High-performance pickleball paddles start with precision manufacturing and innovative production processes. NEX Pickleball’s expert techniques in material selection, production methods, and quality control ensure that our paddles not only meet but exceed the standards required by B2B buyers in today’s competitive market.

In today’s competitive sports equipment market, procurement managers and purchasing agents face the challenge of sourcing high-performance pickleball paddles that balance cost, quality, and efficiency. With global distribution and the need for cost-effective manufacturing, it is critical to work with a manufacturer that combines advanced technology with deep industry expertise. At NEX Pickleball, we address these challenges by using state-of-the-art production techniques and premium materials to deliver paddles that are durable, lightweight, and customizable to your unique requirements.

Procurement managers are often caught between the need for bulk supply at competitive pricing and ensuring that every paddle in their supply chain performs at the highest level. The main issues include:

• Ensuring material quality that provides power, control, and durability,

• Balancing production efficiency with high manufacturing standards, and

• Offering custom options without significantly increasing lead times or production costs.

These challenges require a supplier who not only understands the nuances of pickleball paddle manufacturing but also continuously innovates to deliver products that align with evolving market demands.

The key challenges in manufacturing high-performance pickleball paddles lie in the selection of materials and production techniques:

-

Material Selection

The performance of a pickleball paddle greatly depends on its materials. At NEX Pickleball, we use a variety of premium materials:-

Carbon Fiber: We offer 3K, 12K, and T300 carbon fibers.

• 3K Carbon Fiber delivers strength and flexibility, minimizing vibration during play.

• 12K Carbon Fiber provides a smoother hitting surface and is perfect for competitive play due to its exceptional hardness and durability.

• T300 Carbon Fiber strikes a balance between lightweight design and tensile strength. -

Fiberglass: Particularly E-Glass Fiberglass offers a balance between power and control, with a broader sweet spot ideal for players at various levels.

-

Composite Materials: Combining materials such as carbon fiber with fiberglass or using innovative cores like Bamboo Core Composite and Honeycomb Core ensures that our paddles achieve the best combination of strength, flexibility, and durability.

-

Core Materials: The paddle’s core is pivotal for its performance. We use different types such as Nomex Honeycomb1, Aluminum Honeycomb, and Polymer Honeycomb cores to meet specific player needs, from long-lasting stability to enhanced ball control.

