Custom carbon fiber1 pickleball paddles deliver superior performance, durability, and customization options that can meet even the most demanding market requirements. In today’s competitive sporting goods landscape, manufacturers like NEX Pickleball are setting the standard by combining advanced production processes with custom design capabilities to help businesses stand out.

In the B2B procurement world, decision-makers are often caught in a dilemma: how to balance high performance, quality manufacturing, and competitive pricing when choosing a supplier for custom sports equipment. For distributors and procurement managers, the key is to identify a manufacturing partner that not only offers customization and advanced materials—like 3K, 12K, and T300 carbon fiber1—but also implements proven production techniques, such as hot pressing2, cold pressing3, and thermoforming4. This article compares industry practices and our own approaches, offering a clear, multi-dimensional perspective to help you make an informed decision.

Businesses in the sports equipment sector need to consider many factors. Custom carbon fiber pickleball paddles must deliver exceptional power, control, and comfort while being manufactured cost-effectively at low minimum order quantities (MOQ5). A typical procurement manager weighs features such as:

• Material Quality: Superior carbon fiber variants, including 3K (for durability and vibration reduction), 12K (for a smoother surface and enhanced strength), and T300 (for balanced strength and lightness).

• Production Techniques: The choice between hot pressing, cold pressing, and thermoforming can influence the paddle’s structural integrity, performance, and pricing.

• Customization Options: Ensuring that your unique design solutions—from grip size variations to weight distribution—are achievable without sacrificing performance.

• Quality Control: Consistent manufacturing quality, rigorous testing, and reliable production timelines are fundamental.

Recognizing these challenges underscores why a comprehensive, detailed comparison is critical.

