Quick Answer: Kevlar1 pickleball paddles offer exceptional stiffness and energy transfer, making them ideal for players seeking powerful shots. However, their performance must be evaluated alongside other advanced materials and production processes to ensure they meet your bulk purchasing and quality requirements.

In today’s competitive sports equipment market, selecting the right paddle material is crucial for performance, durability, and cost-effectiveness. Kevlar1 pickleball paddles have emerged as a promising solution due to their inherent stiffness and ability to efficiently transfer energy from the paddle to the ball. For procurement managers and B2B sales executives, understanding the technical merits of Kevlar alongside other materials like Carbon Fiber2, Fiberglass, and various Composite Materials3 is essential. This article provides a comprehensive comparison of these materials, details innovative manufacturing processes, and explains why partnering with a trusted manufacturer like NEX Pickleball results in premium, high-performance products suited for wholesale orders.

Modern pickleball paddles are engineered to maximize power, control, and durability. Here, we explore the primary materials used in high-performance paddles:

- Kevlar1: Known for its stiffness, Kevlar ensures efficient energy transfer during impact, leading to powerful shots. Its rigidity, however, might provide a less forgiving feel for players who prefer a softer touch.

- Carbon Fiber2: Materials like 3K, 12K, and T300 carbon fibers are prized for their strength, flexibility, and resilience. Carbon fiber paddles typically deliver enhanced durability and a smooth surface finish.

- Fiberglass: Offering excellent elasticity and control, fiberglass paddles create a wider sweet spot. They are ideal for players who value a blend of power and ball control.

- Composite Materials3: Combining the brilliance of carbon fiber and fiberglass or incorporating bamboo cores, composites provide a balanced mix of strength, lightness, and flexibility.

To help clarify these differences, consider the table below which compares key performance aspects of these materials:

| Material | Stiffness | Energy Transfer | Durability | Control | Typical Use Case |

|---|---|---|---|---|---|

| Kevlar | High | Excellent | High | Less forgiving | Power players, competitive drives |

| Carbon Fiber (3K/12K/T300) | Medium-High | Very Good | Very High | Smooth and stable | High-performance competitive play |

| Fiberglass | Medium | Good | Medium | Wide sweet spot | Recreational and control-focused players |

| Composite (Hybrid/Bamboo) | Balanced | Good | High | Enhanced grip | All-round performance and custom designs |

The selection of material directly influences the paddle’s properties and suitability for different playing styles and market segments. As you evaluate materials for bulk orders, balancing these attributes with cost and customization options is key.

