Pickleball paddle manufacturing excellence starts with advanced production techniques1 and material expertise – a formula for high-performance, durable solutions that drive your business forward.

In today’s competitive sports equipment industry, procuring high-performance pickleball paddles goes beyond simply choosing a manufacturer. A company like NEX Pickleball stands out by combining advanced production techniques with premium materials, offering a range of customizable solutions2. If you need a partner who can provide precision-engineered paddles designed for both recreational and competitive play, our tailored methods and quality assurance processes are here to meet and exceed your expectations.

Businesses sourcing pickleball equipment often face key challenges:

• Achieving a balance between performance and durability

• Ensuring consistency in quality across large production orders

• Customizing paddle specifications to meet individual brands’ or players’ needs

• Integrating advanced production techniques with innovative material usage

Procurement managers and business development executives must evaluate not only the end product but also the behind-the-scenes processes that deliver reliable high-performance paddles. Our industry insights show that a technology-driven approach enables manufacturers to offer solutions that satisfy both technical requirements and market demand.

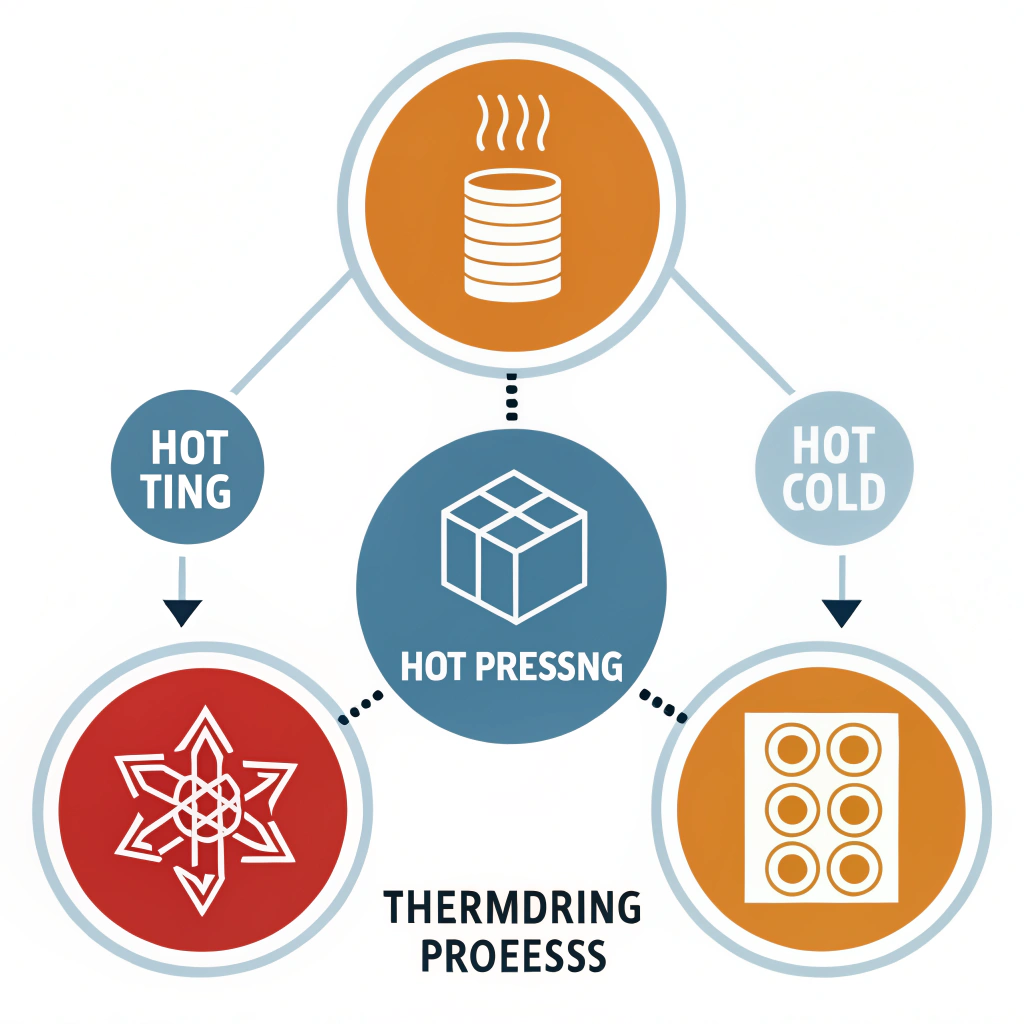

At NEX Pickleball, we pride ourselves on employing three main production processes: **Hot Pressing, Cold Pressing, and Thermoforming3. These are tailored to serve specific performance and design needs.

