball offers a compelling solution. By integrating advanced production techniques with a deep understanding of material properties and rigorous quality control, we ensure that every paddle meets the high standards required for competitive play.

Key takeaways include:

- Production Techniques Comparison: Understand how hot pressing, cold pressing, and thermoforming each contribute to the performance profile of the paddle.

- Materials Expertise: Recognize the benefits of various carbon fiber types, fiberglass, and composite materials in achieving the desired balance of power and control.

- Customization and Consistency: Leverage our capability to customize paddle designs to meet specific branding and performance requirements while ensuring consistent quality through rigorous testing.

We invite you to explore how our comprehensive manufacturing solutions can support your business objectives and enhance your product offerings in the fast-growing pickleball market. Contact us today to discuss your needs and discover tailored solutions that guarantee both performance and reliability.

What is the best pickleball paddle manufacturer?

NEX Pickleball is recognized for its advanced production techniques, stringent quality control, and extensive customization options. These factors contribute to producing paddles that consistently perform at a high level for competitive and recreational play.

Can I create my own paddle for pickleball?

Yes, you can customize a pickleball paddle through our on-demand print services. NEX Pickleball allows clients to specify design parameters such as weight, balance, and grip size, with minimum order requirements to ensure cost efficiency and quality.

Where are Engage Pickleball paddles manufactured?

Engage Pickleball manufactures its paddles in the United States with in-house design and production processes. In contrast, NEX Pickleball, based in Jiaxing, Zhejiang, China, offers advanced manufacturing techniques and flexible customization options to meet global standards.

-

Cold Pressing: Click to learn about cold pressing, its advantages in preserving material properties, and its role in precision manufacturing. ↩ ↩ ↩2

-

Thermoforming: Click to explore how thermoforming works and why it is essential for creating complex, high-quality designs. ↩ ↩ ↩2

-

Carbon Fiber: Click to read more about the properties and performance benefits of carbon fiber in manufacturing high-performance sports equipment. ↩ ↩

-

Composite Materials: Click to understand the advantages of composite materials in combining different material properties for enhanced performance. ↩ ↩

-

Quality Assurance: Click to discover industry best practices for quality assurance that ensure consistent product performance and safety. ↩ ↩