Quick Answer: NEX Pickleball combines advanced manufacturing techniques1 with rigorous quality control and exceptional customer service to deliver high-performance pickleball paddles that meet the demanding needs of B2B sourcing managers and procurement specialists in the sporting goods industry.

In today’s competitive sporting goods market, procurement professionals face the dual challenge of sourcing equipment that not only boasts top-tier performance but also comes with reliable after-sales support and quality assurance. Many companies struggle with the unpredictable nature of production processes while trying to maintain strong customer service. At NEX Pickleball, we address these concerns by integrating advanced manufacturing methods with robust quality control and customer-centered service, ensuring that every paddle we produce is a testament to precision, durability, and excellent technical support.

Problem Description

Businesses in sporting goods manufacturing and distribution require partners who understand the intricacies of both performance engineering and supply chain reliability. When selecting a supplier for pickleball paddles, B2B buyers are particularly concerned with:

• Consistency in quality and production efficiency

• Robust quality assurance and product testing protocols

• Customization capabilities2 – including on-demand printing and bespoke paddle features

• Outstanding customer service and responsive after-sales support

These are essential not only for meeting market demands but also for minimizing cost overruns, production delays, and potential quality issues in final products. Procurement specialists often need to balance technical specifications with evidence of market commitment.

Cause Analysis

The challenges in delivering consistently high-quality pickleball paddles stem from several factors:

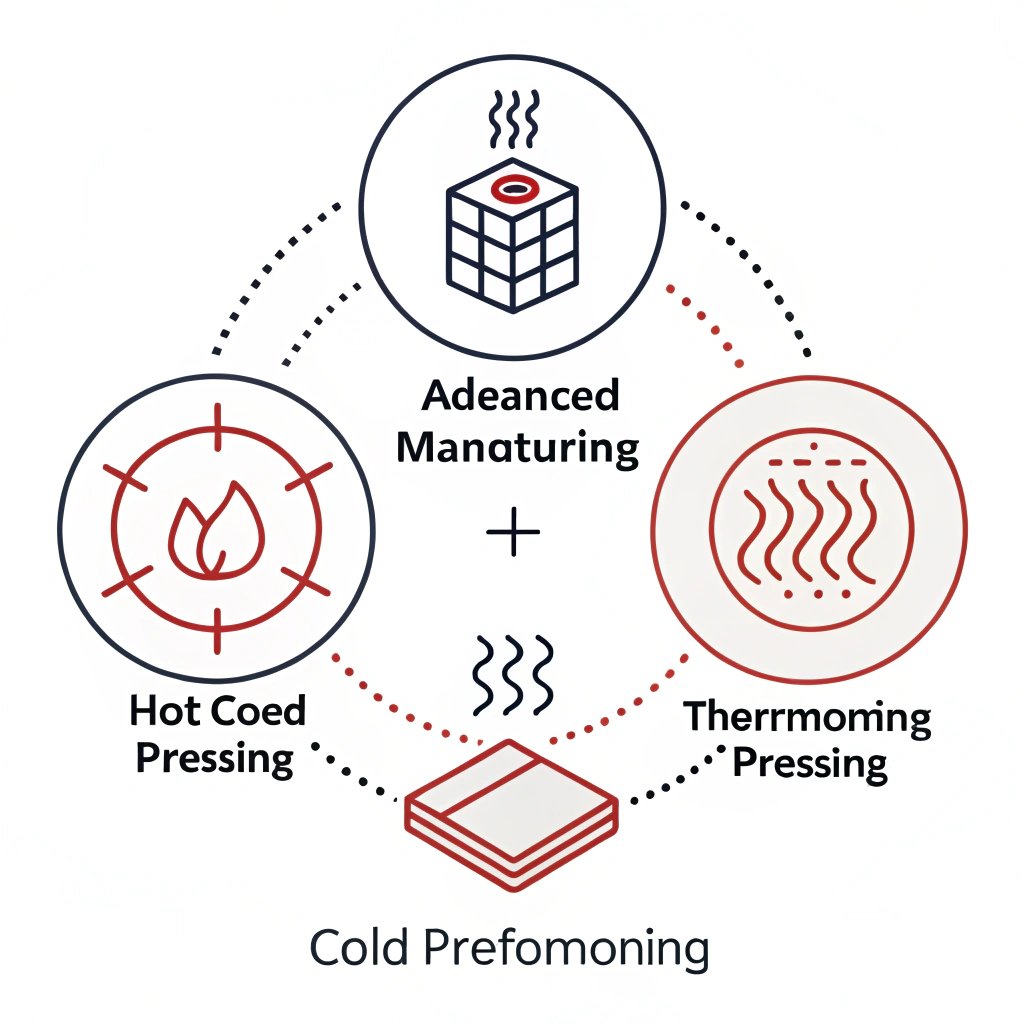

- Complex Production Processes – Manufacturing paddles involves multiple steps such as hot pressing, cold pressing, and Thermoforming3. Each method affects material properties differently, influencing the paddle’s performance and durability.