Hot pressing is a technique that involves heating the paddle material and applying considerable pressure to form a strong, impact-resistant structure. This method is highly efficient for large-scale manufacturing and constantly produces paddles that offer excellent durability.

• Advantages:

- High production efficiency, making it ideal for mass production.

- Creates structurally robust paddles with high impact resistance.

- The process enhances the overall strength and longevity of each paddle.

• Disadvantages:

- High initial equipment investment is required.

- The heat can sometimes alter the intrinsic feel of key materials.

Cold pressing works by applying mechanical pressure at room temperature, ensuring that the material retains its original properties and texture. This method is especially appreciated for paddles that demand precision and control — key aspects for tactical gameplay.

• Advantages:

- Precise controlling of paddle thickness and structure is possible.

- Maintains key material characteristics, which leads to excellent ball feel and responsiveness.

- Ideal for producing paddles with superior control and flexibility for players at all levels.

• Disadvantages:

- The production process takes longer compared to hot pressing.

- Requires high-quality pressure control equipment to maintain consistency across batches.

Thermoforming takes advantage of heating materials to a pliable state, then using molds to create paddles with complex shapes and intricate designs. This method is best suited for customization, where design plays an integral role, and is perfect for premium products.

• Advantages:

- Enables the creation of intricately designed paddles with even material distribution.

- Enhances paddle stability and performance via controlled heating and shaping.

- Suitable for high-performance materials that require careful handling.

• Disadvantages:

- Production times are longer due to the precision required during the forming process.

- Involves higher equipment costs, making it best for products positioned at the premium end of the market.

Below is a comparative table summarizing the three primary production processes used in our manufacturing:

| Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | - High efficiency and structural integrity - Ideal for mass production and high-impact resistance | - High equipment costs - Possible material property alterations |

| Cold Pressing | - Precision control over product dimensions - Maintains material quality for better ball feel and control | - Longer cycle times - Requires advanced pressure regulation |

| Thermoforming | - Enables complex designs and superior material distribution - Perfect for premium custom paddles | - Time-intensive process - Higher cost of equipment |

Our commitment to quality is further strengthened by carefully selected materials that go into each paddle. The use of advanced materials4 such as different grades of carbon fiber, fiberglass, and composite cores ensures that each paddle meets exact performance criteria for power, control, and durability.

Leveraging different types of carbon fiber, our paddles are designed to suit various play styles:

- 3K Carbon Fiber: Offers excellent strength and flexibility, reduces vibration, and is perfect for paddles that need high rebound force.

- 12K Carbon Fiber: With a high thread density, it provides a smoother surface, greater hardness, and improved impact resistance — ideal for competitive play.

- T300 Carbon Fiber: Delivers balanced performance with outstanding tensile strength and reduced paddle weight, creating an optimal blend for both power and finesse.

Fiberglass paddles, particularly those made with E-Glass Fiberglass, are developed to offer a huge sweet spot and enhanced control. This material is widely used when a blend of flexibility and performance is needed, making it a popular choice among both recreational players and professionals.

Our composite solutions merge the benefits of various materials:

- Carbon Fiber and Fiberglass Composite: Balances strength and flexibility to deliver both power and control.

- Bamboo Core Composite: Provides a lightweight yet impact-resistant option, offering a clear and crisp ball hitting experience ideal for prolonged play.

- Honeycomb Core: Utilizes high-density polymers to offer excellent shock absorption and vibration reduction, resulting in an overall durable product.

Crucial to paddle performance is the core material, which influences hardness, control, and the overall feel:

- Nomex Honeycomb Core: Delivers outstanding shock absorption along with durability.

- Aluminum Honeycomb Core: Strikes an optimal balance between power and control, creating a versatile option for various play styles.

- Polymer Honeycomb Core: Known for superior elasticity and minimal vibration, making it ideal for beginners and recreational players seeking comfort.

By integrating these materials, we ensure that every paddle is not just a product, but a finely tuned instrument built for top-tier performance.

Customization is at the core of our solutions. Recognizing that each business has unique requirements, we offer bespoke paddle designs with options including:

- Tailored grip sizes: Ensuring ergonomic comfort for players across various hand sizes.