-

-

Production Process Efficiency

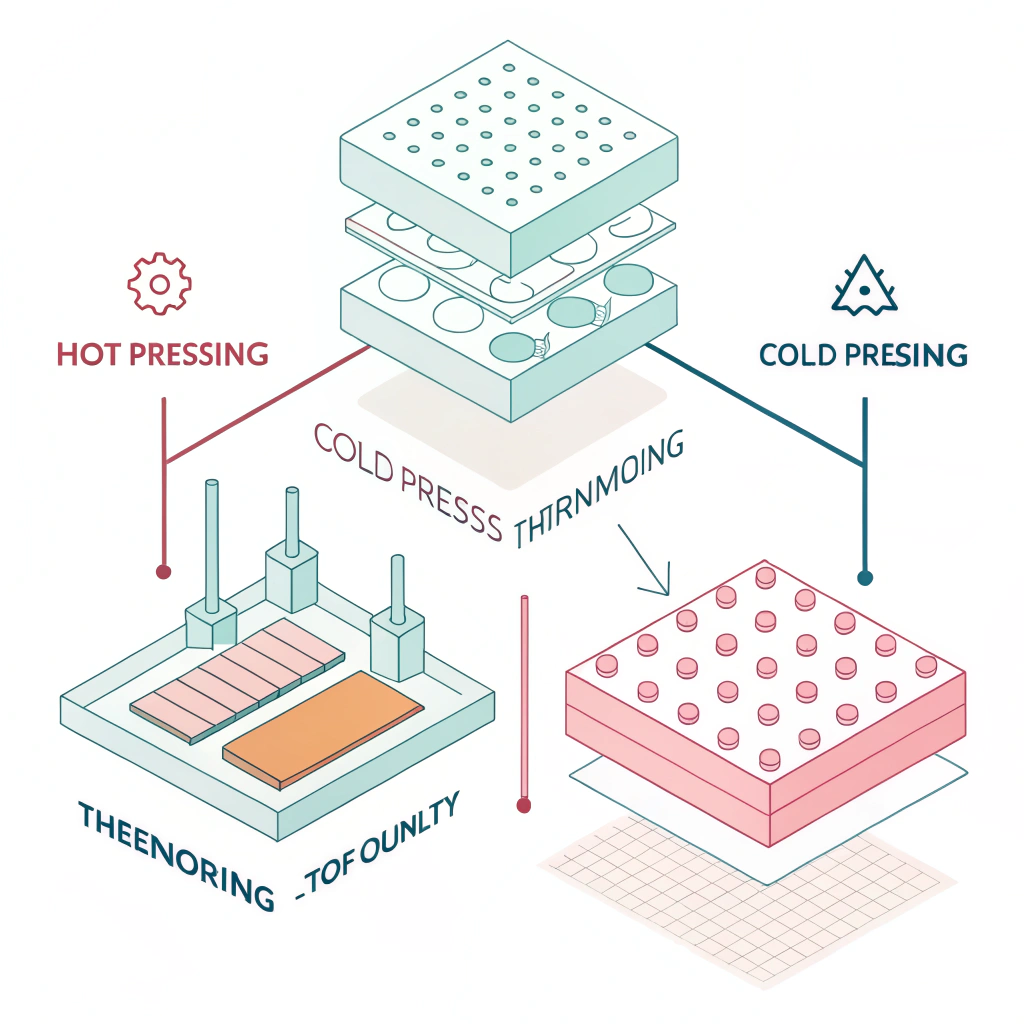

Our commitment to quality is reinforced by our advanced manufacturing processes, designed to optimize both performance and production capacity:- Hot Pressing2: By applying heat and pressure, we create a paddle that is structurally robust and has excellent impact resistance.

- Cold Pressing3: This technique maintains the inherent properties of the raw materials, offering a paddle with precise thickness control and superior ball responsiveness.

- Thermoforming4: Best for intricate designs, thermoforming heats materials to a softening point and uses molds to achieve the perfect shape and structure.

These processes are carefully chosen and monitored to ensure that every paddle meets the highest standards of performance and durability.

To aid in decision-making, we have developed a clear, comparative approach to our production technologies. Below is a table that provides a concise overview:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | - High production efficiency - Strong, durable paddles with excellent impact resistance - Ensures structural integrity for high-performance use |

- Can alter some material properties - Requires high investment in specialized equipment |

| Cold Pressing | - Maintains natural material qualities - Precise control over thickness and structure - Superior ball feel and responsiveness |

- Longer production cycles - Demands high-quality equipment for precise pressure control |

| Thermoforming | - Ideal for complex shapes and designs - Maintains material stability - Suitable for high-performance, premium products |

- Longer production time - Increased equipment and mold costs |

These technologies are not mutually exclusive; they are carefully selected based on the product’s design requirements and the specific performance criteria demanded by our customers.

Our factory in Jiaxing, Zhejiang, China, leverages decades of expertise to deliver paddles that meet both bulk procurement demands and high-performance standards. Here’s how our approach minimizes risk and enhances value in your B2B procurement process:

-

Quality and Consistency

Every batch of paddles undergoes rigorous quality control tests to ensure adherence to strict performance standards. Our testing protocols simulate actual game conditions, ensuring that the paddles demonstrate optimal rebound force, vibration dampening, and ergonomic grip. -

Customization for Market Needs

We understand that different markets and players have unique needs. Our custom paddle options allow businesses to tailor paddle designs, weight distributions, and grip sizes to their target consumer profiles. This flexibility makes it easier to brand products or meet specific regulatory requirements in different regions. -

Production Capacity and Efficiency

With flexible production processes that include high-speed hot pressing and precision cold pressing, we ensure large-scale production without compromising product quality. This efficiency makes us an ideal partner for distribution companies and retailers needing reliable, timely supply.