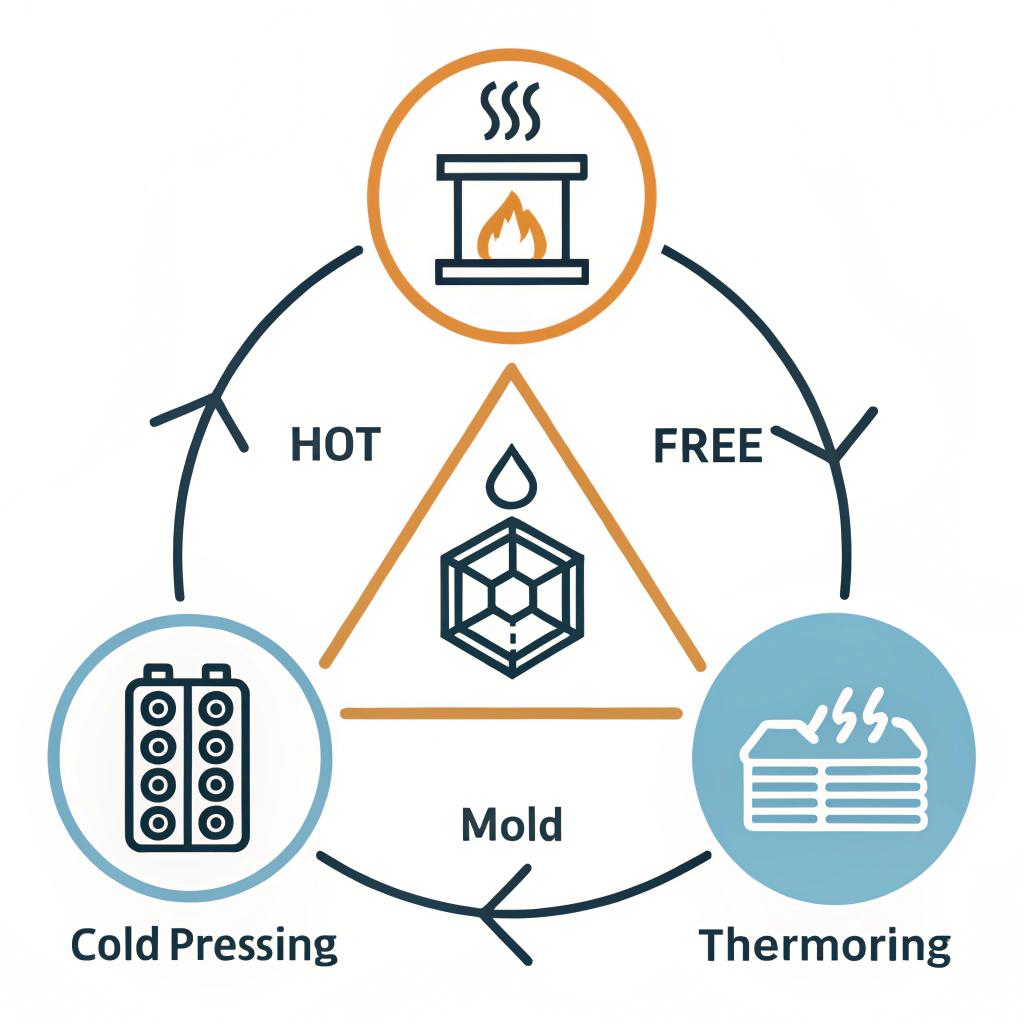

One of the key aspects in the decision-making process is the production technique. Each method brings different benefits and limitations:

Hot pressing involves heating materials and applying pressure to form a high-strength structure.

• Benefits:

– High production efficiency suited to large-scale manufacturing.

– Superior impact resistance and structural integrity, making paddles robust in high-performance scenarios.

• Considerations:

– Requires significant equipment investment and may alter the intrinsic material feel.

In contrast, cold pressing shapes the paddle at room temperature under controlled pressure.

• Benefits:

– Provides precise control over the paddle’s thickness and design detail.

– Preserves the inherent properties of the materials, resulting in enhanced ball control and responsiveness.

• Considerations:

– Production cycle times are longer, and the method requires high-quality pressure control equipment.

Thermoforming heats the material until softened, then molds it into the desired shape, suitable for intricate designs.

• Benefits:

– Enables the creation of paddles with complex designs and evenly distributed materials.

– Maintains stability while also delivering excellent performance.

• Considerations:

– Best suited for premium products due to higher equipment costs and longer production times.

These production techniques are summarized in the following comparison table:

| Production Technique | Advantages | Limitations |

|---|---|---|

| Hot Pressing | High efficiency; strong and durable paddles; excellent impact resistance | High equipment cost; potential material property alteration |

| Cold Pressing | Precise thickness control; retains material’s natural properties; enhanced responsiveness | Longer production cycles; requires precise machinery |

| Thermoforming | Suitable for complex designs; balanced material distribution; excellent performance stability | Higher equipment and production time costs; best for premium products |

The essence of a high-performance paddle lies in its material. Carbon fiber is revolutionary in sports equipment manufacturing due to its exceptional strength-to-weight ratio. Here’s how different types compare:

-

3K Carbon Fiber:

Ideal for paddles needing high rebound force. Its inherent flexibility reduces vibration, providing a sturdy and reliable playing experience. -

12K Carbon Fiber:

With a higher thread density, 12K offers a smoother surface, superior hardness, and increased impact resistance. It is best for competitive play where extreme performance is necessary. -

T300 Carbon Fiber:

Known for remarkable tensile strength, T300 strikes a balance between strength and weight, making it perfect for paddles that must be both powerful and agile.

This diversity in carbon fiber types allows manufacturers and buyers to tailor paddle characteristics precisely to meet player expectations—from recreational participants to elite competitors.

One of the significant strengths of a leading manufacturer like NEX Pickleball is the ability to customize not just the material composition but also the ergonomic design of the paddle. Customization options include:

• Altering weight distribution for better control and speed.

• Various grip sizes to suit different hand dimensions.

• Customized surface texturing to increase ball spin and improve grip.

Such options are crucial for meeting the diverse needs of customers and tailoring products for retail or team-specific branding. Rigorous quality control measures are embedded in every production step. Every paddle goes through:

• Stringent testing protocols to guarantee durability and performance.

• Consistent monitoring during each production phase to ensure precision.

• Post-production inspections to verify that each paddle adheres to the highest standards.

This commitment to strict quality control not only underpins our reputation for excellence but also ensures that our products perform reliably under competitive conditions.

When comparing manufacturers, it is essential to evaluate both technical performance and business practicality. NEX Pickleball distinguishes itself in three primary areas:

-

Advanced Production Techniques:

By employing hot pressing, cold pressing, and thermoforming, we can offer paddles that combine optimal performance with cost-effectiveness. Our production methods guarantee consistent quality and allow fast turnaround times, making us an ideal partner for businesses that require low MOQ and rapid delivery. -

Material Versatility and Customization:

The use of multiple types of carbon fiber ensures that our paddles meet varying performance criteria. Moreover, our customized design options allow clients to tailor features according to the unique needs of their markets, whether for performance optimization or brand-specific aesthetics. -

Competitive Pricing and OEM Solutions:

Our scale of operations, paired with advanced technology and efficient production lines, allows us to offer competitive pricing without compromising on the product’s quality. With OEM capabilities, we support brands in developing their signature styles and meeting the market demand for customized sports equipment.