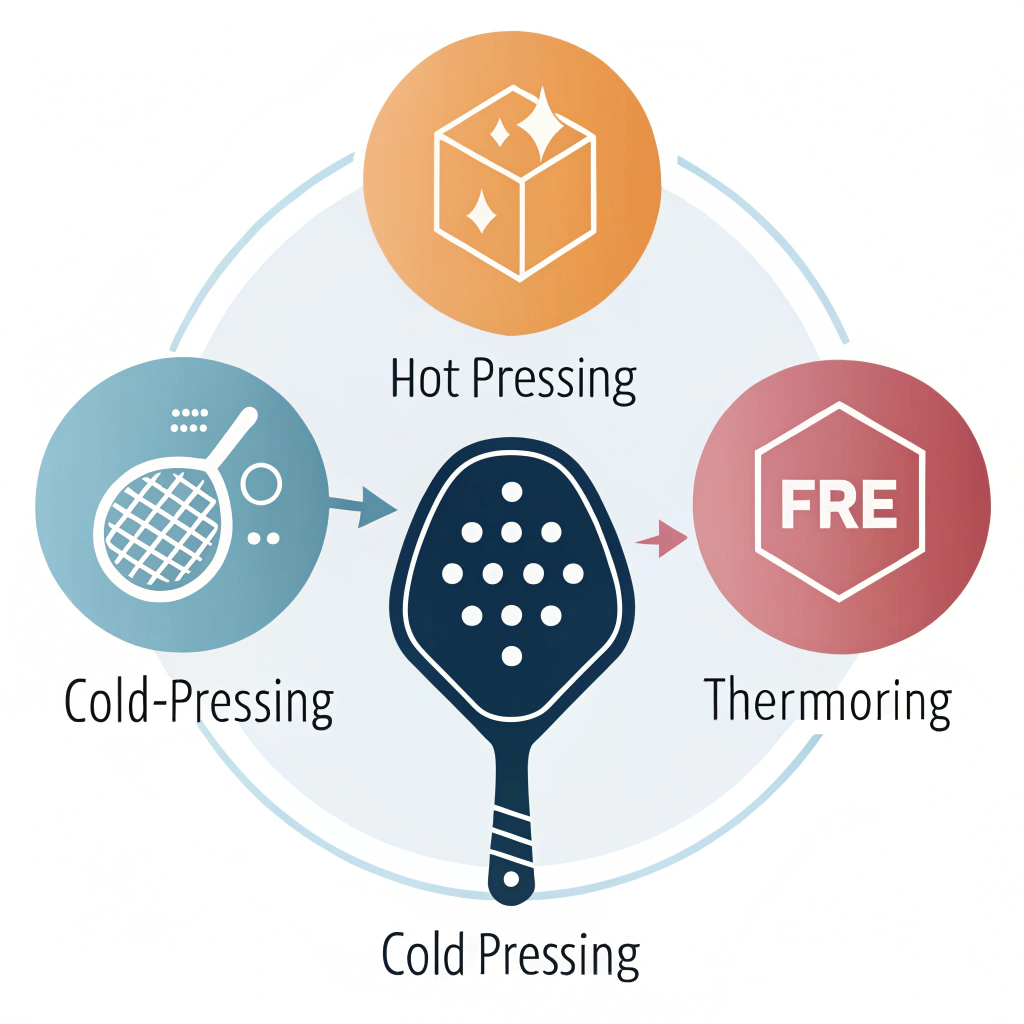

High-performance paddles are not just about cutting-edge materials. The manufacturing process plays an equally important role in ensuring consistency, quality, and reliability. At NEX Pickleball, we employ three advanced production techniques:

Hot pressing involves heating raw materials and applying pressure to form the paddle.

Advantages:

- High production efficiency suitable for large-scale manufacturing.

- Produces paddles with excellent impact resistance and structural integrity.

Disadvantages:

- Temperature variations can slightly alter material properties.

- Requires substantial investment in high-temperature equipment.

In cold pressing, materials are shaped at room temperature under controlled mechanical pressure.

Advantages:

- Precise control over paddle thickness and structure.

- Maintains the original properties of each material, enhancing ball feel and control.

Disadvantages:

- Longer production cycles compared to hot pressing.

- Demands high-quality, precision-controlled equipment.

Thermoforming heats materials to a softening point and uses molds to shape complex designs.

Advantages:

- Allows for intricate, customized paddle designs and precise material distribution.

- Enhances paddle stability and performance with complex geometries.

Disadvantages:

- Requires a longer production time.

- Higher equipment costs, making it ideal for premium or custom orders.

To summarize these production techniques, the following table outlines their main pros and cons:

| Production Technique | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | Fast, efficient, produces high-strength paddles | High investment; potential alteration of material feel |

| Cold Pressing | Precise control, preserves material properties | Longer cycle time; requires precision equipment |

| Thermoforming | Allows complex designs, uniform material distribution | Slower production; higher cost for equipment |

The choice of production process is directly linked to the characteristics of the final paddle product. Manufacturers like NEX Pickleball strategically select the process that best matches the intended performance attributes and cost parameters, ensuring that every paddle consistently meets high-quality standards.

For B2B buyers, partnering with a reliable factory that specializes in high-performance pickleball paddles is critical. NEX Pickleball stands out by offering:

- Strict Quality Control: Every paddle undergoes rigorous testing processes to verify durability, precise weight distribution, and ergonomic comfort. This ensures that every product delivered to wholesale partners meets industry standards.

- Advanced Production Techniques: Leveraging hot pressing, cold pressing, and thermoforming allows us to tailor the paddle performance to diverse customer needs, from competitive durability to recreational playability.

- Customizable Options: Understanding that market demands vary, NEX Pickleball offers on-demand printing and custom design options. Clients can specify design, weight, balance, and grip sizes to align with their unique requirements. This customization capability makes it easier for distributors to differentiate their product lines.