-

Cost-Effectiveness and Competitive Pricing

High-quality production need not come with high costs. By integrating advanced production techniques with bulk manufacturing efficiencies, we offer competitive pricing—a key factor for B2B buyers. Our balance of quality and cost ensures that businesses do not have to compromise on performance while obtaining a favorable cost structure. -

Technological Innovation and Future-Proofing

Innovation is critical in maintaining a competitive edge. Our continual investment in production technology, from enhanced hot pressing equipment to sophisticated thermoforming processes, ensures that we remain at the forefront of pickleball paddle manufacturing. This not only meets today’s market demands but also anticipates future trends in material science and product design.

Consider a major sports equipment distributor evaluating potential suppliers for their national retail chains. The distributor needs to ensure that the paddles offer:

• High durability and long-term performance,

• Consistency across large production runs, and

• Customizability to target different market segments.

Our solution involved integrating high-precision cold pressing for the paddle face, coupled with Nomex Honeycomb cores for superior durability and reduced vibration. The result was a high-performance pickleball paddle that delivered excellent playability and reliability in extensive field tests. The distributor benefited from:

• Reduced product returns due to consistency,

• Enhanced brand reputation from selling reliable equipment, and

• Scalable production that aligned with their nationwide supply chain needs.

This case illustrates that a meticulously designed production process, combined with a commitment to quality at every stage, can significantly enhance market competitiveness.

For procurement managers considering our manufacturing capabilities, it is important to note the following best practices when evaluating a paddle manufacturer:

-

Material Transparency:

Choose suppliers who clearly disclose their material composition, including details on carbon fiber grades, fiberglass options, and core materials. Transparency in material sourcing is critical for ensuring consistency and reliability. -

Process Versatility:

Assess the manufacturing processes a supplier uses. A manufacturer who employs multiple techniques—such as hot pressing, cold pressing, and thermoforming—can offer more targeted solutions based on different player needs and product specifications. -

Customization Potential:

Customization often equates to meeting specific market requirements. The ability to alter paddle design, weight distribution, and grip sizes is crucial for businesses that aim to differentiate their offerings or adapt to niche market segments. -

Robust Quality Control:

Quality control is essential for maintaining high product performance. Ensure that your manufacturing partner employs rigorous testing methods and has established protocols that mimic end-user conditions. -

Scalability5 and Supply Chain Reliability:

The ideal supplier should demonstrate both production capacity and the flexibility to adjust manufacturing volumes in response to market demand. Effective supply chain management further ensures on-time delivery and consistency in product performance.

In summary, as a procurement manager looking for a cost-effective, reliable supplier, partnering with NEX Pickleball offers you a strategic advantage. By leveraging our innovative production processes, commitment to quality, and customization capabilities, you ensure that your customers receive high-performance pickleball paddles that truly enhance the playing experience. Our approach—grounded in advanced materials, precise engineering, and scalable production methods—provides the ideal balance between quality and cost-effectiveness.

We encourage you to review our capabilities, schedule a consultation, and see how our production excellence can meet your wholesale needs now and in the future. With NEX Pickleball, you not only secure a reliable supplier but also gain a partner committed to innovation and excellence in sports equipment manufacturing.

People Also Ask

Q: Which company makes the best pickleball paddles?

A: Leading manufacturers like JOOLA and Selkirk are widely recognized for their high-performance pickleball paddles. However, NEX Pickleball is a key player behind these brands, offering advanced production techniques such as hot pressing, cold pressing, and thermoforming to ensure precision and durability.

Q: Is there a difference between cheap and expensive pickleball paddles?

A: Yes, the difference primarily lies in the materials and construction methods. Expensive paddles typically use advanced materials like high-grade carbon fiber or specialized composites and benefit from precision manufacturing techniques. In contrast, cheaper paddles may use older facing materials and simpler construction methods, resulting in a smaller sweet spot and reduced performance.

-

Nomex Honeycomb: Click to understand the benefits of using Nomex Honeycomb as a core material for enhanced stability and vibration reduction. ↩

-

Hot Pressing: Click to read an article about this advanced production process that uses heat and pressure to create robust, impact-resistant products. ↩

-

Cold Pressing: Click to explore how cold pressing preserves natural material qualities, ensuring precise thickness and superior responsiveness. ↩

-

Thermoforming: Click to learn how thermoforming heats materials to a pliable state, enabling complex designs and consistent quality. ↩

-

Scalability: Click to discover why scalability is crucial for meeting increased production demands while maintaining high quality. ↩