Together, these dimensions form a robust solution for distributors looking to differentiate their product offerings in the marketplace.

A further factor in the decision-making process is comparing industry standards with the technical specifics we offer. Here’s a deeper dive into how custom pickleball paddles stack up against general market alternatives:

| Aspect | NEX Pickleball Custom Paddles | General Market Alternatives |

|---|---|---|

| Material Quality | Premium carbon fiber selections (3K, 12K, T300) for optimized performance and durability | Often use lower-grade materials with inconsistent performance |

| Customization | Extensive options including weight, balance, grip size, and surface modifications | Limited customization; mostly off-the-shelf designs |

| Production Process | Advanced and tested methods: hot pressing, cold pressing, thermoforming, ensuring robust quality control | Basic production techniques may affect durability and feel |

| MOQ Flexibility | Low minimum order quantities suited for B2B clients seeking flexibility | Higher MOQs often imposed, which may restrict small to medium businesses |

| Quality Control | Rigorous, multi-level quality assurance programs in place | Inconsistent quality control procedures leading to variable product performance |

This comparison clearly illustrates that partnering with a specialized manufacturer not only minimizes risks related to product performance but also provides the flexibility required in a dynamic market.

Given the critical factors discussed above, procurement managers and sports equipment distributors should consider the following action steps when choosing a manufacturing partner for custom carbon fiber pickleball paddles:

- Evaluate the production techniques and how they align with your quality and performance expectations. Determine whether the manufacturer offers scalability—especially if low MOQ are essential for your business.

- Examine material options carefully. Look for suppliers who provide a range of carbon fiber types and can explain the benefits of each in your context.

- Confirm that the manufacturing partner has strict quality control processes in place. Detailed testing procedures and multiple quality checkpoints are crucial for ensuring product longevity and performance.

- Consider customization possibilities that could distinguish your offering in the market. A supplier who enables personalized design modifications can give your brand an edge.

- Assess cost-effectiveness in relation to the advanced production processes used. Even with premium techniques, competitive pricing is achievable with efficient production management.

By addressing these points, you can make well-informed decisions that balance technical performance, customization, and pricing effectively.

In conclusion, for businesses seeking high-performance, customizable carbon fiber pickleball paddles with low MOQ, a strategic partnership with a capable manufacturer like NEX Pickleball offers unmatched advantages. Our advanced production methods, diverse material options, and commitment to quality create a reliable, competitive edge in the market. This comprehensive approach ensures every paddle not only enhances player performance but also reinforces your market position and customer satisfaction.

People Also Ask

Q1: What are the benefits of using carbon fiber in pickleball paddles?

A1: Carbon fiber provides a high strength-to-weight ratio, resulting in paddles that are both durable and lightweight. It improves rebound force, reduces vibration, and offers excellent control—making it ideal for both competitive and recreational play.

Q2: How do advanced production techniques like hot pressing and thermoforming impact paddle performance?

A2: Techniques such as hot pressing enhance the paddle’s structural integrity and impact resistance, while thermoforming allows for complex designs and even material distribution. These methods ensure that custom paddles provide consistent performance and durability.

Q3: Why is customization important for B2B buyers of pickleball paddles?

A3: Customization ensures that paddles meet specific market demands by adjusting weight distribution, grip size, and surface texture to optimize performance. This flexibility helps businesses differentiate their products and align them with brand requirements while maintaining competitive pricing.

-

carbon fiber: Click to read more about the properties and manufacturing advantages of carbon fiber, including its strength-to-weight ratio and applications in high-performance equipment. ↩ ↩ ↩2

-

hot pressing: Click to learn about hot pressing, a production technique that uses heat and pressure to enhance structural integrity and efficiency in manufacturing. ↩ ↩

-

cold pressing: Click to explore cold pressing, a method that shapes components at room temperature for precise control over design and material properties. ↩ ↩

-

thermoforming: Click to understand thermoforming, a process that heats materials until soft to mold complex shapes suitable for premium product designs. ↩ ↩

-

MOQ: Click to read about Minimum Order Quantities (MOQ) and how understanding them can help optimize procurement strategies and manage production costs. ↩ ↩