- Custom material selections: Features premium choices like Carbon Fiber, Fiberglass, and a variety of composite materials.

- On-demand printing services: Allows for personalized branding, catering to everything from individual enthusiasts to large-scale sports organizations.

This high level of flexibility ensures that our partners can offer a differentiated product line that resonates well with specific market segments.

Quality Control5 and Testing: Guaranteeing Performance

Quality control is non-negotiable in the manufacturing of high-performance pickleball paddles. Each paddle from NEX Pickleball undergoes rigorous testing, with a focus on:

- Strength and durability assessments: Ensuring that every paddle can endure the demands of competitive play.

- Flexibility and rebound testing: Critical for maintaining optimal performance during dynamic game situations.

- Ergonomic evaluation: Making sure that the paddle is both comfortable and responsive, thereby reducing the risk of fatigue or injury for players.

Our testing processes are designed to detect even the smallest inconsistencies, which allows us to ensure that every product leaving our facility represents the highest standards of craftsmanship and engineering excellence.

When selecting a manufacturing partner, procurement managers commonly weigh the importance of comprehensive production processes, material quality, and customization potential. With NEX Pickleball, the benefits are clear:

-

Consistent Product Quality: Our robust quality control procedures guarantee uniformity and high performance across every batch, ensuring that your brand maintains its reputation for excellence.

-

Innovative Production Techniques: By utilizing state-of-the-art processes like hot pressing, cold pressing, and thermoforming, we deliver products that are not only high-performing but also perfectly tailored to the needs of professional and recreational pickleball players.

-

Custom Solutions for Market Differentiation: In an era where differentiation in sports equipment can significantly impact sales, our customizable paddle options allow your business to offer unique, branded products that cater to specific market segments.

-

Efficient Supply and Timely Delivery: Leveraging high production capacity and advanced technology, we are able to meet large order demands without compromising on quality or delivery schedules.

For businesses seeking to broaden their product portfolio and enhance their competitive edge, partnering with a manufacturer that combines technical prowess with innovative customization is key. Our commitment to excellence is not just a promise; it’s delivered in every paddle we manufacture.

In summary, NEX Pickleball offers a powerful combination of advanced production techniques, high-quality material selection, and meticulous quality control that is essential for manufacturing high-performance pickleball paddles. By choosing us as your manufacturing partner, you are not just sourcing a product; you are investing in solutions that are engineered for excellence and built to support your success in a competitive market.

We invite procurement managers and business development professionals to explore our capabilities and join the growing number of businesses that have already experienced the benefits of partnering with a leader in pickleball paddle manufacturing. It’s time to transform your product offerings with paddles that deliver on every promise—from outstanding durability to exceptional performance.

Action Step: Reach out today for a comprehensive consultation on how our custom paddle solutions can meet your business requirements, and set the stage for market success.

• What is the best pickleball paddle manufacturer?

Our research indicates that the best pickleball paddle manufacturer is one that delivers consistent quality with advanced production techniques. Although models such as the JOOLA Perseus Pro IV and others are popular in the market, the focus should be on a manufacturer’s ability to customize high-performance paddles with precision engineering and rigorous quality control.

• What paddle do most professional pickleball players use?

Professional players typically choose paddles that balance control and power while minimizing vibration. Manufacturing standards and material choices—such as those found in models like the JOOLA Perseus—are critical. The optimal paddle is one that has been thoroughly tested to provide performance attributes like enhanced spin and aggressive control, ensuring peak play conditions.

• How much do professional pickleball paddles cost?

Professional grade pickleball paddles are generally priced between $150 to $250. This price range reflects the use of premium materials, sophisticated production techniques, and comprehensive quality control systems required to ensure a product that meets both aesthetic and performance standards.

-

advanced production techniques: Click to learn how integrating state-of-the-art manufacturing processes can optimize efficiency and enhance product performance. Back ↩

-

customizable solutions: Understand how tailored product designs can meet unique business needs and create market differentiation. Back ↩

-

Thermoforming: Explore the method of heating and molding materials to achieve intricate designs and superior material distribution. Back ↩

-

advanced materials: Discover the benefits of using high-performance materials in manufacturing for improved durability and precision. Back ↩

-

quality control: Read about the robust testing procedures and standards that ensure consistent excellence in every product. Back ↩