- Material Variability – The selection of materials like carbon fiber, fiberglass, and composites is critical. Variability in material performance can result in inconsistent production outcomes if not tightly controlled.

- Quality Assurance Protocols – Lack of rigorous testing and quality control can lead to products that do not meet high-impact resistance and ergonomic requirements.

- Customization Requirements – Custom paddle options, including personalized grip sizes and on-demand printing, require flexible manufacturing processes and a close relationship with clients, adding complexity to order fulfillment.

- After-Sales Support – The critical phase after a sale includes technical support, returns management, and rapid resolution of manufacturing issues, which many suppliers find difficult to standardize.

Understanding these underlying causes sets the stage for a solution-oriented approach that NEX Pickleball uses to overcome these obstacles.

Solution Strategies

NEX Pickleball addresses these challenges through a series of well-defined strategies that cover production excellence, quality assurance, and superior customer service. Below is an overview of our solution framework:

- Advanced Production Techniques

- Hot Pressing: Used to produce paddles with robust impact resistance and structural integrity.

- Cold Pressing: Ensures precise control over paddle thickness and preserves the inherent properties of top-quality materials.

- **Thermoforming3: Facilitates the creation of paddles with intricate designs while maintaining stable performance.

Below is a comparison table summarizing these processes:

| Production Process | Advantages | Disadvantages |

|---|---|---|

| Hot Pressing | High production efficiency; excellent impact resistance; structural integrity | May alter material’s natural feel; requires high investment in equipment |

| Cold Pressing | Precise control over paddle design; maintains material properties; excellent ball feel | Longer production cycles; demands high-quality mechanical control |

| Thermoforming | Allows complex designs; precise material distribution; maintains stability | Longer production time; higher equipment costs; best for premium or custom orders |

-

Material Excellence and Technical Innovation

To ensure every paddle meets exacting standards, we carefully select premium materials:- Carbon Fiber Variants: Such as 3K, 12K, and T300 Carbon Fiber4 each offer unique benefits from high rebound force to superior tensile strength and reduced vibration.

- Fiberglass Options: Including E-Glass Fiberglass5 that provides elasticity and a broader sweet spot for better ball control.

- Composite Solutions: Combining carbon fiber and fiberglass, or integrating bamboo and honeycomb cores, these solutions provide a balance between strength, weight, and feel.

-

Rigorous Quality Assurance and Testing

Every paddle produced undergoes multiple rounds of quality testing. Our quality assurance strategy includes:- In-Process Inspections: Constant monitoring of production parameters to catch any variances early.

- Final Product Testing: Ensuring hardness, rebound consistency, and ergonomic factors are up to standard.

- Client-Specific Customization Checks: For orders with bespoke requirements, additional tests verify that each paddle meets unique client specifications.

-

Customer-Centric Support and After-Sales Service

For us, customer service goes beyond the point of sale. Our after-sales support framework is designed to ensure that:- Any production concerns are addressed immediately.

- Clients have access to dedicated technical service experts.

- There is full transparency in the order-tracking process and post-sale support, covering issues like on-demand print adjustments and return management.

-

Data-Driven Insights and Continuous Improvement

By leveraging industry data and client feedback, we monitor:- Production efficiency metrics

- Customer satisfaction scores

- Return and issue resolution rates

This data-driven approach helps us continuously refine our manufacturing process and service protocols.

-

Custom Paddle Options and Lead Times

NEX Pickleball understands that B2B clients often require custom solutions. We offer flexibility:- Custom paddle designs tailored to different playing styles or team branding.

- A range of grip sizes and weight distributions.

- On-demand print services that allow personalization for teams, retailers, or promotional events.

This customization is supported by a well-coordinated supply chain that ensures reliable and on-time delivery.

-

Case Study: A Commitment to Excellence

Consider a leading sports equipment distributor that recently partnered with NEX Pickleball. They had stringent quality requirements and needed a steady supply of paddles for both retail and team sponsorships. By adopting our integrated approach:- The distributor observed fewer product returns due to improved paddle durability.