When evaluating potential trade partners, consider the level of transparency and technical support a manufacturer provides. NEX Pickleball’s commitment to innovation and quality control not only assures consistent product performance but also streamlines the procurement process by reducing post-sale issues, ultimately benefiting B2B buyers with fewer returns and better customer satisfaction.

The decision to place bulk orders involves balancing performance, cost, and market trends. Here’s why advanced materials and tailored production capabilities translate into significant competitive advantages in bulk procurement:

- Cost-Efficiency at Scale: High production efficiency, especially through hot pressing and thermoforming, enables lower unit costs, making high-performance paddles more accessible for wholesale orders.

- Material Innovation: Incorporating materials such as Kevlar alongside traditional options like carbon fiber and fiberglass caters to diverse player preferences. Kevlar’s stiffness delivers a competitive edge for power-oriented players, while other materials may offer broader control and comfort.

- Customization as a Differentiator: Offering personalized designs, from paddle surface textures to unique branding options, positions your product line as innovative and customer-centric.

- Proven Factory Expertise: With years of experience and associations with top brands like Joola and Selkirk, NEX Pickleball has a strong track record as a trusted OEM partner. Their expertise in using advanced materials and precision production processes ensures that every bulk order meets the rigorous demands of today’s sports equipment market.

These factors help you make informed decisions while planning your growth strategy, aligning the technical specifications with wider market trends and customer expectations.

Advanced materials such as Kevlar1 provide significant performance benefits in pickleball paddles by offering superior stiffness and energy transfer, ideal for players who rely on powerful shots. However, the overall success of the paddle product also relies on the production process and the reputation of the manufacturing partner.

By comparing material properties—Kevlar versus carbon fiber, fiberglass, or composite options—and understanding the nuances of hot pressing, cold pressing, and thermoforming, B2B buyers can confidently select a manufacturing partner who not only meets but exceeds quality control benchmarks. NEX Pickleball’s commitment to precision, quality, and customization makes them a reliable ally for businesses looking to enhance their product offering with high-performance, durable pickleball paddles.

For procurement managers and sales executives evaluating pallet solutions, it is essential to match the technical specifications with cost efficiency and market demands. We invite you to explore NEX Pickleball’s advanced products and reach out to our team for in-depth discussions on how our custom solutions can become a strategic asset to your product portfolio.

-

Are Kevlar pickleball paddles better?

Kevlar pickleball paddles are designed with high stiffness, enabling efficient energy transfer which results in more powerful shots. They are ideal for players who favor aggressive, hard-hitting gameplay, though the trade-off is a less forgiving feel compared to materials with more flex. -

Who makes the highest quality pickleball paddles?

Top-quality pickleball paddles are crafted by manufacturers with robust quality control practices and innovative production techniques. NEX Pickleball, with its advanced fabrication methods and partnerships with well-known brands, exemplifies a manufacturer committed to delivering high-performance products that meet rigorous industry standards. -

What paddle do most professional pickleball players use?

Many professional pickleball players opt for paddles that emphasize balanced performance and enhanced power, such as models designed with premium materials and precision processes. While specific preferences vary, leading choices often come from manufacturers who focus on integrating advanced materials like carbon fiber or Kevlar, ensuring optimal performance on the pro tour.

-

Kevlar: Click to read an in-depth analysis on how Kevlar’s molecular structure contributes to its strength and energy transfer capabilities, offering insights into its applications in high-performance sports equipment. ↩ ↩ ↩2 ↩3 ↩4

-

Carbon Fiber: Click to explore detailed information about Carbon Fiber, including its manufacturing process, properties, and benefits in sports and industrial applications. ↩ ↩ ↩2

-

Composite Materials: Click to understand composite materials, their construction, and how combining different materials can lead to improvements in strength, flexibility, and overall performance. ↩ ↩ ↩2

-

Hot Pressing: Click to learn more about hot pressing technology, its role in manufacturing, and the impact of temperature and pressure on material properties and product integrity. ↩ ↩

-

Thermoforming: Click to discover the thermoforming process, including its advantages for producing complex, customized designs and its applications in various manufacturing industries. ↩ ↩