- They benefited from our consistent production cycles, ensuring that large orders were fulfilled on time.

- Our dedicated customer service team provided proactive updates and resolved minor issues swiftly.

These outcomes not only enhanced their product portfolio but also reduced operational disruptions, supporting their competitive stance in the market.

Actionable Insights and Best Practices

For B2B sourcing managers and procurement specialists, taking the following steps can facilitate smoother supplier relationships and superior product quality:

-

Prioritize Suppliers with Integrated Quality Controls

Look for manufacturers that incorporate rigorous testing protocols at every stage of production. This reduces the likelihood of defective products reaching the market. NEX Pickleball’s multi-layer quality assurance ensures that each paddle is tested for performance, stability, and ergonomic design. -

Demand Transparency in Production Processes

It is essential to know how products are made. Suppliers should be able to explain the merits of processes like hot pressing, cold pressing, and thermoforming. An informed buyer can better assess whether a supplier’s process aligns with the performance standards required in competitive play. -

Evaluate Post-Purchase Support

Regular follow-ups, proactive issue resolution, and accessible technical service form the backbone of exceptional customer service. Ensure that your supplier offers robust after-sales support. NEX Pickleball’s commitment to customer service is reflected in timely updates and clear communication channels. -

Leverage Customization for Market Differentiation

Custom paddle options are not just a value-added service—they offer a competitive edge in markets where personalized equipment leads to greater brand recognition. A strong supplier partner should provide flexible manufacturing capabilities to cater to specialized designs and on-demand printing needs. -

Request Data and References

Before finalizing a supplier, ask for production efficiency data and customer testimonials. This information is crucial in evaluating the reliability and technical prowess of the partner. Our transparent sharing of production success stories and operational metrics underscores our capability in delivering consistent results.

Quality Assurance, Innovation, and Customer Support: An Integrated Approach

The journey to sourcing high-performance pickleball paddles begins with a reliable partner who can merge engineered precision with responsive customer service. At NEX Pickleball, we have built our reputation on:

• Consistent production excellence validated by industry standards

• A diverse range of high-quality materials strategically chosen for their performance benefits

• An unwavering commitment to customer satisfaction, supported by dedicated technical service teams

• Customization options that allow businesses to create a unique market presence

Every aspect of our operation is geared towards ensuring that B2B buyers receive a product that not only delivers top-notch performance on the court but also aligns with their strategic operational needs. In an industry where marginal gains can lead to significant competitive advantages, our integrated approach offers a clear path to enhanced performance and market success.

Conclusion and Action Recommendations

In summary, ensuring quality and service excellence in pickleball equipment sourcing involves more than just manufacturing paddles—it requires an end-to-end solution that covers advanced production techniques, rigorous quality control, and a steadfast commitment to customer support. By integrating processes such as hot pressing, cold pressing, and thermoforming with a robust quality assurance program, NEX Pickleball meets the high expectations of B2B partners seeking reliability and innovation.

Procurement specialists are encouraged to engage with suppliers who provide clear production insights, demonstrated quality data, and comprehensive after-sales support. By choosing partners with proven expertise and a customer-first mindset, companies can secure a competitive advantage in the sporting goods market.

Take the next step by reviewing your current supplier’s production and service protocols, and consider how partnering with a manufacturer like NEX Pickleball can drive improvements in your product offerings and overall supply chain reliability. Your players deserve the best equipment, and your business deserves a supplier who makes excellence a standard.

People Also Ask

Q: What is the best pickleball company?

A: Leading pickleball brands include Joola, Selkirk, CRBN, and Gearbox, known for their premium paddles. Many of these brands benefit from the technical precision and quality assurance provided by manufacturing partners like NEX Pickleball, which use advanced production techniques and stringent quality control measures to ensure superior performance and durability.

-

advanced manufacturing techniques: Reading the article provides insights into modern production methods that leverage technology to enhance product quality and operational efficiency. Back ↩

-

Customization capabilities: Reading the article helps you understand how bespoke production and on-demand customization can offer a competitive edge in the market. Back ↩

-

Thermoforming: Reading the article explains this advanced molding process, including its benefits for achieving intricate designs and consistent performance. Back ↩ ↩2

-

T300 Carbon Fiber: Reading the article sheds light on the properties of T300 Carbon Fiber, including its balance of durability, weight, and performance characteristics. Back ↩

-

E-Glass Fiberglass: Reading the article provides insights into how E-Glass Fiberglass contributes to material elasticity and overall equipment performance. Back ↩